Roof batten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

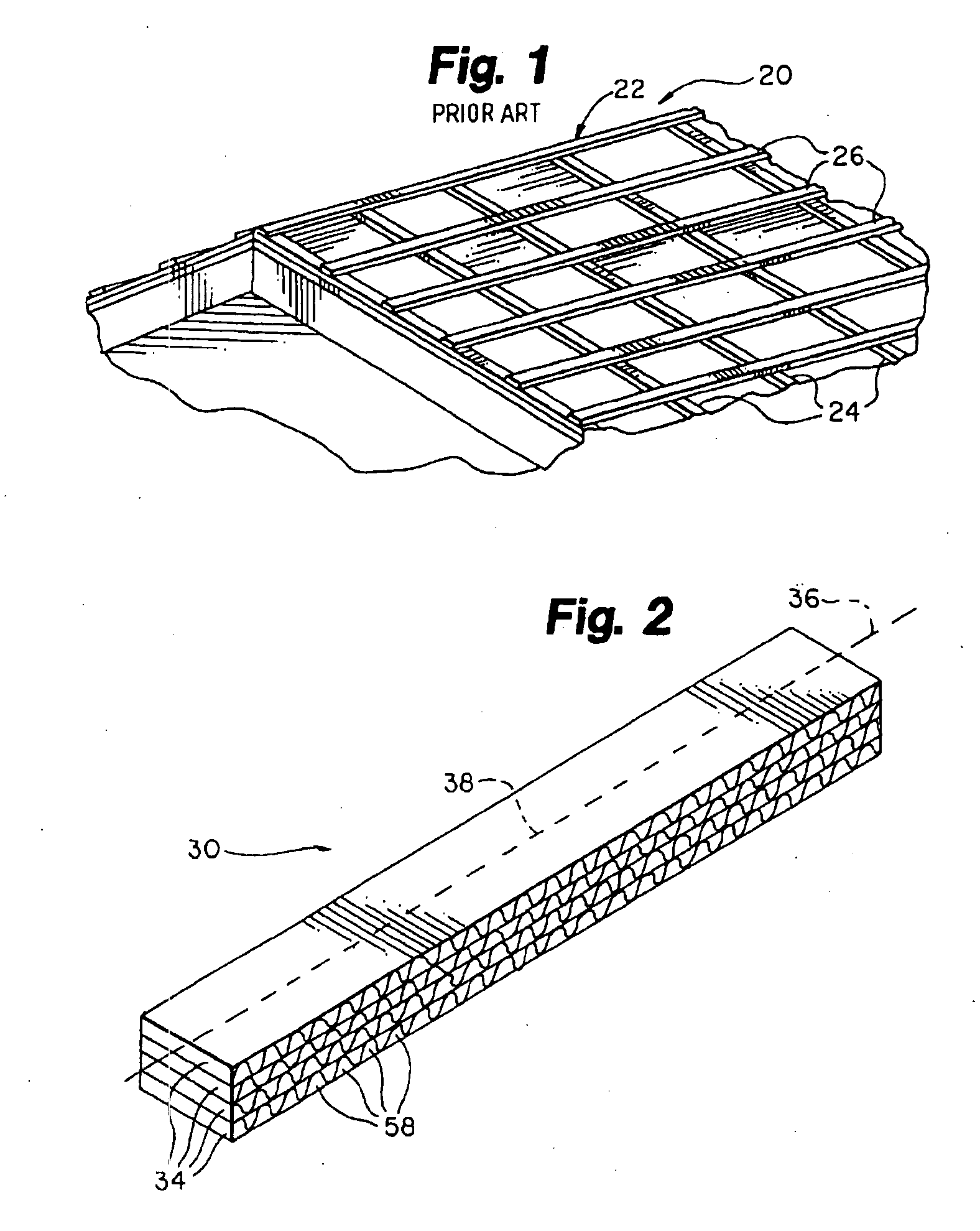

[0020]Referring to FIGS. 2 and 3, exemplary batten (spacer) 30 is depicted. Batten 30 generally includes one or more layers 34 and may be characterized by longitudinal axis 36. Layers 34 are described below and generally serve two functions. The first function is to allow water to drain therethrough. The second is to enable air exchange. These complimentary functions prevent water pooling and promote drying on roofs on which batten 30 is installed. While one or more layers 34 are contemplated to be within the scope of this invention, if a plurality of layers 34 are present, these layers may be stacked and fixed to each other by such means as stitching 38. However, other fastening means which may be used include hot air welding (or other fastening means using thermal energy), ultrasonic welding, infrared bonding, staples, glue, or other methods known to the art.

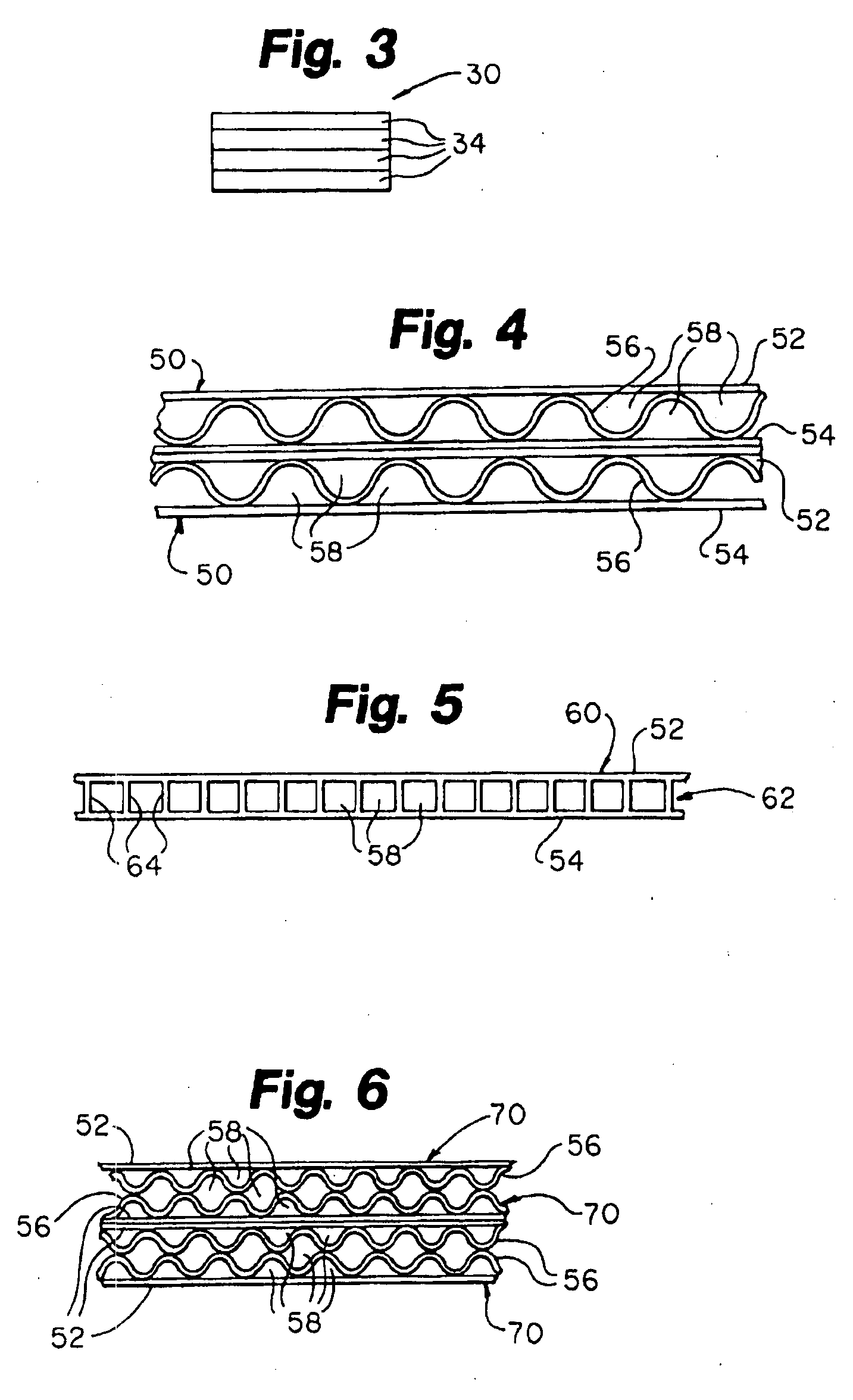

[0021]One embodiment of two layers of layer 34 is depicted in FIG. 4 generally as layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com