Waterproof decking method and apparatus

a technology of waterproof decking and waterproof joists, applied in the direction of roof tools, snow traps, building roofs, etc., can solve the problems of subflooring and joist rot, sheathing that is sometimes not fully watertight, and prone to damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

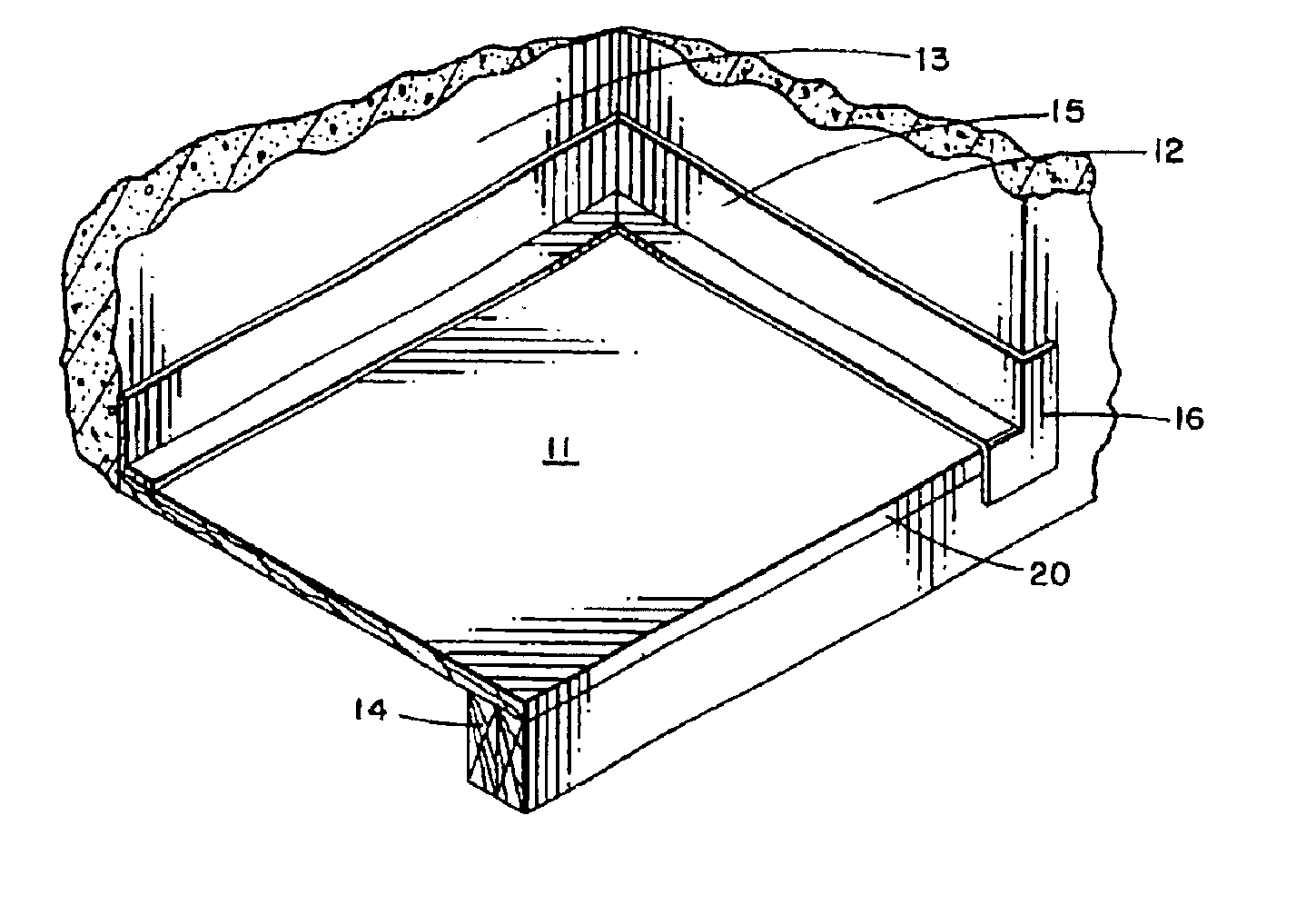

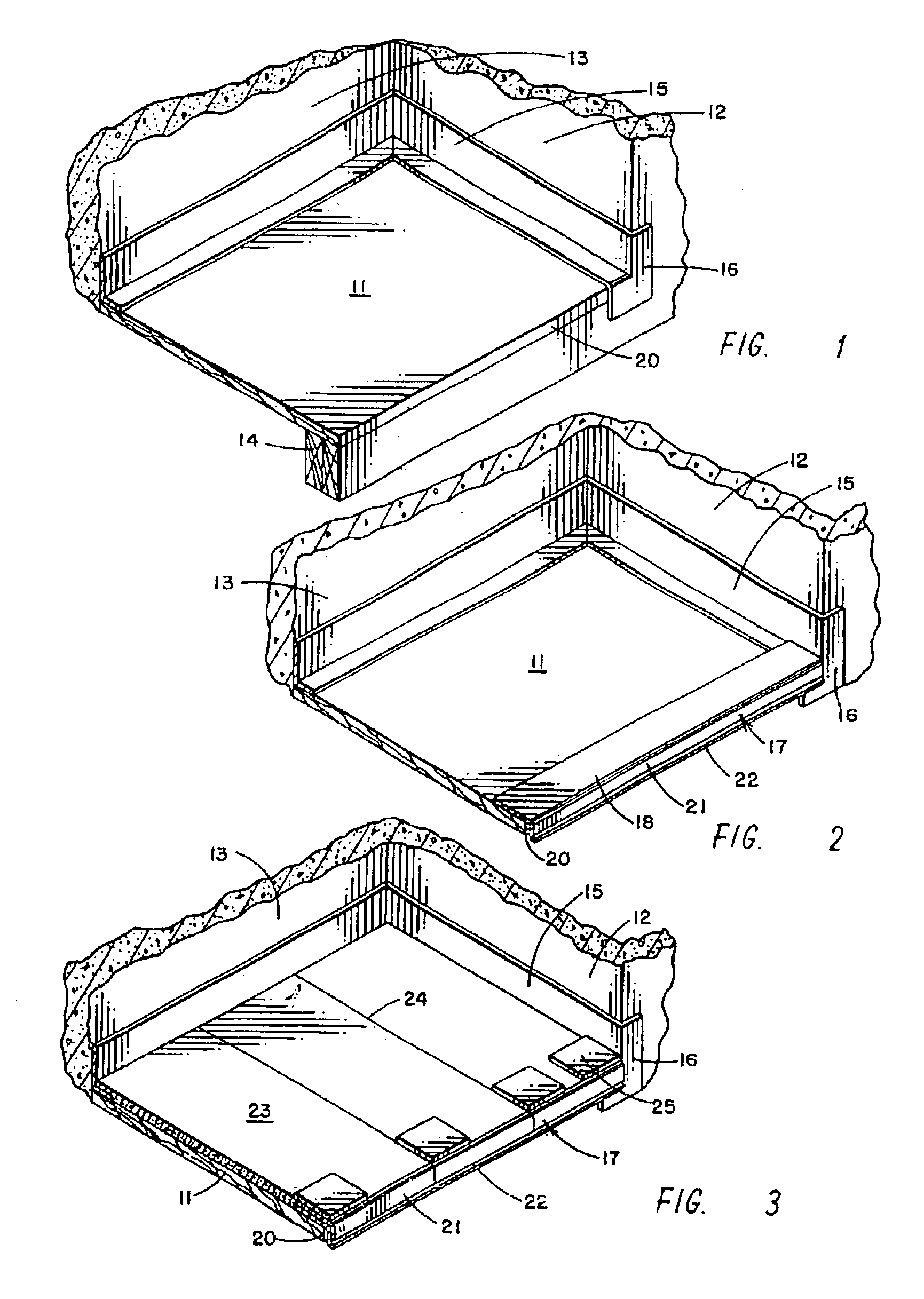

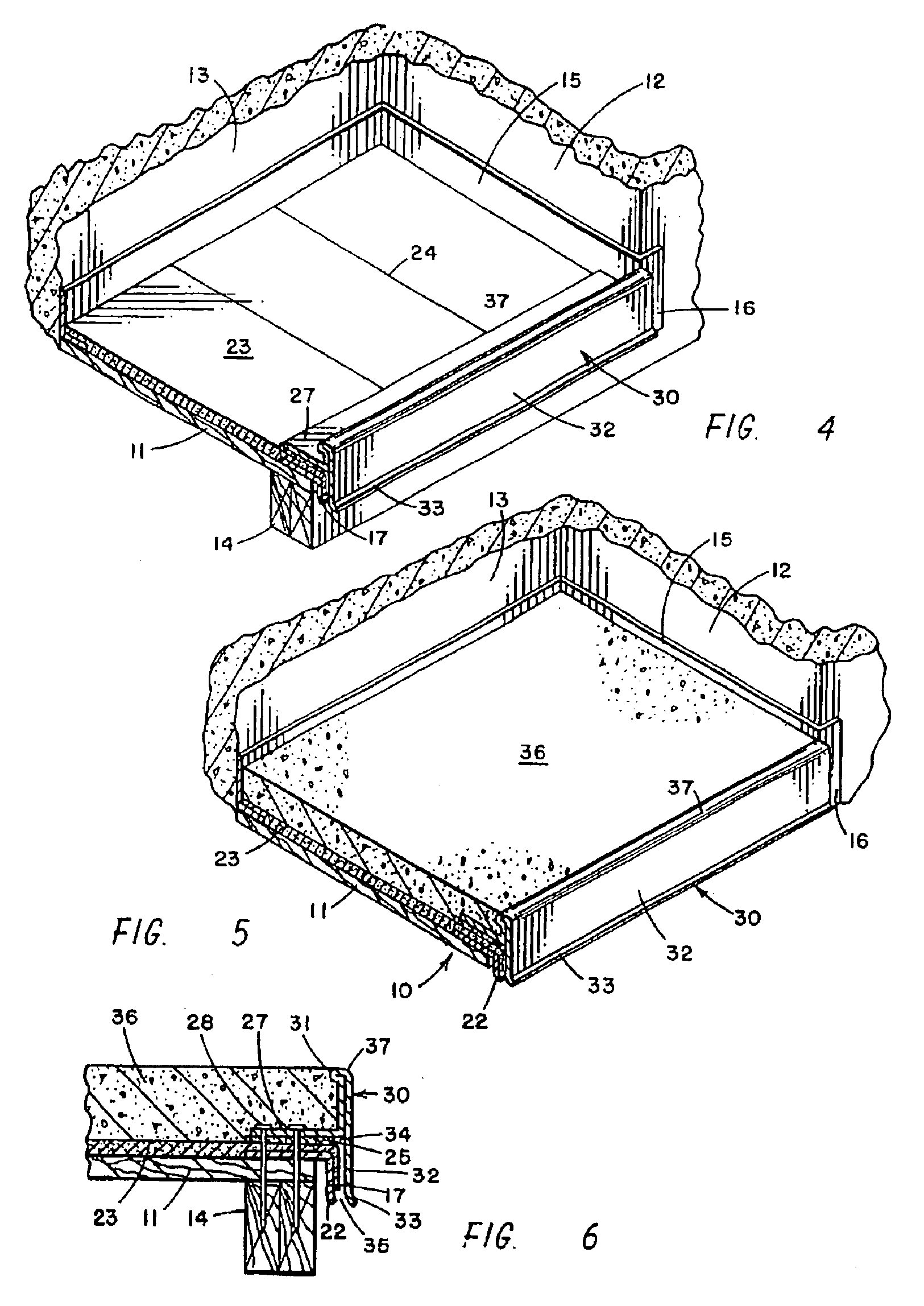

[0015]Referring to FIGS. 1-6 of the drawings, a portion of a concrete deck 10 in FIG. 5 is formed by first attaching a subfloor 11 in FIG. 1, which subfloor may be ¾ plywood or tongue and groove subfloor. The subfloor 11 is mounted to adjacent concrete or wood sidewalls 12 and rear walls 13. The deck has an open front. A pair of 2×10 wooden joists 14 are shown supporting the front edge of the subflooring but other joists could also be incorporated into the deck. The subflooring 11 has metal flashing 15 attached at the corners over the edge of the subflooring and along the walls 12 and 13 and has outside corner flashing 16 applied to the wall corner. In the case of a post support, the flashing 15 and 16 is wrapped around the post.

[0016]In FIG. 2, a drip edge 17 has been attached along the front edge 20 of the subfloor 11 which edge is the open side of the deck and adjacent the front supporting joint 14. The drip edge 17 has a metal portion 18 extending a short distance over the subfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com