Rotary shelf assembly mechanism having a post height adjustment device and a novel shelf construction and self retaining element for securing the shelves to the post

a technology of height adjustment device and assembly mechanism, which is applied in the direction of display hangers, dismountable cabinets, cabinets, etc., can solve the problems of not providing vertical adjustment, wasting cabinet space in the corner either above or below the kitchen counter, and the combination of elements is obviously more expensive than desired, so as to achieve the effect of easy adjustment of the height of the shelf assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

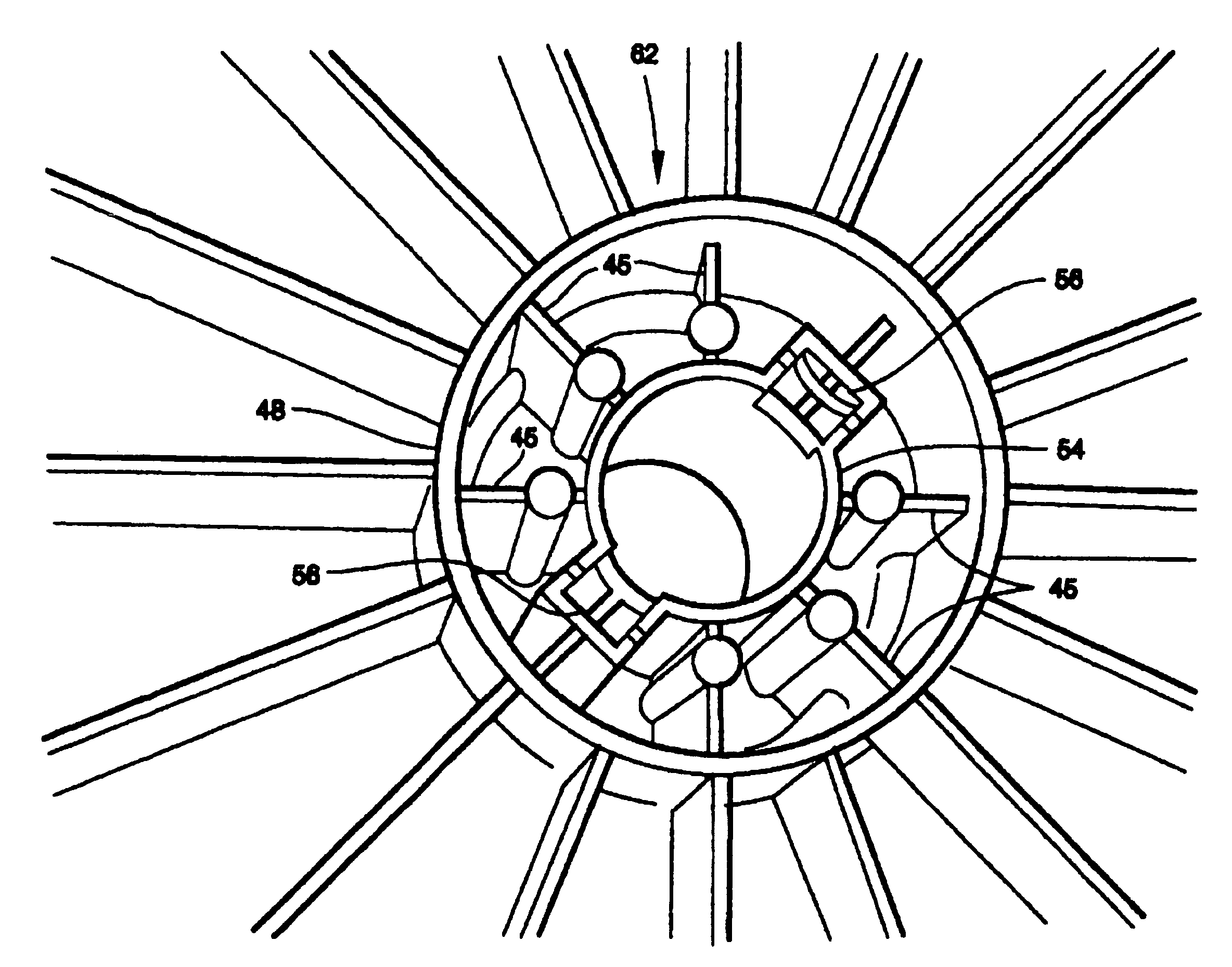

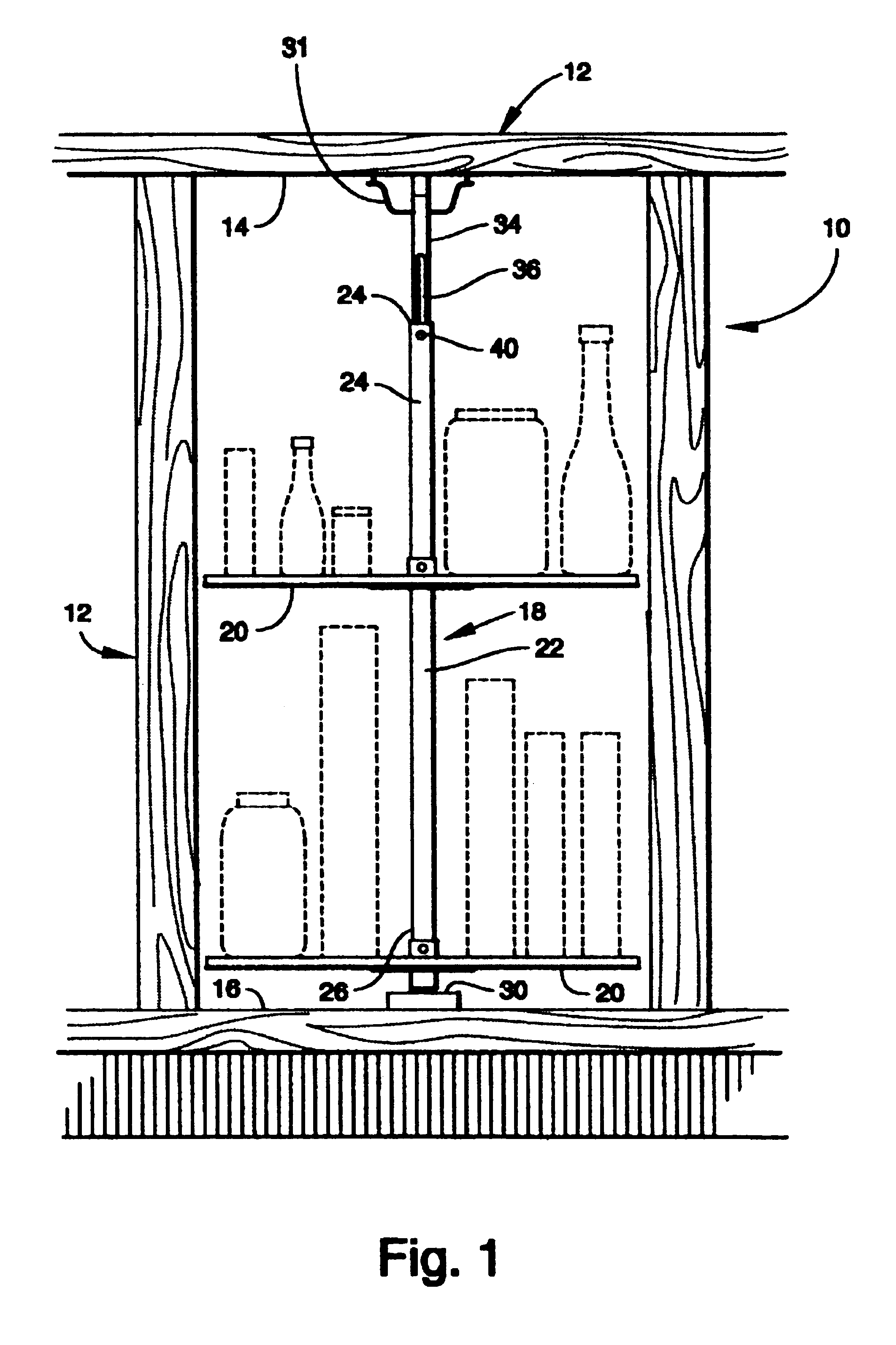

[0045]A rotational shelf assembly incorporating various features of the present invention is illustrated generally at 10 in FIG. 1. Shelf assembly 10 is designed to be installed in a cabinet 12 having installation surfaces comprising a ceiling surface or top 14 and a floor surface or bottom 16. However, it will be appreciated that the use of the assembly 10 is not confined to cabinet interiors and can be adapted for mounting in various storage areas having the necessary installation surfaces. Moreover, it will be understood that while assembly 10 has been titled a rotational shelf assembly, the term “shelf” as used herein encompasses various support structures for supporting items to be stored.

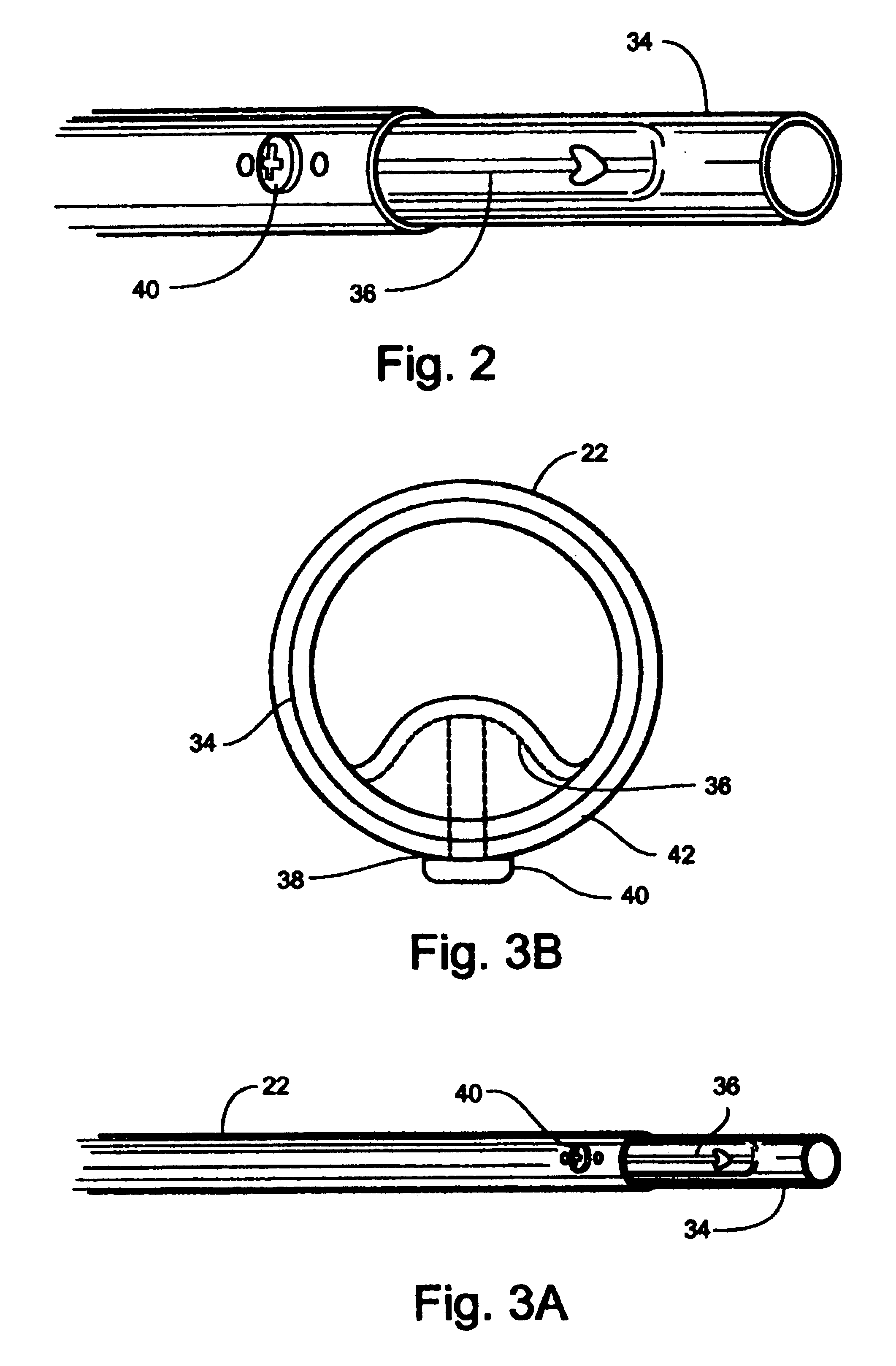

[0046]As shown in FIG. 1, assembly 10 comprises a support assembly 18 for rotatably mounting adjustable shelves 20. Support assembly 18 includes a first rotational support post 22 having upper and lower end portions 24, 26, the lower end portion 26 engagably supported by mounting bracket 30 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com