Target for color characterization of color printer

a color printer and color characterization technology, applied in the field of color characterization of color printers, can solve the problems of increasing the burden involved in characterization of a color printer, increasing the complexity of the mapping between colorant values and color measurements, and increasing the number of color patches, etc., to achieve good color characterization of the printer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

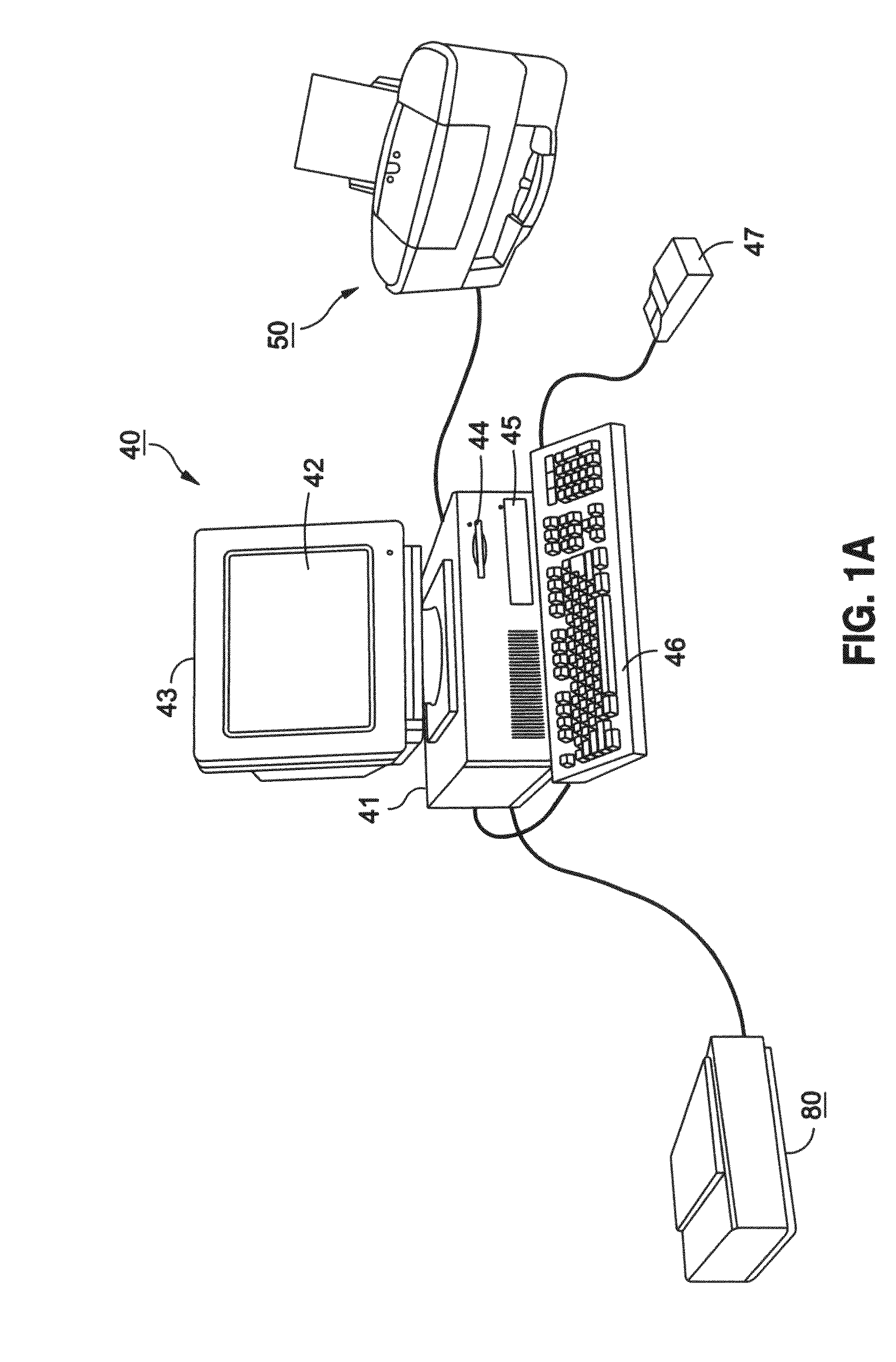

[0045]FIG. 1(a) shows the external appearance of a representative computing system including a data processing system 40, peripherals and digital devices which may be used in connection with the practice of an exemplary embodiment of the present invention. The data processing system 40 includes host processor 41 which comprises a personal computer (hereinafter “PC”), preferably a personal computer which has a windows-based operating system, although the data processing system 40 may be another type of computer which has a non-windows-based operating system. Provided with the data processing system 40 are a color monitor 43 including a display screen 42, a keyboard 46 for entering text data and user commands, and a pointing device 47. The pointing device 47 preferably comprises a mouse for pointing and for manipulating objects displayed on the display screen 42.

[0046]The data processing system 40 includes a computer-readable memory medium such as computer fixed disk 45 and / or floppy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| color characterization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com