Tuning saboted projectile performance through bourrelet modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

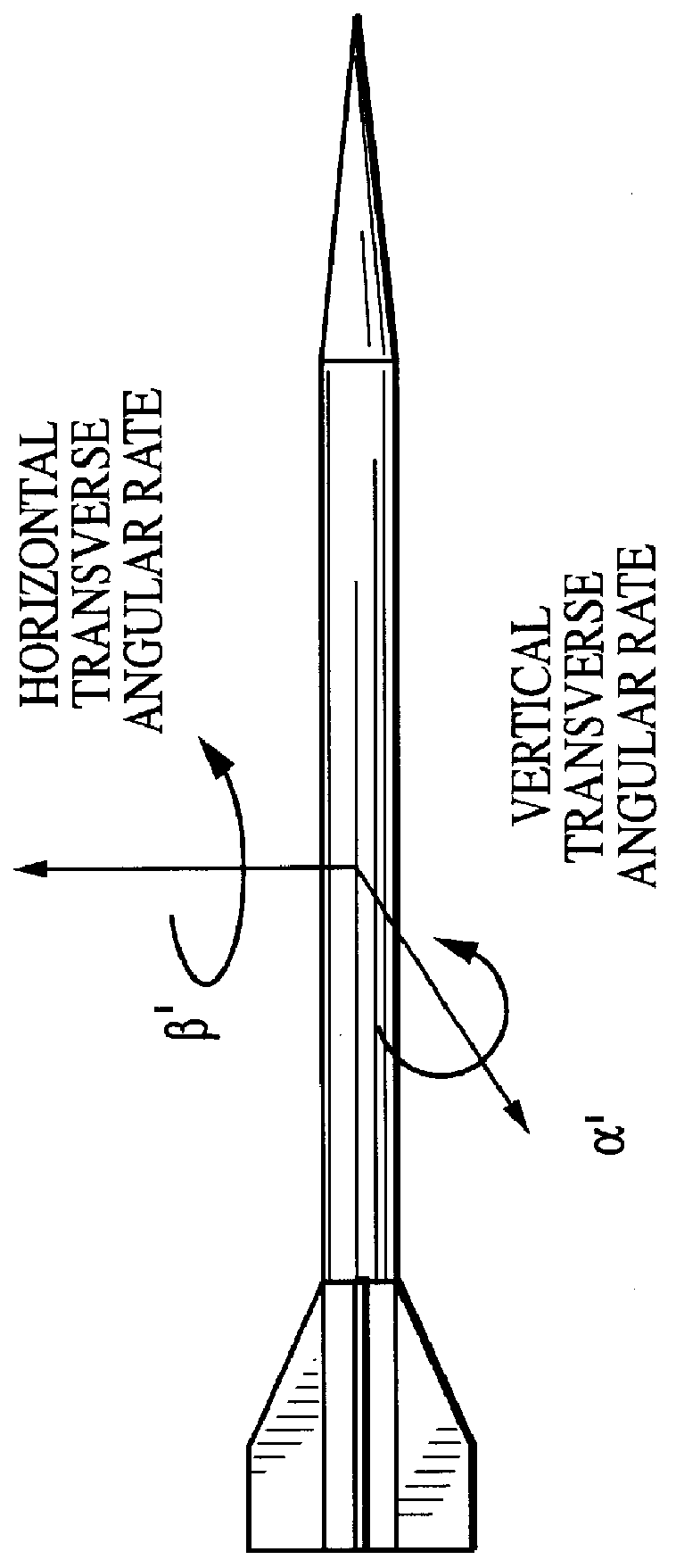

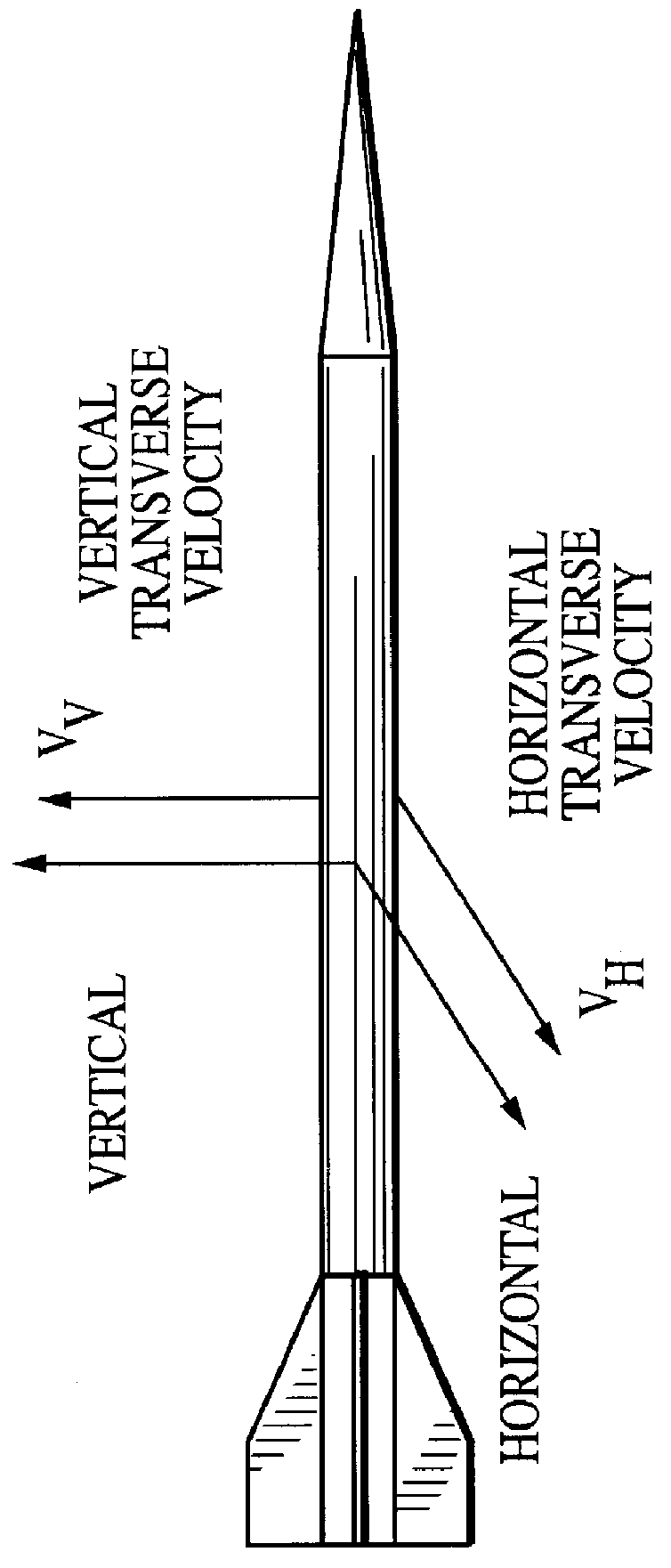

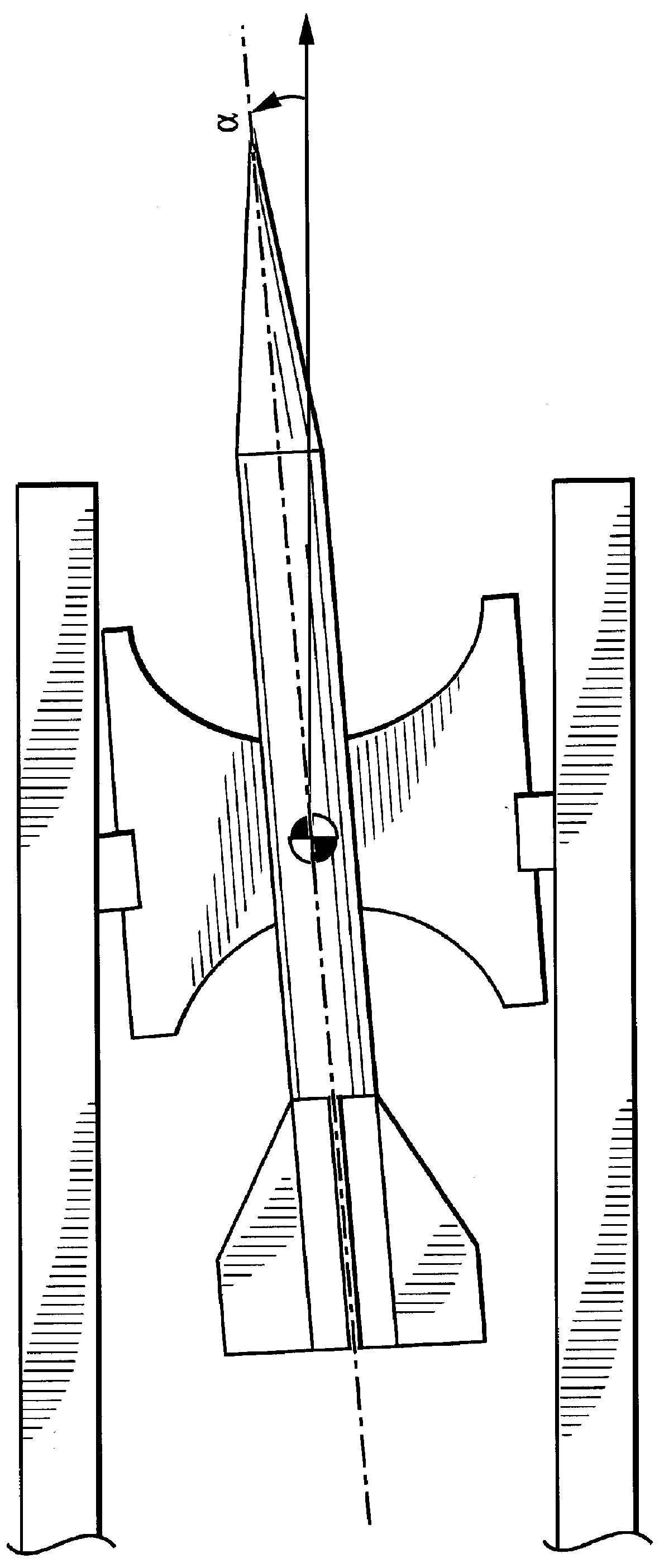

In order to understand shot accuracy, the entire process of projectile launch and flight must be understood. The vector from the line of fire to the impact is defined as the projectile jump. It is convenient to break this vector up into a series of parts that correlate with different aspects of launch and flight. When this is done, jump is defined as

wherein,

MP=Muzzle Pointing Angle: The direction the end of the gun tube is pointing when the projectile exits the gun;

CV=Crossing Velocity Jump: The velocity of the muzzle of the gun tube at projectile exit;

CG=Center-of-Gravity Jump: The velocity of the CG of the flight projectile at muzzle exit relative to a coordinate frame attached to the muzzle;

SD=Sabot Discard Disturbance: The change in the trajectory of the flight projectile due to disengagement of the sabot from the flight projectile;

AJ=Aerodynamic Jump: The jump associated with integrating the angle of attack of the flight projectile during the time of flight; and

GD=Gravity Drop:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com