Operation management apparatus, operation management method, and operation management program

a technology of operation management and operation management, applied in the direction of instruments, heating types, static/dynamic balance measurement, etc., can solve the problems of power consumption local increase, contract demand cannot be controlled, and the average value of purchased power during the demand time unit may exceed the contract demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

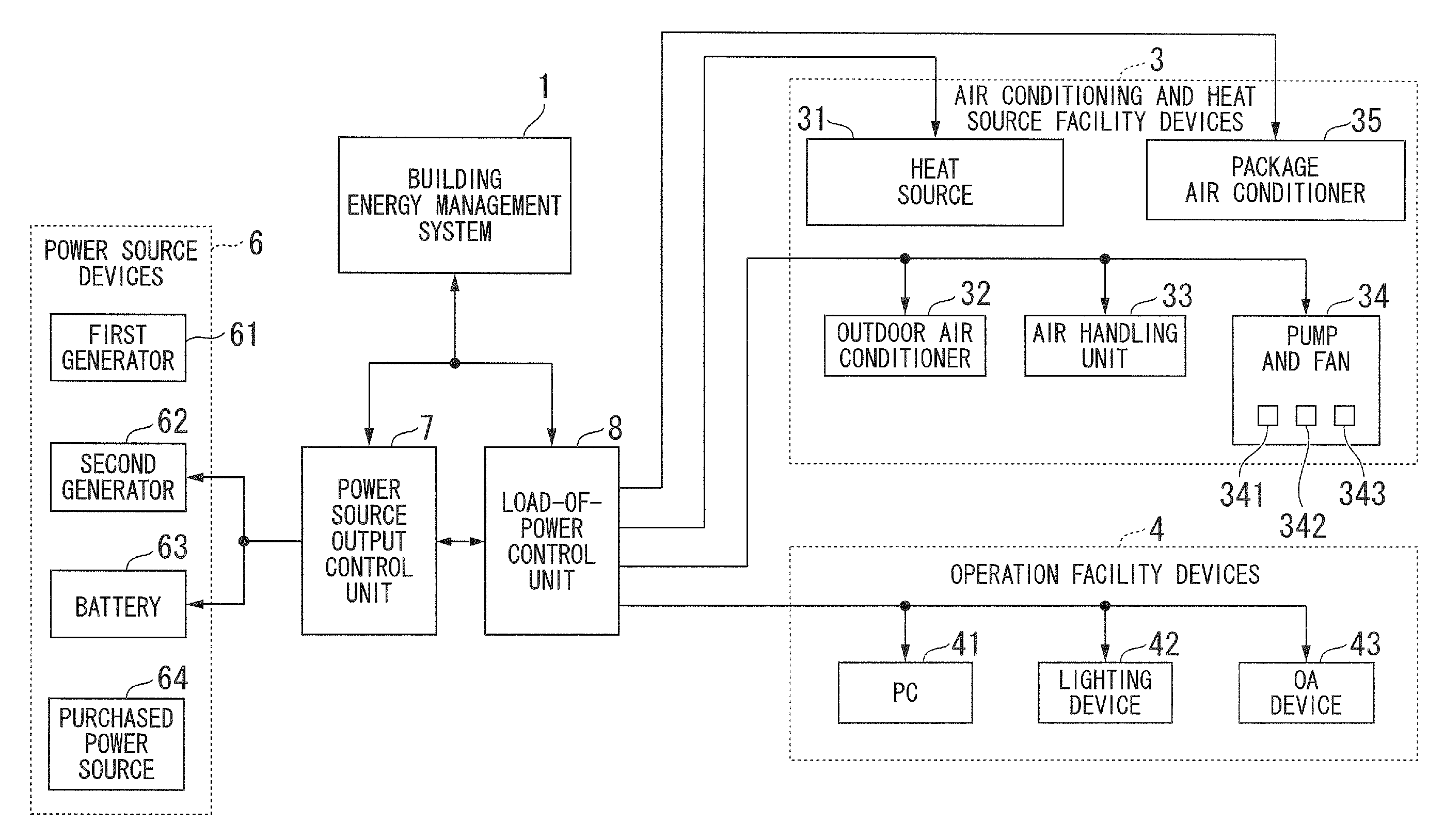

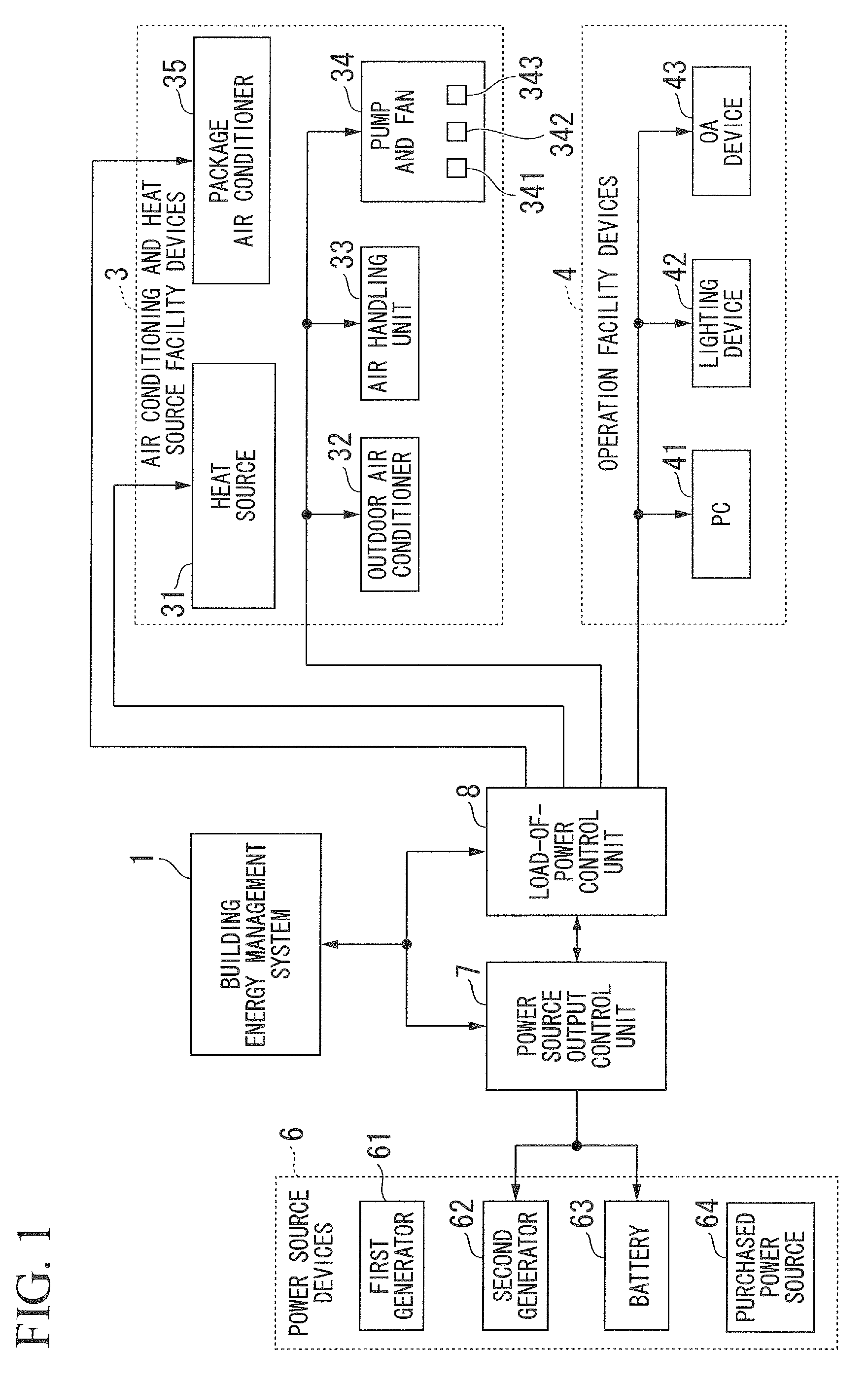

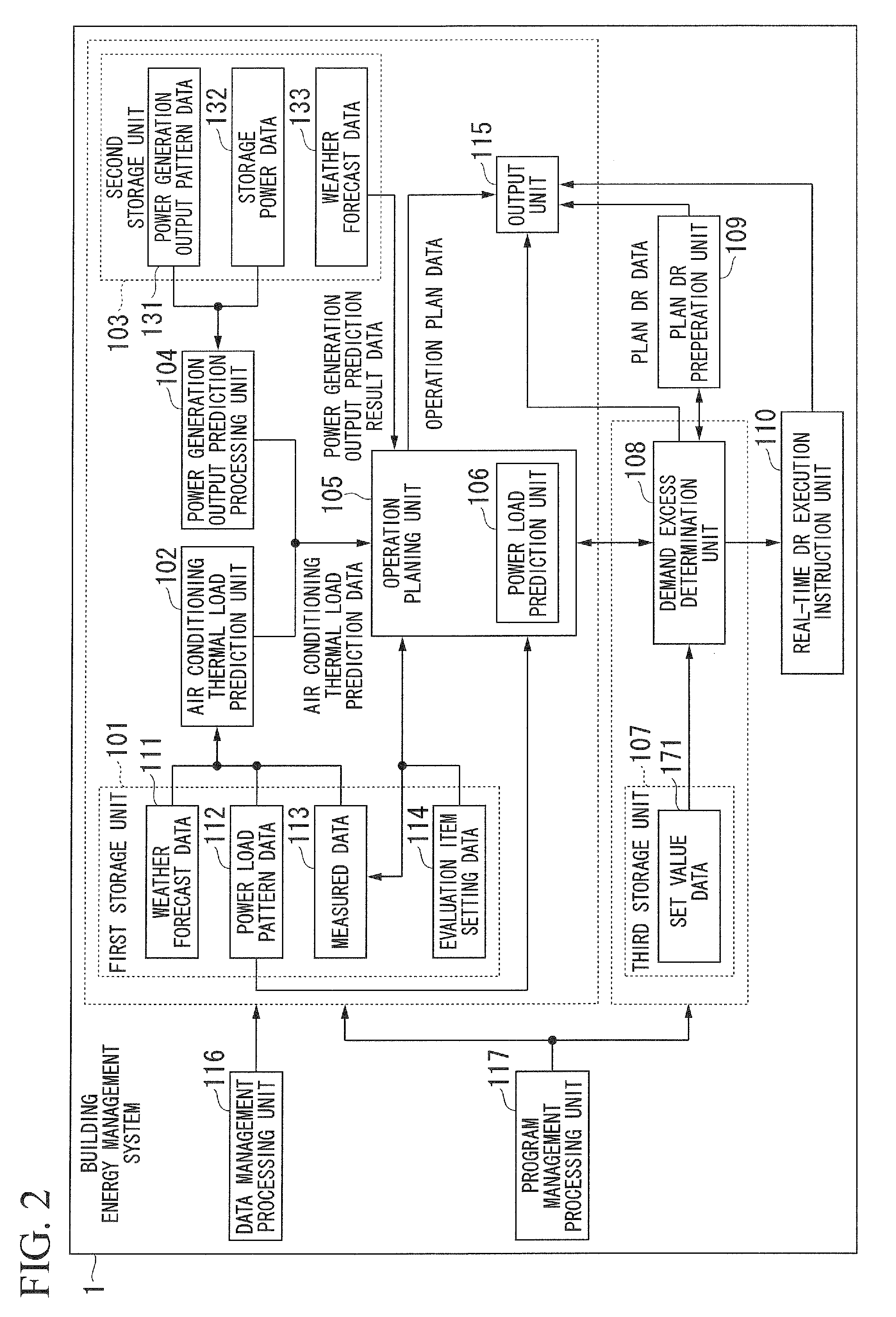

[0036]Hereinafter, an example of a smart grid system including a building energy management system 1 according to an embodiment of the present invention will be described in detail with reference to FIG. 1.

[0037]FIG. 1 is a block diagram showing an example of a configuration of a smart grid system according to a first embodiment of the present invention.

[0038]Referring to FIG. 1, the smart grid system includes the building energy management system 1, air conditioning heat source facility devices 3, operation facility devices 4, power source devices 6, a power source output control unit 7, and a load-of-power control unit 8.

[0039]The smart grid system includes the air conditioning heat source facility devices 3 and the operation facility devices 4 as a load device. Furthermore, fluctuation of a power consumption of the air conditioning heat source facility devices 3 is heavier in comparison with the operation facility devices 4 due to a heat source of the air conditioning heat source...

second embodiment

[0274]The present invention is not limited to the above-described configuration, and a configuration shown in FIG. 20 may be used. FIG. 20 is a block diagram showing an example of a smart grid system according to the second embodiment. The same reference numerals are applied to a configuration having a function similar to that of the configuration shown in FIG. 1, and thus the detailed description thereof will be omitted.

[0275]As shown in FIG. 20, the building energy management system 17 further includes a communication unit 93 in comparison with the above-described building energy management system 1. The communication unit 93 is connected to a central management apparatus 92 through a network. Power load devices 94 include the air conditioning heat source facility device 3 and the operation facility device 4.

[0276]The central management apparatus 92 includes an information acquisition unit 921, a management storage unit 922, a management control unit 923, a communication unit 924,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com