Ceiling fan outlet box

a ceiling fan and outlet box technology, applied in the field of ceiling boxes, can solve the problems of not providing sufficient strength, requiring additional mounting means for proper support, and ears that cannot be threaded through holes, and achieve the effect of superior structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

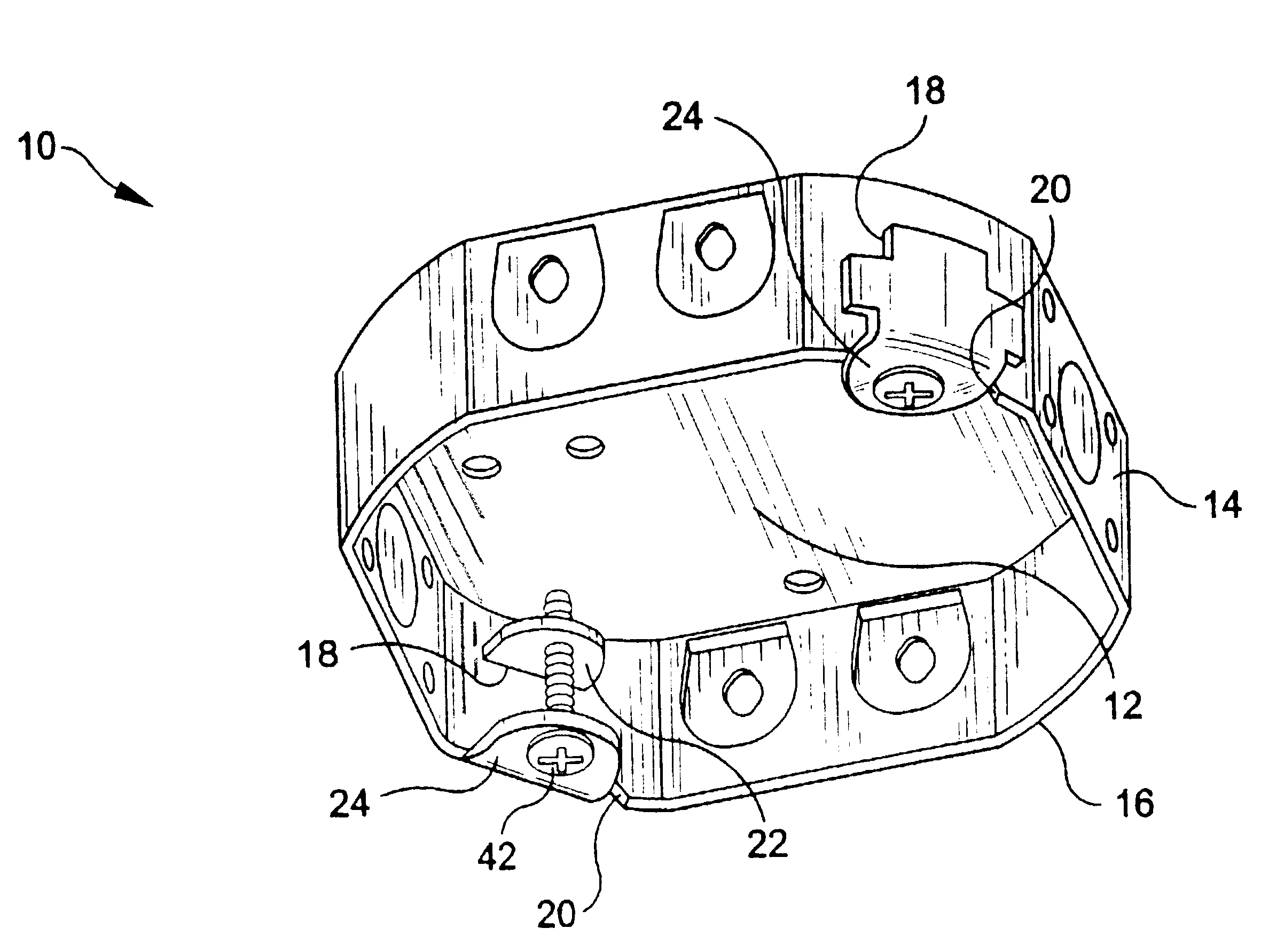

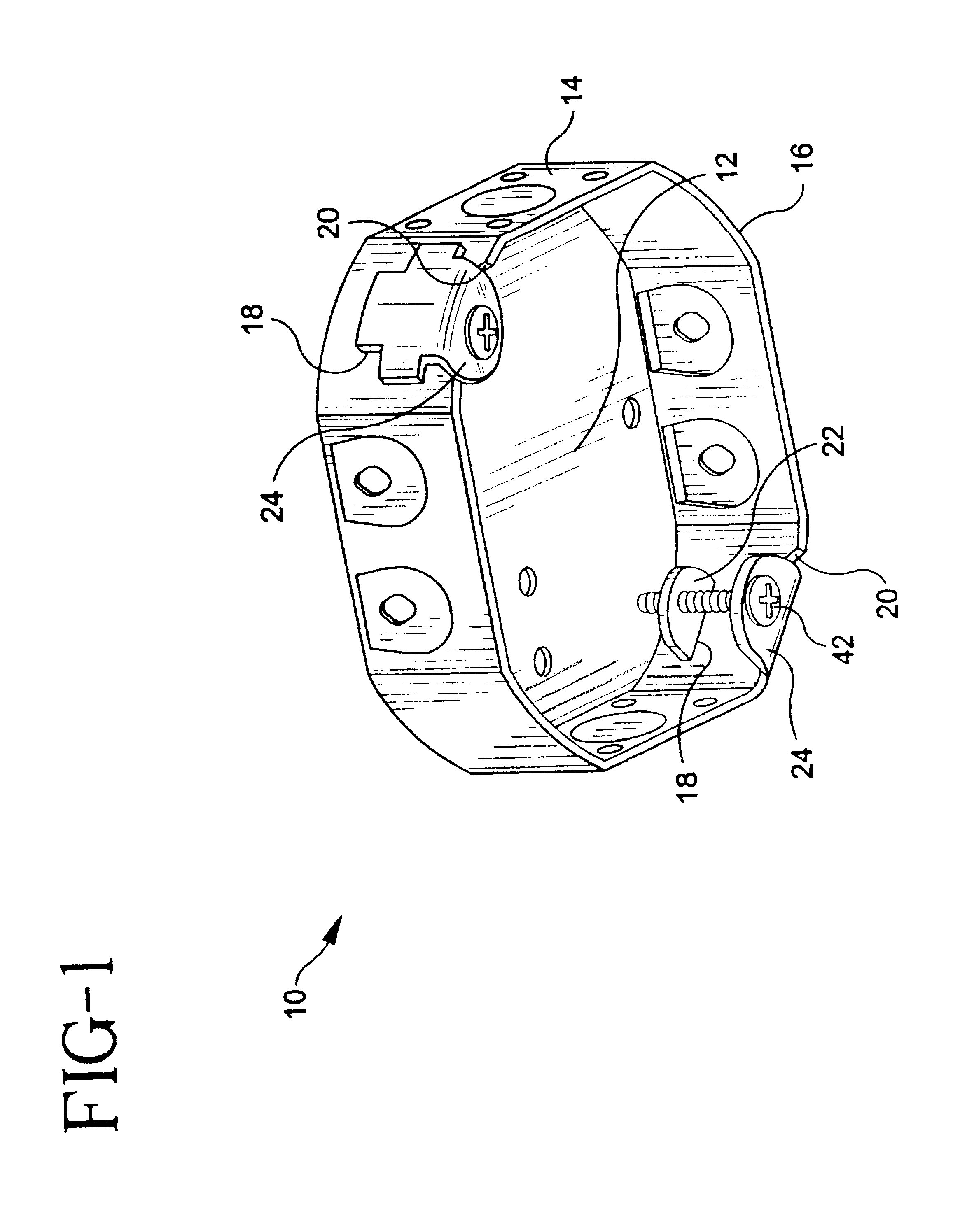

Referring initially to FIG. 1, an electrical ceiling box 10 is shown, comprising a top portion 12 peripherally bounded by side portion 14. Top portion 12 and side portion 14 may be formed from separate pieces of metal and rigidly secured to one another, as by welding, or they may be contiguous components of a single piece of metal formed by stamping or any other suitable process. As with conventional ceiling boxes, box 10 has an open end defined by edge 16, which faces downward upon normal installation.

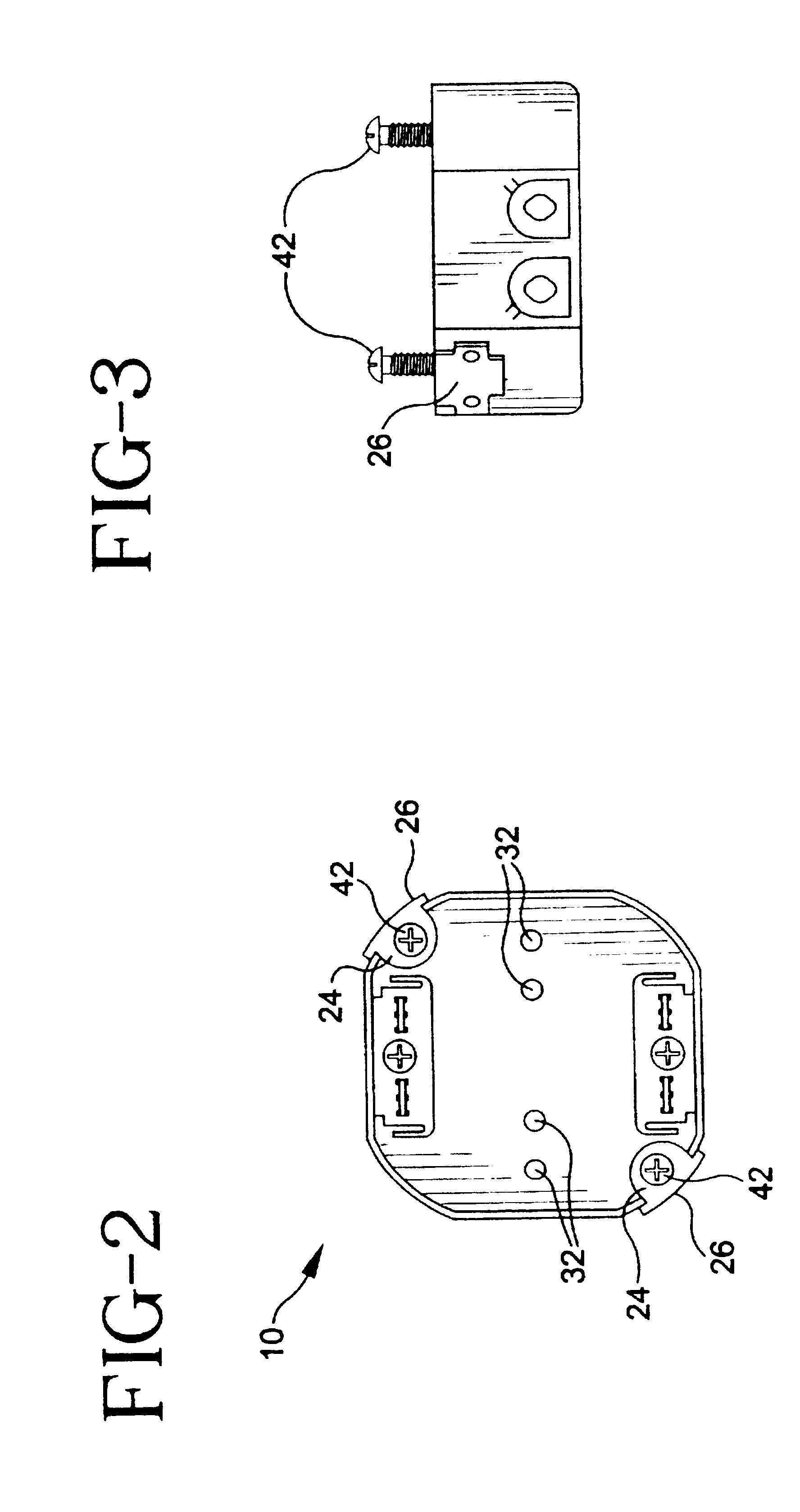

In the preferred embodiment of this invention, box 10 is generally octaganol in shape, as best seen in FIG. 2. A pair of slots 18, best seen in FIG. 10, are formed in opposite sides of box 10, as are a pair of recesses 20 formed in edge 16. Each slot 18 and its accompanying recess 20 are specially adapted to receive ears 22 and 24, respectively, of ear lug 26, best seen in FIGS. 7-9. As seen in FIG. 9, ears 22 and 24 are spaced apart and separated by a web portion 28, which preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com