Patents

Literature

37results about How to "Avoid misjudgment of weld failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Easy-to-distinguish detection process used for electronic tube

InactiveCN105372019AAvoid mistakesEasy to observe the lossDetection of fluid at leakage pointAlcoholVacuum extraction

The invention discloses an easy-to-distinguish detection process used for an electronic tube, comprising a vacuum detection bench which is in connection with a detection board through an enclosed telescoping port; the detection board is provided with a bleeder hole in communication with the vacuum in the vacuum detection bench; the vacuum detection bench is also provided with an alcohol storage box which is provided with a syringe and three pigment pipes storing organic pigments. The process utilizes the syringe to extract the alcohol stored in the alcohol storage box, and inject the alcohol at the sealing end of the tube, allowing the sealing end to be covered by the alcohol; then the vacuum detection bench performs vacuum extraction; sealing is proven to be sound if the alcohol at the sealing end does not disappear clearly or rapidly, and sealing is proven to be poor if the alcohol disappears rapidly, thereby adjusting the sealing end.

Owner:CHENGDU GUOGUANG ELECTRIC

A Gap Inspection Device for Combined Finishing Components

InactiveCN106813850AAvoid volatilityEasy to observe the lossFluid-tightness measurement using fluid/vacuumAlcoholLiquid medium

The invention discloses a gap inspection device for combined finishing devices. A flexible pouch is arranged on the support plate, and liquid medium is filled in the pouch; There is an alcohol storage box, on which a syringe is arranged, and three pigment tubes for storing organic pigments. There is a difference in color between the colored alcohol of the present invention and the material of the pipe itself, which is convenient for observing the loss of alcohol. If the alcohol at the sealing end disappears obviously and quickly, it proves the sealing Good, if the alcohol disappears quickly, the seal is defective, so adjust the seal end.

Owner:重庆市鑫耀机械厂

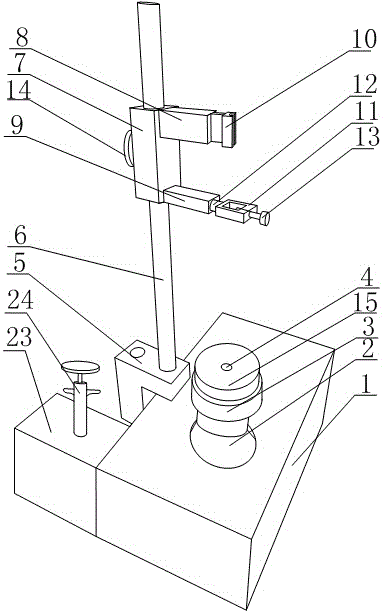

Multipoint-supporting weld joint quick detection device of multiple kinds of electronic pipes

InactiveCN105258871AAvoid mistakesDisappear quicklyMeasurement of fluid loss/gain rateLiquid mediumEngineering

The invention discloses a multipoint-supporting weld joint quick detection device of multiple kinds of electronic pipes. The rapid detection device comprises a vacuum detection bench. A flexible capsule bag is arranged on a support disc. The capsule bag is filled with liquid medium. An alcohol storing box is arranged on the vacuum detection bench. An injector and three pigment pipes storing organic pigment are arranged on the alcohol storing box. The rapid detection device also comprises a high-pressure gas storage tank which is connected with a cone-shaped spray nozzle via a soft pipe. A flat press plate is arranged on the side face of a rectangular frame body on which a fastening bolt is arranged. By rotating the rectangular frame body, a pipe can be clamped or compressed and the rapid detection device is applicable for different specifications of pipes. A layer of silicone rubber sheet is arranged as a buffer structure on the flat press plate, so the pipes can be protected and sealing performance can be improved.

Owner:CHENGDU GUOGUANG ELECTRIC

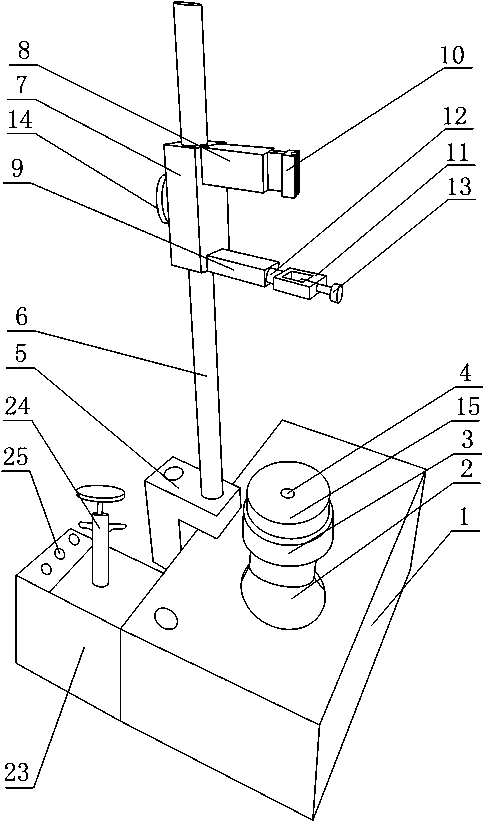

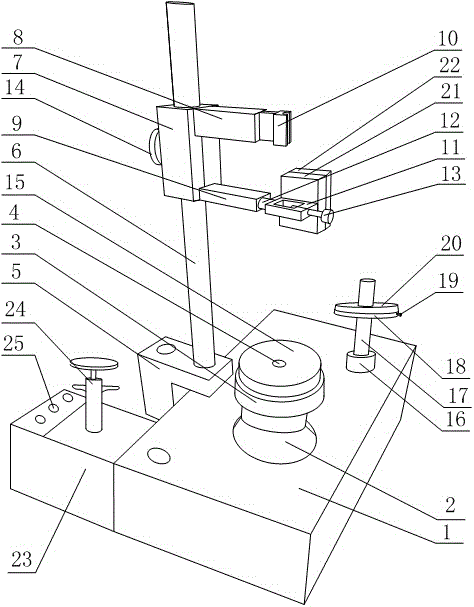

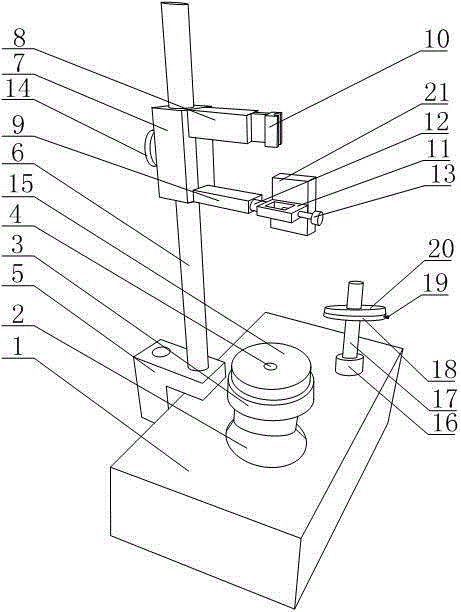

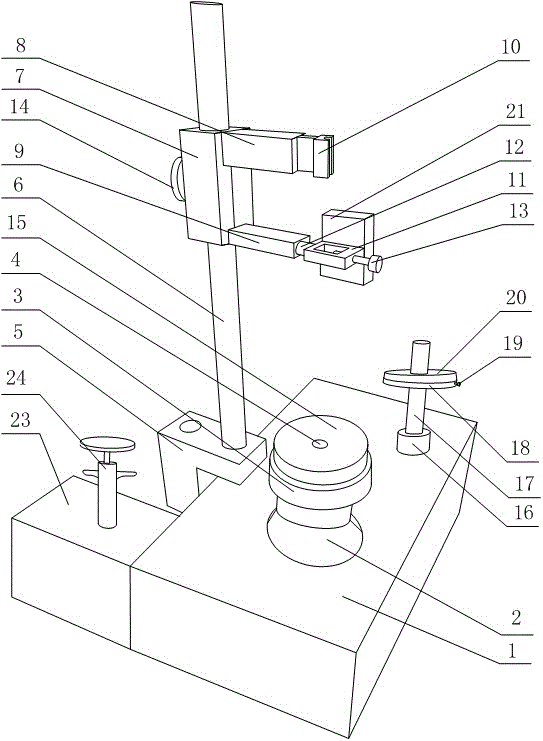

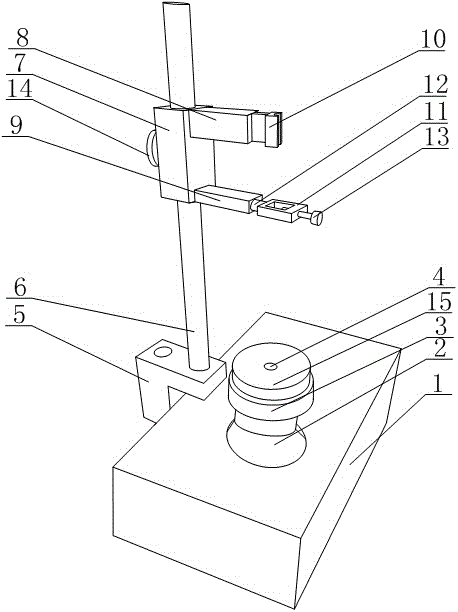

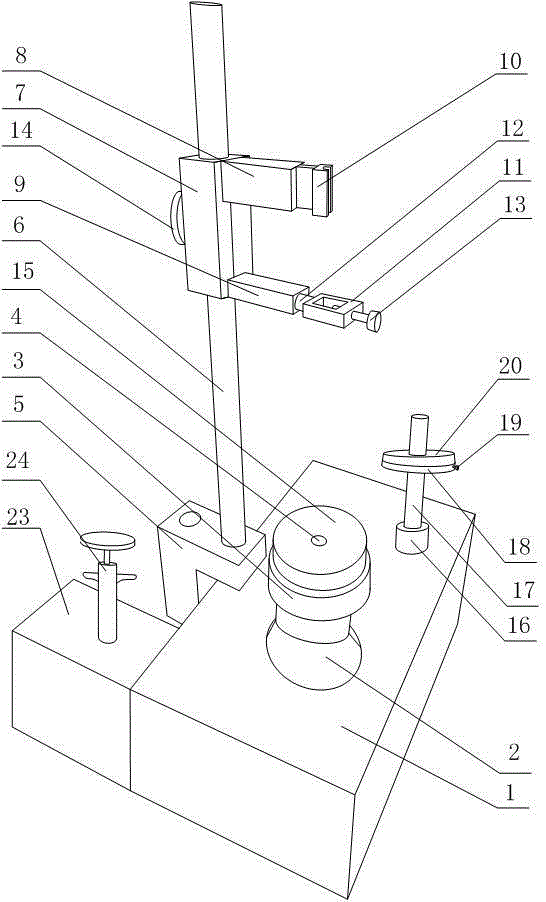

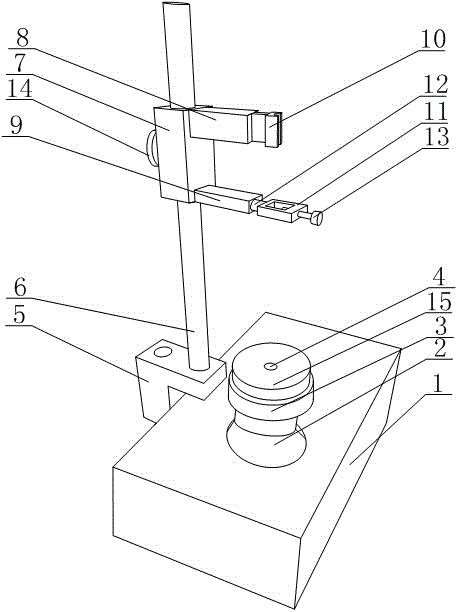

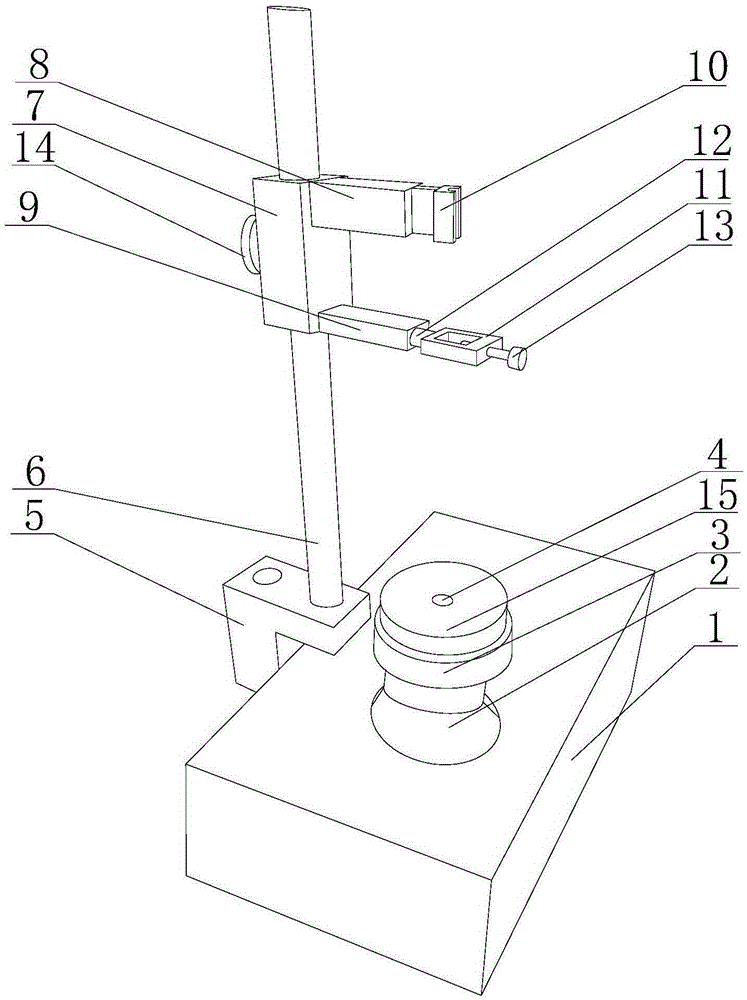

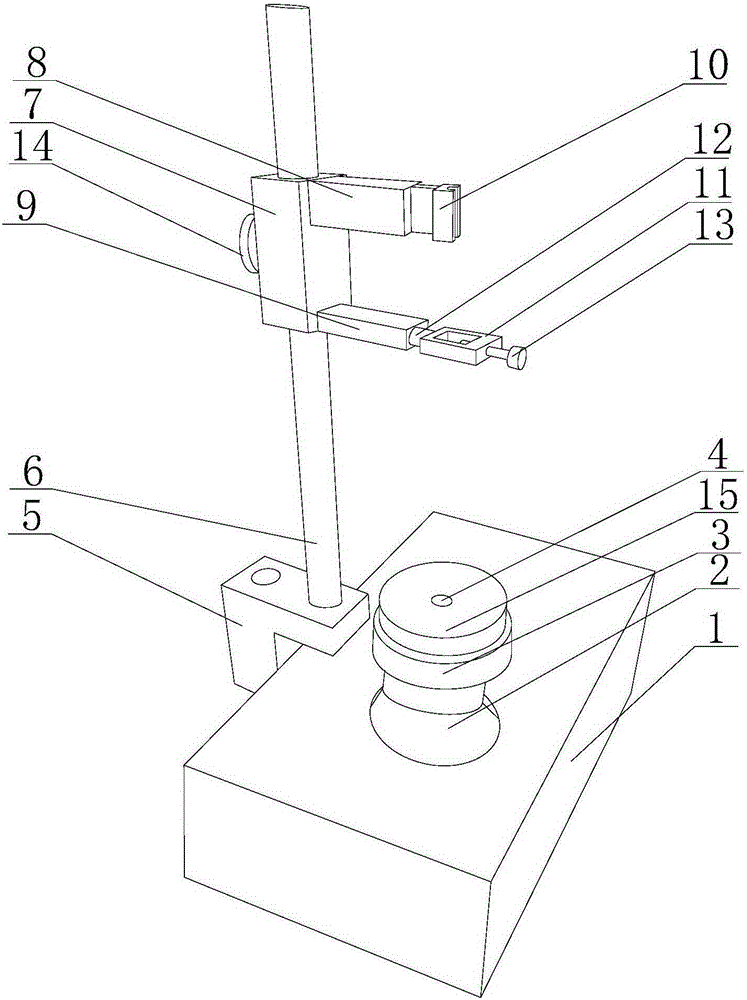

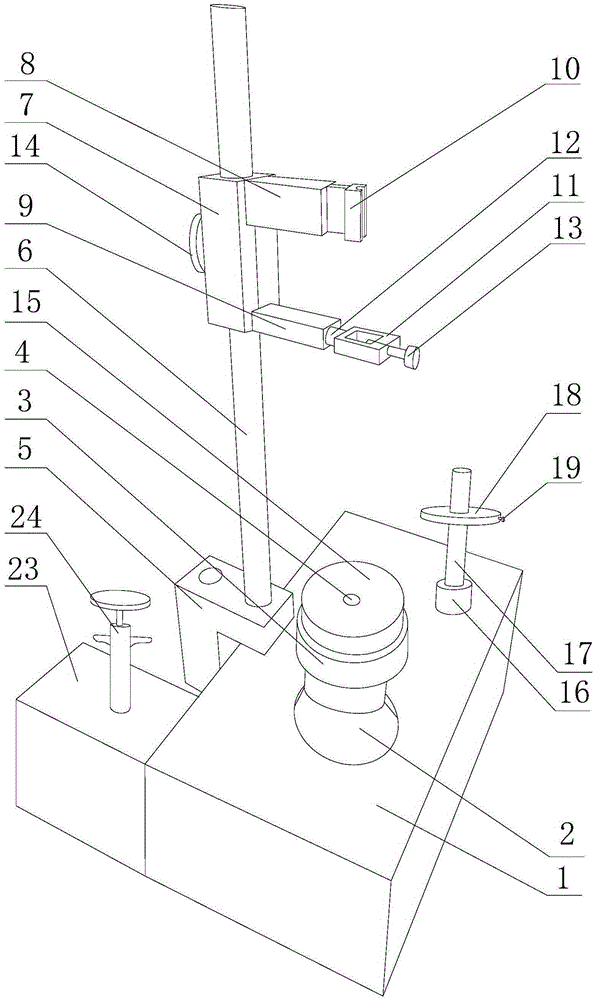

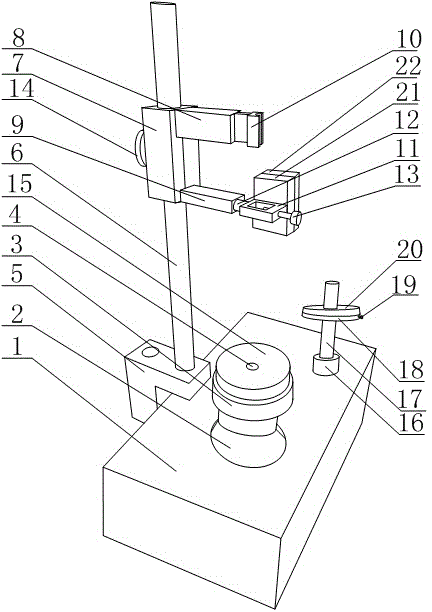

Weld joint detection device of electronic pipe

InactiveCN105258873AHigh speedGood repeatabilityMeasurement of fluid loss/gain rateAir pumpEngineering

The invention discloses a weld joint detection device of an electronic pipe. The detection device comprises a vacuum detection bench. A detection plate face is connected to the vacuum detection bench via an enclosed telescoping opening. An air pumping hole which is in vacuum communication with the interior of the vacuum detection bench is arranged in the detection plate face. The detection device also comprises a balancing pedestal. A support rod is arranged on the balancing pedestal. A fixed body capable of up-down moving along the support rod is installed on the support rod. An upper cross arm and a lower cross arm are arranged on the fixed body. A guiding block is arranged on the upper cross arm. A guiding groove is arranged in the guiding block. A clamping mechanism is connected to the lower cross arm. The detection device can perform weld joint detection for many kinds of electronic pipes, is especially applicable for test of electronic pipes and is characterized and advantaged by fast speed, high repeatability and high reliability.

Owner:CHENGDU GUOGUANG ELECTRIC

Multi-point support easily distinguishable welding line device for various kinds of electronic tubes

InactiveCN105300607AAvoid mistakesEasy to observe the lossFluid-tightness measurement using fluid/vacuumLiquid mediumAlcohol

The invention discloses a multi-point support easily distinguishable welding line device for various kinds of electronic tubes, comprising a vacuum detection table; a support plate is provided with a flexible bag which is filled with a liquid medium; and the vacuum detection table is provided with an alcohol storage box which is provided with a syringe and three pigment tubes for storing organic pigment. A horizontal pressure plate is arranged on the side of a rectangle frame body of the invention; the rectangle frame body is provided with a fastening bolt; and the clamping or pressing the tube can be switched through rotation of the rectangle frame body. The multi-point support easily distinguishable welding line device is applicable to the tubes with various specifications, and the horizontal pressure plate is provided with a layer of a silicone rubber sheet as a buffer structure, which not only protects the tubes, but also improves the sealing.

Owner:CHENGDU GUOGUANG ELECTRIC

Multi-point support welding line fast detection process for various kinds of electronic tubes

InactiveCN105300612AAvoid mistakesDisappear quicklyFluid-tightness measurement using fluid/vacuumLiquid mediumEngineering

The invention discloses a multi-point support welding line fast detection process for various kinds of electronic tubes, comprising a vacuum detection table; a support plate is provided with a flexible bag which is filled with a liquid medium; the vacuum detection table is provided with an alcohol storage box which is provided with a syringe and three pigment tubes for storing organic pigment; a high pressure gas storage tank is also included; and high pressure gas storage tank the is connected to a cone-shaped nozzle through a flexible tube. A horizontal pressure plate is arranged on the side of a rectangle frame body of the invention; the rectangle frame body is provided with a fastening bolt; and the clamping or pressing the tube can be switched through rotation of the rectangle frame body. The multi-point support welding line fast detection device is applicable to the tubes with various specifications, and the horizontal pressure plate is provided with a layer of a silicone rubber sheet as a buffer structure, which not only protects the tubes, but also improves the sealing.

Owner:CHENGDU GUOGUANG ELECTRIC

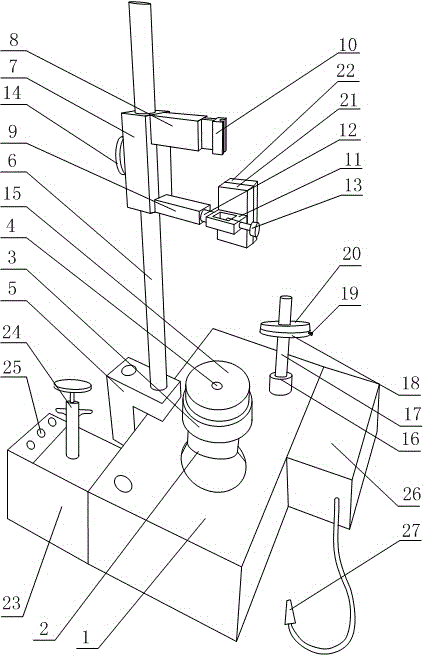

No-clean weld joint detection device used for bent type electronic pipes

InactiveCN105258881AGuaranteed cleanlinessImprove sealingMeasurement of fluid loss/gain rateInjectorEngineering

The invention discloses a no-clean weld joint detection device used for bent-type electronic pipes. The weld joint detection device comprises a vacuum detection bench. A movable pedestal is configured on the vacuum detection bench. A stand column is arranged on the movable pedestal. A support disc capable of up-down moving along the stand column is installed on the stand column via a lock pin. An alcohol storing box is arranged on the vacuum detection bench. An injector is configured to the alcohol storing box. According to the invention, the injector is used for extracting and injecting alcohol in the alcohol storing box to a sealing end of the pipe body, so the sealing end is covered by the alcohol; then vacuum extraction is performed by the vacuum detection bench; and if the alcohol on the sealing end does not disappear obviously and rapidly, it means that the weld joint detection device is well sealed, and if the alcohol disappears quickly, it means that the weld joint detection device is not well sealed, so the sealing end can be adjusted.

Owner:CHENGDU GUOGUANG ELECTRIC

Multipoint-supporting easy-distinguishing weld joint detection technology of multiple types of electronic pipes

InactiveCN105258862AAvoid mistakesEasy to observe the lossDetection of fluid at leakage pointAlcoholLiquid medium

The invention discloses a multipoint-supporting easy-distinguishing weld joint detection technology of multiple types of electronic pipes. A flexible capsule bag is arranged on a support disc. The capsule bag is filled with liquid medium. An alcohol storing box is arranged on the vacuum detection bench. An injector and three pigment pipes storing organic pigment are arranged on the alcohol storing box. According to the invention, based on the color difference between colorful alcohol and a pipe body material, it is easy to observe the volatile condition of the alcohol; if the alcohol in a sealed end does not be volatile obviously and rapidly, it is proved that the sealed end is highly sealed; and if the alcohol in the sealed end is volatile rapidly, it means that the sealed end is not well sealed and should be adjusted.

Owner:CHENGDU GUOGUANG ELECTRIC

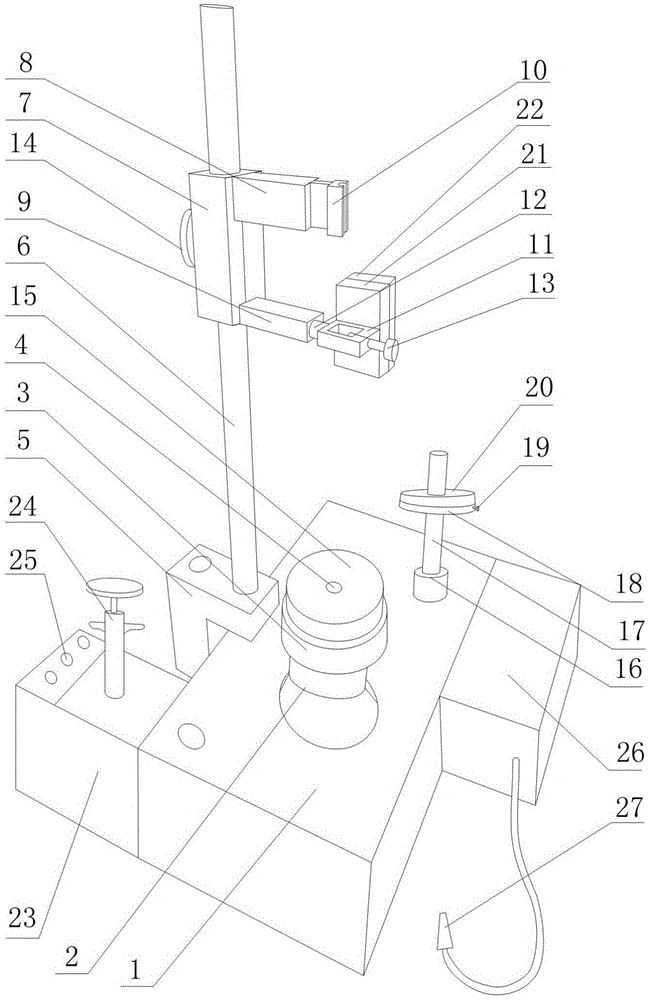

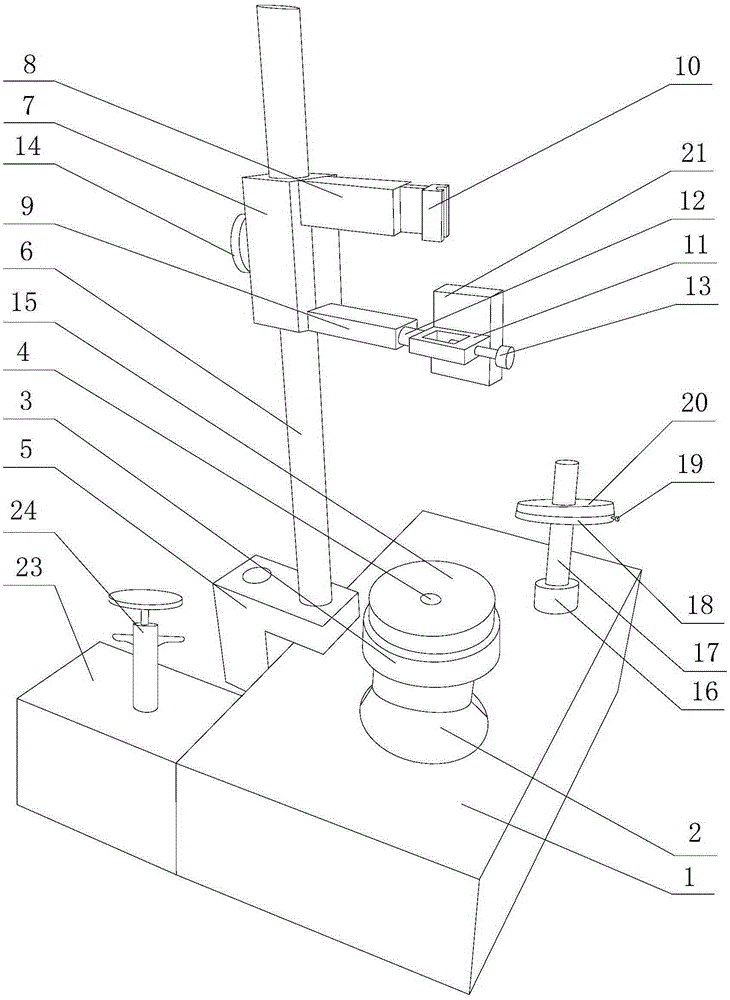

Multipoint support detection method of weld seams of multi-type electronic fittings

InactiveCN105334009AExpand the scope of detectionRealize detectionMeasurement of fluid loss/gain rateLiquid mediumMovable type

The invention discloses a multipoint support detection method of weld seams of multi-type electronic fittings. The method comprises a vacuum detection bench, the vacuum detection bench is provided with a movable type base, the movable type base is provided with an upright column, the upright column is provided with a support disc capable of vertically moving along the upright column through a lock pin, the support disc is provided with a flexible bag, and the bag is filled with a liquid medium. The side surface of a rectangular box body is provided with a flat clamp, the flat clamp has a certain thickness, the rectangular box body is connected with a lower transverse arm through a rotating shaft, the rectangular box body is provided with a fastening bolt, through rotating the rectangular box body, switching into clamping or compaction of a fitting can be realized, the method is applied to fittings with different specifications, when the fitting is placed on the flexible bag, the fitting is naturally oriented downwards under the effect of gravity, and the liquid medium drives the bag to wrap and fix the fitting and exhibit a support effect, such that fixation of hardware is reduced, and the electronic fitting is effective protected.

Owner:CHENGDU GUOGUANG ELECTRIC

A no-clean weld detection device with multi-point support for various titanium alloy parts

InactiveCN106813859ARealize detectionExpand the scope of detectionDetection of fluid at leakage pointAlcoholLiquid medium

The invention discloses a non-cleaning welding seam detection device with multi-point support of various titanium alloy parts, which comprises a vacuum detection table, a movable base is arranged on the vacuum detection table, and a column is arranged on the movable base. A support plate that can move up and down along the column is installed on the column through a lock pin. A flexible bladder is set on the support plate, and the bladder is filled with liquid medium; There is an alcohol storage box on which a syringe is configured. In the present invention, a flat pressing plate is arranged on the side of the rectangular frame body, and a fastening bolt is arranged on the rectangular frame body. By rotating the rectangular frame body, it can be switched to clamping or compressing the pipe fittings, which is suitable for pipe fittings of different specifications. For pipe fittings, a layer of silicon rubber sheet is arranged on the flat plate as a buffer structure, which not only protects the pipe fittings, but also improves the sealing performance.

Owner:重庆市瑞友机械厂

No-clean welding seam detection method used for bent electronic pipe fittings

InactiveCN105352681AGuaranteed cleanlinessImprove sealingMeasurement of fluid loss/gain rateWeld seamInjector

The invention discloses a no-clean welding seam detection method used for a bent electronic pipe fitting. The no-clean welding seam detection method comprises a vacuum detection stand, wherein the vacuum detection stand is equipped with a mobile base, a stand column is arranged on the mobile base, and a supporting disc which can move up and down along the stand column is installed on the stand column through a locking pin; an alcohol storage box is arranged on the vacuum detection stand, and an injector is equipped on the alcohol storage box. According to the no-clean welding seam detection method, the injector is used for extracting alcohol in the alcohol storage box and injecting the alcohol to a sealed end of the pipe fitting, so that the sealed end is covered with alcohol, then the vacuum detection stand is used for conducting vacuum extraction, if the alcohol at the sealed end does not disappear obviously and quickly, then the sealing is proved to be good, and if the alcohol disappears quickly, then the sealing is shown to be defective, thereby adjusting the sealed end.

Owner:CHENGDU GUOGUANG ELECTRIC

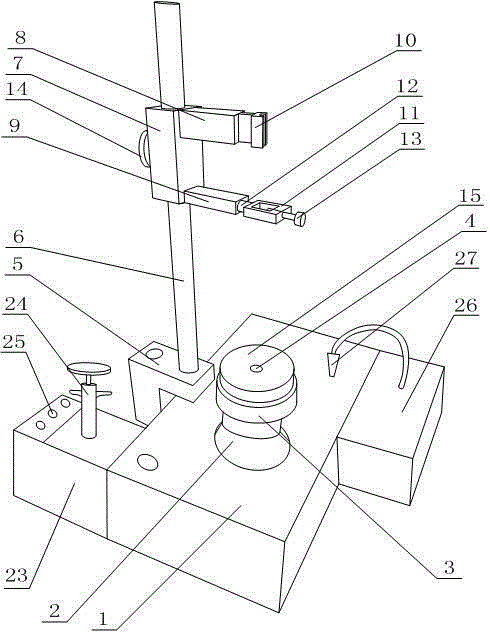

Multi-point support welding line detection device for bending electronic tubes

InactiveCN105300604AAvoid mistakesEasy to observe the lossMeasurement of fluid loss/gain rateLiquid mediumEngineering

The invention discloses a multi-point support welding line detection device for bending electronic tubes, comprising a vacuum detection table which is equipped with a mobile pedestal; the mobile pedestal is provided with a stand column; a support plate is installed on the stand column through a lock pin, wherein the support plate can be moved up and down along the stand column; the support plate is provided with a flexible bag which is filled with a liquid medium; the vacuum detection platform is provided with an lcohol storage box which is provided with a syringe and three pigment tubes storing the organic pigment. The flexible bag is filled with the liquid medium. When the tube is placed on the flexible bag, under the effect of gravity the liquid medium drives the flexible bag to wrap and fix the tube under the gravity, which plays a fixing role, reduces the rigid fixing and effectively protects the electronic tubes.

Owner:CHENGDU GUOGUANG ELECTRIC

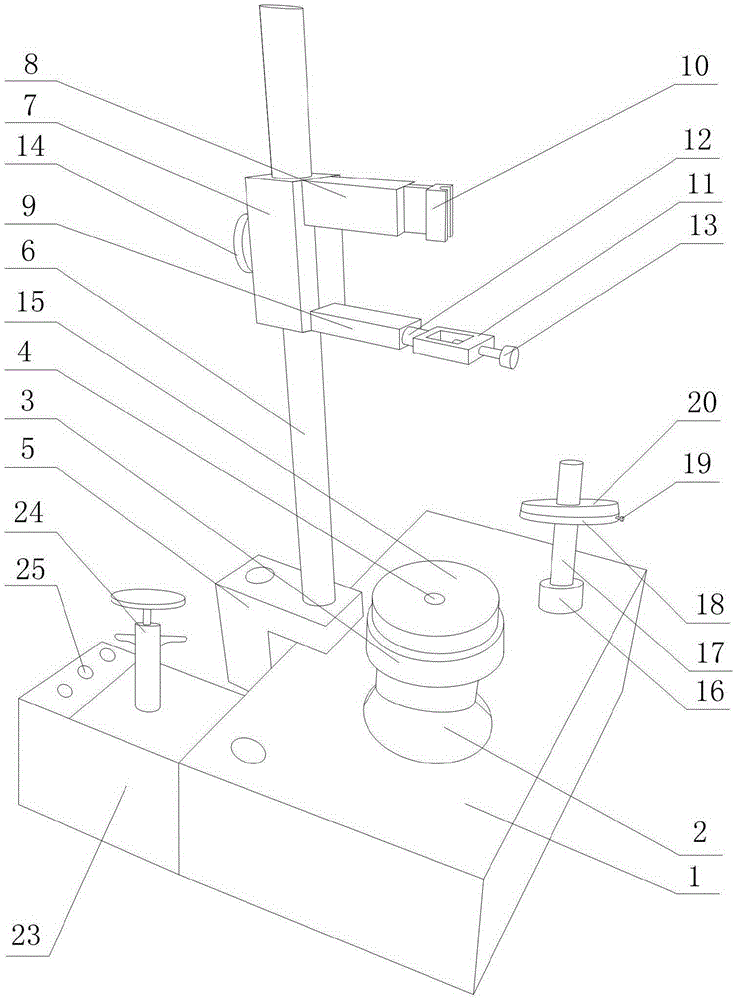

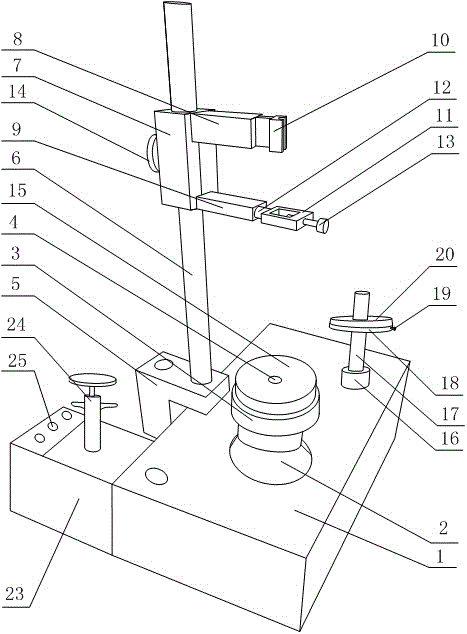

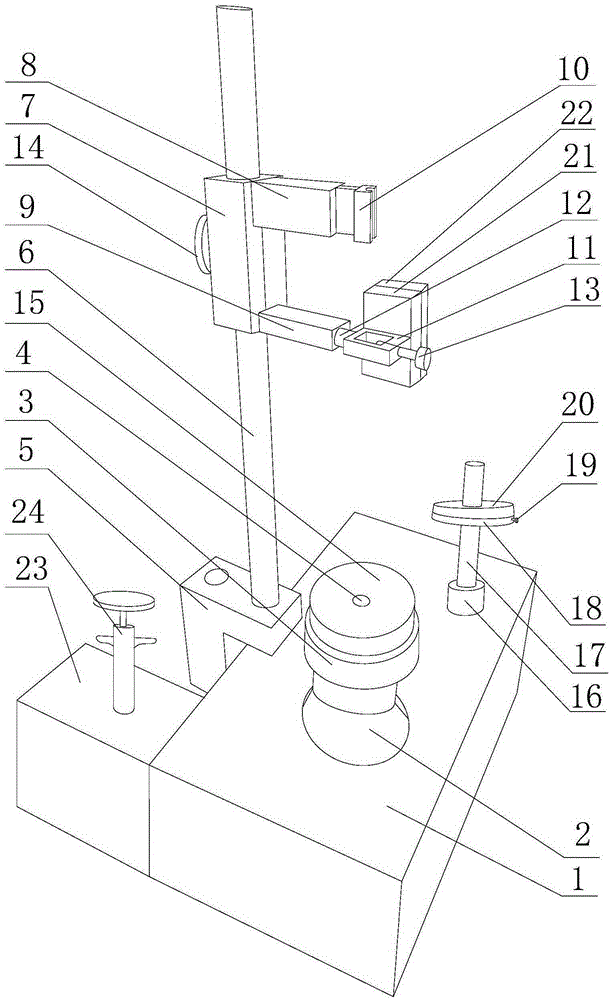

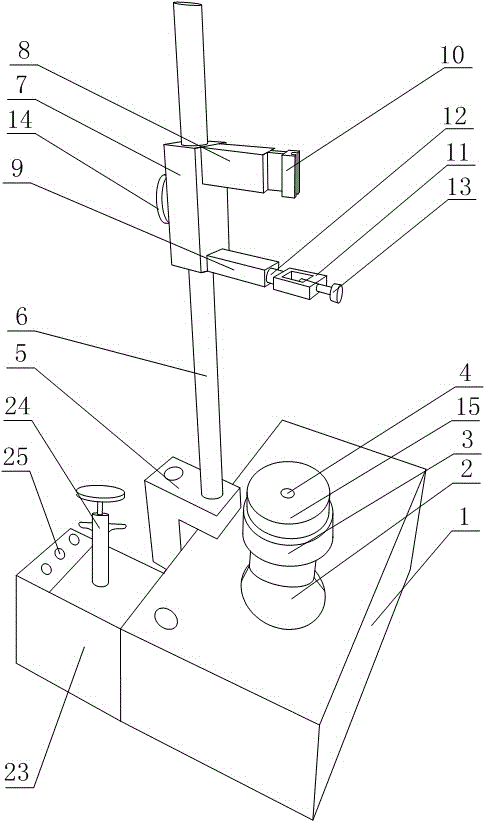

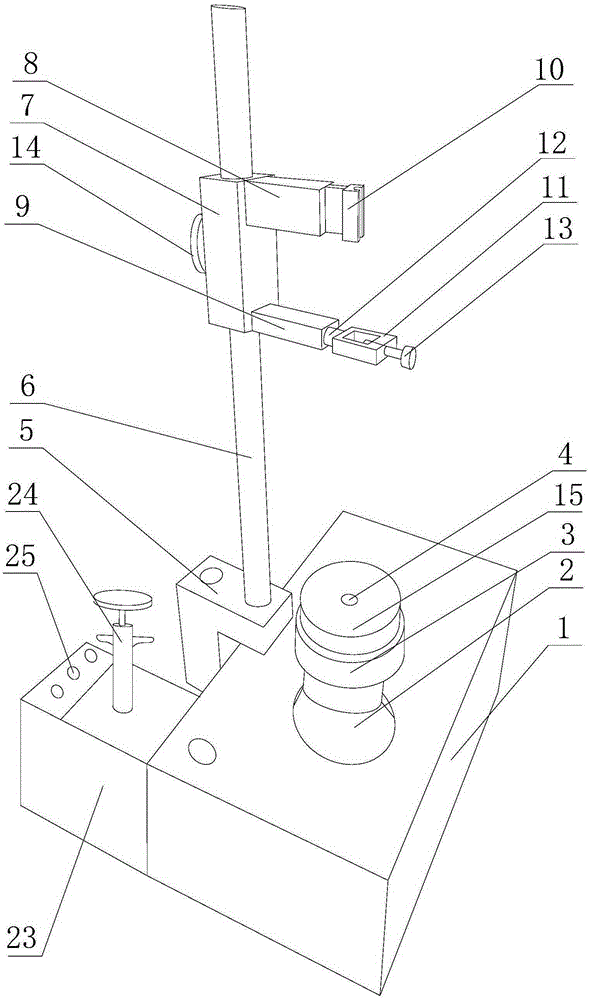

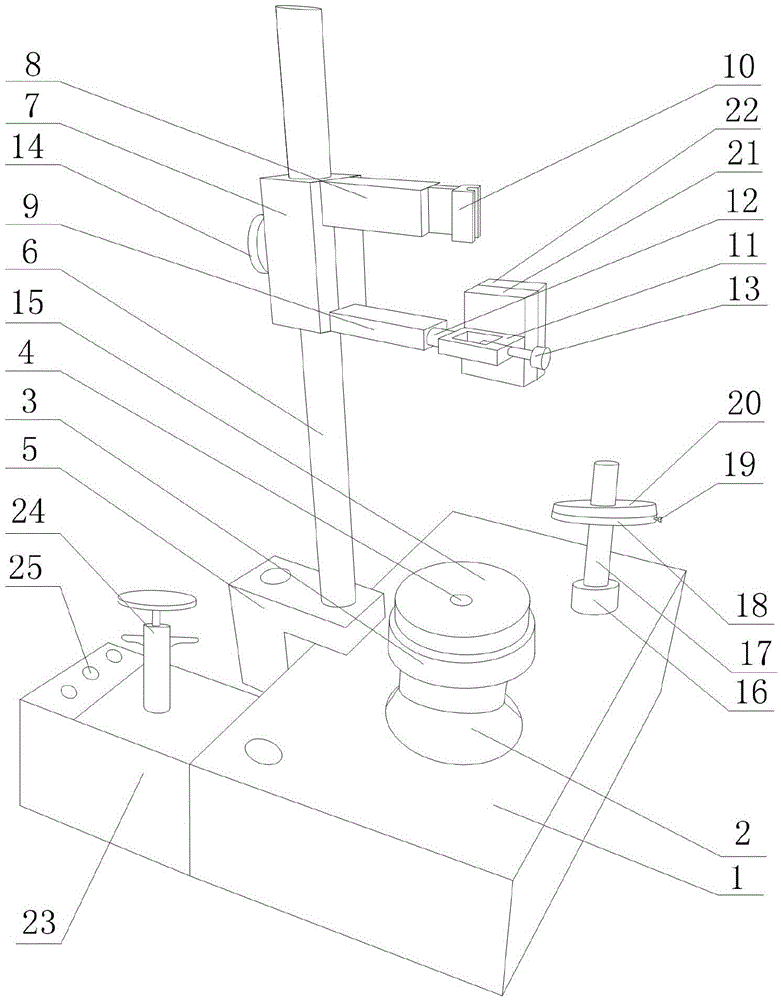

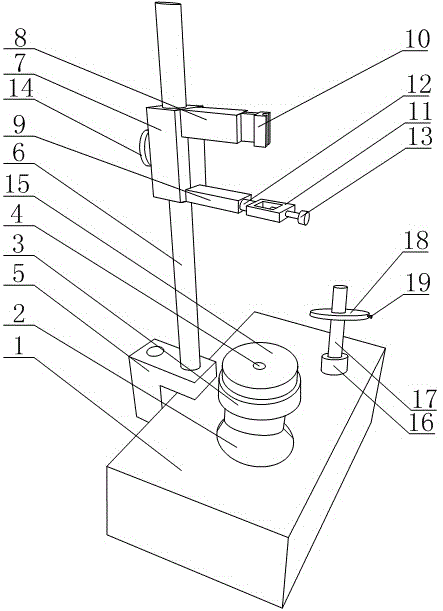

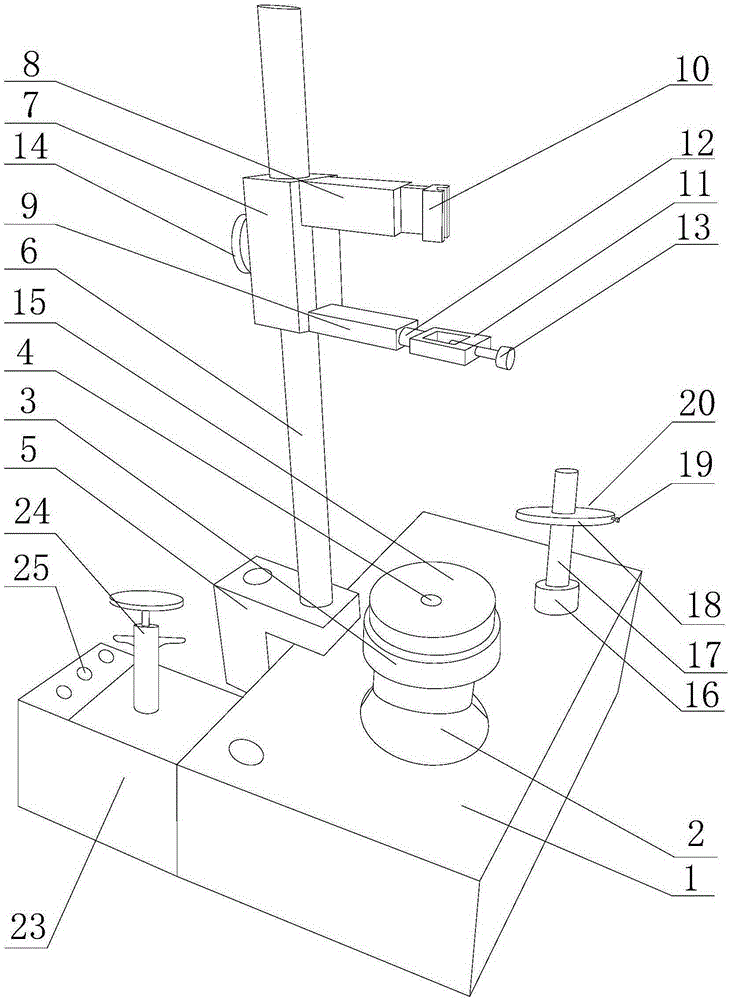

Multipoint-support no-cleaning weld detection method for multiple types of electronic pipes

InactiveCN105387979AAvoid misjudgment of weld failureObviously disappearMeasurement of fluid loss/gain rateSyringeEngineering

The invention discloses a multipoint-support no-cleaning weld detection method for multiple types of electronic pipes, which comprises a vacuum detection table. A mobile base is configured on the vacuum detection table; a vertical column is arranged on the mobile base; a supporting disc capable of vertically moving along the vertical column is arranged on the vertical column via a locking pin; a flexible bag is arranged on the supporting disc; the bag is filled with a liquid medium; the vacuum detection table is also provided with an alcohol storage box; and a syringe is arranged on the alcohol storage box; the side surface of a rectangular frame body is provided with a flat clamping plate with a certain thickness, the rectangular frame body is connected onto a lower transverse arm via a rotation shaft, a fastening bolt is arranged on the rectangular frame body, clamping or pressing on a pipe can be switched through rotating the rectangular frame body, the method is applied to pipes of different specifications, and when the pipe is placed on the flexible bag and is downward naturally under effects of gravity, the liquid medium drives to the bag to coat and fix the pipe, a supporting role is played, rigid fixing is reduced, and the electronic pipe can be effectively protected.

Owner:CHENGDU GUOGUANG ELECTRIC

Weld joint detector for electronic tube

InactiveCN105424285AHigh speedGood repeatabilityFluid-tightness measurement using fluid/vacuumEngineeringElastic plastic

The invention discloses a weld joint detector for an electronic tube. The detector comprises a vacuum detection platform, the vacuum detection platform is connected with a detection panel via an enclosed telescopic port, and an exhausting hole in vacuum communication with the internal of the vacuum detection platform is arranged in the detection panel; and a counterweight pedestal is also included, a support rod is arranged on the counterweight pedestal, a fixed body which can move up and down along the support rod is mounted on the support rod, an upper transverse arm and a lower transverse arm are arranged on the fixed body, a guiding block is arranged on the upper transverse arm, the guiding block is provided with a guide groove, and the lower transverse arm is connected with a clamping mechanism. The detector can be used to detect weld joints of different types electronic tubes, the guiding block made of elastic plastics is elastic to certain extent, when the tube is placed in the guide groove, the guiding block can fix the tube via the elasticity and prevent the tube from damage, the detector is especially suitable for testing the electronic tubes, and the detector is characterized by high speed and reliability.

Owner:CHENGDU GUOGUANG ELECTRIC

Easily distinguishable welding line detection device for electronic tube welding line

InactiveCN105300631AAvoid mistakesEasy to observe the lossMeasurement of fluid loss/gain rateVacuum extractionAlcohol

The invention discloses a easily distinguishable welding line detection device for an electronic tube welding line. The easily distinguishable welding line detection device comprises a vacuum detection table which is connected to a detection board through a sealing telescopic interface; the detection board is provided with a bleeder hole which is in vacuum communication with the internal of the vacuum detection table; the vacuum detection table is provided with an alcohol storage box which is equipped with a syringe and three pigment tubes for storing organic pigments. The electronic tube member welding line cleaning free detection device utilizes the syringe to draw the alcohol inside the alcohol storage box and injects the alcohol at the sealing end of the tube member in order to make the sealing end covered by the alcohol; the vacuum detection table performs vacuum extraction; if the alcohol on the sealing end is fast and obviously disappeared, good sealing is proved; and if the alcohol is fast disappeared, the defect in sealing exists and the adjustment on the sealing end is performed.

Owner:CHENGDU GUOGUANG ELECTRIC

An easy-to-distinguish detection process for welding seams of titanium alloy multi-arc components

InactiveCN106813863AAvoid mistakesEasy to observe the lossDetection of fluid at leakage pointVacuum extractionPipe fitting

The invention discloses an easy-to-distinguish detection process for welding seams of titanium alloy multi-arc components, comprising a vacuum detection platform, on which a detection plate is connected through a closed telescopic opening, and a detection plate is set on the detection plate There is an air extraction hole connected with the internal vacuum of the vacuum testing platform; an alcohol storage box is also arranged on the vacuum testing platform, and a syringe and three paint tubes for storing organic pigments are arranged on the alcohol storage box. The present invention uses a syringe to extract the alcohol in the alcohol storage box, and injects it on the sealing end of the pipe fitting, so that the sealing end is covered by alcohol, and then the vacuum detection platform carries out vacuum extraction. If the alcohol at the sealing end disappears obviously and quickly, it is proved The seal is good, if the alcohol disappears quickly, it means that the seal is defective, so adjust the seal end.

Owner:重庆市瑞友机械厂

Multi-point support cleaning free welding line detection device for bending type electronic tubes

InactiveCN105300634AExpand the scope of detectionRealize detectionMeasurement of fluid loss/gain rateLiquid mediumEngineering

The invention discloses a multi-point support welding line detection device for bending type electronic tubes, comprising a vacuum detection table which is equipped with a mobile pedestal; the mobile pedestal is provided with a stand column; a support plate is installed on the stand column through a lock pin, wherein the support plate can be moved up and down along the stand column; the support plate is provided with a flexible bag which is filled with a liquid medium; the vacuum detection platform is provided with a alcohol storage box which is provided with a syringe and three pigment tubes storing the organic pigment. The flexible bag is filled with the liquid medium. When the tube is placed on the flexible bag, the liquid medium drives the flexible bag to wrap and fix the tube under the gravity, which plays a fixing role, reduces the rigid fixing and effectively protects the electronic tubes.

Owner:CHENGDU GUOGUANG ELECTRIC

Interface examination device for finish finishing of combined part

InactiveCN106813873AAvoid mistakesEasy to observe the lossMeasurement of fluid loss/gain rateAlcoholLiquid medium

The invention discloses an interface examination device for the finish finishing of a combined part, and the device comprises a vacuum detection platform. A supporting disc is provided with a flexible bag, and the flexible bag contains a liquid medium. The vacuum detection platform is also provided with an alcohol storage box, and the alcohol storage box is provided with an injector and three pigment pipes for storing organic pigments. A side surface of a rectangular frame body is provided with a flat compression plate, and the rectangular frame body is provided with a fastening bolt. The clamping or compression of paired pipes can be switched through the rotation of the rectangular frame body. The device is suitable for different types of pipes. The flat compression plate is provided with a silicone rubber sheet serving as a buffering structure, thereby protecting the pipes, and improving the sealing performance.

Owner:重庆市鑫耀机械厂

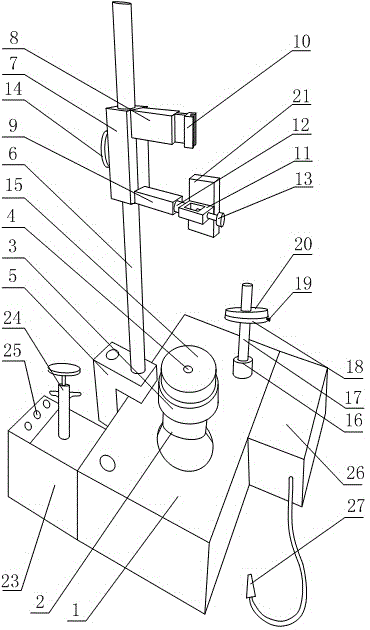

Electronic tube member welding line fast detection device

InactiveCN105300606AAvoid false conclusionsImprove sealingMeasurement of fluid loss/gain rateSpray nozzleHigh pressure

The invention discloses an electronic tube member welding line fast detection device. A vacuum detection table is provide with an alcohol storage box which is equipped with a syringe and three pigment tubes storing organic pigments; a high pressure gas storage tank is also included; and the high pressure gas storage tank is connected to a cone-shaped nozzle through a flexible tube. When the detection is finished, the valve on the flexible tube is opened through pressing, the gas in the high pressure gas storage tank is sprayed out through the flexible tube and the cone-shaped nozzle to evaporate and remove the alcohol coated on the surface of the workpiece so as to fast restore and clean the tube member. The invention greatly shortens the later stage cleaning work and greatly improves the detection speed.

Owner:CHENGDU GUOGUANG ELECTRIC

A welding seam detection method for multi-arc surface of titanium alloy

InactiveCN106813845ARealize detectionExpand the scope of detectionFluid-tightness measurement using fluid/vacuumPipe fittingWeld seam

The invention discloses a welding seam detection method for titanium alloy multi-arc surface, comprising a vacuum detection table, a movable base is arranged on the vacuum detection table, a column is arranged on the movable base, and a column is arranged on the column A support plate that can move up and down along the column is installed through the lock pin. When the detection device of the present invention is in use, first install the electronic pipe fitting to be measured on the detection panel so that one end thereof communicates with the air extraction hole, and the other end of the pipe fitting is sealed by a rubber pad; the lower cross arm fixes the pipe fitting, The upper cross arm guides and supports the pipe fittings. A movable base is arranged on the vacuum testing table, and a column is arranged on the movable base. The middle part of the pipe fittings is placed on the supporting plate as the third support point of the curved pipe fittings, so that the weld seam inspection can be realized for the curved pipe fittings of any shape and structure.

Owner:重庆市瑞友机械厂

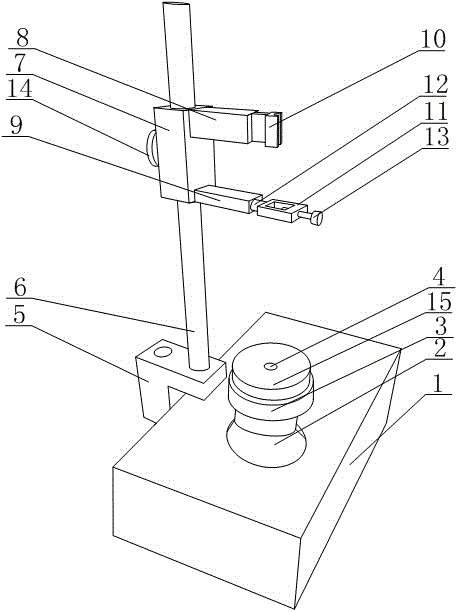

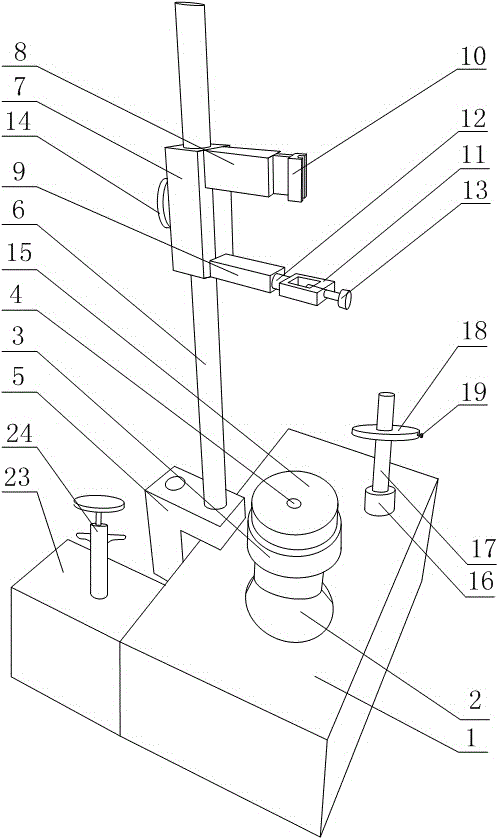

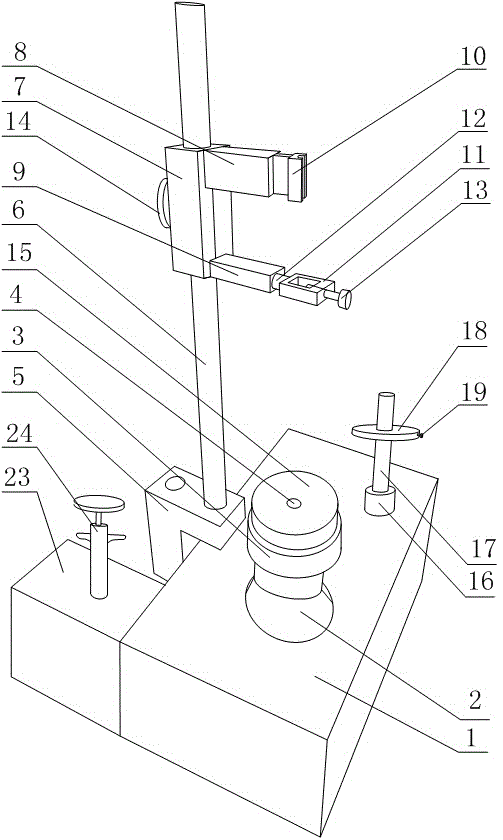

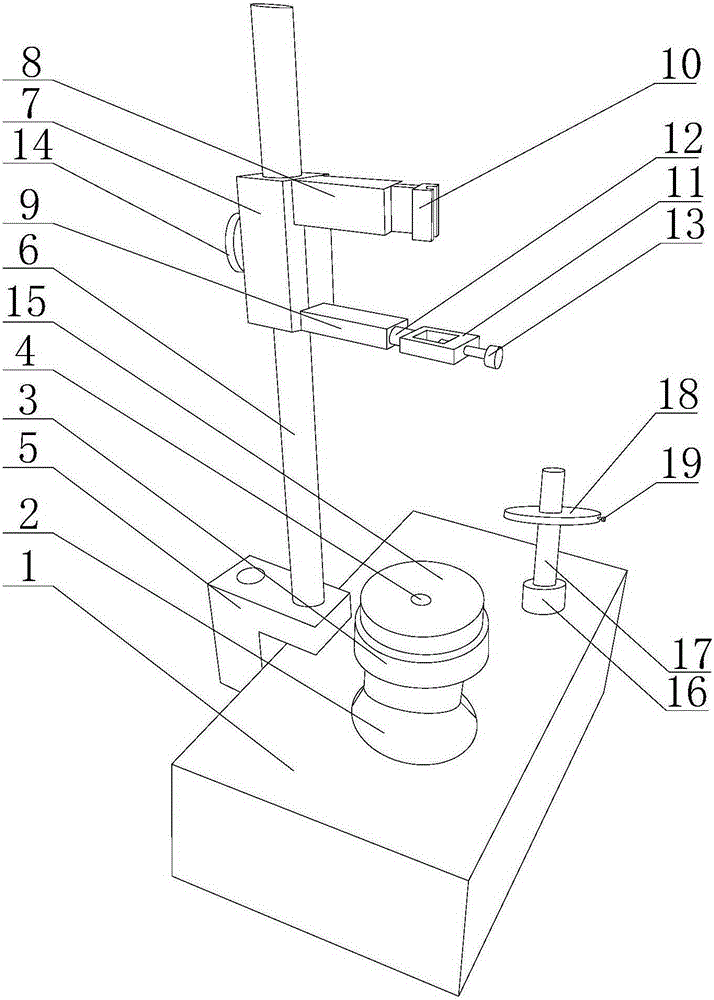

Weld joint detection method for electronic tube

InactiveCN105424288AHigh speedGood repeatabilityDetection of fluid at leakage pointEngineeringRepeatability

The invention discloses a weld joint detection method for an electronic tube. A vacuum detection platform is included, the vacuum detection platform is connected with a detection panel via an enclosed telescopic port, an exhausting hole in vacuum communication with the internal of the vacuum detection platform is arranged in the detection panel, a counterweight pedestal is also included, a support rod is arranged on the counterweight pedestal, a fixed body which can move up and down along the support rod is mounted on the support rod, an upper transverse arm and a lower transverse arm are arranged on the fixed body, a guiding block is arranged on the upper transverse arm, the guiding block is provided with a guide groove, and the lower transverse arm is connected with a clamping mechanism. The method can be used to detect weld joints of different types of electronic tubes, and is characterized by high speed, repeatability and reliability.

Owner:CHENGDU GUOGUANG ELECTRIC

Interface checking technique for finishing combined taper spare part

The invention discloses an interface inspection process for finishing combined taper parts, which comprises a vacuum detection table, a flexible bladder is arranged on the support plate, and liquid medium is filled in the bladder; There is also an alcohol storage box on the vacuum testing table, which is equipped with a syringe and three paint tubes for storing organic pigments, and also includes a high-pressure gas storage tank, which is connected to a high-pressure gas storage tank through a hose. Conical nozzle. In the present invention, a flat pressing plate is arranged on the side of the rectangular frame body, and a fastening bolt is arranged on the rectangular frame body. By rotating the rectangular frame body, it can be switched to clamping or compressing the pipe fittings, which is suitable for pipe fittings of different specifications. For pipe fittings, a layer of silicon rubber sheet is arranged on the flat plate as a buffer structure, which not only protects the pipe fittings, but also improves the sealing performance.

Owner:重庆市鑫耀机械厂

Welding seam detection method for titanium alloy weldment

InactiveCN106813858AHigh speedGood repeatabilityDetection of fluid at leakage pointPipe fittingWeld seam

The invention discloses a welding seam detection method of a titanium alloy weldment, which comprises a vacuum detection platform, on which a detection plate surface is connected through a closed telescopic opening, and a vacuum detection platform is arranged on the detection plate surface It also includes a counterweight base, on which a support rod is arranged, a fixed body that can move up and down along the support rod is installed on the support rod, and a An upper cross arm and a lower cross arm are provided with a guide block on the upper cross arm, a guide groove is arranged on the guide block, and a clamping mechanism is connected to the lower cross arm. The invention can detect the welding seam of various electronic pipe fittings, is especially suitable for the testing of electronic pipe fittings, and has the characteristics and advantages of high speed, good repeatability and high reliability.

Owner:重庆市瑞友机械厂

A weld detection device for a titanium alloy weldment

InactiveCN106813839AHigh speedGood repeatabilityFluid-tightness measurement using fluid/vacuumPipe fittingWeld seam

The invention discloses a weld detection device for a titanium alloy weldment, which comprises a vacuum detection platform, on which a detection plate surface is connected through a closed telescopic opening, and a vacuum detection platform is arranged on the detection plate surface It also includes a counterweight base, on which a support rod is arranged, a fixed body that can move up and down along the support rod is installed on the support rod, and a An upper cross arm and a lower cross arm are provided with a guide block on the upper cross arm, a guide groove is arranged on the guide block, and a clamping mechanism is connected to the lower cross arm. The invention can detect the welding seam of various electronic pipe fittings, is especially suitable for the testing of electronic pipe fittings, and has the characteristics and advantages of high speed, good repeatability and high reliability.

Owner:重庆市瑞友机械厂

Electronic tube member welding line cleaning free detection device

InactiveCN105300605AAvoid false conclusionsImprove sealingFluid-tightness measurement using fluid/vacuumAlcoholVacuum extraction

The invention discloses an electronic tube member welding line cleaning free detection device, comprising a vacuum detection table which is connected to a detection board through a sealing telescopic interface; the detection board is provided with a bleeder hole which is in vacuum communication with the internal part of the vacuum detection table; the vacuum detection table is provided with an alcohol storage box which is equipped with a syringe. The electronic tube member welding line cleaning free detection device utilizes the syringe to draw the alcohol inside the alcohol storage box and injects the alcohol at the sealing end of the tube member in order to make the sealing end covered by the alcohol; the vacuum detection table performs vacuum extraction; if the alcohol on the sealing end is fast and obviously disappeared, good sealing is proved; and if the alcohol is fast disappeared, the defect in sealing exists and the adjustment on the sealing end is performed.

Owner:CHENGDU GUOGUANG ELECTRIC

A Titanium Alloy Tube Weld Inspection Process for Multiple Welding Planes

InactiveCN106813834AAvoid mistakesGuaranteed cleanlinessFluid-tightness measurement using fluid/vacuumVacuum extractionAlcohol

The invention discloses a titanium alloy pipe welding seam detection process for multi-welding planes, comprising a vacuum detection platform, a movable base is arranged on the vacuum detection platform, a column is arranged on the movable base, and a column is installed on the column A supporting plate that can move up and down along the column is installed through the lock pin; an alcohol storage box is also arranged on the vacuum detection table, and a syringe is arranged on the alcohol storage box. The present invention uses a syringe to extract the alcohol in the alcohol storage box, and injects it on the sealing end of the pipe fitting, so that the sealing end is covered by alcohol, and then the vacuum detection platform carries out vacuum extraction. If the alcohol at the sealing end disappears obviously and quickly, it is proved The seal is good, if the alcohol disappears quickly, it means that the seal is defective, so adjust the seal end.

Owner:重庆市瑞友机械厂

Welding seam detection method used for bent electronic pipe fitting

InactiveCN105352665AExpand the scope of detectionRealize detectionFluid-tightness measurement using fluid/vacuumPipe fittingWeld seam

The invention discloses a welding seam detection method used for a bent electronic pipe fitting. The welding seam detection method comprises a vacuum detection stand, wherein the vacuum detection stand is equipped with a mobile base, a stand column is arranged on the mobile base, and a supporting disc which can move up and down along the stand column is installed on the stand column through a locking pin. When the welding seam detection method is adopted, the electronic pipe fitting to be measured is installed on a detection panel, one end is communicated with an air exhaust hole, the other end of the pipe fitting is sealed through a rubber cushion block; and a lower cross arm is used for fixing the pipe fitting, and an upper cross arm is used for guiding and supporting the pipe fitting. According to the welding seam detection method, the vacuum detection stand is equipped with the mobile base, the stand column is arranged on the mobile base, the supporting disc which can move up and down along the stand column is installed on the stand column through the locking pin, and the middle part of the bent pipe fitting is placed on the supporting disc and serves as a third supporting point of the bent pipe fitting, so that the welding seam detection of bent pipe fittings of any shape structure can achieved.

Owner:CHENGDU GUOGUANG ELECTRIC

A detection process for the welding seam of multi-curved titanium alloy assembly

InactiveCN106813868AGuaranteed cleanlinessImprove sealingMeasurement of fluid loss/gain rateLiquid mediumAlcohol

The invention discloses a welding seam detection process of a multi-curved titanium alloy assembly, which comprises a vacuum detection table, a movable base is arranged on the vacuum detection table, a column is arranged on the mobile base, and a column is installed on the column. A support plate that can move up and down along the column is installed through the lock pin, and a flexible pouch is set on the support plate, and the pouch is filled with liquid medium; The storage box is provided with a syringe on the alcohol storage box. In the present invention, a flat pressing plate is arranged on the side of the rectangular frame body. The flat pressing plate has a certain thickness. The rectangular frame body is connected to the lower cross arm through a rotating shaft. A fastening bolt is arranged on the rectangular frame body. By rotating the rectangular frame body, , can be switched to clamp or compress the pipe fittings, suitable for pipe fittings of different specifications, when the pipe fittings are placed on the flexible pouch, it will naturally go downward under the action of gravity, the liquid medium drives the pouch to wrap and fix the pipe fittings, and Play a supporting role, reduce the rigid fixation, and effectively protect the electronic pipe fittings.

Owner:重庆市瑞友机械厂

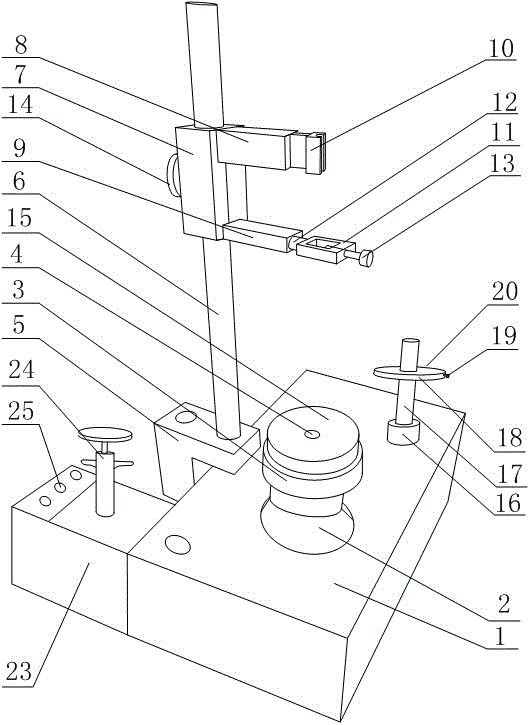

Multi-point support detection method for welding joints of multiple kinds of electronic pipe fittings

InactiveCN105300618AExpand the scope of detectionRealize detectionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateLiquid mediumPipe fitting

The invention discloses a multi-point support detection method for welding joints of multiple kinds of electronic pipe fittings. The multi-point support detection method is characterized by comprising a vacuum detection platform; the vacuum detection platform is provided with a mobile base; the mobile base is provided with a stand column, on which a support plate is installed through a lock pin, wherein the lock pin can move up and down along the stand column; and the support plate is provided with a flexible bag which is filled with a liquid medium. The invention is provided with a horizontal pressing plate on the side of a rectangle frame body; the horizontal pressing plate has a certain thickness; the rectangle frame body is connected to a lower transverse arm through a rotation shaft; a fastening bolt is arranged on the rectangle frame body; the conditions of clamping and pressing the pipe fitting can be switched through rotation of the rectangle frame body, which is applicable to the pipe fittings with various specifications; a layer of silicone rubber pad is arranged on the horizontal pressing plate as a buffer structure, which not only protects the pipe fittings, but also improves the sealing performance.

Owner:CHENGDU GUOGUANG ELECTRIC

A welding seam inspection process for multi-bending titanium alloy pipe fittings

InactiveCN106813869AAvoid mistakesEasy to observe the lossMeasurement of fluid loss/gain rateLiquid mediumPipe fitting

The invention discloses a welding seam detection process of a multi-curvature titanium alloy pipe fitting, which comprises a vacuum detection table, a movable base is arranged on the vacuum detection table, a column is arranged on the movable base, and a column is passed on the column. The lock pin is equipped with a support plate that can move up and down along the column. A flexible pouch is set on the support plate, and the pouch is filled with liquid medium. An alcohol storage is also set on the vacuum testing platform. The alcohol storage box is equipped with a syringe and three pigment tubes for storing organic pigments. The inside of the flexible pouch of the detection device of the present invention is filled with liquid medium. When the pipe is placed on the flexible pouch, it will naturally go downward under the action of gravity, and the liquid medium will drive the pouch to wrap and fix the pipe, and play a supporting role, reducing the Rigid fixing effectively protects the electronic pipe fittings.

Owner:重庆市瑞友机械厂

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com