Pipe joint made of resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

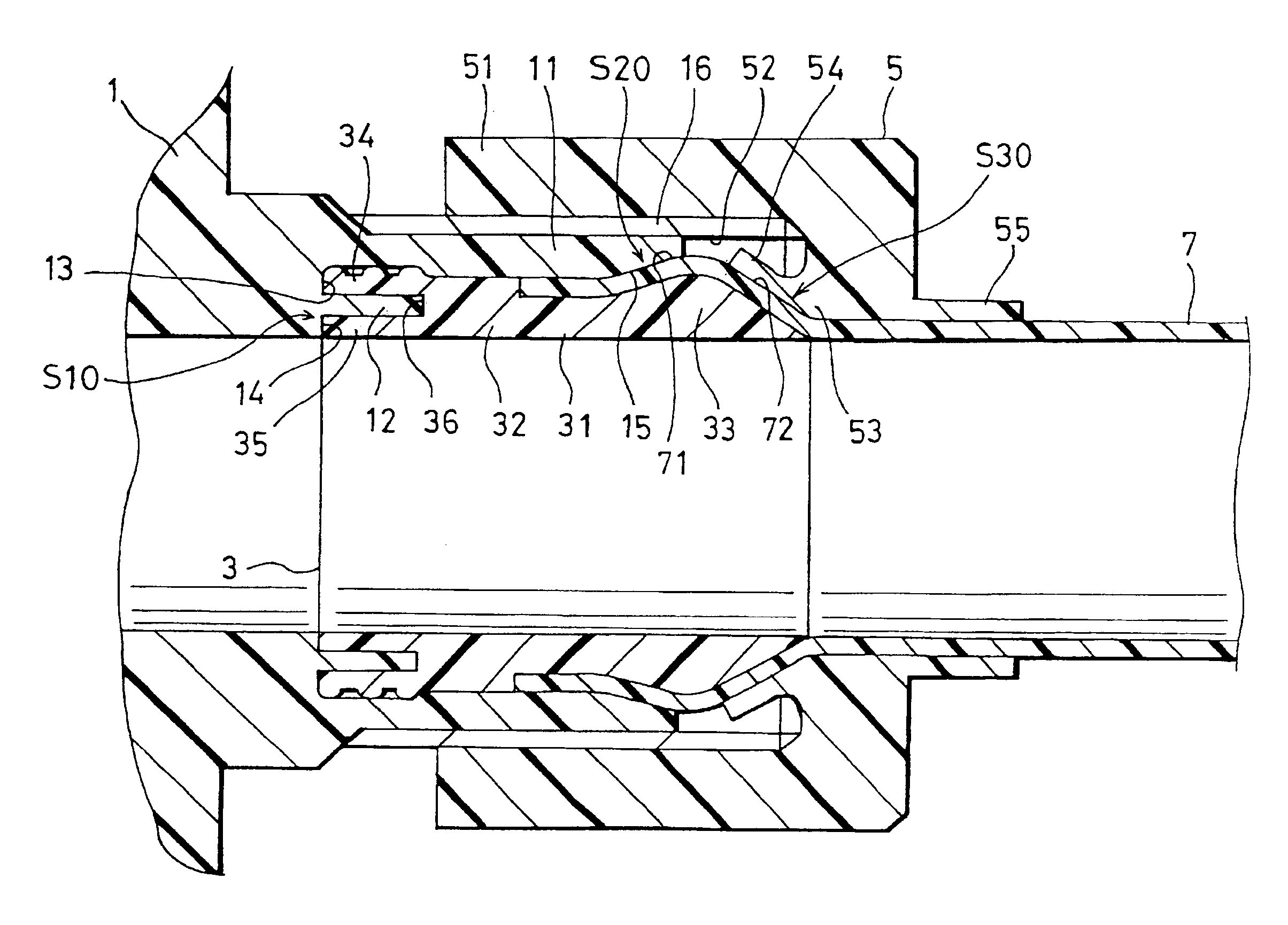

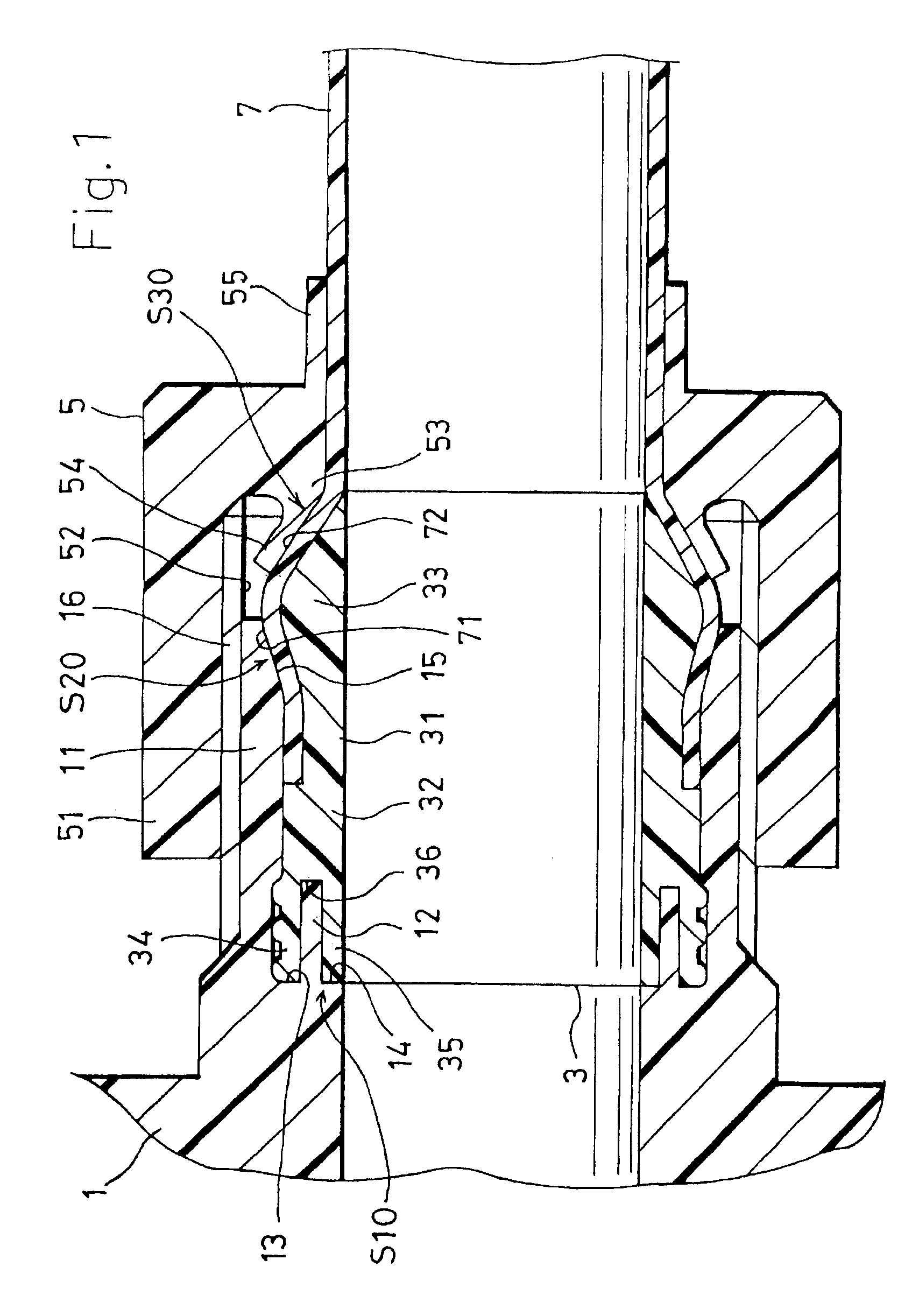

[0051]Referring now to the drawing, preferred embodiments of the present invention are described below.

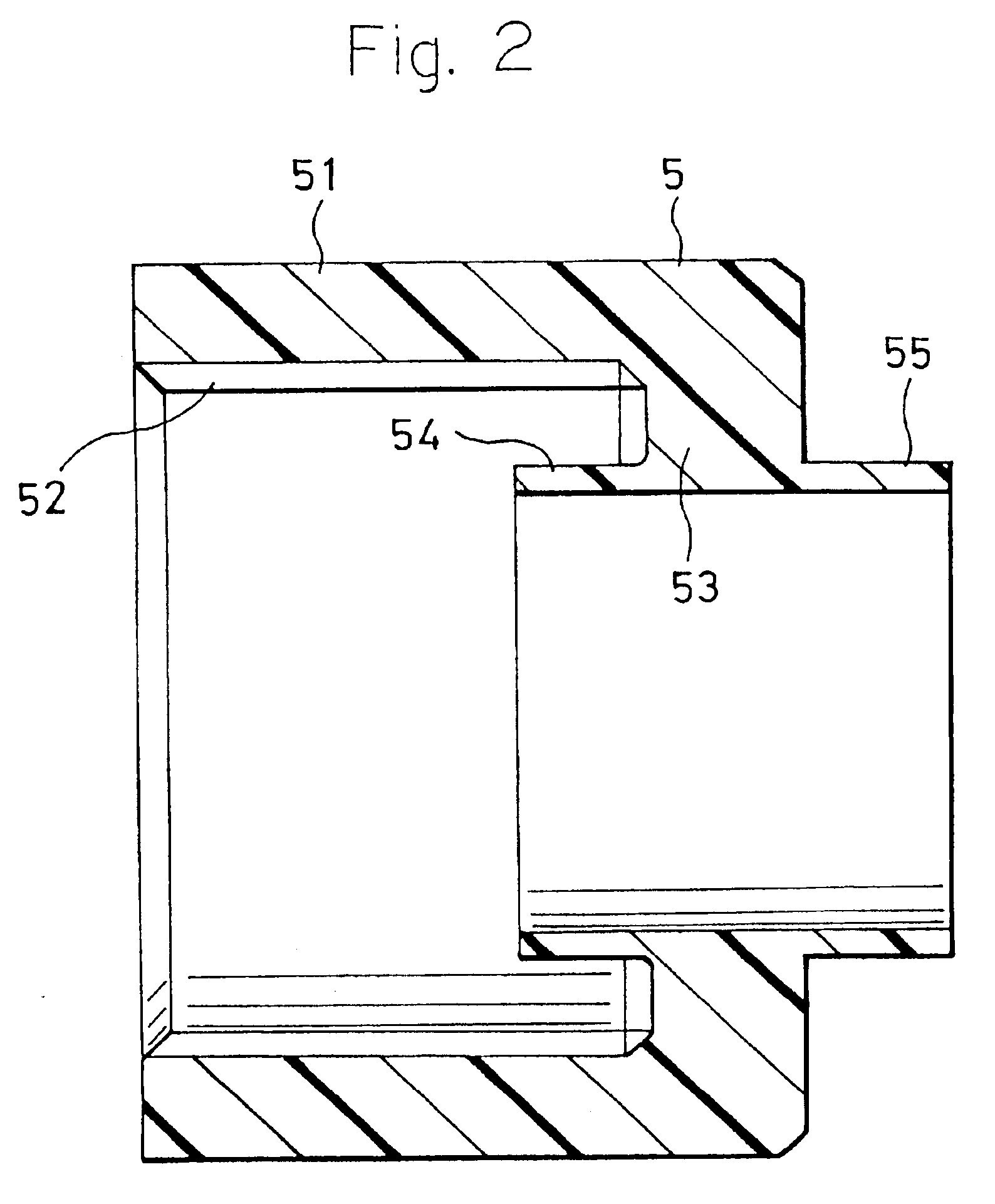

[0052]A pipe joint made of resin as shown in FIGS. 1 and 7 includes a cylindrical joint body 1, a cylindrical inner ring 3, and a cap nut shaped pushing ring 5. The joint body 1, the inner ring 3 and the pushing ring 5 are individually made of a synthetic resin such as PFA (perfluoro-alkoxyfluoro plastics), PTFE (polytetrafluoroetylene), ETFE (etylene-tryfluoro-etylene), CTFE (chloro-tryfluoro-etylene), ECTEE (etylene-chloro-tryfluoro-etylene), having a superior feature in resistance to chemicals and resistance to heat.

[0053]The joint body 1 has a cylindrical receiving port 11 on at least one axial end portion thereof. The joint body 1 is provided with a short cylindrical portion 12 protruding in the inside area defined by the receiving port 11, and being concentric with the receiving port 11, forming an annular groove portion 13 disposed between the cylindrical portion 12 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com