Shaping slurry and shaping method

a technology of slurry and granules, applied in the field of slurry shaping, can solve the problems of granules not being able to undergo changes in properties, affecting the mechanical strength between layers, and possible droplet discharge failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

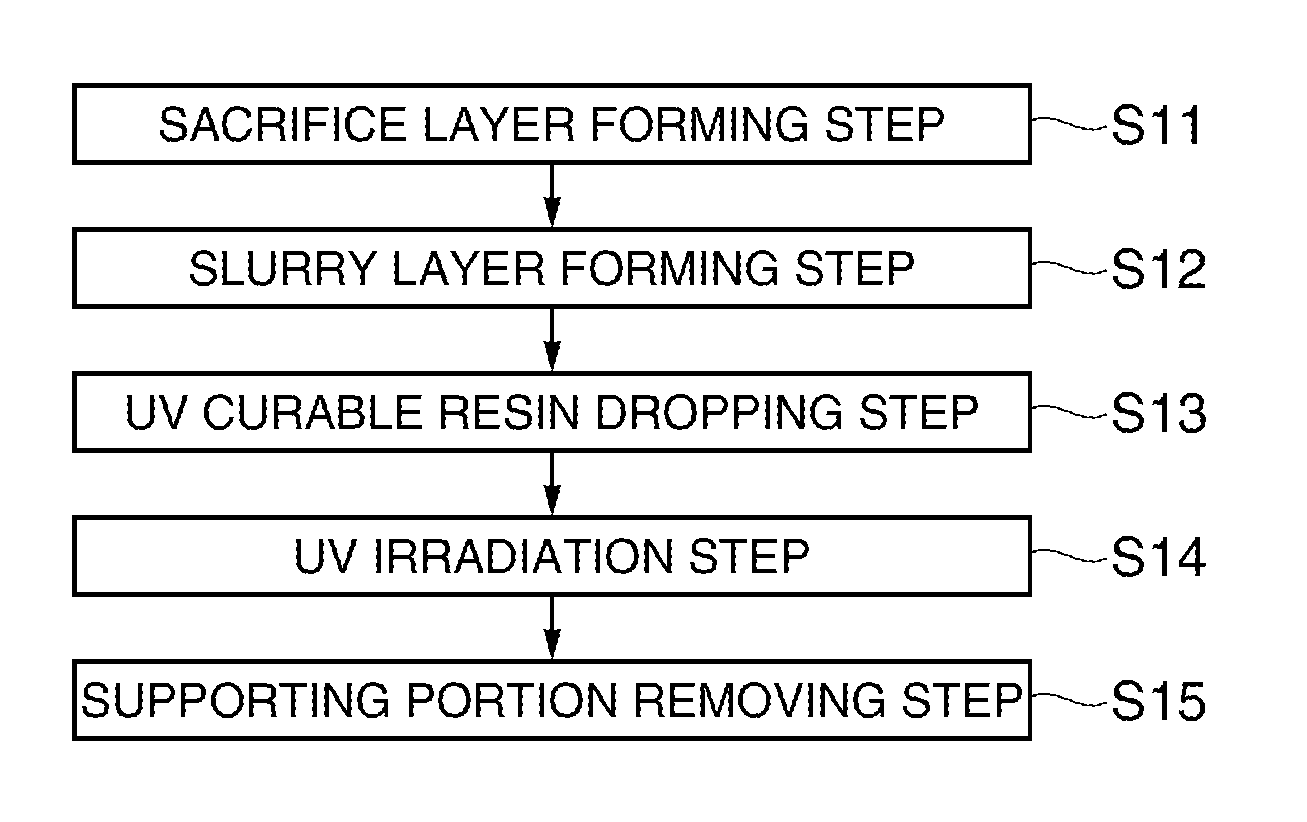

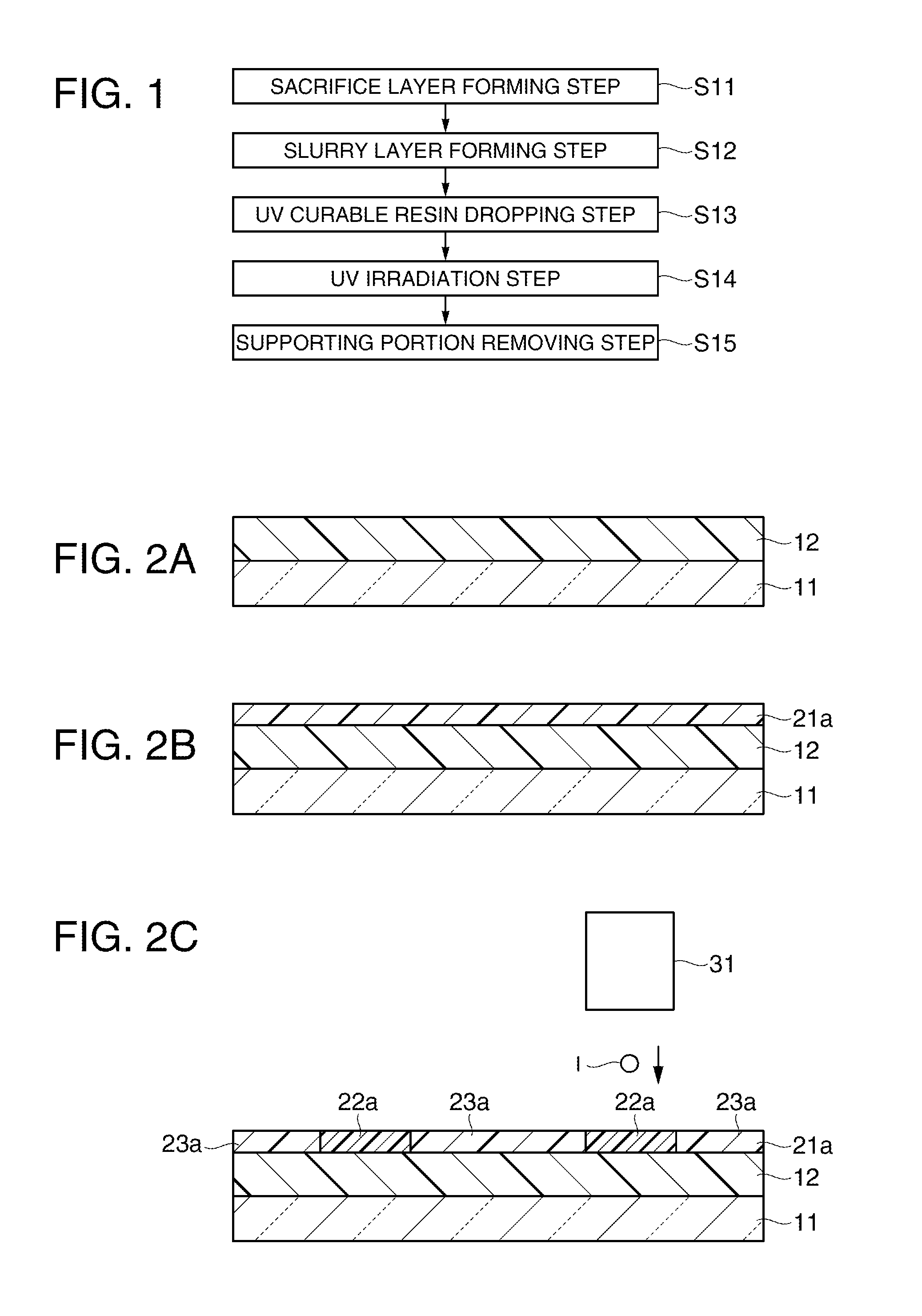

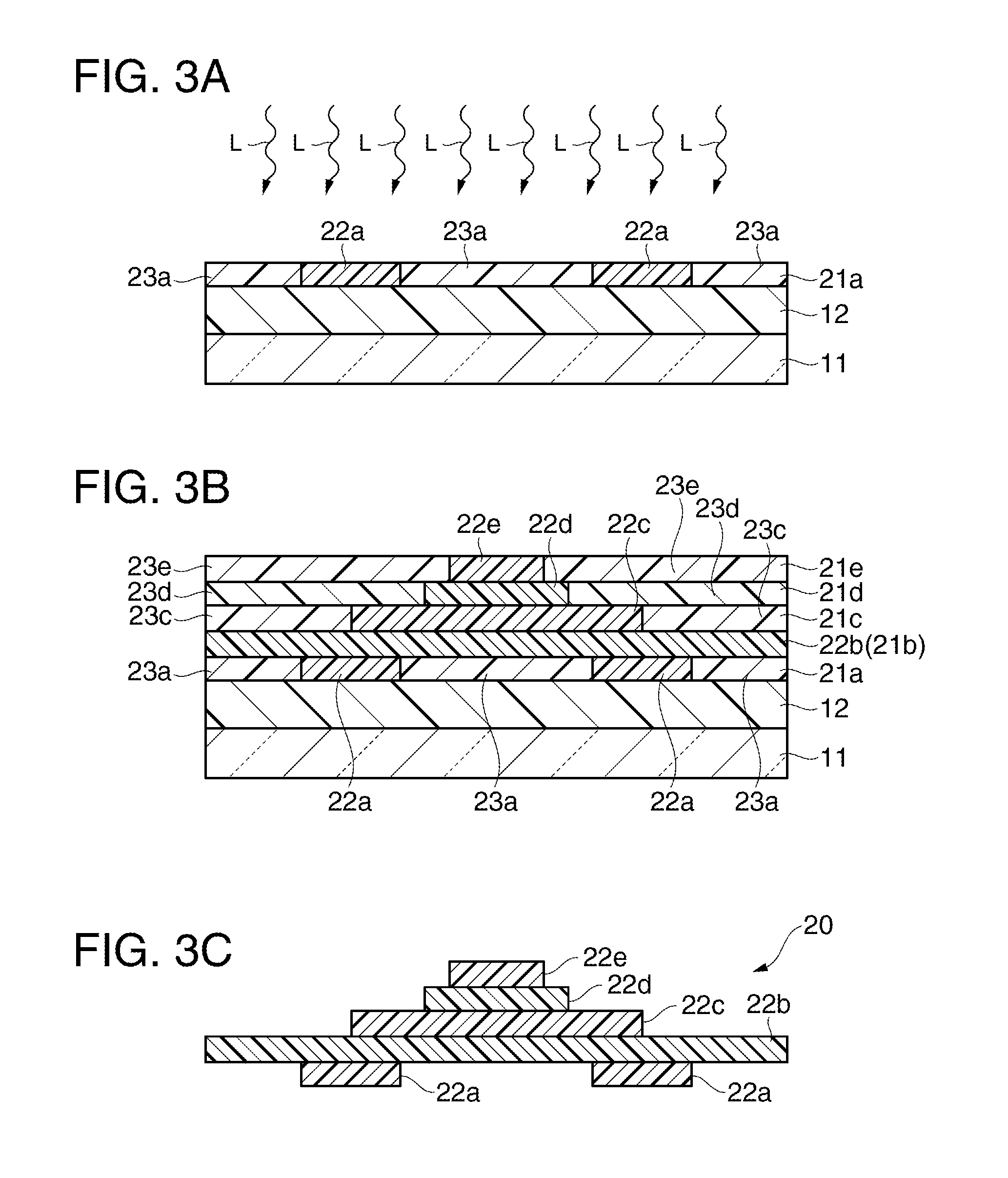

Method used

Image

Examples

examples

[0104](A) Chaline R-1705, (B) water, and (C) various Povals were mixed in the following proportions to form a slurry.

[0105](A):(B):(C)=7:3.1:0.22 (unit, g)

[0106]Five different Povals (JP-05, JP-15, JP-24, JT-05, JT-15) with different polymerization degrees and different saponification degrees were used. The slurries were evaluated with regard to the fixing strength between slurry layers laminated at 23° C., and solubility for 18° C. cold water. The fixing strength was evaluated by measuring the tensile elastic modulus according to the methods of JISK7161 and JISK7162. Table 1 below presents the evaluation results for the fixing strength and solubility of the slurries using the different Povals.

[0107]

TABLE 1Polymerization SaponificationFixingProductdegreedegreestrengthSolubilityJP-0550088GoodExcellentJP-151,50087GoodGoodJP-242,40088AcceptableAcceptableJT-0550094AcceptableAcceptableJT-151,50093GoodAcceptable

[0108]As presented in Table 1, among the Povals having saponification degrees ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com