Actuator pivot shaft rolling bearing with seal

a technology of rolling bearing and pivot shaft, which is applied in the direction of bearing components, shafts and bearings, gas turbine plants, etc., can solve the problems of reducing the available vtg actuation torque, affecting the operation of the actuating shaft, so as to reduce the friction, reduce the rolling resistance, and reduce the friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]A turbocharger is generally known and includes a turbine and a compressor, wherein a compressor impeller is rotatably driven via a rotating shaft by a turbine wheel. The rotating shaft passes through a bearing housing between a turbine housing and a compressor housing.

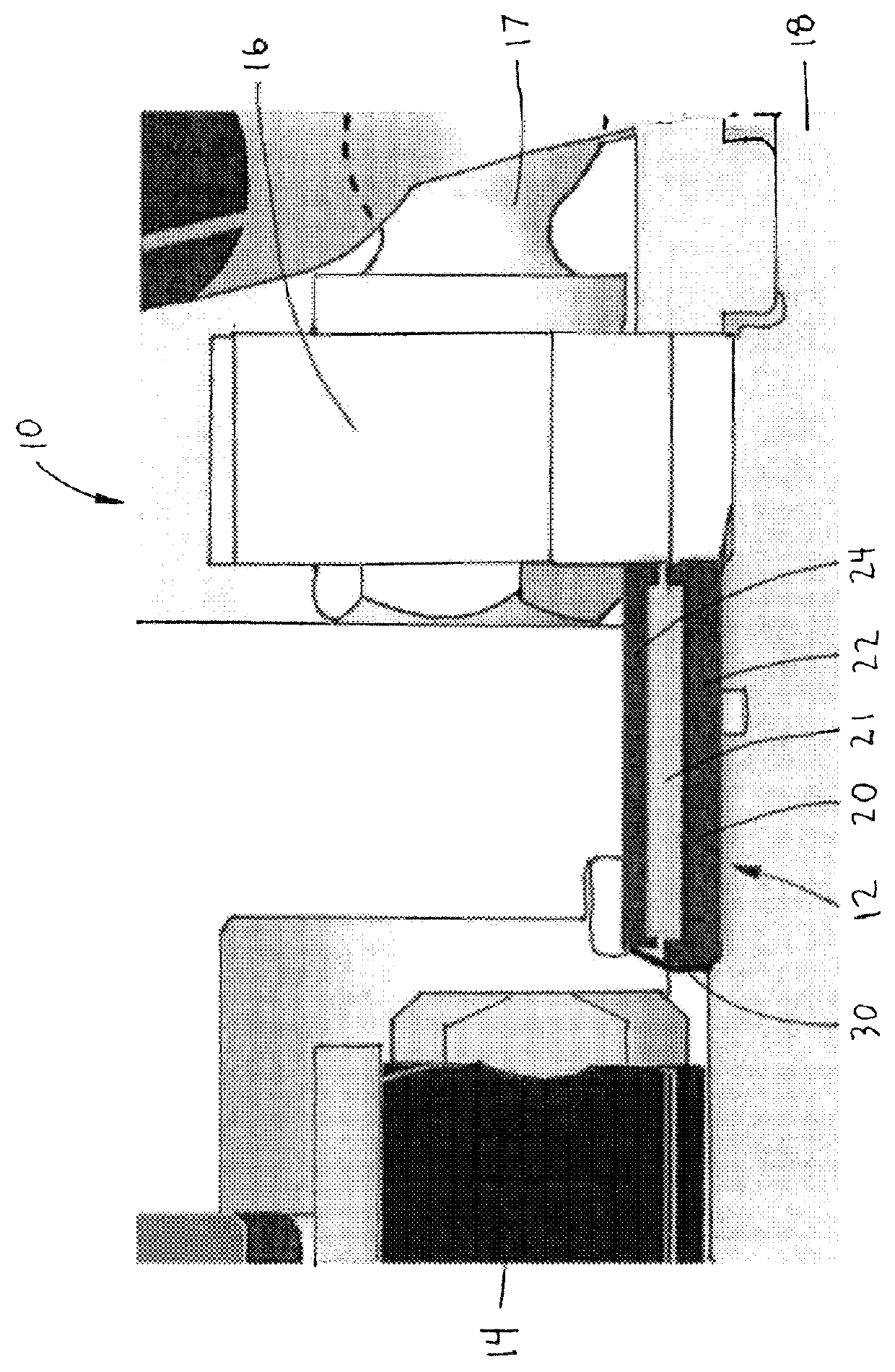

[0017]The variable turbine geometry (VTG) turbocharger 10 may include an actuator pivot shaft assembly 12 as shown in FIG. 1 with a portion between a large block 14 and a VTG lever 16 with a ball 17 on the VTG lever 16. The actuator pivot shaft 18 defines an axis of rotation partially surrounded by a rolling-element bearing 20.

[0018]The VTG turbocharger 10 may include an actuator pivot shaft bearing assembly 12 with a rolling-element bearing 20 with a rolling element 21 between an inner race 22 and outer race 24. The inner race 22 is closest to the actuator pivot shaft 18 with a smaller circumference than the outer race 24. The rolling elements 21 used in rolling-element bearings 20 is shown in the figure as a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com