Magnetic recording device and magnetic recording method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

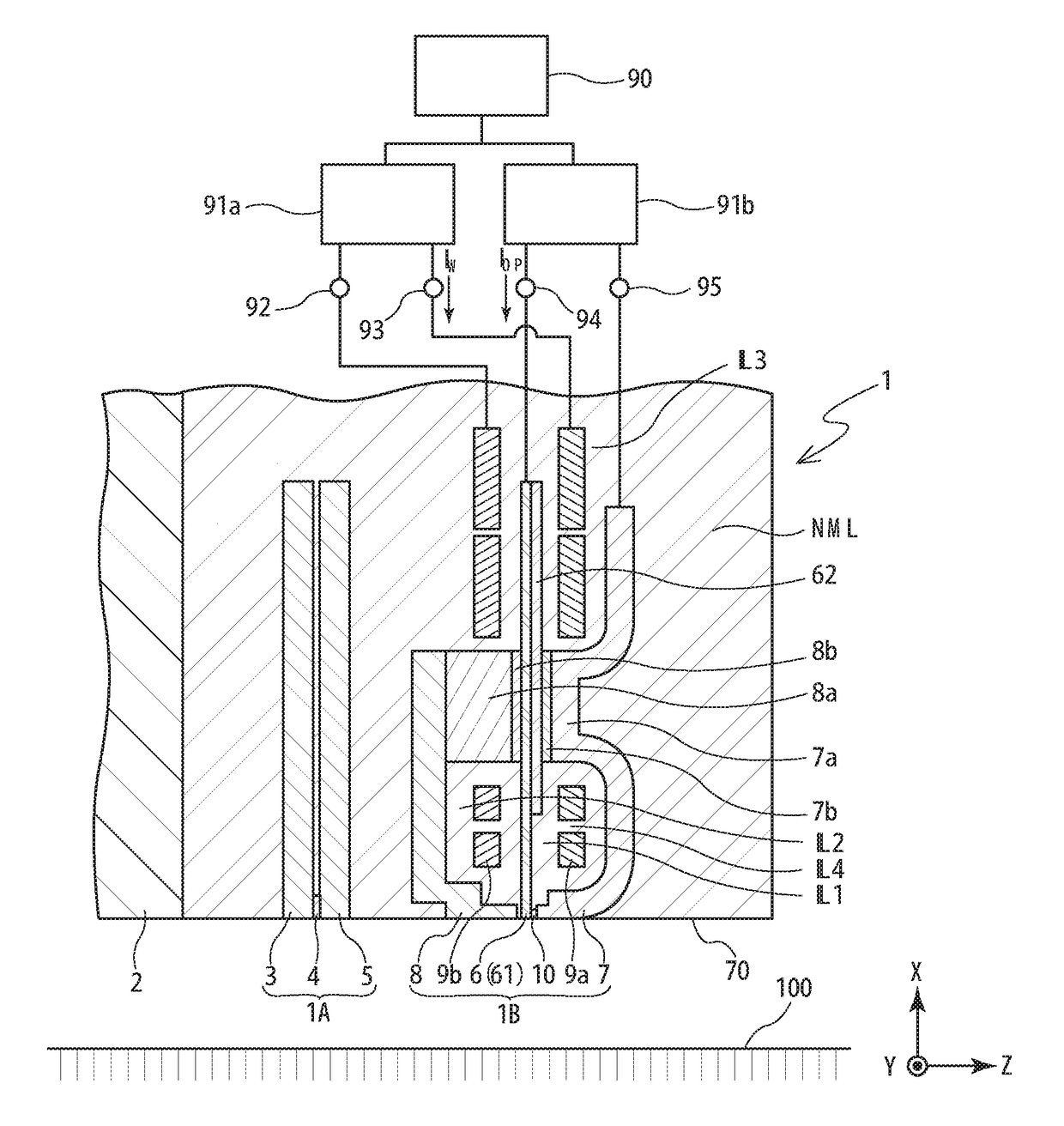

[0109]Using the magnetic recording device having the configuration shown in FIGS. 1 to 9, signals were recorded on a magnetic disc, the signals were read with the reproducing head 1A of the microwave assisted head 1, and the SN ratios (dB) of the reproduced signals were measured. The results are shown in FIG. 13.

[0110]Here, upon recording signals, the recording current waveform data DWW as shown in FIG. 10A were created based on the signals to record, the unit drive current waveforms UOP were created as shown in FIGS. 11A and 11B, and the drive current waveform data DOPW as shown in FIG. 10B were created. The signals recorded on a magnetic disc included a signal S1 corresponding to a relatively short polarity reversal interval GPR1, a signal S3 corresponding to a relatively long polarity reversal interval GPR3, and a signal S2 corresponding to a polarity reversal interval GPR2 in-between. The relationship between the threshold time TH for creating the drive current waveform data DOP...

reference example 1

[0113]Signals were recorded on a magnetic disc in the same manner as in Example 1 except that no drive current IOP was applied while recording the signals. The signals were read with the reproducing head 1A of the microwave assisted head 1, and the SN ratios (dB) of the reproduced signals were measured. The results are shown in FIG. 13.

[0114]FIG. 13 is a graph showing the SN ratios (dB) of the signals S1 to S3. The results shown in FIG. 13 confirmed that it is possible to improve the SN ratio of the signal S1 corresponding to a relatively short polarity reversal interval GPR and prevent deterioration in quality of the signal S3 corresponding to a relatively long polarity reversal interval GPR3 by controlling supply of the drive current IOP according to the length of the polarity reversal interval GPR in the recording current waveform data DWW based on the signals to be recorded as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com