Thermocycler and lifting element

a technology of lifting element and rotating rod, which is applied in the field of rotating rod, can solve the problems of requiring suitable and correspondingly heavy and expensive handling devices for applying relatively large forces, affecting the operation of the machine, so as to facilitate the manual removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

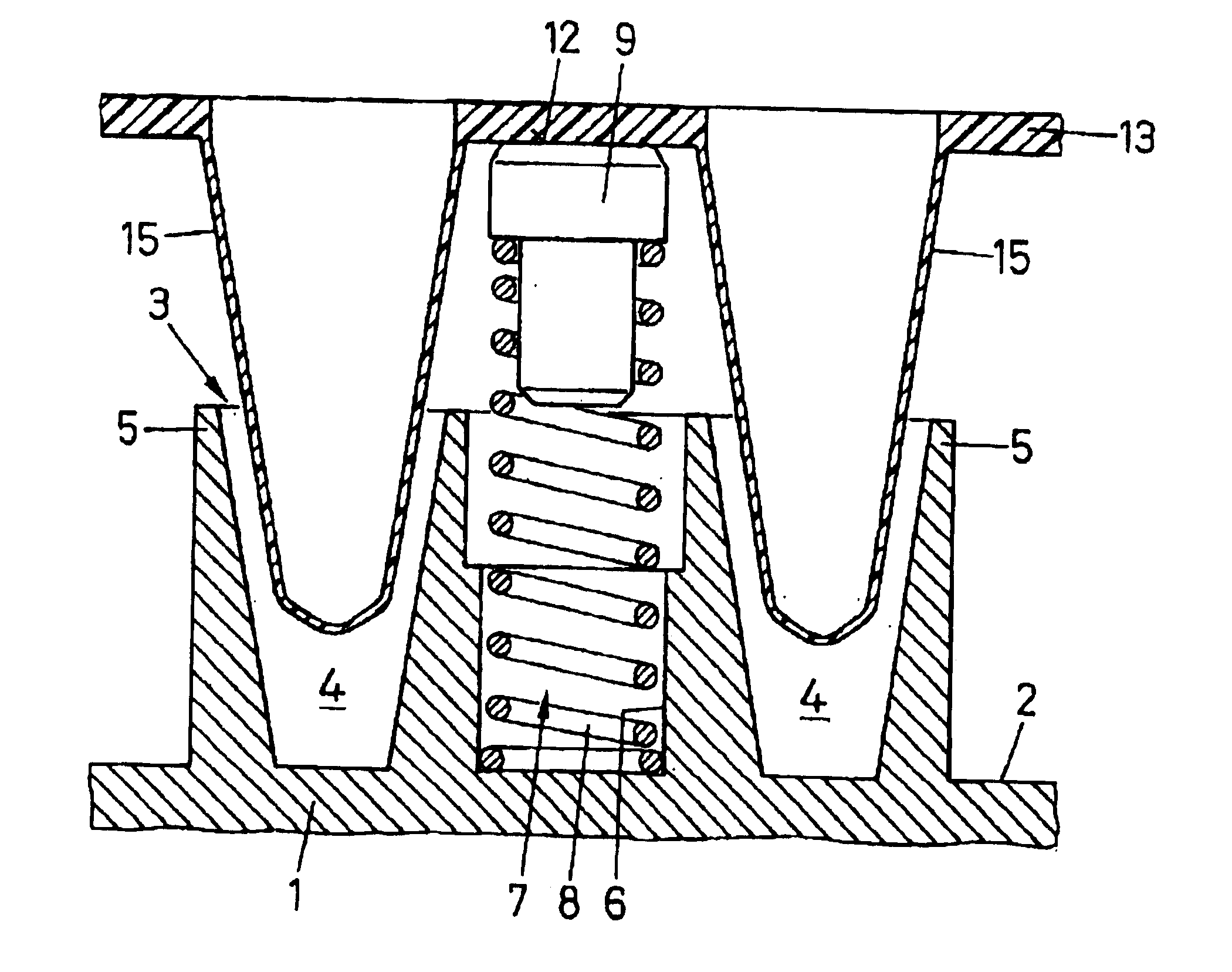

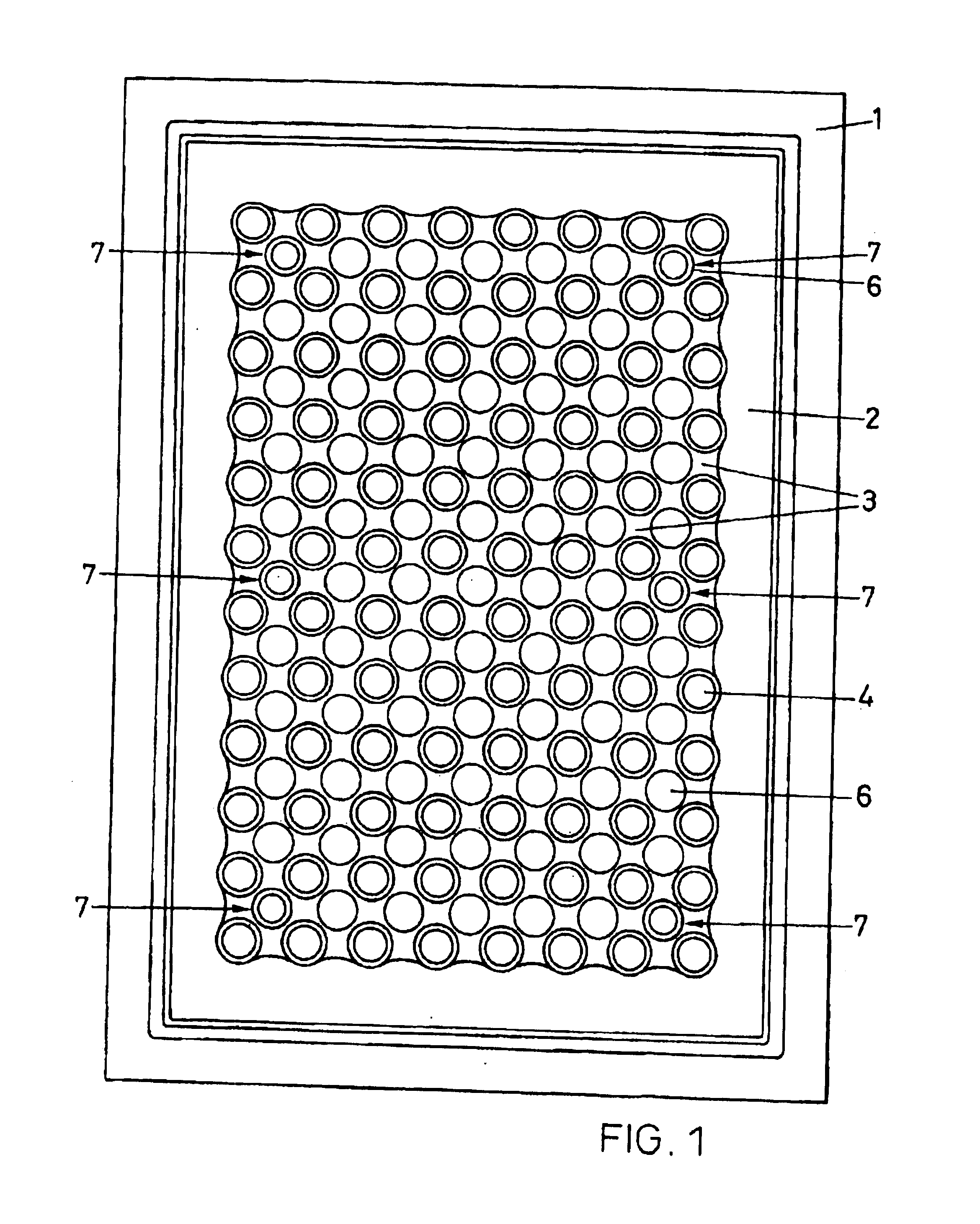

[0012]The thermocycler, which may be suitable, for example, for holding an 8×12 microtitre plate having the dimensions 85 mm×130 mm, has a heating plate 1 which forms a heating surface 3 which is surrounded by an edge strip 2 and is somewhat higher than said edge strip and in which round indentations 4 are arranged in a regular square grid, each of which indentations is surrounded by an all-round wall 5 (FIG. 2) projecting beyond the base level of the heating surface 3. In each case, a blind hole 6 is provided between four indentations 4.

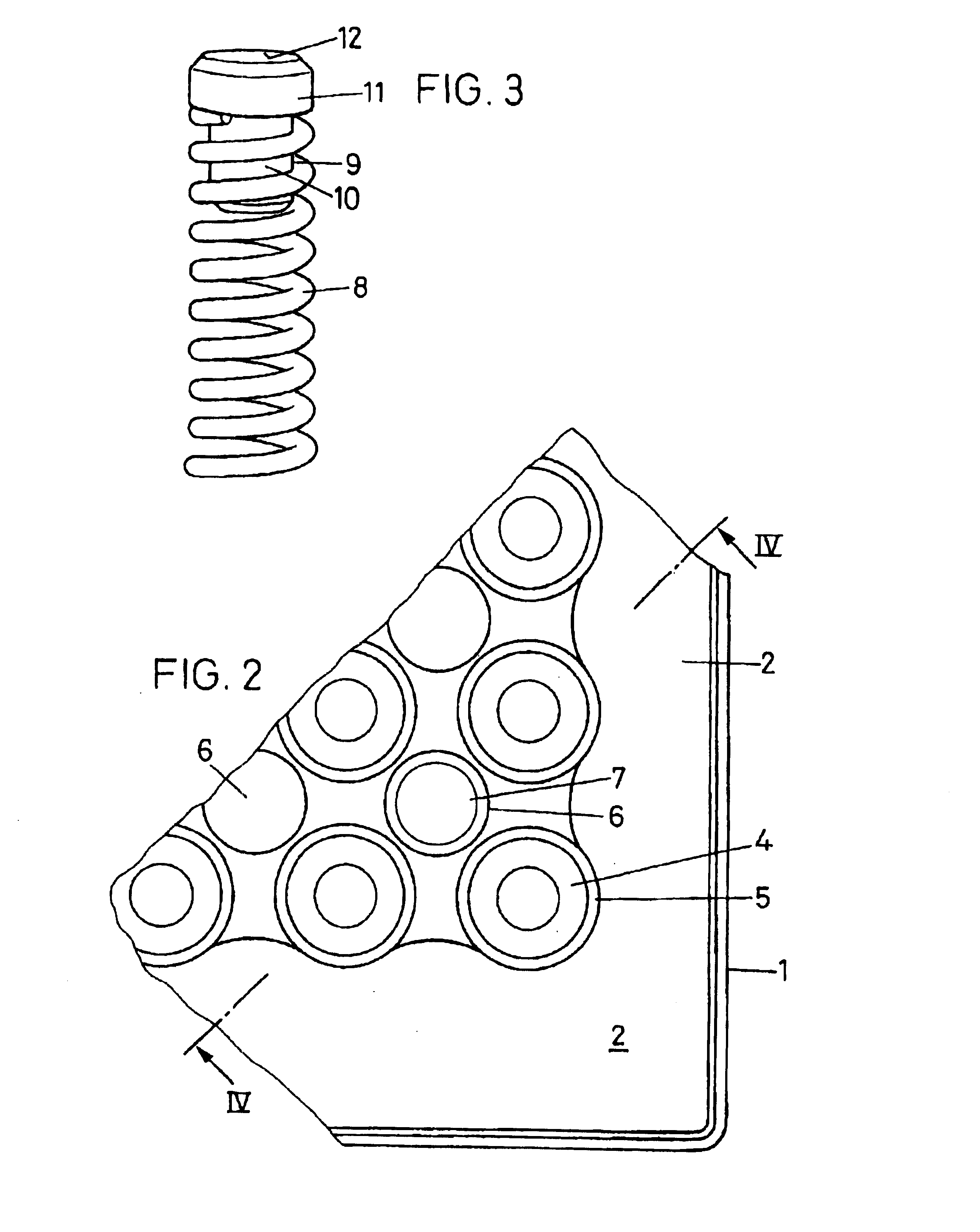

[0013]Six lifting elements 7 are arranged in six of the blind holes 6 altogether, distributed approximately uniformly over the heating surface 3. Each of the lifting elements 7 consists (FIG. 3) of a cylindrical coil spring 8 of stainless steel, the lowermost winding of which is somewhat wider than the other windings, and a contact pin 9 whose approximately cylindrical shaft 10 is inserted into the upper end of the coil spring 8 and is held therein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com