Linear actuator

a technology of linear actuators and actuators, applied in the direction of mechanical energy handling, dynamo-electric machines, gearing, etc., can solve the problem of lack of versatility of structures, etc., and achieve the effect of effective absorption, high accuracy, and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Structure

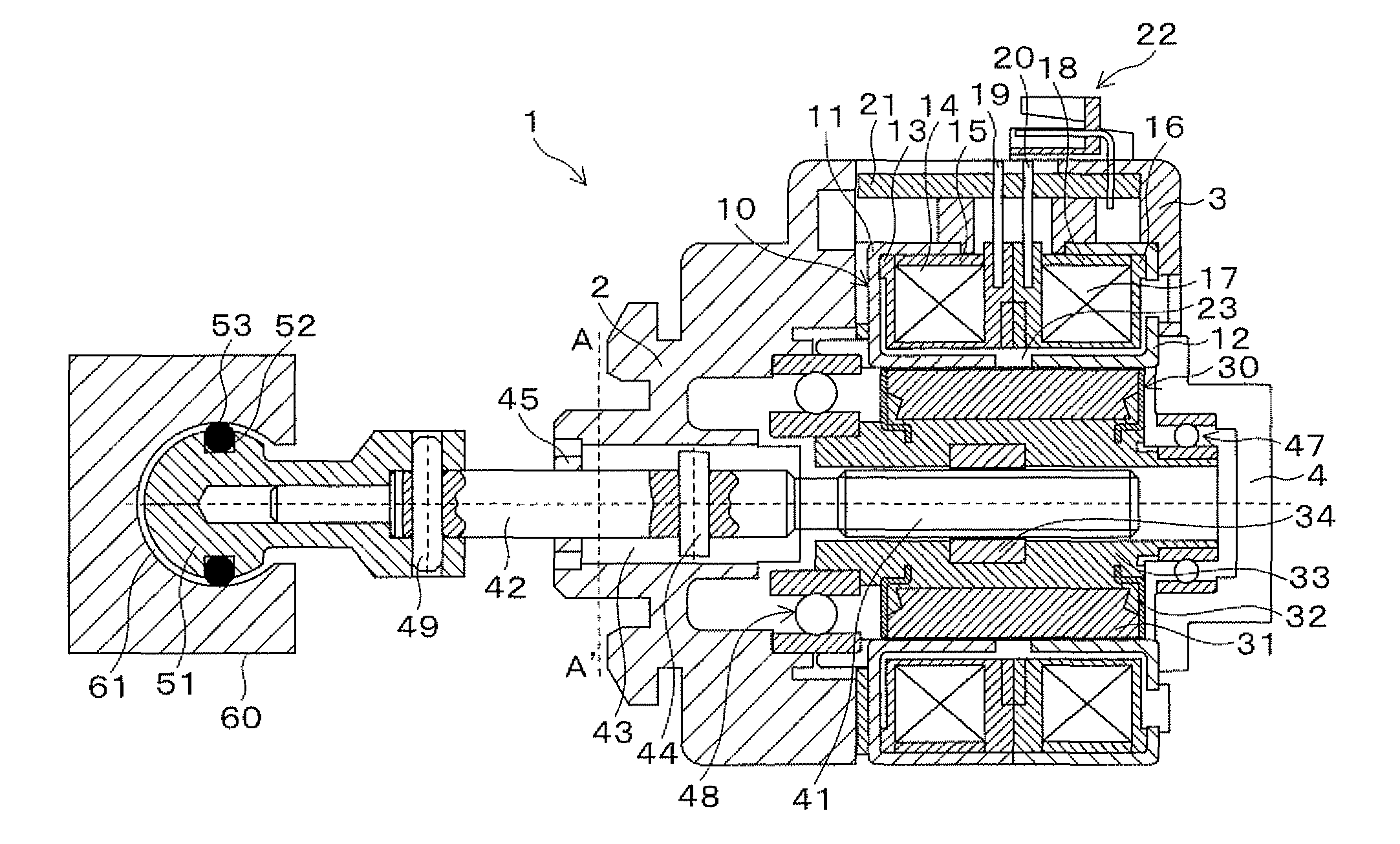

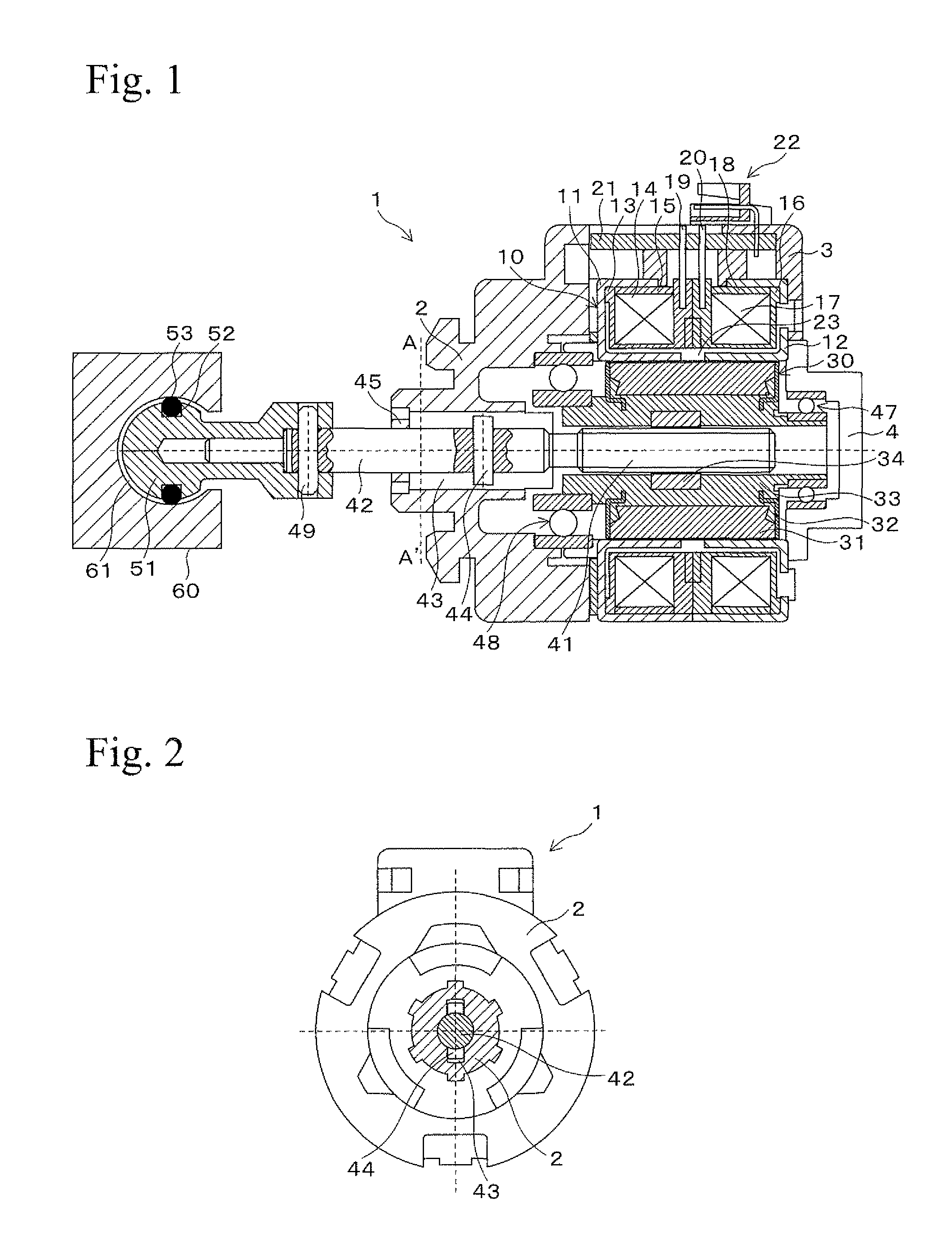

[0016]FIG. 1 shows a linear actuator 1 of an embodiment. The linear actuator 1 has a linear drive device using engagement of an external screw and an internal screw. The linear actuator 1 has a housing 2, a pin holder 3, and a stator assembly 4. The housing 2, the pin holder 3, and the stator assembly 4 are uniformly formed into an outer frame of the linear actuator 1.

[0017]The housing 2, the pin holder 3, and the stator assembly 4 are formed by mold forming (injection forming) using raw resin material. The outer frame formed of the housing 2, the pin holder 3, and the stator assembly 4 has an inside to which a stator unit 10 is fixed. The stator unit 10 has an approximately tubular shape and rotatably contains a rotor unit 30, which will be described later. The stator unit 10 is formed of a stator yoke 11, stator yoke 12, a bobbin 13, a coil (field coil) 14, a coil cover 15, a bobbin 16, a coil (field coil) 17, and a coil cover 18.

[0018]The stator yokes 11 and 12 are stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com