Method for thermal-displacement-type strengthened extraction in drill hole

a technology of thermal displacement and enhanced extraction, which is applied in the direction of fluid removal, borehole/well accessories, insulation, etc., to achieve the effects of low cost, convenient implementation and safe and reliabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]This disclosure will be hereinafter detailed in an embodiment with reference to the accompanying drawings.

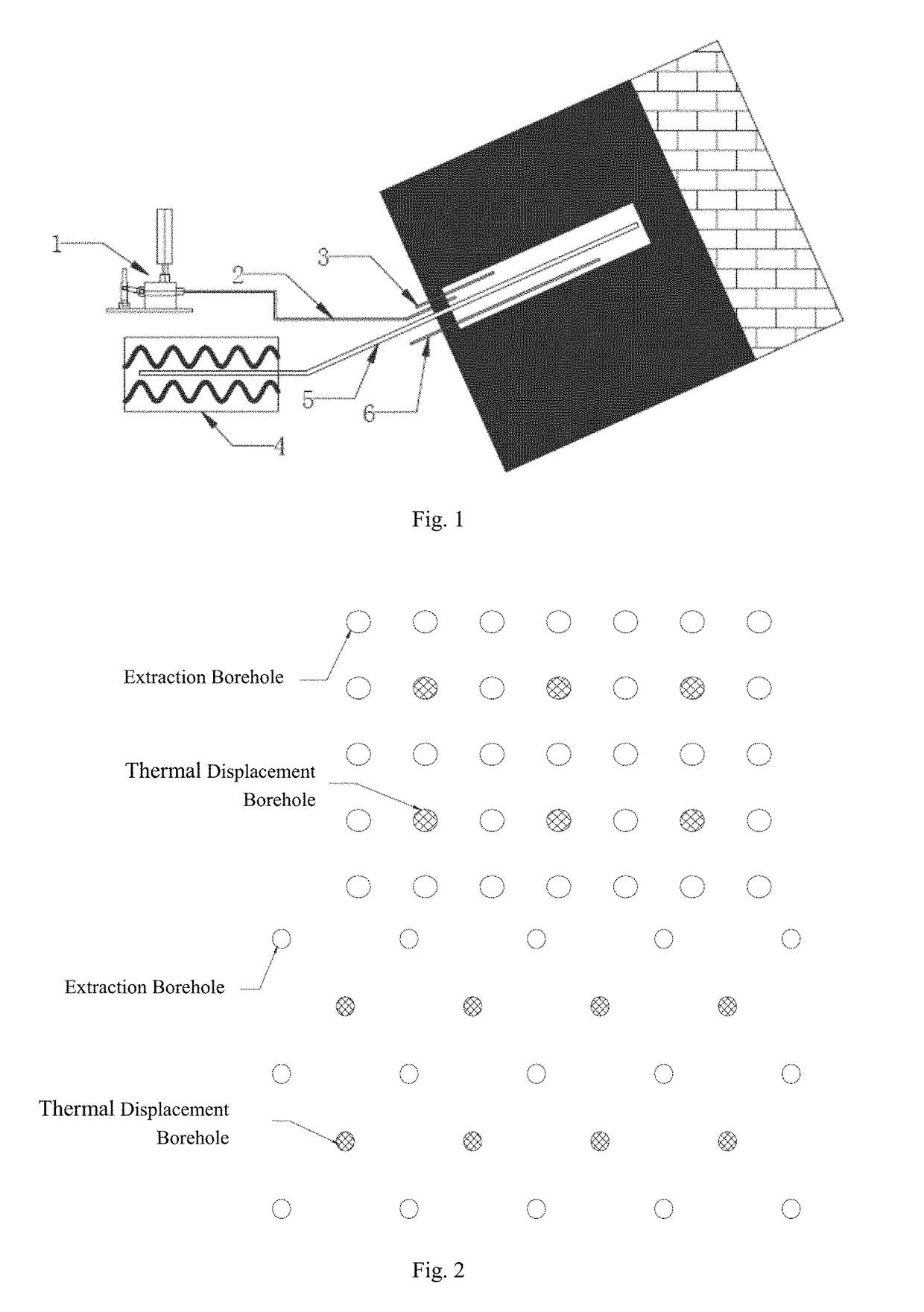

[0017]The method for gas extraction enhanced by thermal displacement in boreholes provided in this disclosure comprises drilling boreholes crossing a coal seam and drilling boreholes down the coal seam:[0018]a. arranging extraction borehole sites at an interval in the coal seam in a way that the extraction boreholes are within the scope of influence of thermal displacement boreholes;[0019]b. sequentially drilling extraction boreholes, sealing the boreholes, and connecting the boreholes into a gas extraction pipe network for gas extraction;[0020]c. arranging a plurality of thermal displacement boreholes among the plurality of extraction boreholes in a way that the thermal displacement boreholes and the extraction boreholes are arranged in a staggered manner, as shown in FIG. 2;[0021]d. sequentially drilling a thermal displacement borehole; inserting a grouting pipe 2, a ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com