Crushing, screening and magnetic separation device for high-purity quartz powder

A high-purity quartz powder, crushing and screening technology, applied in the direction of filtration, solid separation, magnetic separation, etc., can solve the problems of reduced screening efficiency, reduced production efficiency, and blockage of the screening network in the work process, so as to protect the health of the body , improve quality and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

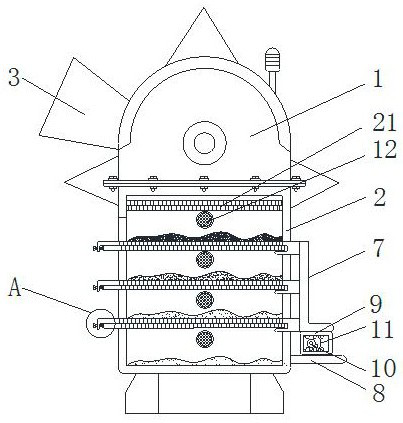

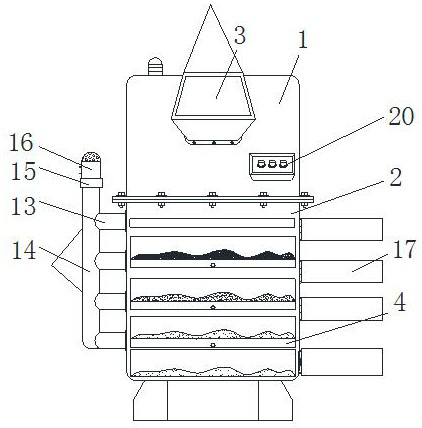

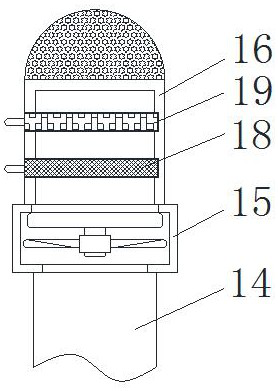

[0028] Such as Figure 1-5 As shown, the present invention provides a technical solution: a crushing and screening magnetic separation device for high-purity quartz powder, comprising a housing 1, the housing 1 is made of stainless steel, and the outer surface of the housing 1 is provided with There is an aluminum alloy coating, and the thickness of the aluminum alloy coating is 0.5 mm to 2 mm. The lower surface of the housing 1 is fixedly connected to the upper surface of the filter assembly 2, the inner surface of the filter assembly 2 is provided with a magnetic separation structure 21 and a first filter structure 4, the first filter structure 4 is located below the magnetic separation structure 21, The magnetic separation structure 21 is made of a magnetic material, and the magnetic separation structure 21 is used to remove the impurities in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com