Process for producing a high stability desulfurized heavy oils stream

a technology of desulfurized heavy oil and process, which is applied in the direction of thermal non-catalytic cracking, water treatment refining, and aqueous alkaline solution raffination, etc., can solve the problems of difficult removal of sulfur, many refineries lack the conversion equipment necessary to process these heavier crude oils, and the inability of partial conversion techniques to perform significant conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

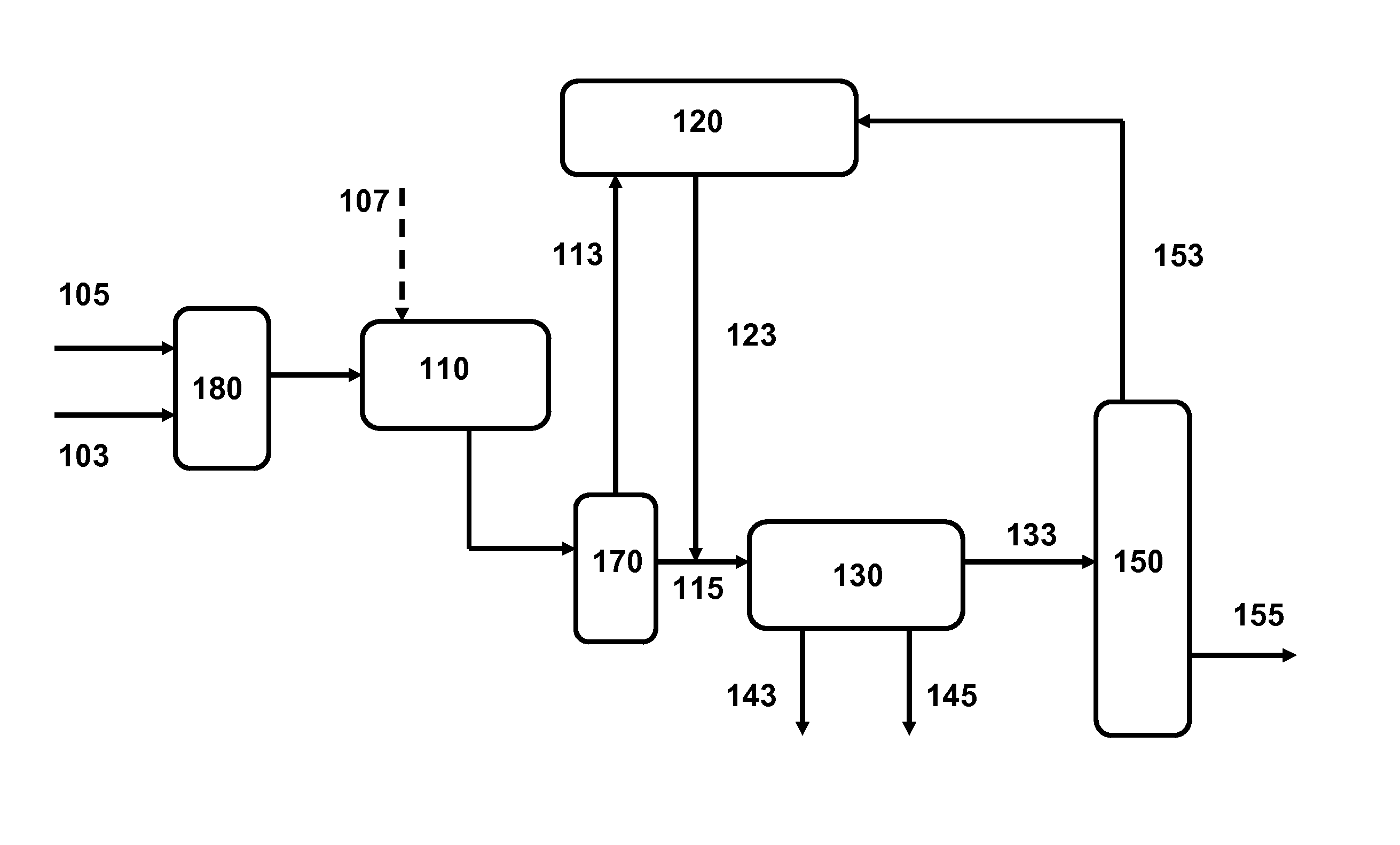

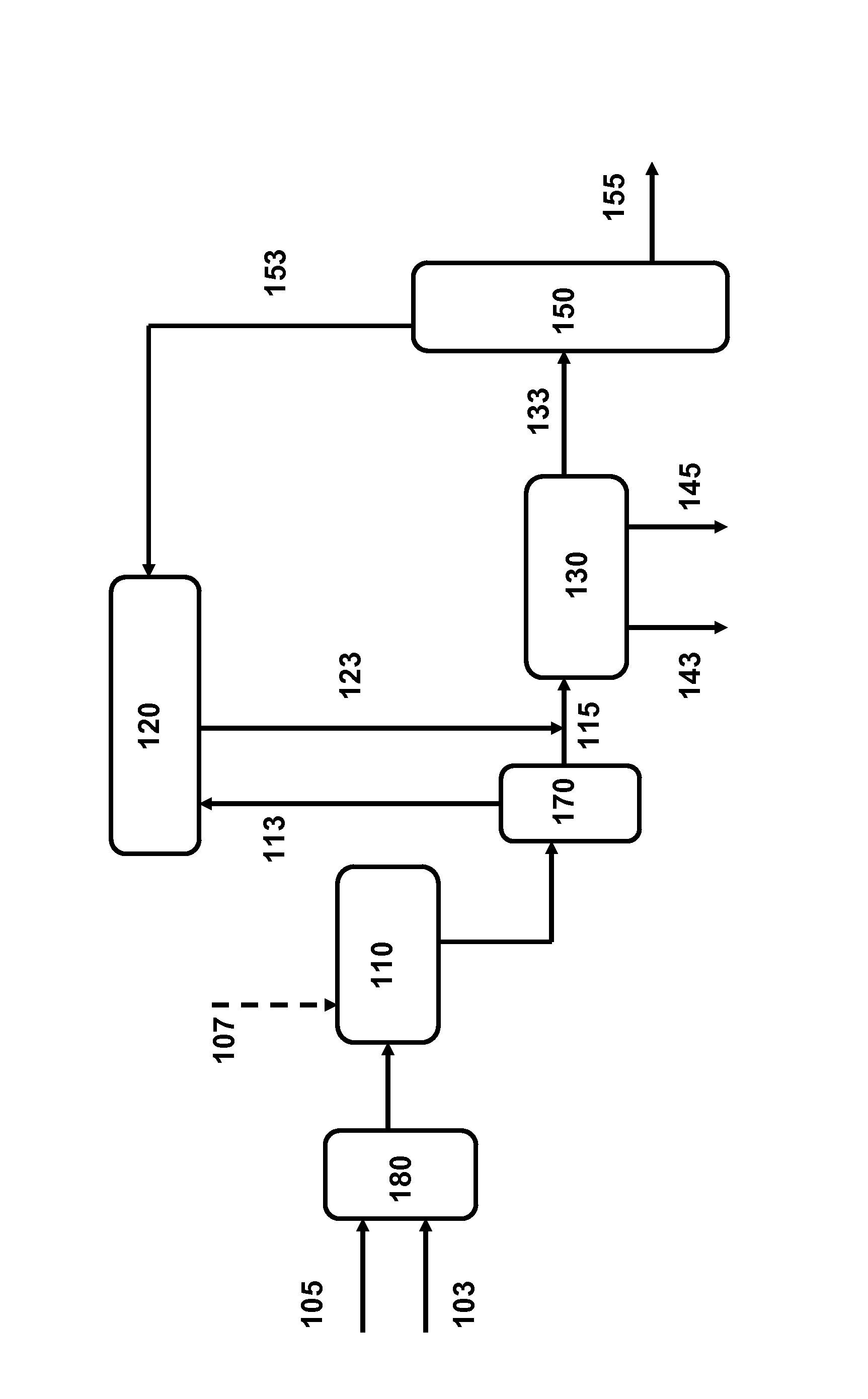

Image

Examples

example 1

Light Ends Fractionation

[0065]By way of example, molecular property modeling was carried out on a theoretical composition of a paraffin froth treated feed which had been converted via an alkali metal desulfurization process to an API of 21.7. In this example, the desulfurization results in about 70% 1050F+ conversion. The total liquid product stream was then theoretically distilled to varying percentages to demonstrate the effect of distillation on the API and the SBN of the final system. The results of the calculation are shown in Table 1 below:

[0066]

TABLE 1Removal via topping of light ends effects on API and SBN%RemovedAPISBNΔ APIΔ SBN0%21.789.41%20.991.1−0.8+1.72%20.292.6−1.5+3.23%19.594.1−2.2+4.74%19.095.4−2.7+6.0

[0067]It may be seen that the removal of only 4% of the lightest liquids results in an API decrease of 2.7 to 19, the pipeline specification, and an SBN increase of 6 units. If a larger than 6 unit SBN increase were desired, it would be desirable to convert the product ...

example 2

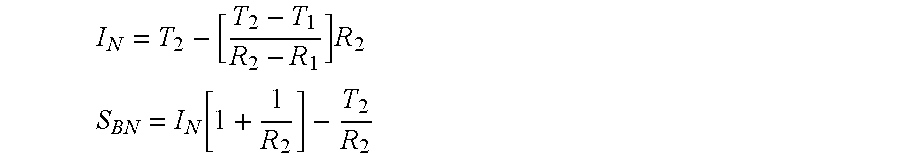

Example of Trim Deasphalting

[0068]To determine the degree of product losses a trim deasphalting / compatibilization scheme might involve, a series of conversion products generated using KOH as an alkali metal reagent catalyst were deasphalted using heptane and using a 1:1 mix of heptane and toluene. The deasphalting was done using a 10:1 ratio of solvents to oil. The heptane deasphalting is expected to result in a final product that has an IN value (insolubility number) of approximately 0, while the 1:1 heptane:toluene deasphalting is expected to result in a product having an IN of approximately 50. At the IN=50 level, a heavy oil product would be not only self compatible, but also generally compatible with most other crude oils (those with SBN values >70).

[0069]Table 2 shows the results from the trim deasphalting runs. All of the conversion products were first diluted in toluene and filtered to remove the toluene insolubles (shown in the table as % TI). All of the conversion products...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com