Automatic slicing apparatus

a slicing machine and automatic technology, applied in the direction of metal-working machine components, manufacturing tools, instruments, etc., can solve the problem of small fear of failing to make the specimen of sliced pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]Hereunder, there is explained about an embodiment of the present invention while referring the drawings.

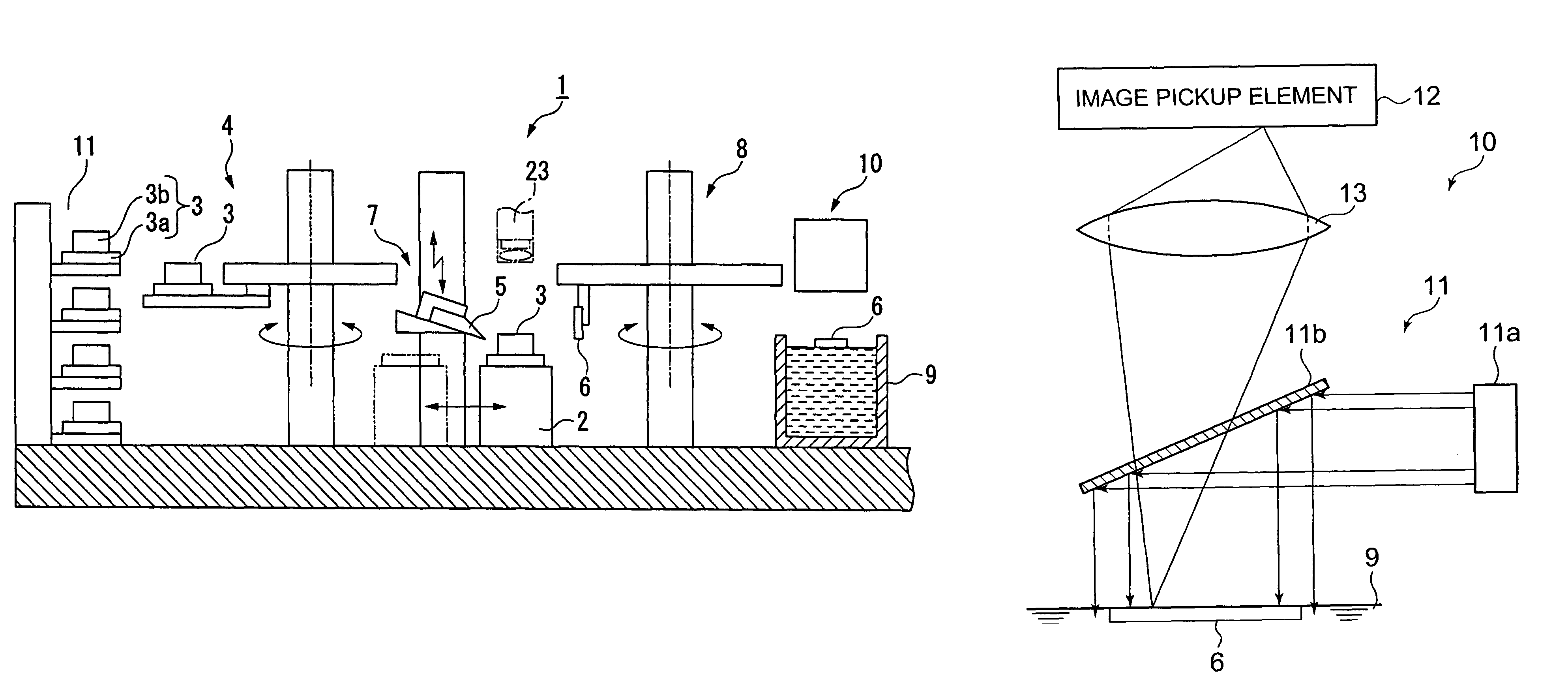

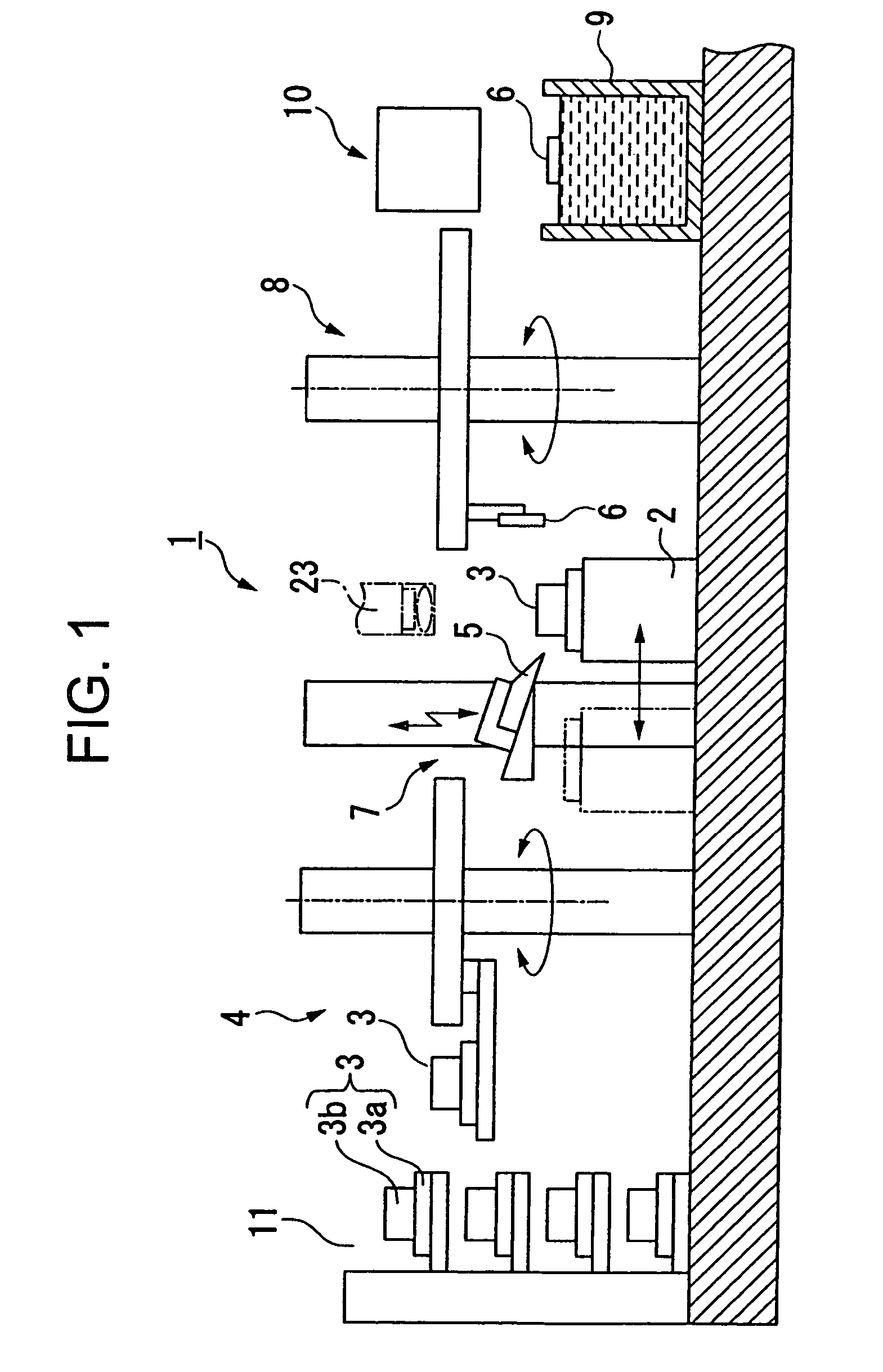

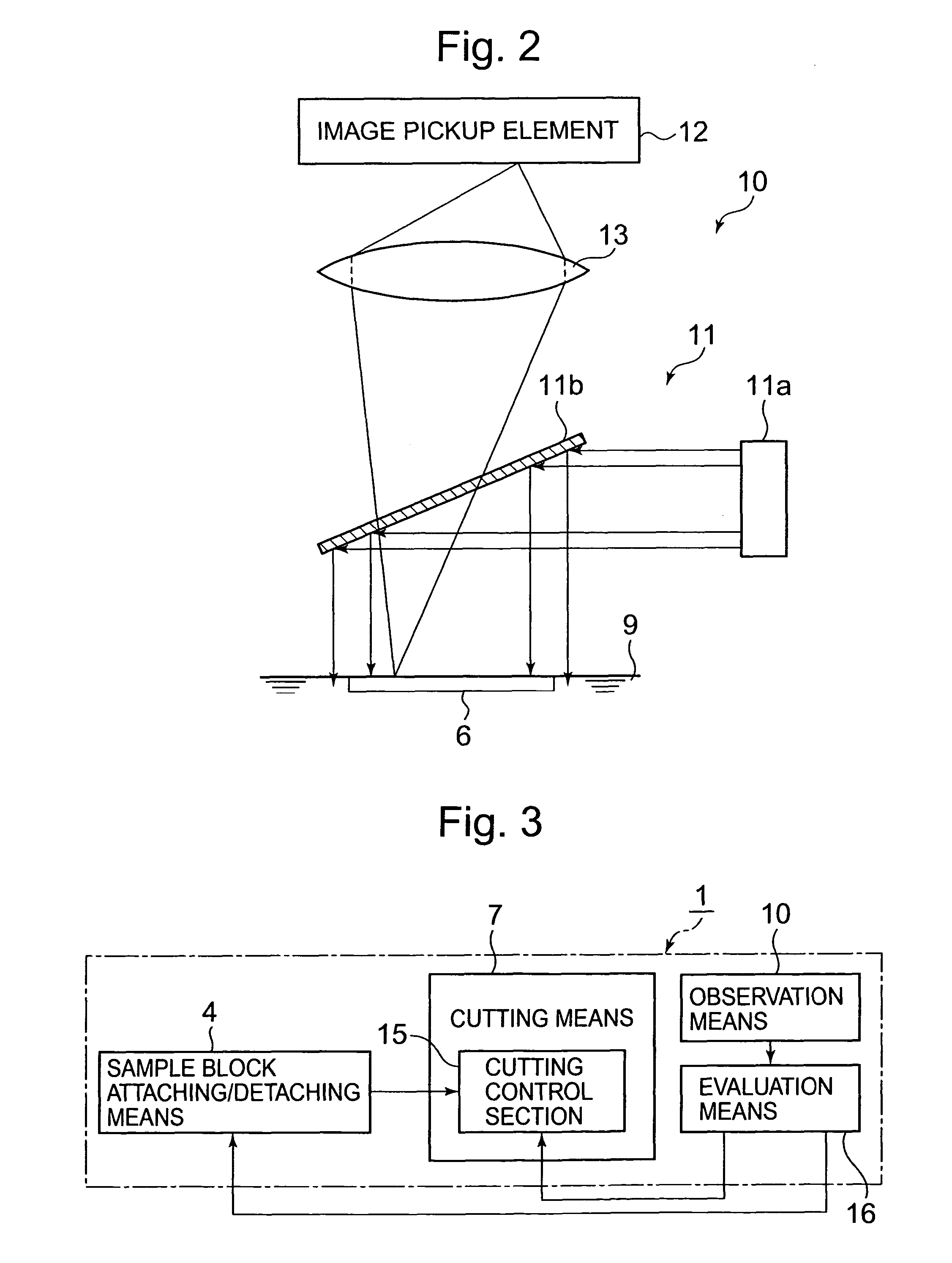

[0049]FIG. 1 is a view showing a constitution of an automatic slicing apparatus, FIG. 2 a view showing an observation means, and FIG. 3 a function block diagram of a control system in the automatic slicing apparatus. An automatic slicing apparatus 1 possesses a sample block attaching / detaching means 4 comprising a block handling robot, which, on the basis of an exchange command signal, detaches a sample block 3 attached to a cutting base 2 and instead attaches the new sample block 3 to the cutting base 2, a cutting means 7 which relatively moves a knife 5 with respect to the sample block 3 having been attached to the cutting base 2 to thereby cut a sliced piece 6 of a predetermined thickness, a carrier means 8 carrying the sliced piece 6 having been cut by the cutting means 7, and an observation means 10 observing the sliced piece 6 having been carried till a water tank 9 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| microscope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com