Embeddable mounting device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

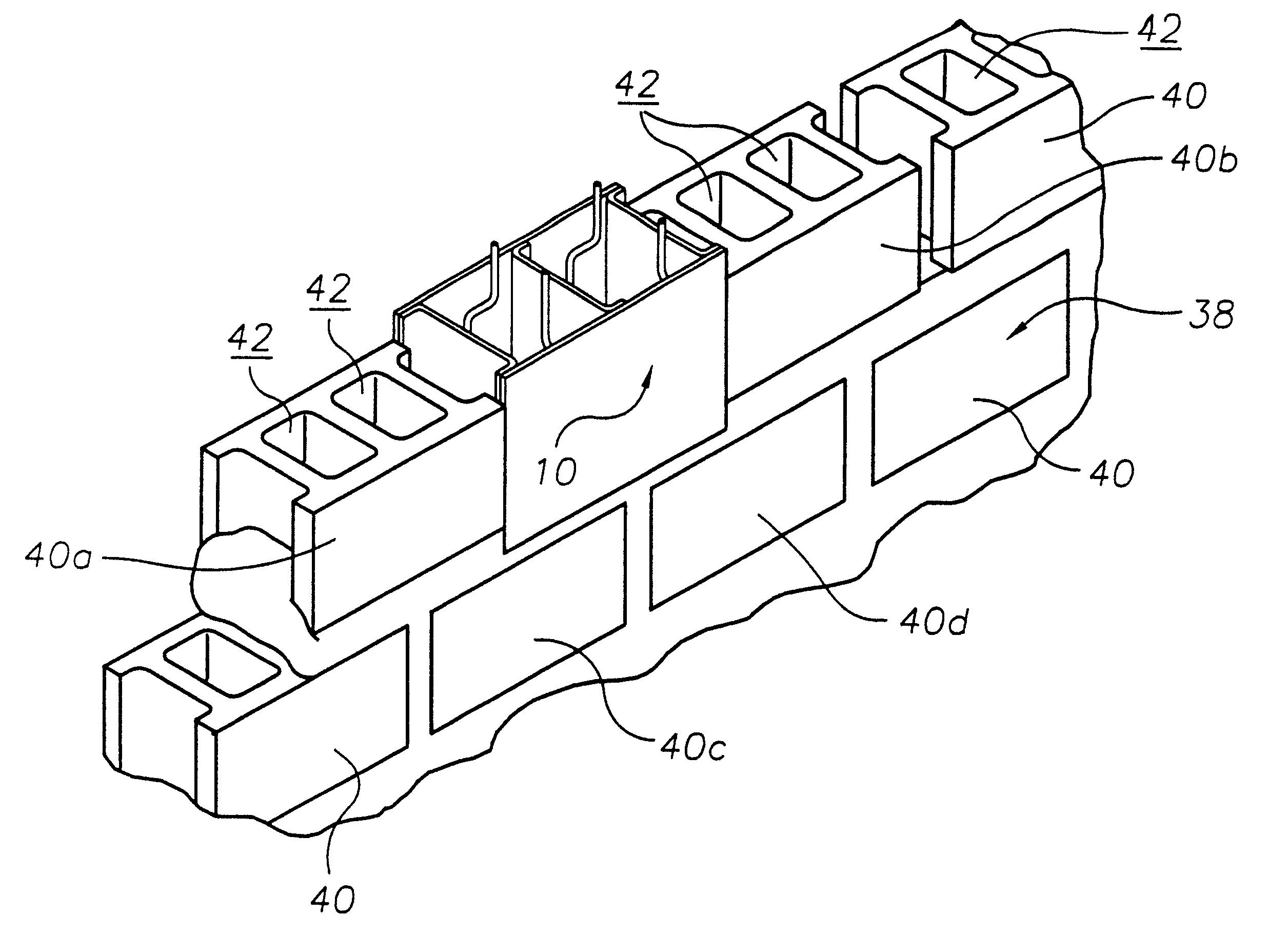

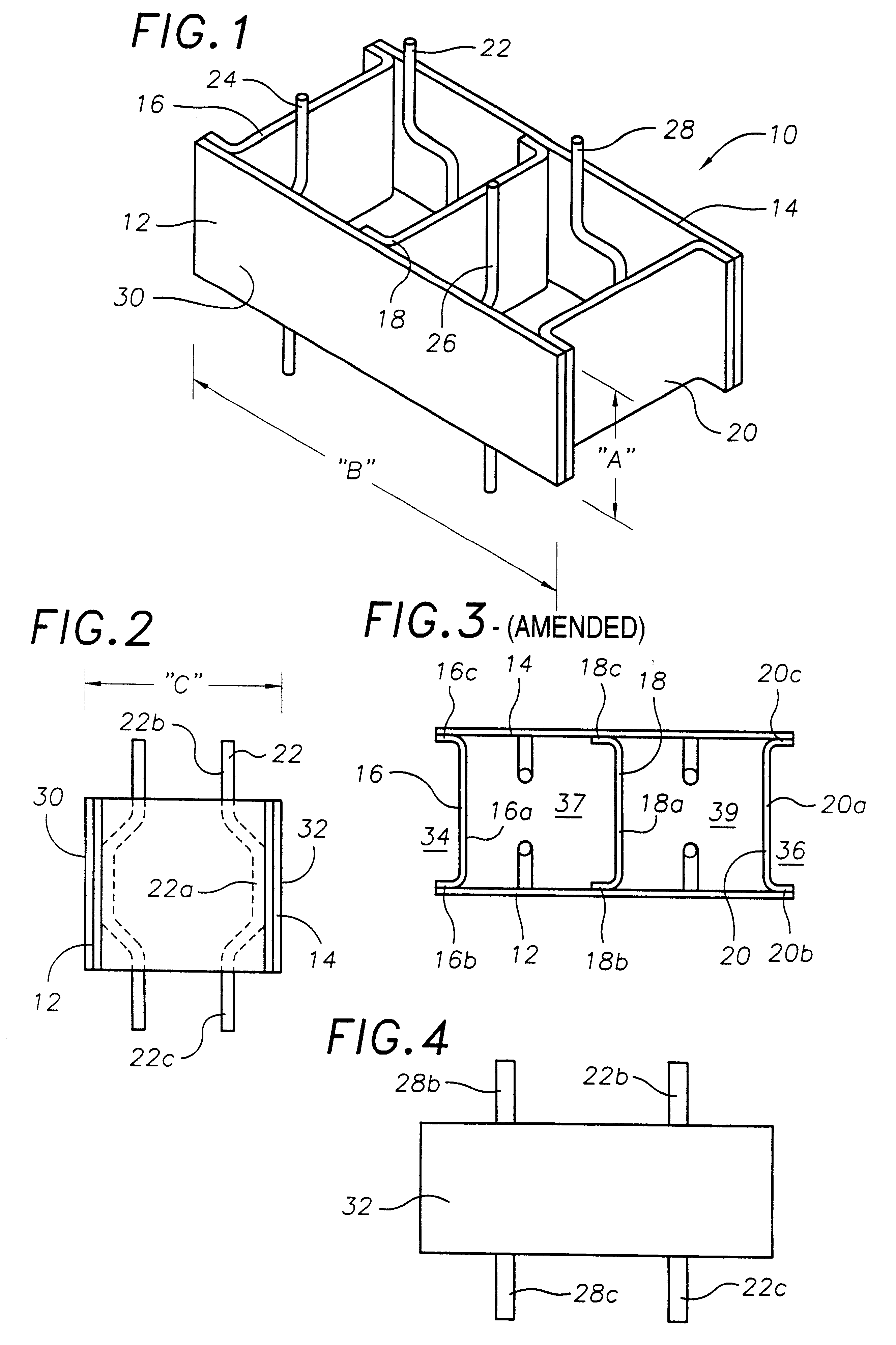

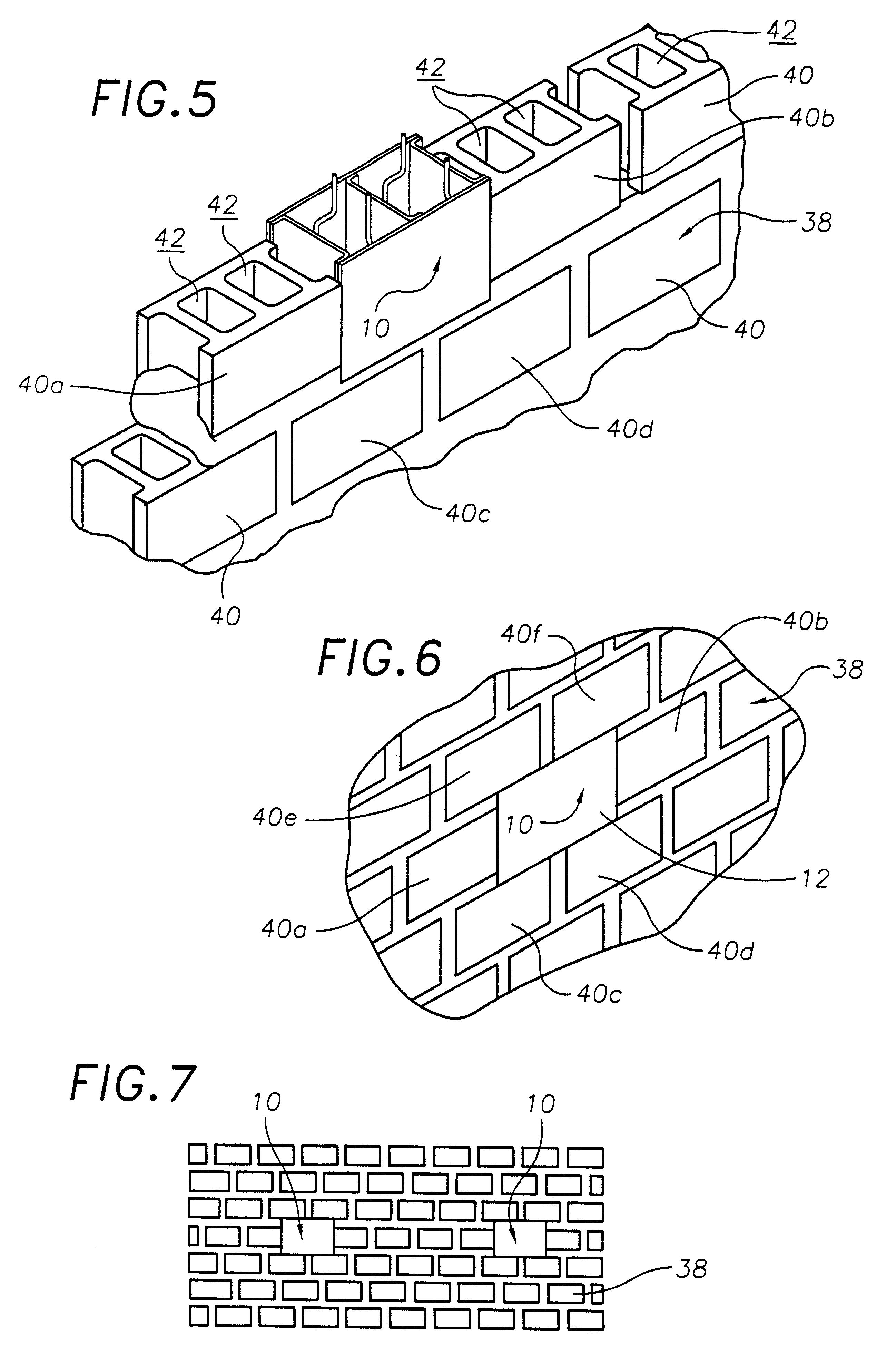

FIG. 1 is a perspective view of an exemplary embodiment of the embeddable mounting device of the present invention generally designated by the numeral 10. Mounting device 10 includes a first rectangular metal plate member 12; a second rectangular metal plate member 14; first, second and third vertical spacer members 16,18,20; and four vertical reinforcing bars 22,24,26,28. In this embodiment first and second metal plate members 12,14 are both one-quarter (1 / 4") inch thick mild steel plates having a height "A" of eight and five-eighths (85 / 8") inches and a width "B" of sixteen and three-quarters 163 / 4") inches. With reference to FIG. 2, first and second plate members 12,14 are secured together and spaced a distance "C", between an outwardly facing first outer surface 30 (more clearly shown in FIG. 1) and outwardly facing second outer surface 32 (more clearly shown in FIG. 4), a distance of seven and five-eights (75 / 8") inches, by the three vertical spacer members 16,18,20 (FIG. 3). E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com