Method for producing temporary prosthesis

a dental prosthesis and temporary technology, applied in dental prosthetics, dental prosthetics, dentistry, etc., can solve the problems of occlusal problems, wear easily and have relatively low strength, and the above problems of wear become even more visible, so as to achieve less susceptible to wear and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

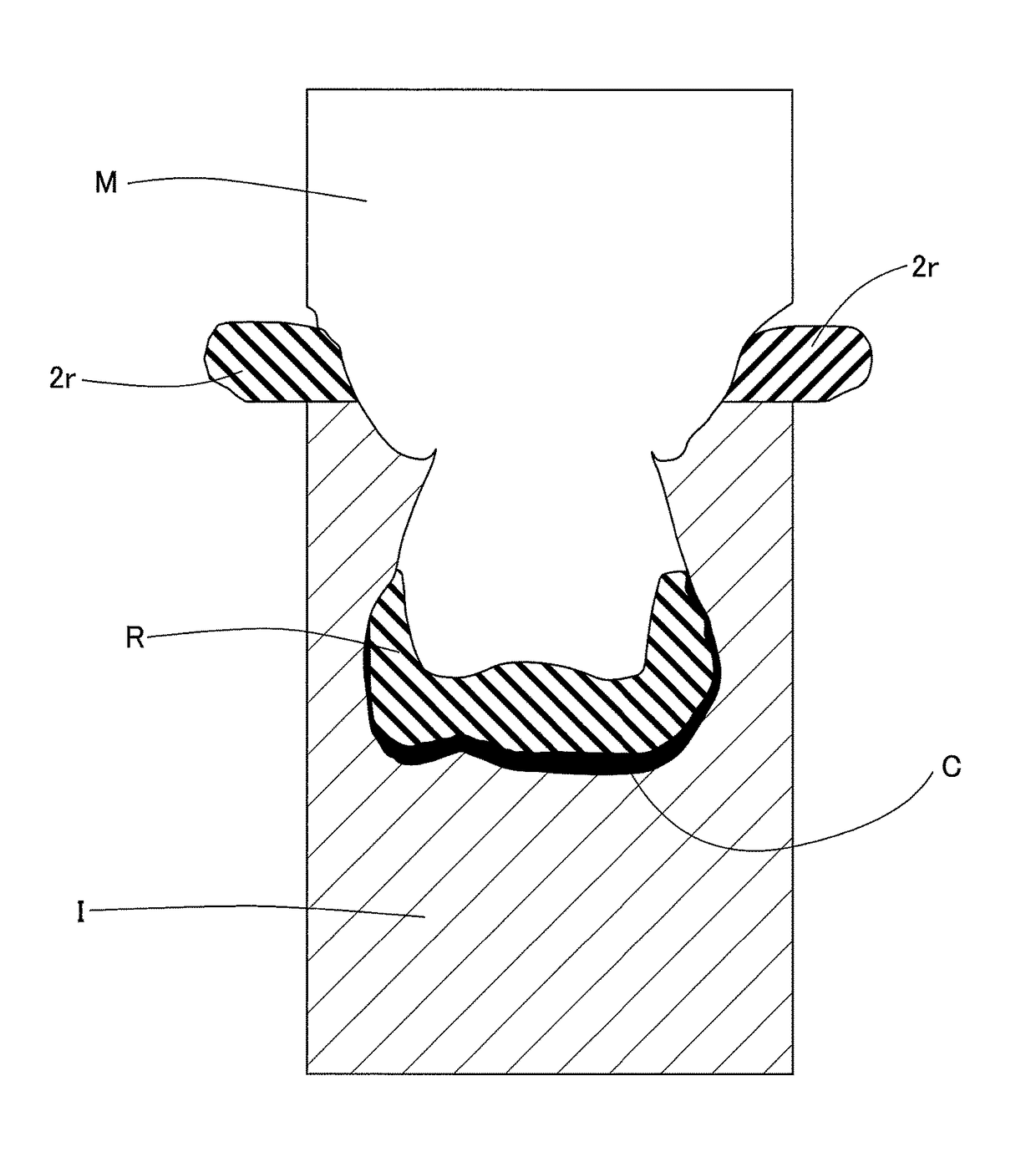

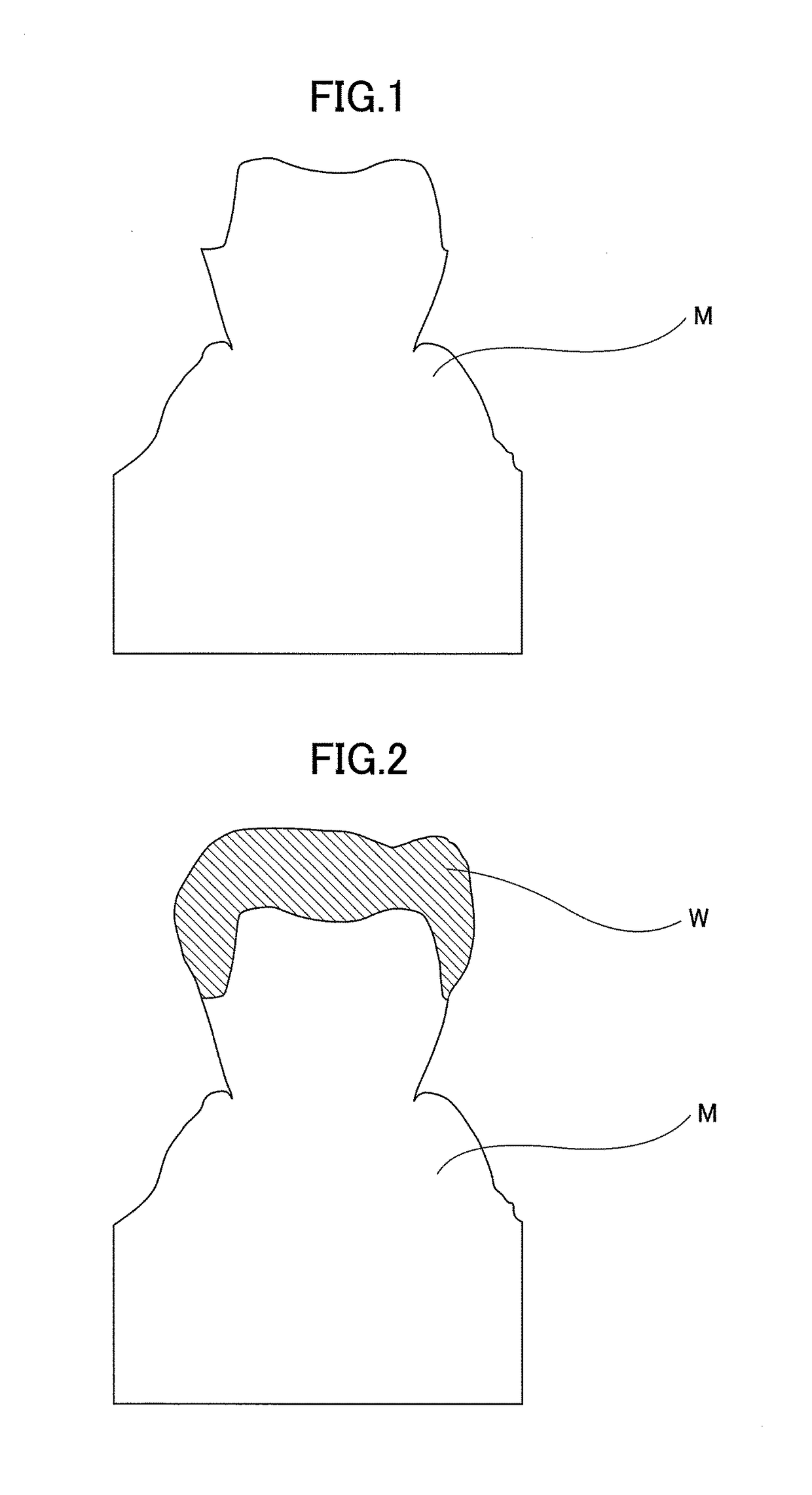

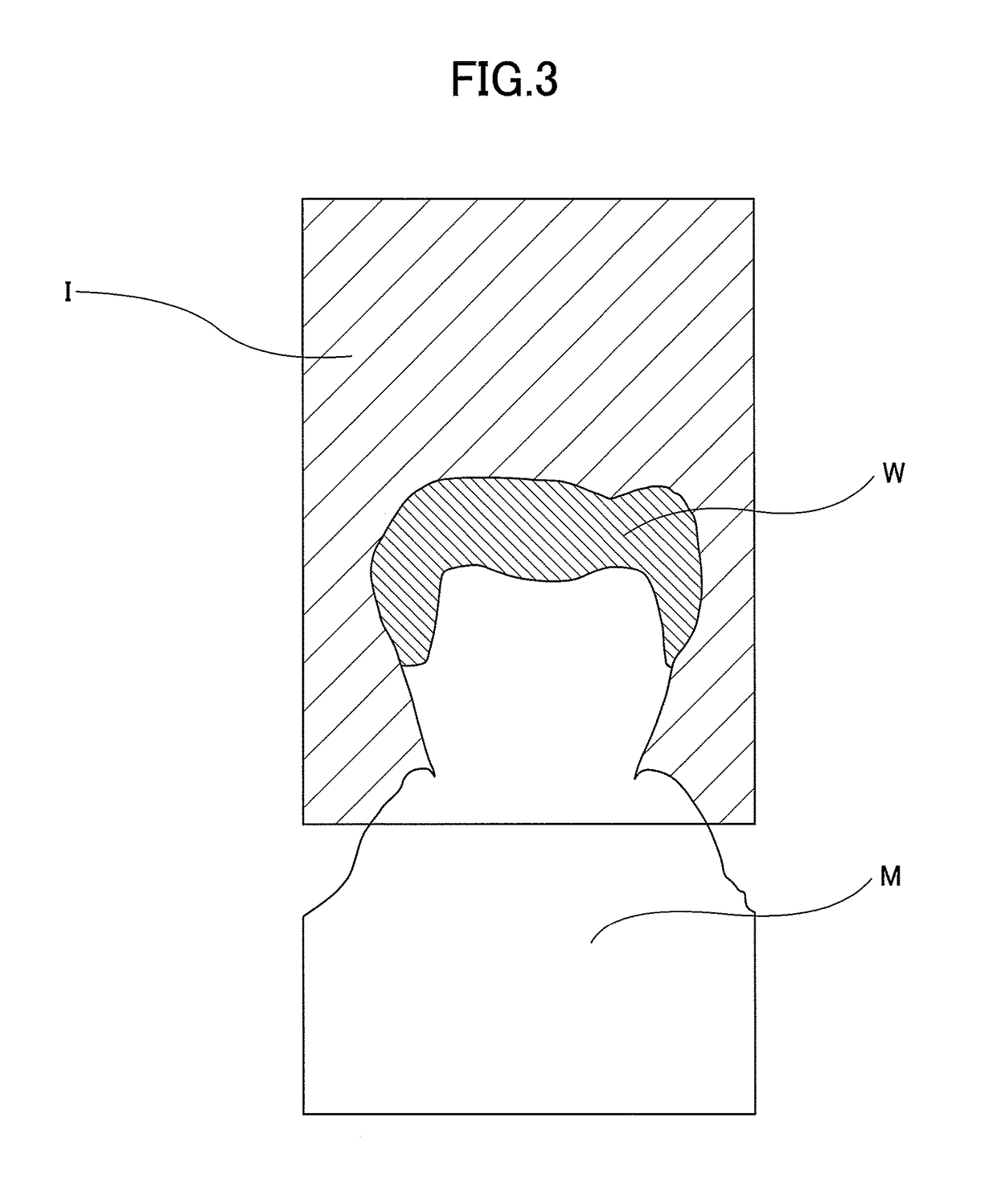

[0037]In the following, methods for producing a temporary prosthesis according to the present invention are described in detail with reference to the accompanying drawings. A first method for producing a temporary prosthesis according to the present invention is described below. First, as illustrated in FIGS. 1 and 15, a prepared tooth model M replicating an oral cavity including a prepared tooth TT that has been arranged into a shape for receiving a temporary prosthesis, namely, a tooth that has been subjected to an abutment tooth or formation of a cavity, is fabricated using a conventional technique. The prepared tooth model M is preferably fabricated using conventional dental plaster but may also be fabricated using other techniques such as polymerization of resin, cutting, 3D printing, and the like, for example.

[0038]Then, using the prepared tooth model M, a prosthesis model W having the same shape as that of the temporary prosthesis to be produced is fabricated with wax, synthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com