Pressurized water closet flushing system

a pressurized water closet and flushing technology, applied in the field of pressurized water closets, can solve the problems of relatively inefficient propulsion energy that affects the waste extraction of the toilet bowl, and achieve the effect of improving the waste extraction energy and improving the consistency and reliability of the flushing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

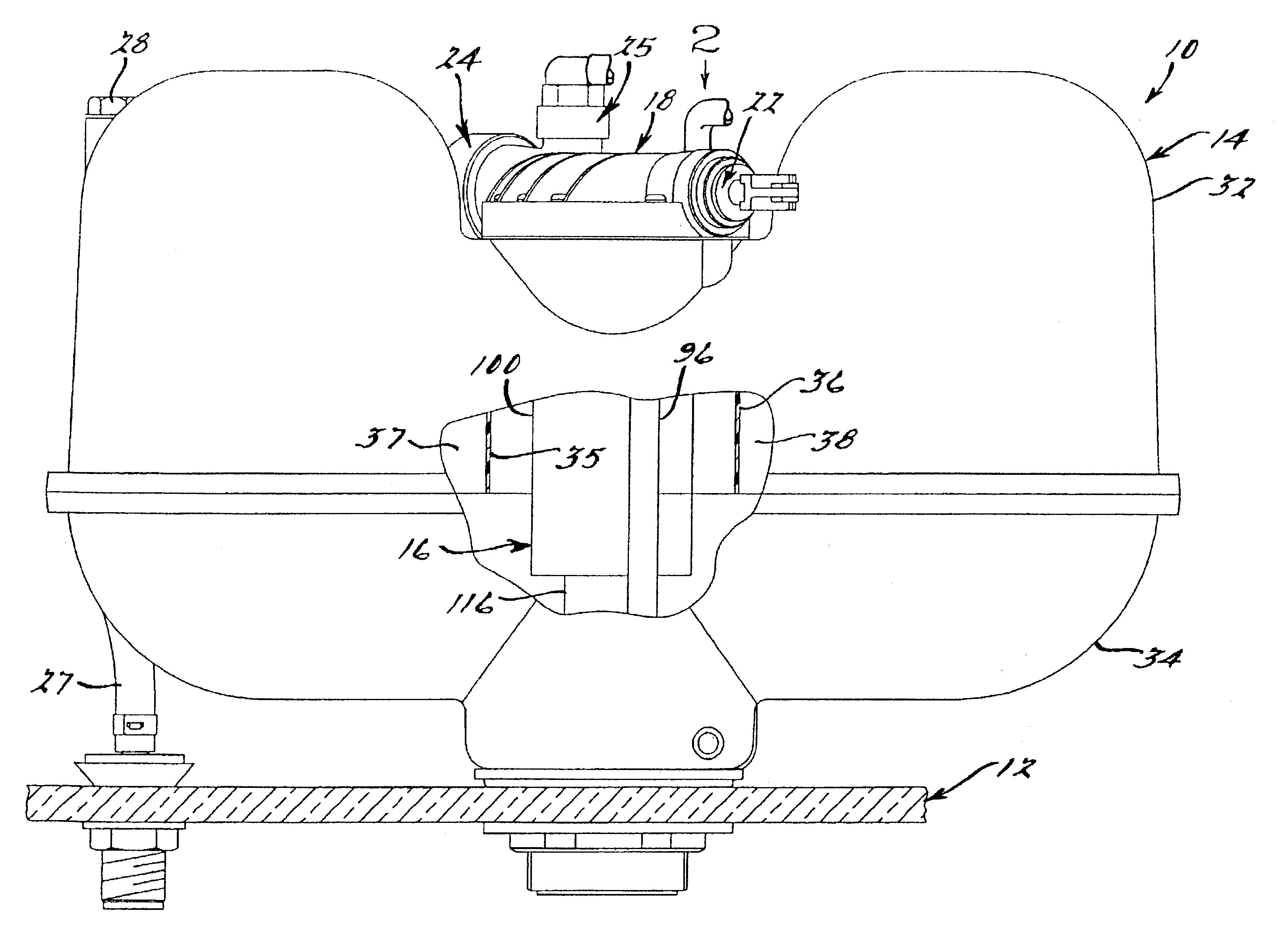

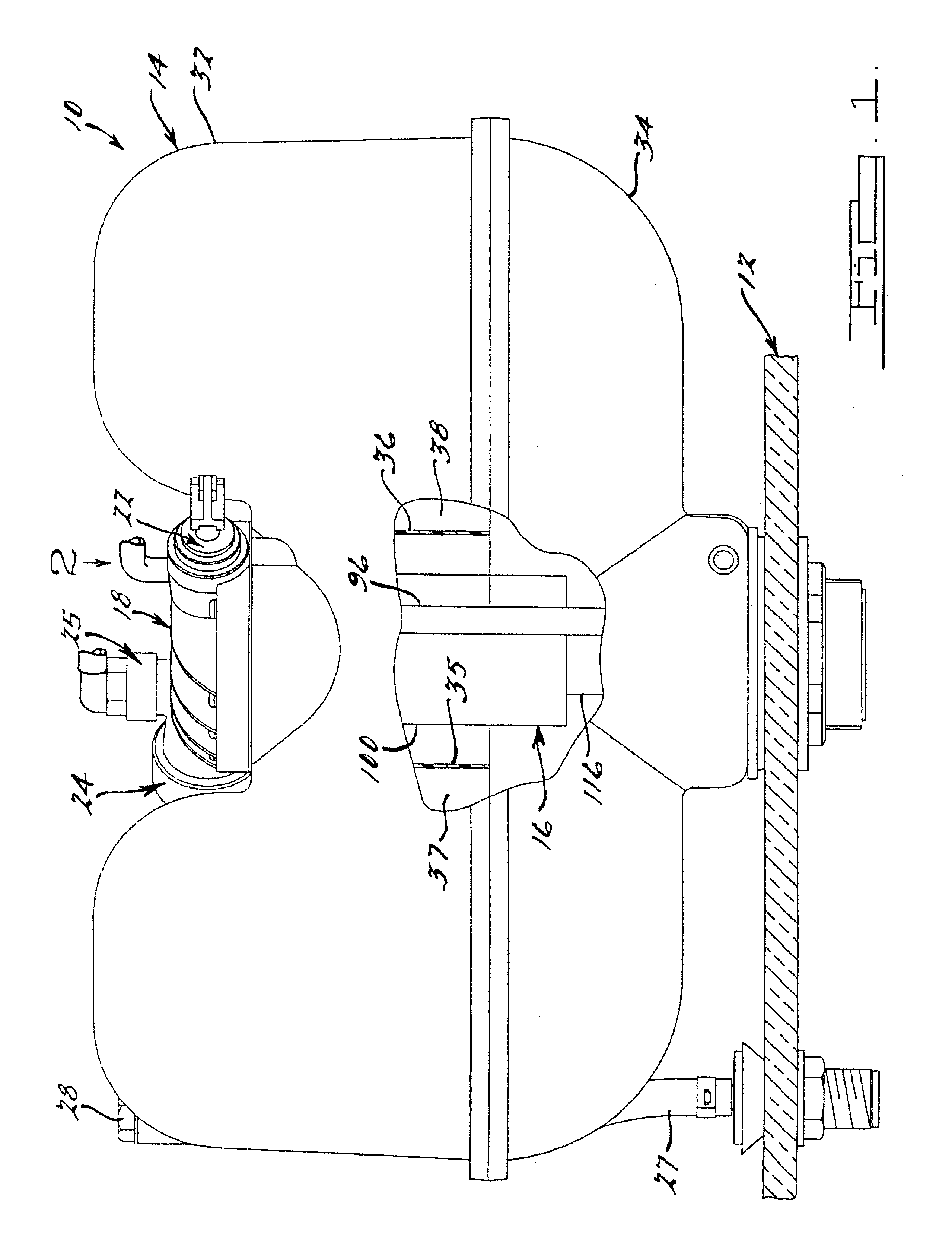

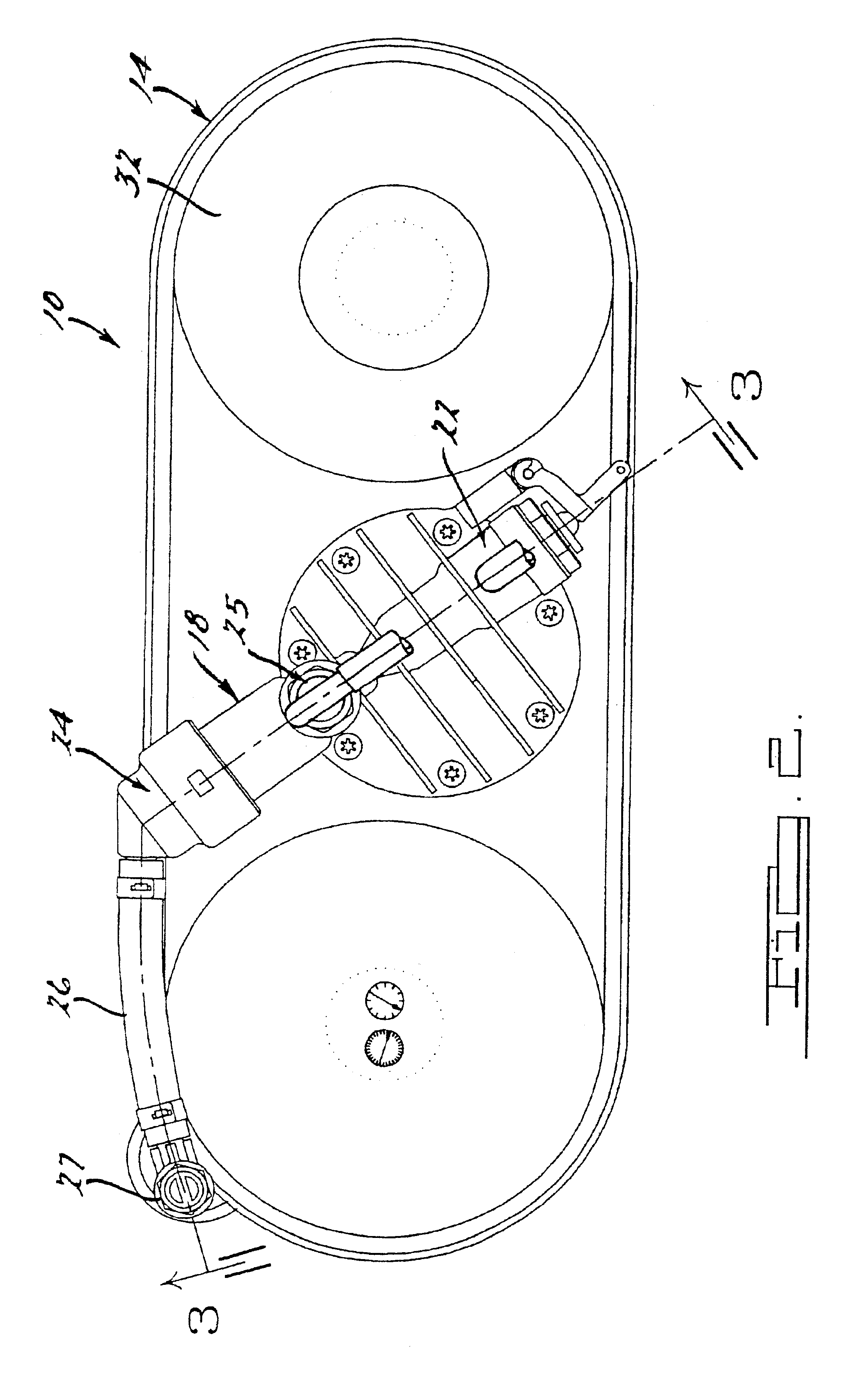

As seen in FIGS. 1 and 2, a pressurized water closet flushing system 10, in accordance with a preferred and constructed embodiment of the present invention, is shown in operative association with a conventional water closet tank 12. Major components of the system 10 are a water vessel 14, an internal flush valve assembly 16, and a manifold 18 comprising an integral flush valve actuator 22, a water pressure regulator 24, an air induction regulator 25 as seen in FIG. 3, a disinfectant reservoir 26.

Water is supplied to the system 10 from a pressurized source (not shown) and flows upwardly without restriction through an inlet conduit 27 and vacuum breaker 28, thence laterally to the manifold 18. Water is free to flow through the conduit 27 to the manifold 18 at system pressure thence, after regulation, to both the flush valve assembly 16 and water vessel 14, as will be described.

The size of the water vessel 14 is dictated by energy requirements of the system 10. In the preferred constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com