Dual interleaved DC to DC switching circuits realized in an integrated circuit

a switching circuit and integrated circuit technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problem that the converter has not been realized in the integrated circuit form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The preferred embodiment of the present invention is intended for use for a buck converter, and accordingly, the same will be described in detail with respect to such converters. However, it is to be understood that the principles of the present invention are also applicable to other types of converters, including step-up converters, as are also well known in the art.

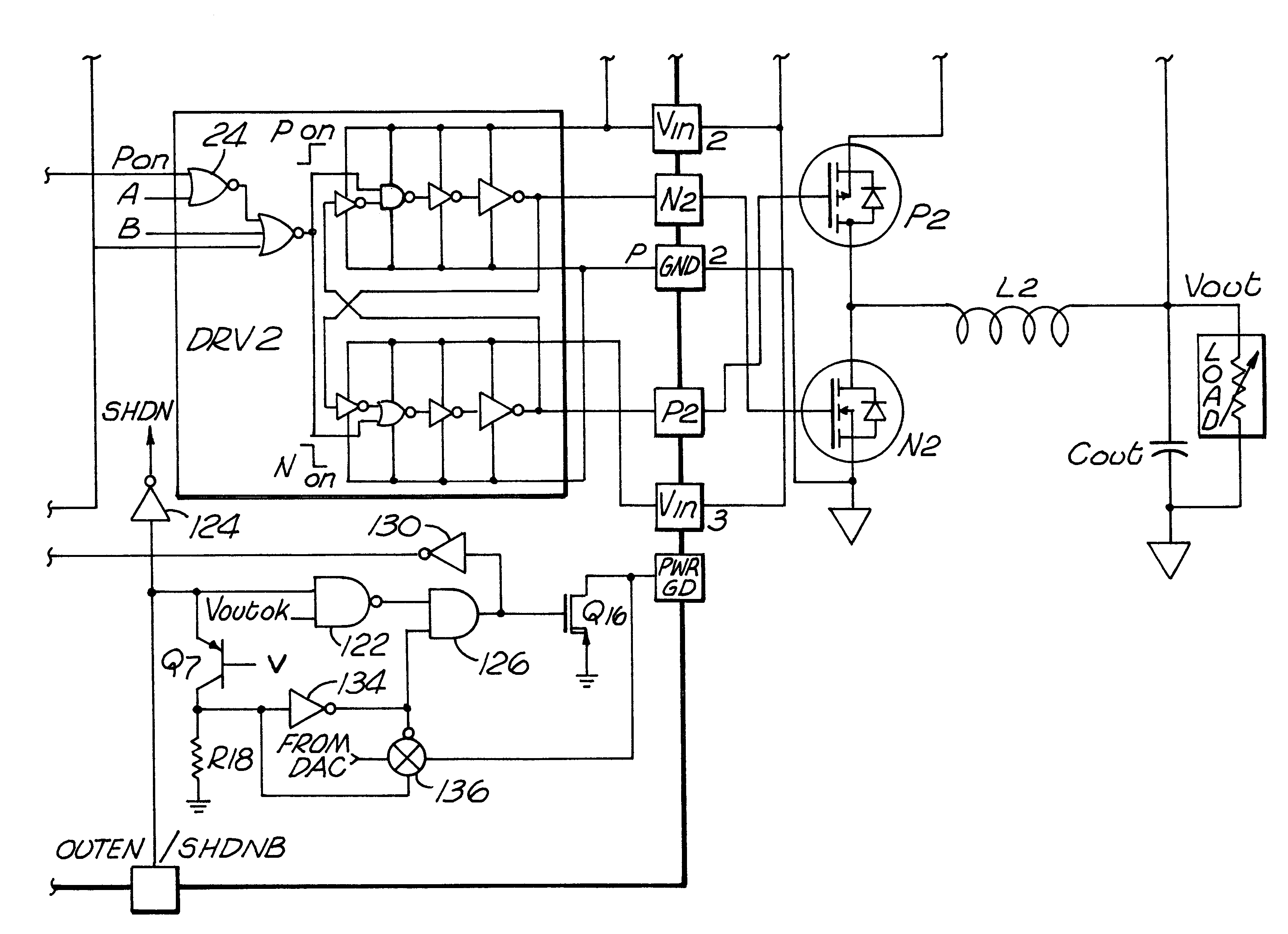

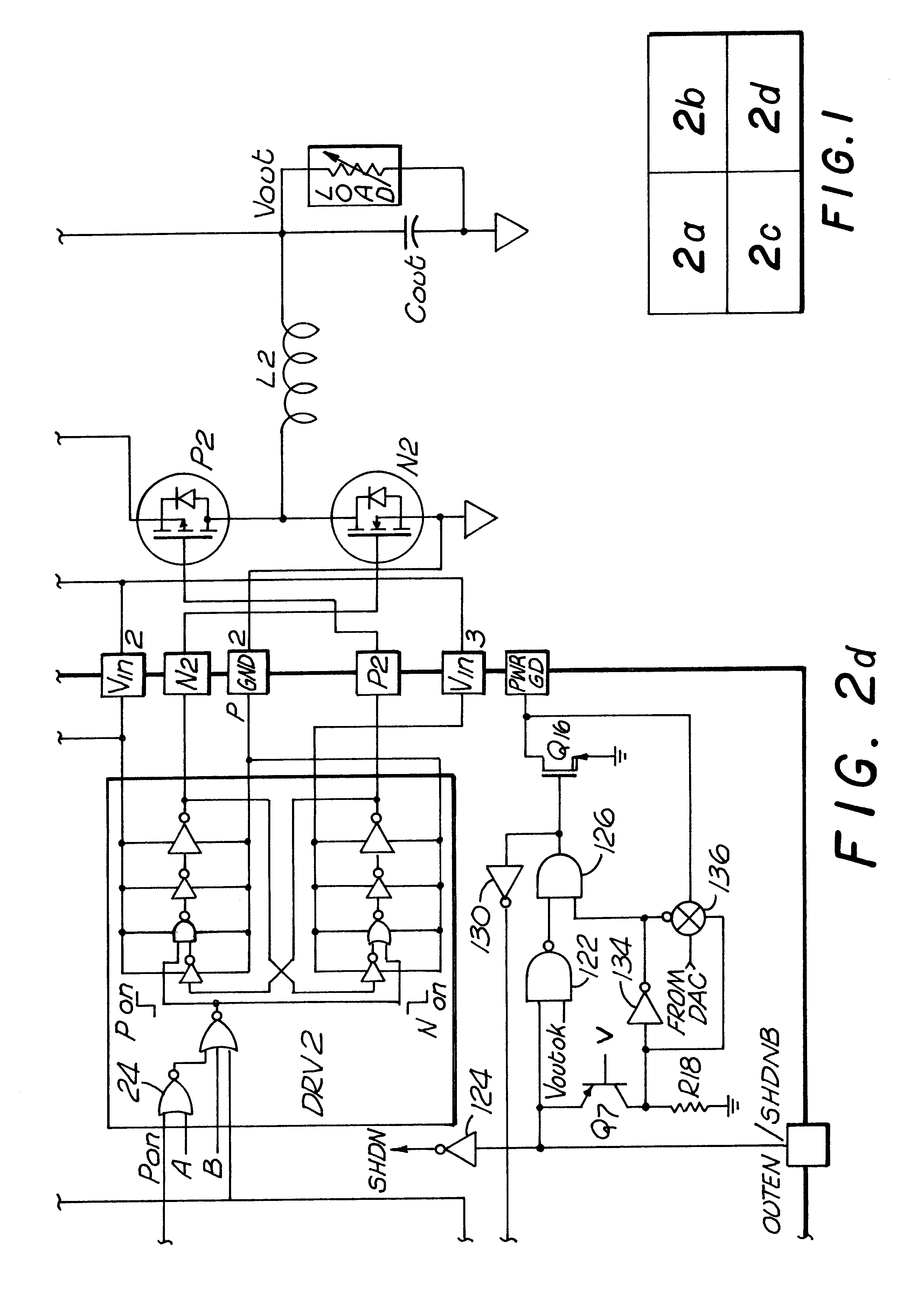

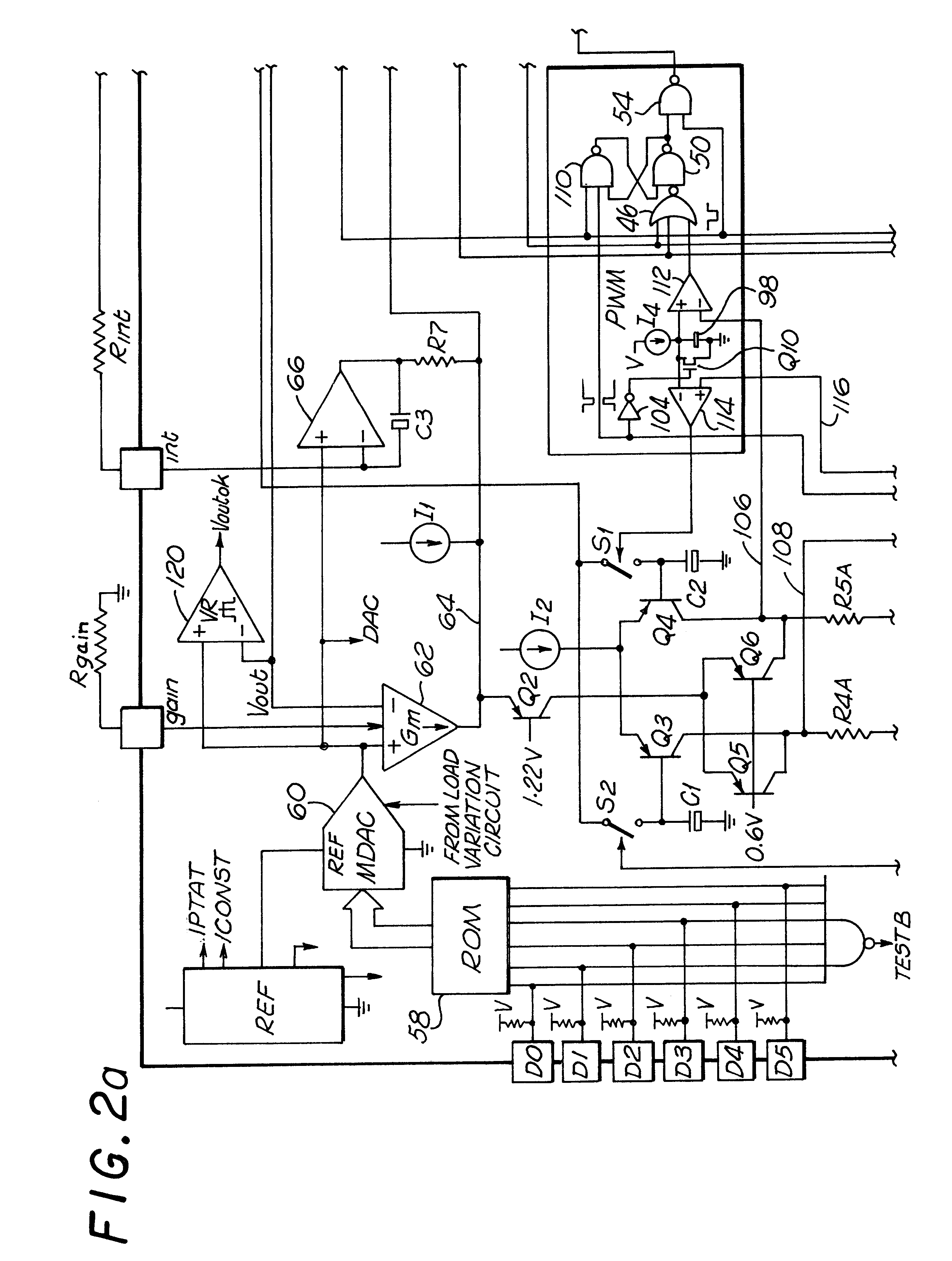

Now referring to FIG. 2, comprised of FIGS. 2a through 2d, a circuit diagram of the preferred embodiment may be seen. (FIGS. 2a through 2d are drawn in a proportion allowing the fitting together of the Figures in the manner illustrated in FIG. 1 to form the overall circuit of FIG. 2.) In this embodiment, the input voltage Vin is provided through optional resistor Rin and optional inductor Lin to capacitor Cin and the current sensing resistor Rsense. The resistor Rin, the inductor Lin and the capacitor Cin provide filtering of the switching noise to reduce the feedback of that noise to the power source of the input volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com