Anti-reflection structure with graded refractive index layer and optical apparatus including same

a refractive index layer and anti-reflection technology, applied in the field of anti-reflection structure, can solve the problems of inability to achieve sufficient mechanical strength, inability to secure physical or mechanical strength inability to wipe the surface of the minute roughness structure, etc., to achieve high mechanical strength of the surface and high anti-reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

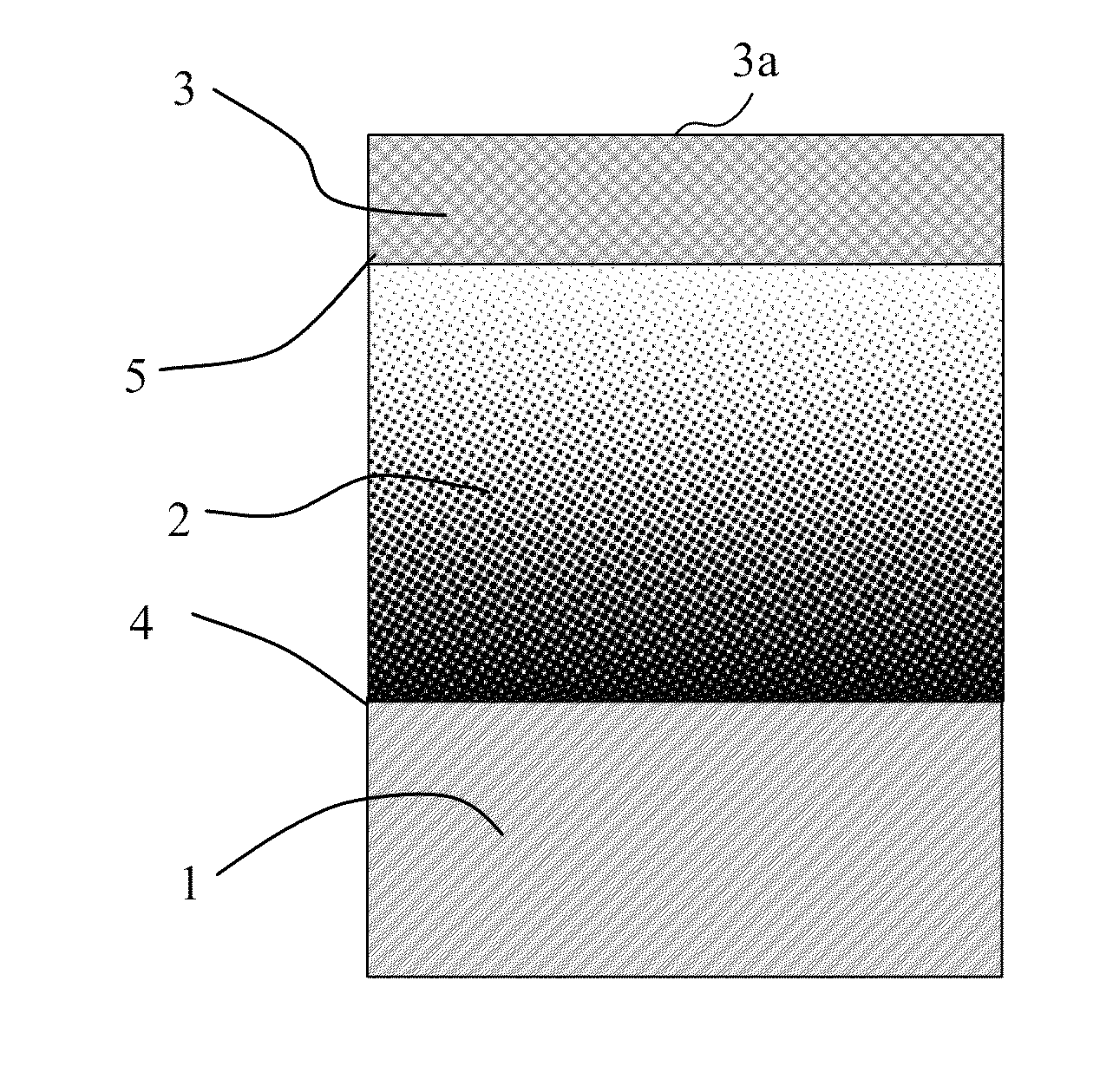

[0051]A more detailed description will be made of the anti-reflection structure of Embodiment 1 with reference to FIG. 1. The graded refractive index layer 2 and the low refractive index layer 3 are laminated on the surface of the substrate 1. The refractive index of the graded refractive index layer 2, as described above, decreases from the substrate side interface 4 toward the low refractive index layer side interface 5. The low refractive index layer 3 is a porous layer (mesoporous layer) being formed of mesoporous silica and having an even refractive index. The mesoporous silica includes a lot of minute holes in silica as shown in FIG. 14. The refractive index of the low refractive index layer 3 is decided depending on the rate (hole rate) of the minute holes occupying the mesoporous silica. A higher hole rate of the mesoporous silica provides a lower refractive index.

[0052]The graded refractive index layer 2 is a layer formed by binary vapor deposition of TiO2 and SiO2. The ref...

embodiment 2

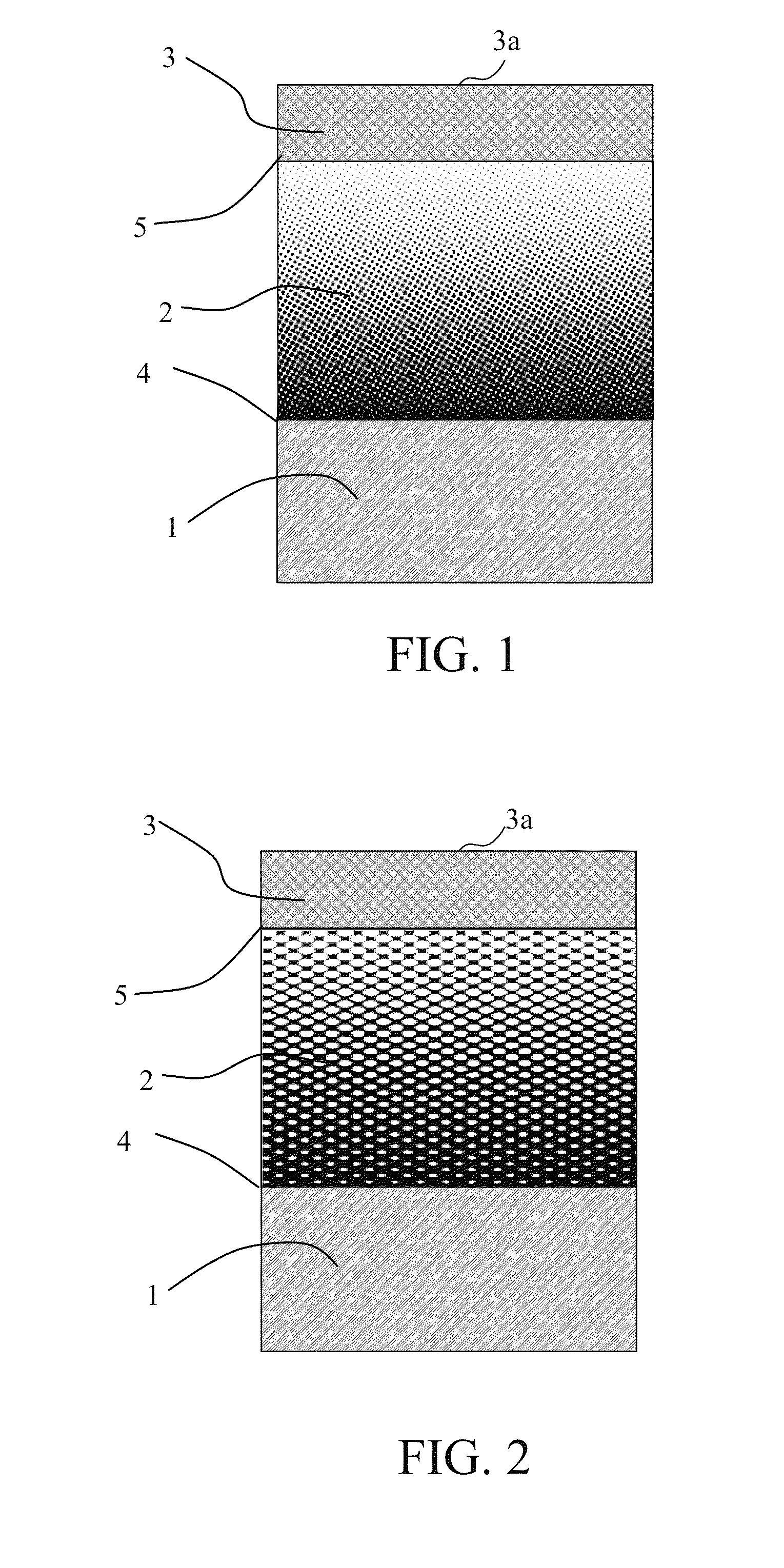

[0065]A more detailed description will be made of the anti-reflection structure of Embodiment 2 with reference to FIG. 2. The graded refractive index layer 2 and the low refractive index layer 3 are laminated on the surface of the substrate 1. The refractive index of the graded refractive index layer 2, as described above, decreases from the substrate side interface 4 toward the low refractive index layer side interface 5. As in Embodiment 1, the low refractive index layer 3 is a porous layer being formed of mesoporous silica and having an even refractive index.

[0066]The graded refractive index layer 2 is a porous layer (mesoporous layer) being formed of mesoporous SnO2 and having a structure in which a lot of minute holes are formed in SnO2. As with the mesoporous silica, a higher hole rate of the mesoporous SnO2 provides a lower refractive index. In this embodiment, as shown in FIG. 15, the hole rate in the graded refractive index layer 2 decreases as a distance to the substrate s...

embodiment 3

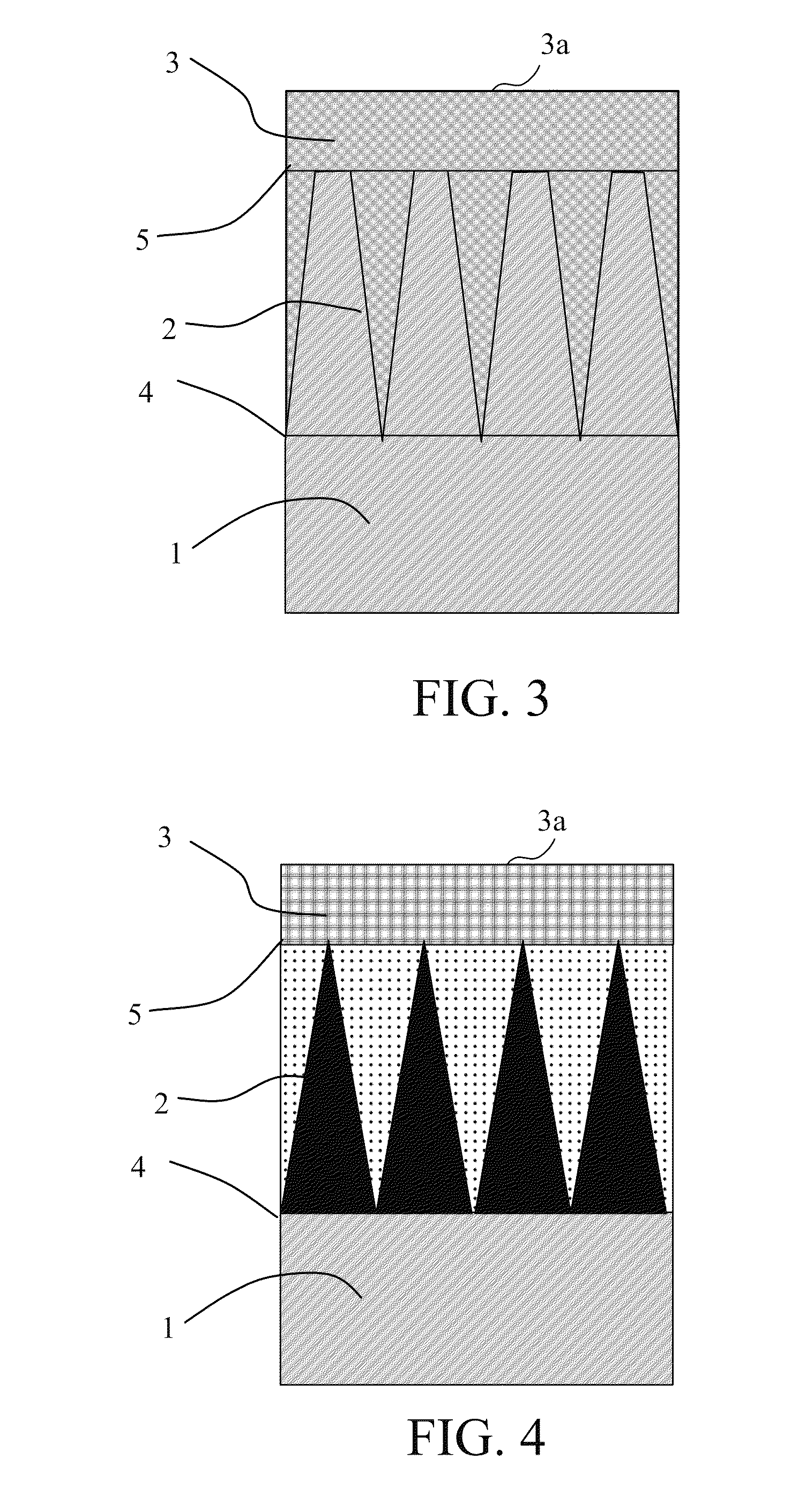

[0073]A more detailed description will be made of the anti-reflection structure of Embodiment 3 with reference to FIG. 3. The graded refractive index layer 2 and the low refractive index layer 3 are laminated on the surface of the substrate 1. The refractive index of the graded refractive index layer 2, as described above, decreases from the substrate side interface 4 toward the low refractive index layer side interface 5. As in Embodiment 1, the low refractive index layer 3 is a porous layer (mesoporous layer) being formed of mesoporous silica and having an even refractive index.

[0074]The graded refractive index layer 2 includes a base layer being formed of a same medium as that of the substrate 1 and having minute roughness (minute convex portions forming concave area therearound). A pitch (dimension) of the convex portions is about ½λ that is smaller than the using wavelength λ. Moreover, the convex portions occupy a volume of almost 100% in the graded refractive index layer 2 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com