Patents

Literature

32results about How to "Precise control of hot state size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces

The invention discloses a thermal bulging process for special-shaped high-temperature-alloy rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a special-shaped high-temperature-alloy rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the ring workpiece axially along the inner circumference of the rolled ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 820 DEG C to 860 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 10s to 11s, and the deflection ranges from 0.7% to 0.9%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 790 DEG C to 830 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.8% to 1 %. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 760 DEG C to 800 DEG C, the bulging time ranges from 30s to 40s, the pressure holding time ranges from 25s to 28s, and the deflection ranges from 0.9% to 1.1%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging method for aluminum alloy special-shaped ring-rolled piece

The invention discloses a thermal bulging method for an aluminum alloy special-shaped ring-rolled piece. The method comprises the following steps of: assembling a hot-rolled aluminum alloy special-shaped ring-rolled piece on the periphery of a preheated bulging block in a bulging machine, and starting the bulging machine to make the bulging block extrude the ring-rolling piece radially from the inner circumferential surface of the ring-rolled piece to finish first bulging, wherein the bulging temperature is 350-410 DEG C, the bulging time is 15-20 seconds, the dwelling time is 11-14 seconds, and the deflection is 0.4-0.8 percent; rotating the ring-rolled piece by 45 degrees along a central axis to finish a first rotation; performing second bulging according to the operation above, wherein the bulging temperature is 300-370 DEG C, the bulging time is 20-30 seconds, the dwelling time is 16-18 seconds, and the deflection is 0.5-1.1 percent; rotating the ring-rolled piece once according to a first rotating direction to finish second rotation; and performing third bulging according to the operation above, wherein the bulging temperature is 270-330 DEG C, the bulging time is 30-40 seconds, the dwelling time is 25-28 seconds, and the deflection is 0.5-1.1 percent. The size accuracy of the bulged ring-rolled piece can be up to 1-2 per thousand of a corresponding size; and the aluminum alloy special-shaped ring-rolled piece is manly applied to the fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for rectangular stainless steel rolled ring workpieces

ActiveCN102489616AHigh dimensional accuracySmall amount of reboundShaping toolsTime rangeMarine navigation

The invention discloses a thermal bulging process for rectangular stainless steel rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a rectangular stainless steel rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the ring workpiece axially along the inner circumference of the rolled ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 890 DEG C to 950 DEG C, the bulging time ranges from 15s to 25s, the pressure holding time ranges from 7s to 8s, and the deflection ranges from 0.9% to 1.2%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 850 DEG C to 910 DEG C, the bulging time ranges from 15s to 25s, the pressure holding time ranges from 9s to 10s, and the deflection ranges from 0.7% to 1 %. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 800 DEG C to 870 DEG C, the bulging time ranges from 25s to 35s, the pressure holding time ranges from 13s to 15s, and the deflection ranges from 0.5% to 0.8%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for forming irregular ring piece by utilizing stainless-steel rectangular ring rolled piece through thermal bulging

ActiveCN102513457AHigh dimensional accuracyPrecise control of bulge sizeShaping toolsAbnormal shapedAerospace

The invention discloses a method for forming an irregular ring piece by utilizing a stainless-steel rectangular ring rolled piece through thermal bulging, comprising the following steps of: sleeving the heated stainless-steel rectangular ring rolled piece on the periphery of a pre-heated bulging blockin a bulging machine; starting the bulging machine so that the ring rolled piece is squeezed by the bulging block in a radial direction along the inner circumference surface of the ring rolled piece and becomes the irregular ring blank after being deformed for 11-13%, thus completing primary bulging; rotating the irregular ring blank for 45 degrees along an center axis, thus completing primary rotation; carrying out secondary bulging with the deformation amount of 1.8-2% and secondary rotation on the irregular ring blank according to the previous steps; carrying out tertiary bulging with the deformation amount of 1.4-1.6% and tertiary rotation on the irregular ring blank according to the previous steps; and carrying out quartus bulging with the deformation amount of 1.2-1.4% and quartus rotation on the irregular ring blank according to the previous steps, so as to obtain the irregular ring piece. The size precision of the irregular ring piece can reach 0.1-0.2% of the corresponding size. The irregular ring piece formed by using the method disclosed by the invention is mainly used for fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for thermally bulging high-temperature alloy rectangular ring rolled member

ActiveCN102500705AHigh dimensional accuracySmall amount of reboundShaping toolsSuperalloyHot Temperature

The invention discloses a method for thermally bulging a high-temperature alloy rectangular ring rolled member. The method comprises the following steps of: sleeving a hot rolled high-temperature alloy rectangular ring rolled member on the periphery of a pre-heated bulged block in a bulging machine, and starting the bulging machine to enable the bulged block to extrude the ring rolled member from the inner circumferential surface of the ring rolled member in a radial direction, so that bulging for the first time is completed, wherein the bulging temperature is 800-850 DEG C, the bulging time is 20-30 s, the pressure maintaining time is 9-10 s, and the deformation is 0.6-0.8%; rotating the ring rolled member along a central axis for 45 DEG, so that rotating for the first time is completed; then, carrying out bulging for the second time according to the above operations, wherein the bulging temperature is 770-820 DEG C, the bulging time is 20-30 s, the pressure maintaining time is 17-18 s, and the deformation is 0.7-0.9%; rotating the ring rolled member again according to the first rotary direction, so that rotating for the second time is completed; and carrying out bulging for the third time according to the above operations, wherein the bulging temperature is 740-790 DEG C, the bulging time is 30-40 s, the pressure maintaining time is 25-28 s, and the deformation is 0.8-1%. The size precision of the bulged ring rolled member can be up to 0.001-0.002 of that of corresponding sizes. The ring rolled member disclosed by the invention is mainly applied to the fields, such as aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for flash-welded stainless steel ring workpieces

The invention discloses a thermal bulging process for flash-welded stainless steel ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a flash-welded stainless steel ring workpiece which is annealed is sleeved on the periphery of a preheated bulging block in a bulging machine after being heated, and the bulging block squeezes the ring workpiece axially along the inner circumference of the ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 950 DEG C to 1040 DEG C, the bulging time ranges from 22s to 28s, the pressure holding time ranges from 18s to 20s, and the bulging deflection ranges from 0.12% to 0.15%. The primary rotation is completed by rotating the ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 920 DEG C to 1010 DEG C, the bulging time ranges from 20s to 25s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.08% to 0.09%. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 890 DEG C to 980 DEG C, the bulging time ranges from 25s to 30s, the pressure holding time ranges from 21s to 23s, and the deflection ranges from 0.09% to 1%. The dimensional precision of the ring workpiece can be 1%. to 2%. of the corresponding precision after the ring workpiece is bulged, and the ring workpiece is mainly used for the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal expansion method for titanium alloy flash welding collar piece

ActiveCN102397937AHigh dimensional accuracyReduced dimensional accuracyThermal expansionFlash welding

The invention discloses a thermal expansion method for a titanium alloy flash welding collar piece, which comprises the following steps: heating an annealed titanium alloy flash welding collar piece, sleeving the titanium alloy flash welding collar piece on the periphery of a preheated expanding block in an expanding machine, and starting the expanding machine to allow the expanding block to press the collar piece radically from the internal circumferential surface of the collar piece to accomplish primary expansion, wherein the expansion temperature is 750 to 850 DEG C, the expansion time is 10 to 15 seconds, the pressure-keeping time is 8 to 9 seconds and the deformation rate is 0.1 to 0.15 percent; rotating the collar piece 45 DEG around a central axis to accomplish primary rotation; performing secondary expansion by the same operation, wherein the expansion temperature is 730 to 830 DEG C, the expansion time is 22 to 23 seconds, the pressure-keeping time is 18 to 20 seconds, and the deformation rate is 0.7 to 0.9 percent; rotating the collar piece in the same direction as the primary rotation to accomplish secondary rotation; and performing tertiary rotation by the same operation, wherein the expansion time is 700 to 800 DEG C, the expansion time is 33 to 43 seconds, the pressure-keeping time is 28 to 30 seconds and the deformation rate is 0.8 to 1 percent. The specification precision of the expanded collar piece can reach 0.1 to 0.2 of a corresponding specification, and the expanded collar piece is mainly used in the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Process for forming special-shaped ring workpieces from aluminum alloy rectangular rolled ring workpieces by hot bulging

ActiveCN102500707AHigh dimensional accuracyPrecise control of bulge sizeShaping toolsMaterials scienceAerospace

The invention discloses a process for forming special-shaped ring workpieces from aluminum alloy rectangular rolled ring workpieces by hot bulging, which includes: sleeving a heated aluminum alloy rectangular rolled ring workpiece onto the periphery of a preheated bulging block in a bulging machine, squeezing the rolled ring part by the bulging block radially from the inner circumference surface of the rolled ring part after starting the bulging machine, completing the primary bulging after the rolled ring part is deformed by 10%-18% to form a special-shaped ring blank, completing the primary rotation by rotating the special-shaped ring blank around the center axis by 45 degrees; completing the secondary bulging by repeating the above steps to deform the specials-shaped ring blank by 1.3%-2% and completing the secondary rotation; completing the tertiary bulging with deformation of 1.3%-2% and completing the tertiary rotation; completing the fourth bulging with deformation of 0.8%-1%; and finally obtaining the special-shaped ring workpiece. The dimension precision of the special-shaped ring workpiece can be 1%.-2%. of the corresponding dimension, and is mainly used for making rotor parts such as cylindrical casings and the like in the aerospace field.

Owner:GUIZHOU ANDA AVIATION FORGING

Process for forming special-shaped ring workpieces from bearing steel rectangular rolled ring workpieces by hot bulging

ActiveCN102500708AHigh dimensional accuracyOrganizational influenceShaping toolsAbnormal shapedMaterials science

The invention discloses a process for forming special-shaped ring workpieces from bearing steel rectangular rolled ring workpieces by hot bulging, which includes: sleeving a heated bearing steel rectangular rolled ring workpiece onto the periphery of a preheated bulging block in a bulging machine, squeezing the rolled ring part by the bulging block radially from the inner circumference surface of the rolled ring part after starting the bulging machine, completing the primary bulging after the rolled ring part is deformed by 8%-11% to form a special-shaped ring blank, completing the primary rotation by rotating the special-shaped ring blank around the center axis by 45 degrees; completing the secondary bulging by repeating the above steps to deform the specials-shaped ring blank by 1%-2% and completing the secondary rotation; completing the tertiary bulging with deformation of 0.5%-1% and completing the tertiary rotation; completing the fourth bulging with deformation of 0.5%-1%; and finally obtaining the special-shaped ring workpiece. The dimension precision of the special-shaped ring workpiece can be 1%.-2%. of the corresponding dimension, and is mainly used for making rotor parts such as cylindrical casings and the like in the aerospace field.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for rectangular titanium-alloy rolled ring workpieces

The invention discloses a thermal bulging process for rectangular titanium-alloy rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a rectangular titanium-alloy rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the rolled ring workpiece axially along the inner circumference of the rolled ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 780 DEG C to 830 DEG C, the bulging time ranges from 13s to 17s, the pressure holding time ranges from 10s to 12s, and the deflection ranges from 0.3% to 0.8%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 750 DEG C to 800 DEG C, the bulging time ranges from 13s to 17s, the pressure holding time ranges from 10s to 12s, and the deflection ranges from 0.5% to 1%. The second rotation is completed by rotating the rolled ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 700 DEG C to 770 DEG C, the bulging time ranges from 15s to 20s, the pressure holding time ranges from 12s to 14s, and the deflection ranges from 0.6% to 1%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging method for high-temperature alloy flashing welding ring piece

ActiveCN102500704AHigh dimensional accuracyReduced dimensional accuracyShaping toolsSuperalloyMarine navigation

The invention discloses a thermal bulging method for a high-temperature alloy flashing welding ring piece. The thermal bulging method comprises the following steps that: the high-temperature alloy flashing welding ring piece subjected to annealing treatment is heated and then sheathed on the periphery of a preheated bulging block in a bulging machine; the bulging machine is started to enable the bulging block to extrude the ring piece along the radial direction from the inner circumferential surface of the ring piece so as to complete the first bulging, wherein the bulging temperature is within 800 DEG C-950 DEG C, the bulging time is within 22s-28s, the pressure-holding time is within 10s-12s, and the deformation is within 0.6%-0.8%; the ring piece rotates by 45 degrees along the central axis to complete the first rotating; the second bulging is carried out according to the operation above, wherein the bulging temperature is within 770 DEG C-920 DEG C, the bulging time is within 25s-30s, the pressure-holding time is within 20s-22s, and the deformation is within 0.7%-0.9%; the second rotating is completed by rotating the ring piece again towards the direction the same as that of the first rotating; and the third bulging is carried out according to the operation process above, wherein the bulging temperature is within 740-890 DEG C, the bulging time is within 30s-40s, the temperature-holding time is within 26s-28s, and the deformation is within 0.8%-1%. The dimensional precision of the bulged ring piece can reach 0.1%-0.2% of the corresponding dimension, and the thermal bulging method is mainly applied to the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for special-shaped bearing steel rolled ring workpieces

ActiveCN102489598AHigh dimensional accuracySmall amount of reboundMarine navigationMaterials science

The invention discloses a thermal bulging process for special-shaped bearing steel rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a special-shaped bearing steel rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the rolled ring workpiece axially along the inner circumference of the ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 880 DEG C to 910 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 11s to 16s, and the deflection ranges from 0.4% to 0.8%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 850 DEG C to 890 DEG C, the bulging time ranges from 25s to 35s, the pressure holding time ranges from 18s to 20s, and the deflection ranges from 0.8% to 1%. The second rotation is completed by rotating the rolled ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 820 DEG C to 860 DEG C, the bulging time ranges from 25s to 35s, the pressure holding time ranges from 18s to 22s, and the deflection ranges from 0.8% to 1.2%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for thermally bulging aluminium alloy rectangular ring rolled piece

The invention discloses a method for thermally bulging an aluminium alloy rectangular ring rolled piece. The method comprises the following steps: sleeving a hot rolled aluminium alloy rectangular ring rolled piece on the peripheries of preheated bulging blocks in a bulging machine and starting the bulging machine to ensure the bulging blocks to radially extrude the ring rolled piece from the inner circumferential surface of the ring rolled piece to complete first bulging, wherein the bulging temperature is 330-400 DEG C, the bulging time is 15-20 seconds, the dwell time is 12-14 seconds and the deformation amount is 0.5-0.9%; then ensuring the ring rolled piece to rotate 45 degrees along a central axis to complete first rotation; later, carrying out second bulging according to the above operations, wherein the bulging temperature is 290-350 DEG, the bulging time is 18-30 seconds, the dwell time is 13-16 seconds and the deformation amount is 0.6-1%; rotating the ring rolled piece again in the first rotation direction to complete second rotation; and then carrying out third bulging according to the above operations, wherein the bulging temperature is 250-320 DEG C, the bulging time is 25-35 seconds, the dwell time is 20-23 seconds and the deformation amount is 0.6-1.1%. The dimensional accuracy of the bulged ring rolled piece can be 1-2 per mill of the corresponding dimension. The method is mainly used in the fields such as aerospace.

Owner:GUIZHOU ANDA AVIATION FORGING

Hot bulging method for rectangular bearing steel rolled ring

The invention discloses a hot bulging method for a rectangular bearing steel rolled ring; the hot bulging method comprises the following steps of: sleeving a rectangular bearing steel hot-rolled ring at the periphery of a preheated bulging block in a bulging machine, starting the bulging machine so that the bulging block extrudes the rolled ring along the radial direction on the surface of the inner circumference of the rolled ring to complete primary bulging, wherein the bulging temperature is 860 DEG C to 900 DEG C, the bulging time is 20s-30s, the pressure holding time is 12s-15s, and the deformation amount is 0.4%-0.7%; then leading the rolled ring to rotate by 45 degrees along a central axis to complete primary rotation; afterwards, carrying out secondary bulging according to the operation, wherein the bulging temperature is 830 DEG C to 870 DEG C, the bulging time is 25s-35s, the pressure holding time is 18s-22s, and the deformation amount is 0.6%-1%; rotating the rolled ring again to complete secondary rotation according to the primary rotation direction; and carrying out third bulging according to the operation, wherein the bulging temperature is 800 DEG C to 840 DEG C, the bulging time is 25-40s, the pressure holding time is 16s-20s, and the deformation amount is 0.6%-1.1%. The dimensional accuracy of the bulged rolled ring can reach 0.1%-0.2% of the corresponding dimension; and the bulged rolled ring is mainly applied to the fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Hot bulge forming method for aluminum-alloy flash buttwelding ring components

ActiveCN102489593AHigh dimensional accuracyReduced dimensional accuracyMarine navigationMaterials science

The invention discloses a hot bulge forming method for aluminum-alloy flash buttwelding ring components, which comprises the following steps of: after heating an aluminum-alloy flash buttwelding ring component subjected to annealing treatment, sleeving the aluminum-alloy flash buttwelding ring component on the periphery of a bulge forming block (subjected to preheating) in a bulge forming machine, and starting the bulge forming machine, so that the bulge forming block extrudes the ring component along the radial direction from the interior circumferential surface of the ring component so as to complete the first bulge forming, wherein the bulge forming temperature is 420-470 DEG C, the bulge forming time is 12-15s, the dwell time is 7-8s, and the deflection is 0.08-0.09%; rotating the ring component at an angle of 45 degrees along a central axis so as to complete the first rotation; then, performing the second bulge forming according to the operations above, wherein the bulge forming temperature is 390-440 DEG C, the bulge forming time is 20-35s, the dwell time is 15-16s, and the deflection is 0.7-0.8%; rotating the ring component again along the direction of the first rotation so as to complete the second rotation; and performing the third bulge forming according to the operations above, wherein the bulge forming temperature is 360-410 DEG C, the bulge forming time is 20-25s, the dwell time is 20-22s, and the deflection is 0.9-1%. The size precision of a ring component subjected to bulge forming can reach 0.1-0.2% of a corresponding size, and the method is mainly used in the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging method of stainless-steel irregular ring rolled piece

ActiveCN102513456AHigh dimensional accuracySmall amount of reboundShaping toolsAbnormal shapedMaterials science

The invention discloses a thermal bulging method of a stainless-steel irregular ring rolled piece, and the method comprises the following steps of: sleeving the hot-rolled stainless-steel irregular ring rolled piece on the periphery of a pre-heated bulging block in a bulging machine; starting the bulging machine so that the ring rolled piece is squeezed from the inner circumference surface of the ring rolled piece in a radial direction, thus completing primary bulging, wherein the bulging temperature is 910-970 DEG C, the bulging time is 18-30 seconds, the pressure holding time is 8-9 seconds and the deformation amount is 0.9-1.1%; rotating the ring rolled piece around a center axis for 45 degrees, thus completing primary rotation; carrying out secondary bulging according to the previous steps, wherein the bulging temperature is 870-930 DEG C, the bulging time is 18-30 seconds, the pressure holding time is 12-14 seconds and the deformation amount is 0.8-1%; rotating the ring rolled piece according to a primary rotating direction again, thus completely secondary rotation; and carrying out tertiary bulging according to the previous steps, wherein the bulging temperature is 820-890 DEG C, the bulging time is 28-40 seconds, the pressure holding time is 18-20 seconds and the deformation amount is 0.6-0.9%. The size precision of the bulged ring rolled piece can reach 0.1-0.2% of the corresponding size. The bulged ring rolled piece formed by using the method disclosed by the invention is mainly used for fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Hot bulging method for forming rectangular titanium alloy rolled ring into special-shaped ring

ActiveCN102489596BHigh dimensional accuracyPrecise control of bulge sizeTitanium alloyMaterials science

The invention discloses a hot bulging method for forming a rectangular titanium alloy rolled ring into a special-shaped ring; the hot bulging method comprises the following steps of: sleeving a heated rectangular titanium alloy rolled ring at the periphery of a preheated bulging block of a bulging machine, starting the bulging machine so that the bulging block extrudes the rolled ring along the radial direction on the surface of the inner circumference of the rolled ring till the deformation amount of the rolled ring is 10%-12%, and the rolled ring is formed into a special-shaped ring blank, thereby completing primary bulging, and then leading the special-shaped ring blank to rotate by 45 degrees along a central axis to complete primary rotation; and afterwards, according to the operation, carrying out secondary bulging with 0.9%-1.5% of deformation amount and secondary rotation, third bulging with 0.9%-1.5% of deformation amount and third rotation, and fourth bulging with 0.5%-1% of deformation amount on the special-shaped ring blank, thereby obtaining the special-shaped ring. The dimensional accuracy of the special-shaped ring can reach 0.1%-0.2% of the corresponding dimension; and the special-shaped ring is mainly applied to the fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for flash-welded stainless steel ring workpieces

The invention discloses a thermal bulging process for flash-welded stainless steel ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a flash-welded stainless steel ring workpiece which is annealed is sleeved on the periphery of a preheated bulging block in a bulging machine after being heated, and the bulging block squeezes the ring workpiece axially along the inner circumference of the ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 950 DEG C to 1040 DEG C, the bulging time ranges from 22s to 28s, the pressure holding time ranges from 18s to 20s, and the bulging deflection ranges from 0.12% to 0.15%. The primary rotation is completed by rotating the ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 920 DEG C to 1010 DEG C, the bulging time ranges from 20s to 25s, the pressure holding time ranges from 16s to 18s, and the deflection ranges from 0.08% to 0.09%. The second rotation is completed by rotating the ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 890 DEG C to 980 DEG C, the bulging time ranges from 25s to 30s, the pressure holding time ranges from 21s to 23s, and the deflection ranges from 0.09% to 1%. The dimensional precision of the ring workpiece can be 1%. to 2%. of the corresponding precision after the ring workpiece is bulged, and the ring workpiece is mainly used for the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Hot bulging method for rectangular bearing steel rolled ring

The invention discloses a hot bulging method for a rectangular bearing steel rolled ring; the hot bulging method comprises the following steps of: sleeving a rectangular bearing steel hot-rolled ring at the periphery of a preheated bulging block in a bulging machine, starting the bulging machine so that the bulging block extrudes the rolled ring along the radial direction on the surface of the inner circumference of the rolled ring to complete primary bulging, wherein the bulging temperature is 860 DEG C to 900 DEG C, the bulging time is 20s-30s, the pressure holding time is 12s-15s, and the deformation amount is 0.4%-0.7%; then leading the rolled ring to rotate by 45 degrees along a central axis to complete primary rotation; afterwards, carrying out secondary bulging according to the operation, wherein the bulging temperature is 830 DEG C to 870 DEG C, the bulging time is 25s-35s, the pressure holding time is 18s-22s, and the deformation amount is 0.6%-1%; rotating the rolled ring again to complete secondary rotation according to the primary rotation direction; and carrying out third bulging according to the operation, wherein the bulging temperature is 800 DEG C to 840 DEG C, the bulging time is 25-40s, the pressure holding time is 16s-20s, and the deformation amount is 0.6%-1.1%. The dimensional accuracy of the bulged rolled ring can reach 0.1%-0.2% of the corresponding dimension; and the bulged rolled ring is mainly applied to the fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for thermally bulging high-temperature alloy rectangular ring rolled member

ActiveCN102500705BHigh dimensional accuracySmall amount of reboundShaping toolsSuperalloyHot Temperature

The invention discloses a method for thermally bulging a high-temperature alloy rectangular ring rolled member. The method comprises the following steps of: sleeving a hot rolled high-temperature alloy rectangular ring rolled member on the periphery of a pre-heated bulged block in a bulging machine, and starting the bulging machine to enable the bulged block to extrude the ring rolled member from the inner circumferential surface of the ring rolled member in a radial direction, so that bulging for the first time is completed, wherein the bulging temperature is 800-850 DEG C, the bulging time is 20-30 s, the pressure maintaining time is 9-10 s, and the deformation is 0.6-0.8%; rotating the ring rolled member along a central axis for 45 DEG, so that rotating for the first time is completed; then, carrying out bulging for the second time according to the above operations, wherein the bulging temperature is 770-820 DEG C, the bulging time is 20-30 s, the pressure maintaining time is 17-18 s, and the deformation is 0.7-0.9%; rotating the ring rolled member again according to the first rotary direction, so that rotating for the second time is completed; and carrying out bulging for the third time according to the above operations, wherein the bulging temperature is 740-790 DEG C, the bulging time is 30-40 s, the pressure maintaining time is 25-28 s, and the deformation is 0.8-1%. The size precision of the bulged ring rolled member can be up to 0.001-0.002 of that of corresponding sizes. The ring rolled member disclosed by the invention is mainly applied to the fields, such as aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for special-shaped bearing steel rolled ring workpieces

The invention discloses a thermal bulging process for special-shaped bearing steel rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a special-shaped bearing steel rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the rolled ring workpiece axially along the inner circumference of the ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 880 DEG C to 910 DEG C, the bulging time ranges from 20s to 30s, the pressure holding time ranges from 11s to 16s, and the deflection ranges from 0.4% to 0.8%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 850 DEG C to 890 DEG C, the bulging time ranges from 25s to 35s, the pressure holding time ranges from 18s to 20s, and the deflection ranges from 0.8% to 1%. The second rotation is completed by rotating the rolled ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 820 DEG C to 860 DEG C, the bulging time ranges from 25s to 35s, the pressure holding time ranges from 18s to 22s, and the deflection ranges from 0.8% to 1.2%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging method for high-temperature alloy flashing welding ring piece

ActiveCN102500704BHigh dimensional accuracyReduced dimensional accuracyShaping toolsSuperalloyMarine navigation

Owner:GUIZHOU ANDA AVIATION FORGING

Method for thermally bulging aluminium alloy rectangular ring rolled piece

The invention discloses a method for thermally bulging an aluminium alloy rectangular ring rolled piece. The method comprises the following steps: sleeving a hot rolled aluminium alloy rectangular ring rolled piece on the peripheries of preheated bulging blocks in a bulging machine and starting the bulging machine to ensure the bulging blocks to radially extrude the ring rolled piece from the inner circumferential surface of the ring rolled piece to complete first bulging, wherein the bulging temperature is 330-400 DEG C, the bulging time is 15-20 seconds, the dwell time is 12-14 seconds and the deformation amount is 0.5-0.9%; then ensuring the ring rolled piece to rotate 45 degrees along a central axis to complete first rotation; later, carrying out second bulging according to the above operations, wherein the bulging temperature is 290-350 DEG, the bulging time is 18-30 seconds, the dwell time is 13-16 seconds and the deformation amount is 0.6-1%; rotating the ring rolled piece again in the first rotation direction to complete second rotation; and then carrying out third bulging according to the above operations, wherein the bulging temperature is 250-320 DEG C, the bulging time is 25-35 seconds, the dwell time is 20-23 seconds and the deformation amount is 0.6-1.1%. The dimensional accuracy of the bulged ring rolled piece can be 1-2 per mill of the corresponding dimension. The method is mainly used in the fields such as aerospace.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging method for aluminum alloy special-shaped ring-rolled piece

The invention discloses a thermal bulging method for an aluminum alloy special-shaped ring-rolled piece. The method comprises the following steps of: assembling a hot-rolled aluminum alloy special-shaped ring-rolled piece on the periphery of a preheated bulging block in a bulging machine, and starting the bulging machine to make the bulging block extrude the ring-rolling piece radially from the inner circumferential surface of the ring-rolled piece to finish first bulging, wherein the bulging temperature is 350-410 DEG C, the bulging time is 15-20 seconds, the dwelling time is 11-14 seconds, and the deflection is 0.4-0.8 percent; rotating the ring-rolled piece by 45 degrees along a central axis to finish a first rotation; performing second bulging according to the operation above, wherein the bulging temperature is 300-370 DEG C, the bulging time is 20-30 seconds, the dwelling time is 16-18 seconds, and the deflection is 0.5-1.1 percent; rotating the ring-rolled piece once according to a first rotating direction to finish second rotation; and performing third bulging according to the operation above, wherein the bulging temperature is 270-330 DEG C, the bulging time is 30-40 seconds, the dwelling time is 25-28 seconds, and the deflection is 0.5-1.1 percent. The size accuracy of the bulged ring-rolled piece can be up to 1-2 per thousand of a corresponding size; and the aluminum alloy special-shaped ring-rolled piece is manly applied to the fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for forming irregular ring piece by utilizing stainless-steel rectangular ring rolled piece through thermal bulging

ActiveCN102513457BHigh dimensional accuracyPrecise control of bulge sizeShaping toolsMaterials scienceAerospace

The invention discloses a method for forming an irregular ring piece by utilizing a stainless-steel rectangular ring rolled piece through thermal bulging, comprising the following steps of: sleeving the heated stainless-steel rectangular ring rolled piece on the periphery of a pre-heated bulging blockin a bulging machine; starting the bulging machine so that the ring rolled piece is squeezed by the bulging block in a radial direction along the inner circumference surface of the ring rolled piece and becomes the irregular ring blank after being deformed for 11-13%, thus completing primary bulging; rotating the irregular ring blank for 45 degrees along an center axis, thus completing primary rotation; carrying out secondary bulging with the deformation amount of 1.8-2% and secondary rotation on the irregular ring blank according to the previous steps; carrying out tertiary bulging with the deformation amount of 1.4-1.6% and tertiary rotation on the irregular ring blank according to the previous steps; and carrying out quartus bulging with the deformation amount of 1.2-1.4% and quartus rotation on the irregular ring blank according to the previous steps, so as to obtain the irregular ring piece. The size precision of the irregular ring piece can reach 0.1-0.2% of the corresponding size. The irregular ring piece formed by using the method disclosed by the invention is mainly used for fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for rectangular titanium-alloy rolled ring workpieces

The invention discloses a thermal bulging process for rectangular titanium-alloy rolled ring workpieces, which includes steps of primary bulging; primary rotation; secondary rotation; secondary bulging and tertiary bulging. In the primary bulging, a rectangular titanium-alloy rolled ring workpiece which is treated by thermal rolling is sleeved on the periphery of a preheated bulging block in a bulging machine, and the bulging block squeezes the rolled ring workpiece axially along the inner circumference of the rolled ring workpiece after the bulging machine is started so that the primary bulging is completed, wherein the bulging temperature ranges from 780 DEG C to 830 DEG C, the bulging time ranges from 13s to 17s, the pressure holding time ranges from 10s to 12s, and the deflection ranges from 0.3% to 0.8%. The primary rotation is completed by rotating the rolled ring workpiece along the center axis by 45 degrees. The secondary bulging is completed by processes of the primary bulging, wherein the bulging temperature ranges from 750 DEG C to 800 DEG C, the bulging time ranges from 13s to 17s, the pressure holding time ranges from 10s to 12s, and the deflection ranges from 0.5% to 1%. The second rotation is completed by rotating the rolled ring workpiece again along the direction the same with that of the primary rotation. The tertiary bulging is completed by the processes of the primary bulging again, wherein the bulging temperature ranges from 700 DEG C to 770 DEG C, the bulging time ranges from 15s to 20s, the pressure holding time ranges from 12s to 14s, and the deflection ranges from 0.6% to 1%. The dimensional precision of the rolled ring workpiece can be 1%. to 2%. of the corresponding precision after the rolled ring workpiece is bulged, and the rolled ring workpiece is mainly used for the fields of space navigation and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging process for rectangular stainless steel rolled ring workpieces

ActiveCN102489616BHigh dimensional accuracySmall amount of reboundShaping toolsMaterials scienceHot rolled

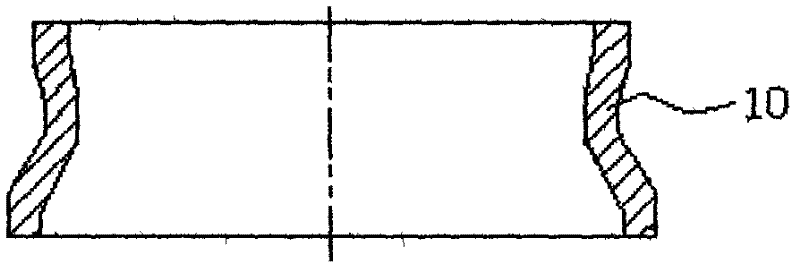

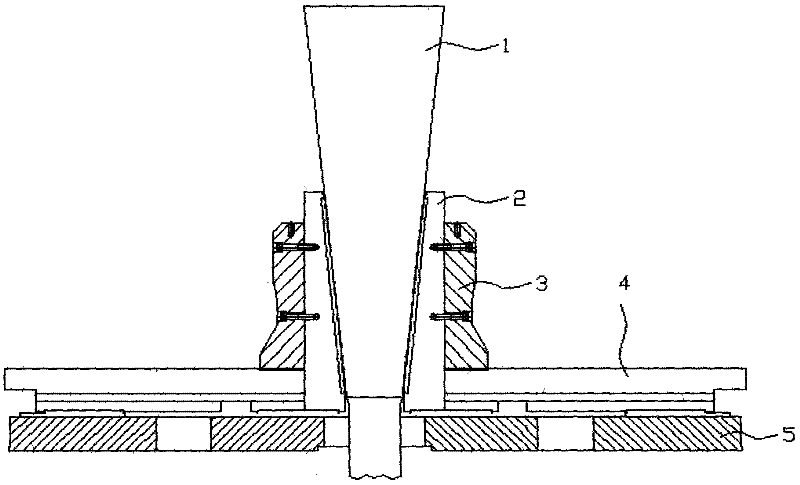

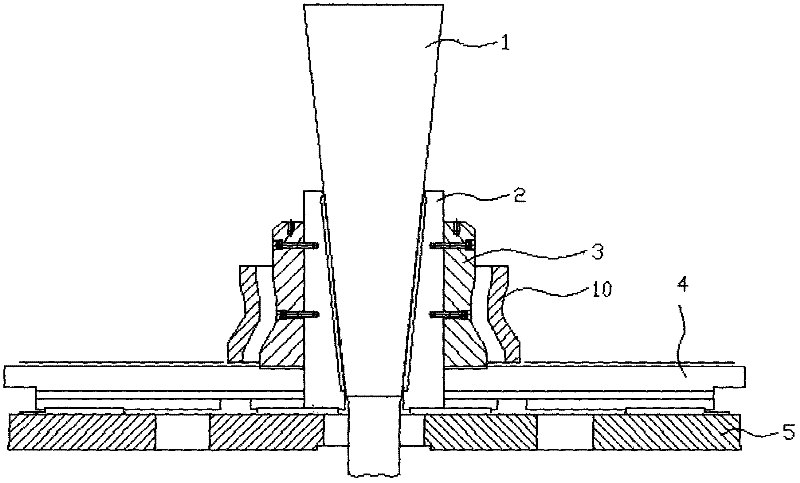

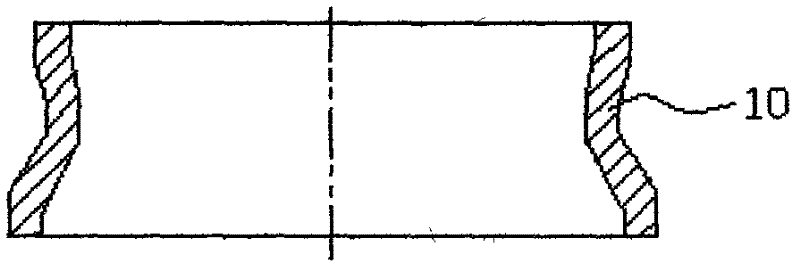

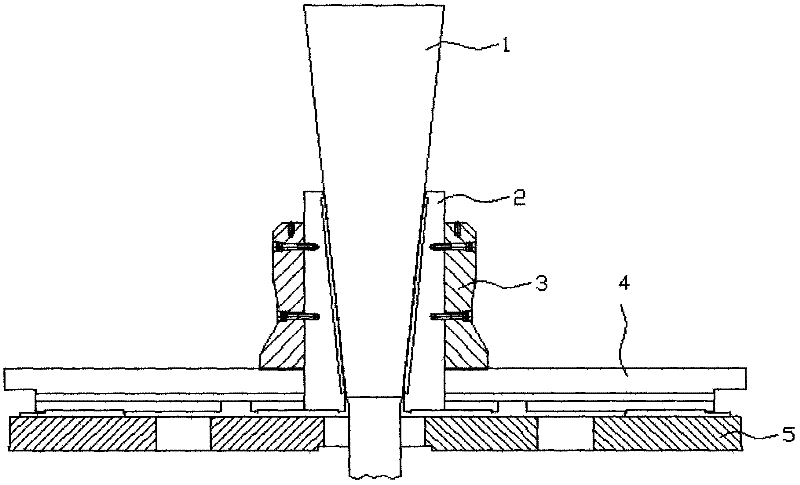

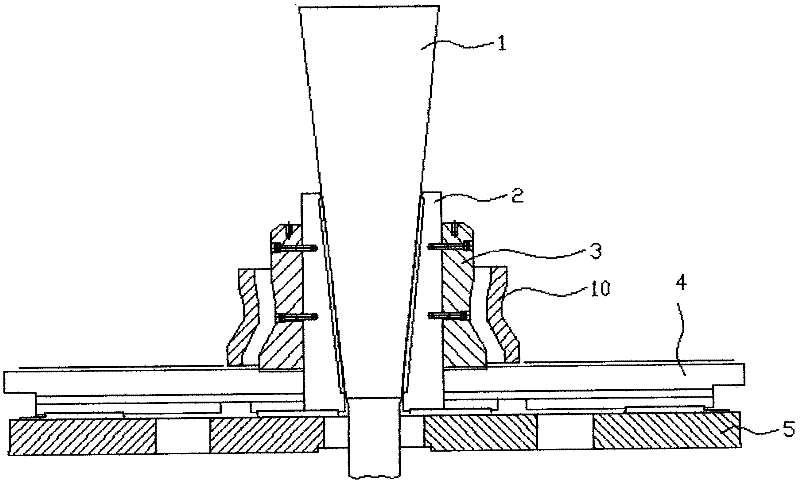

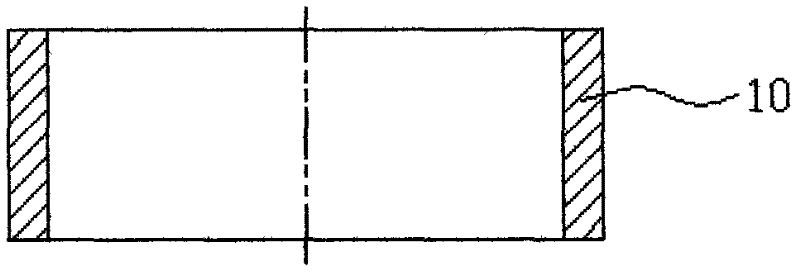

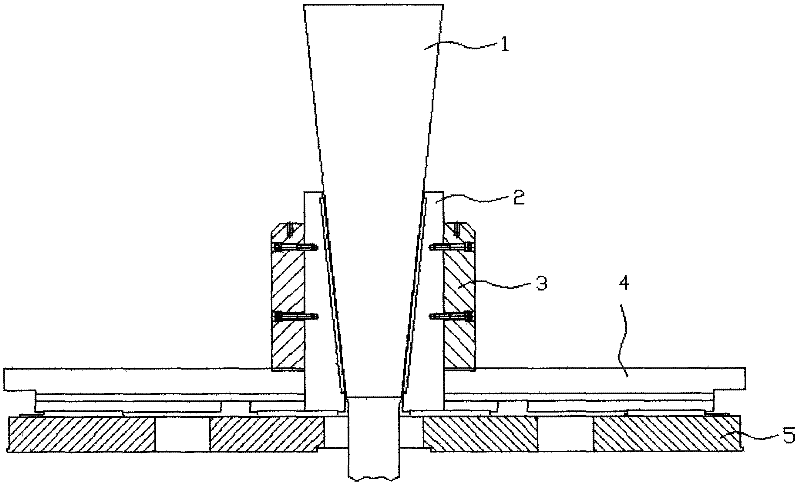

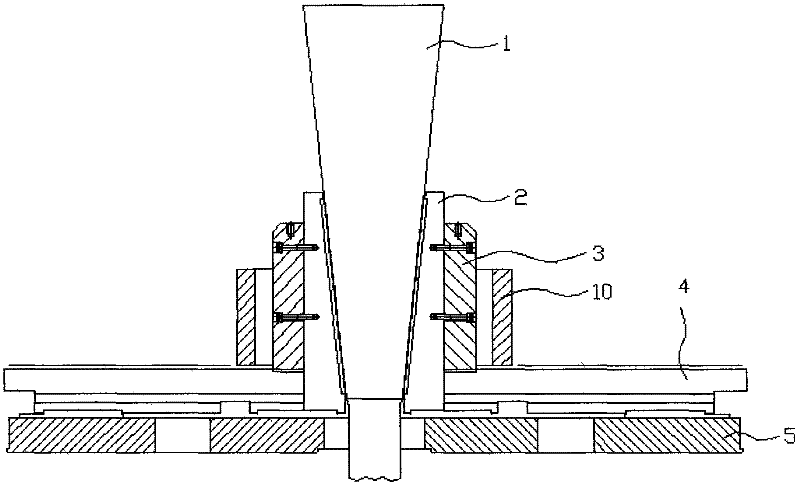

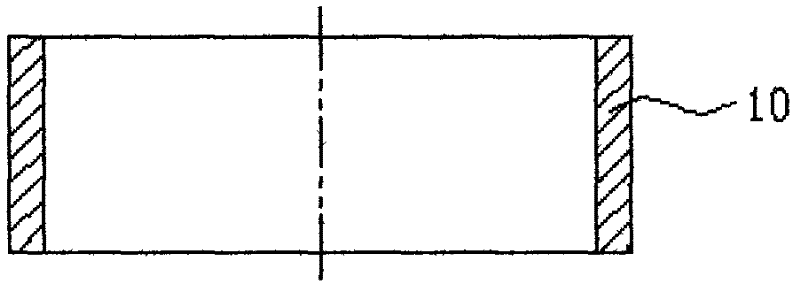

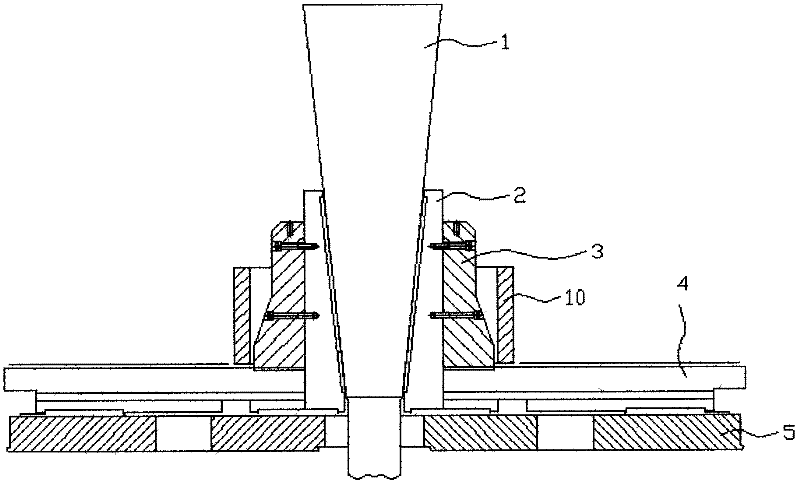

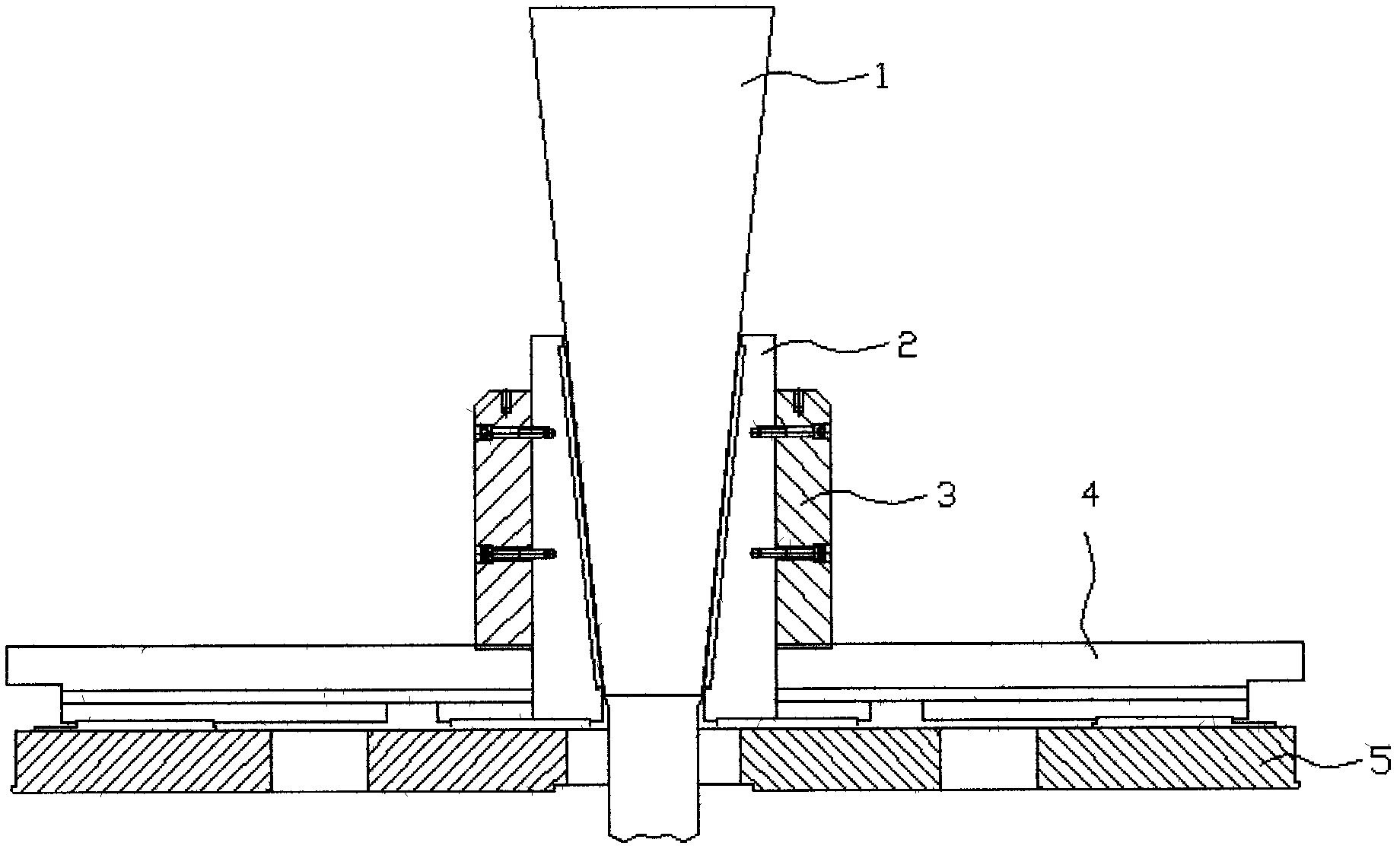

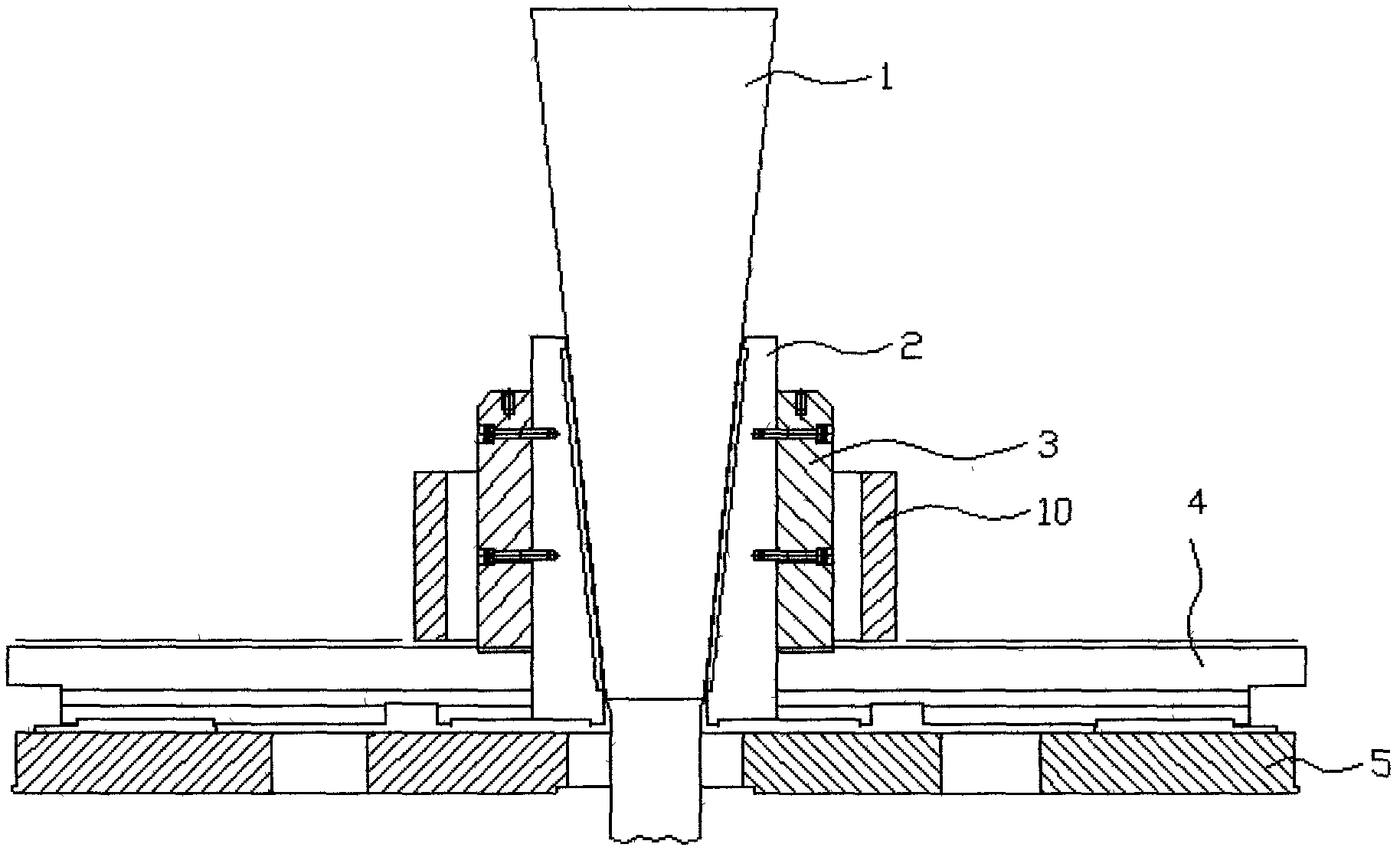

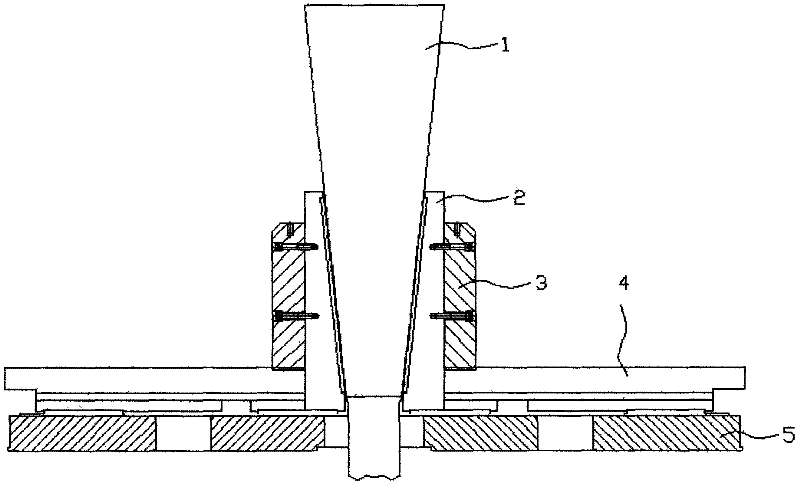

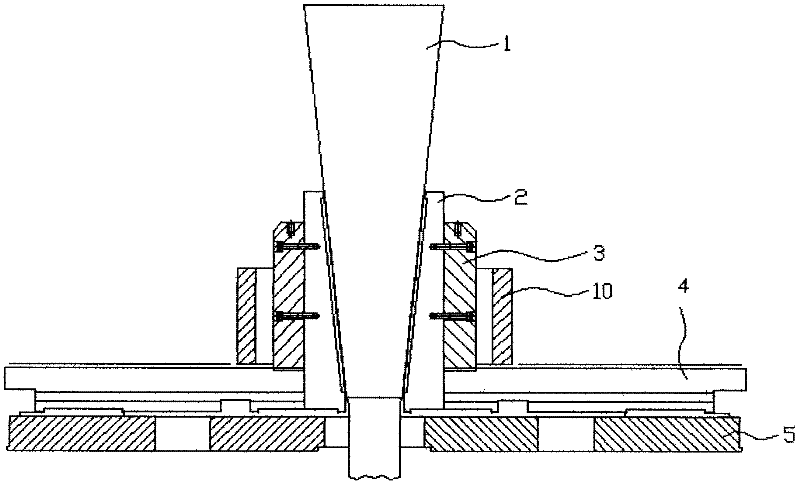

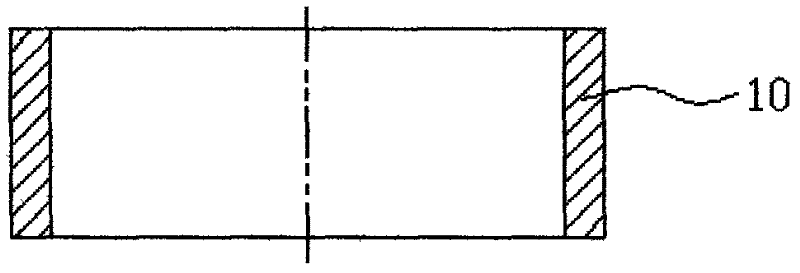

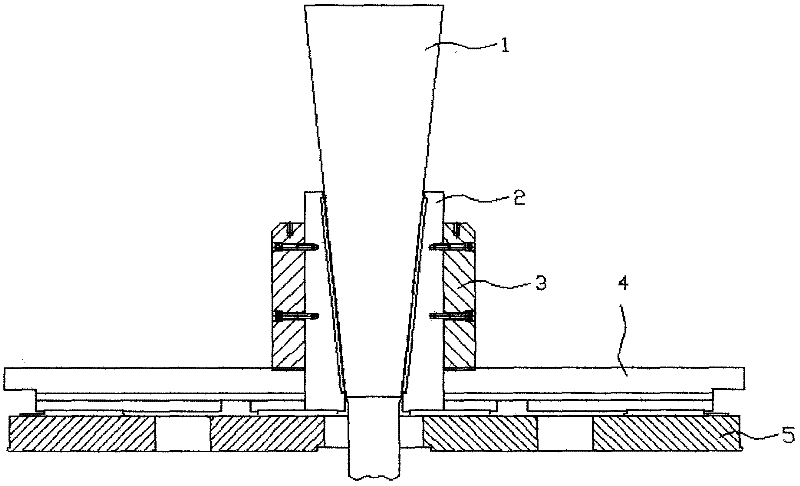

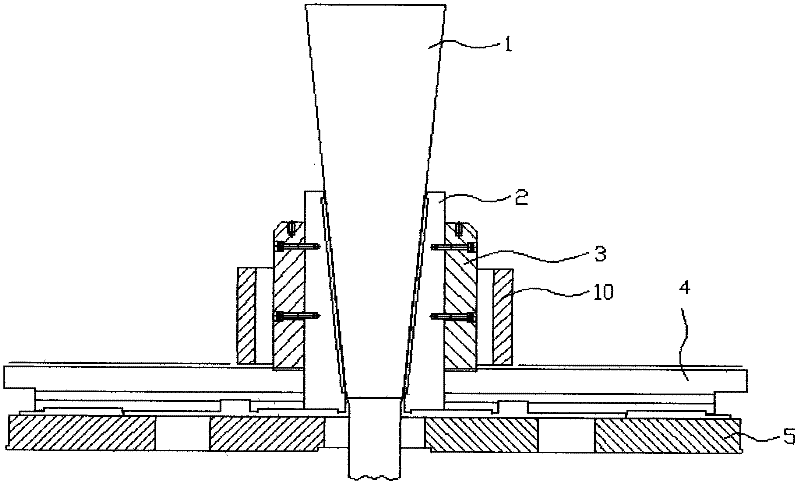

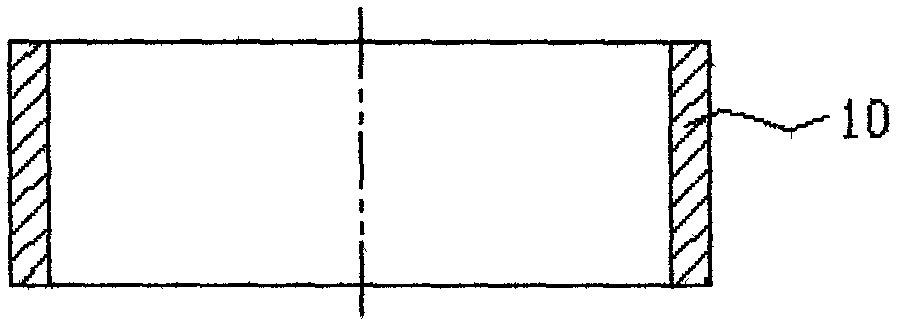

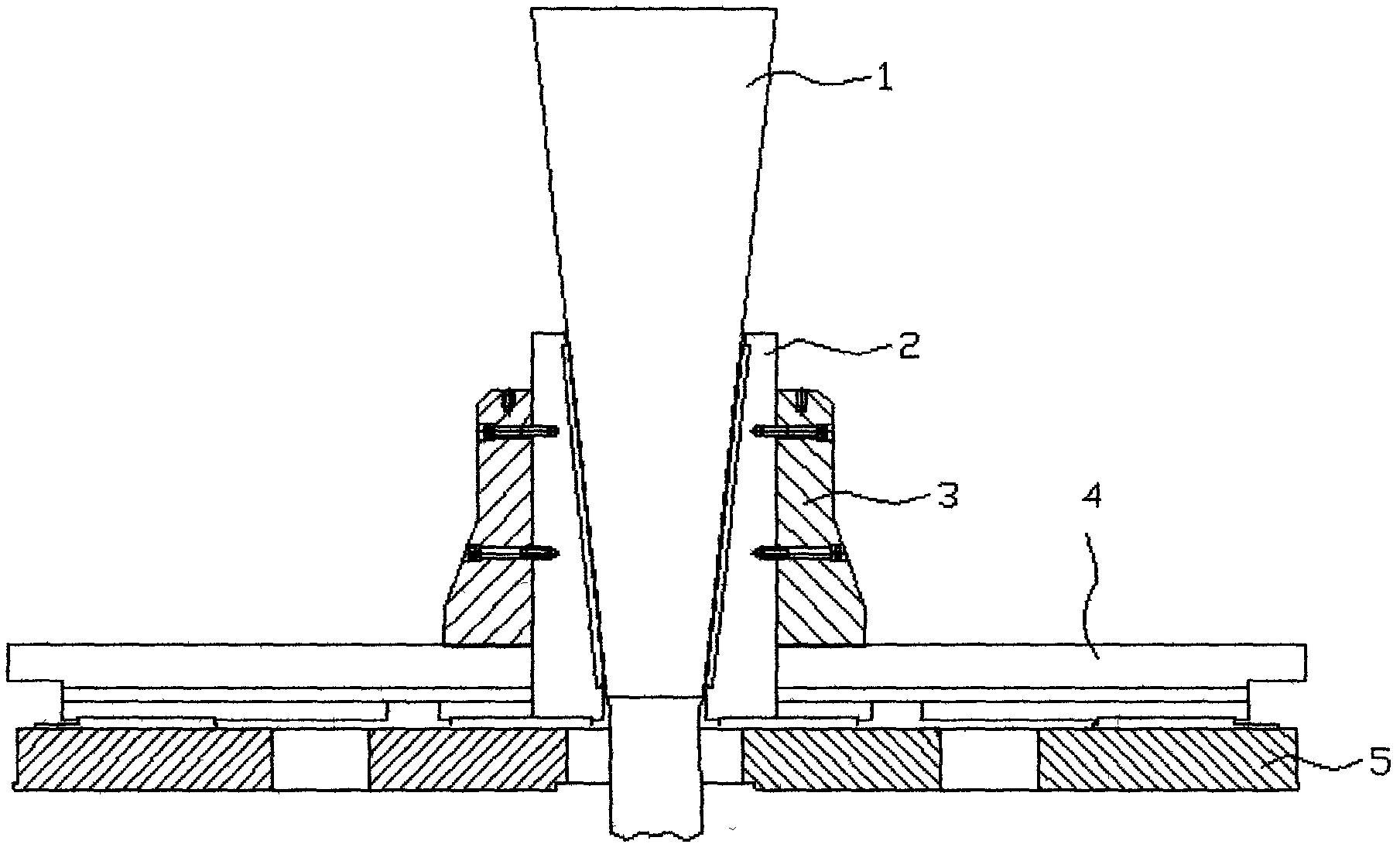

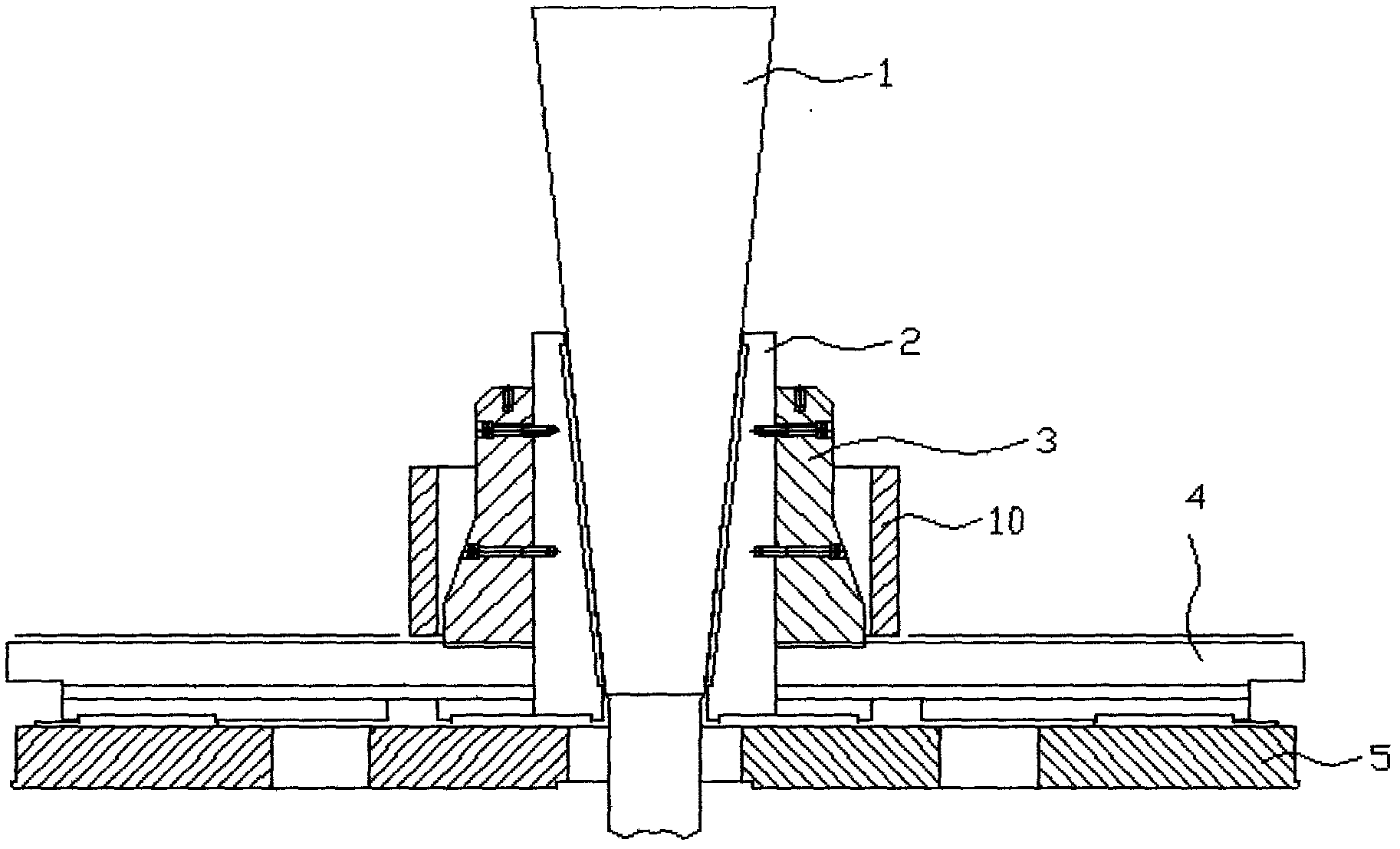

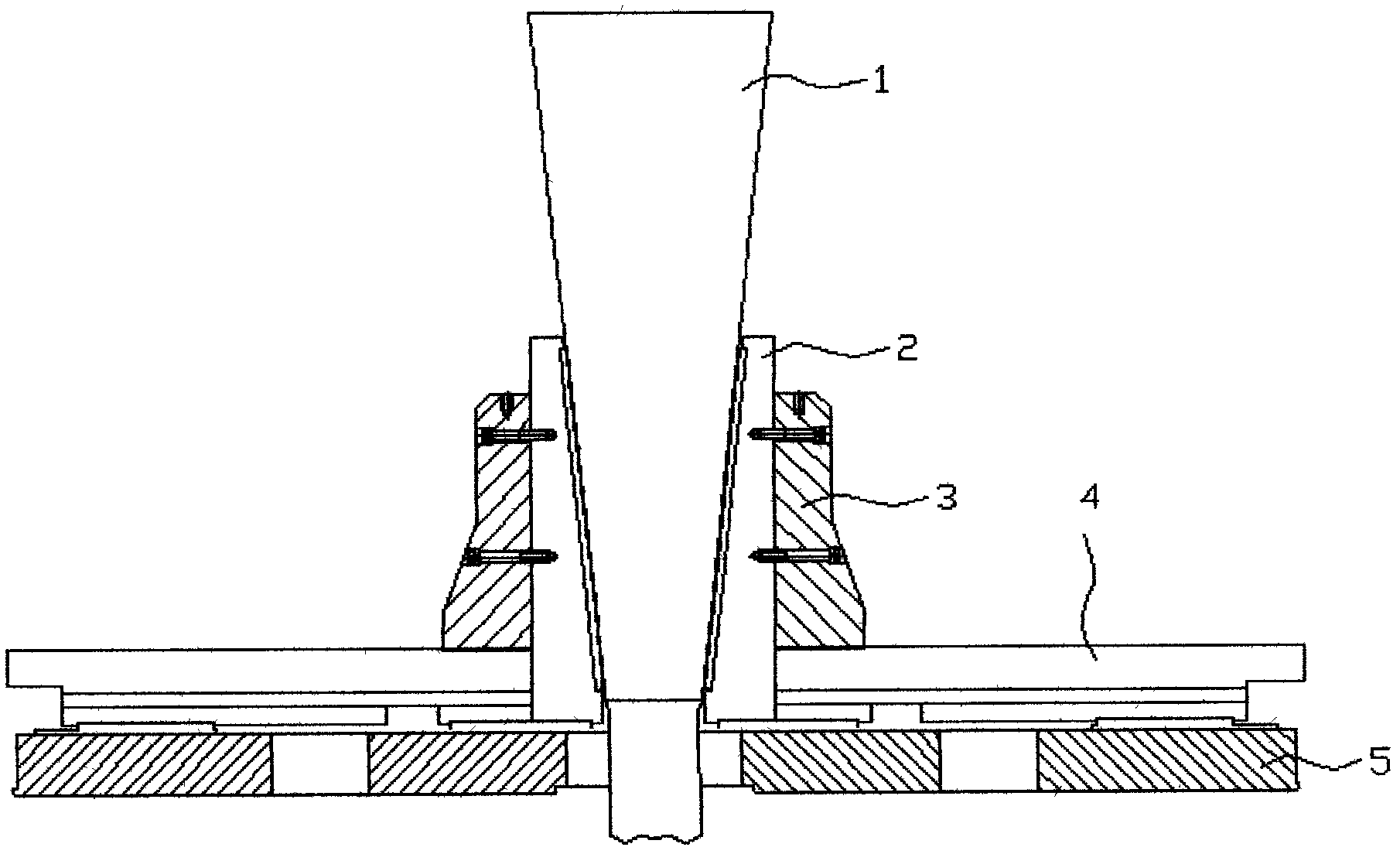

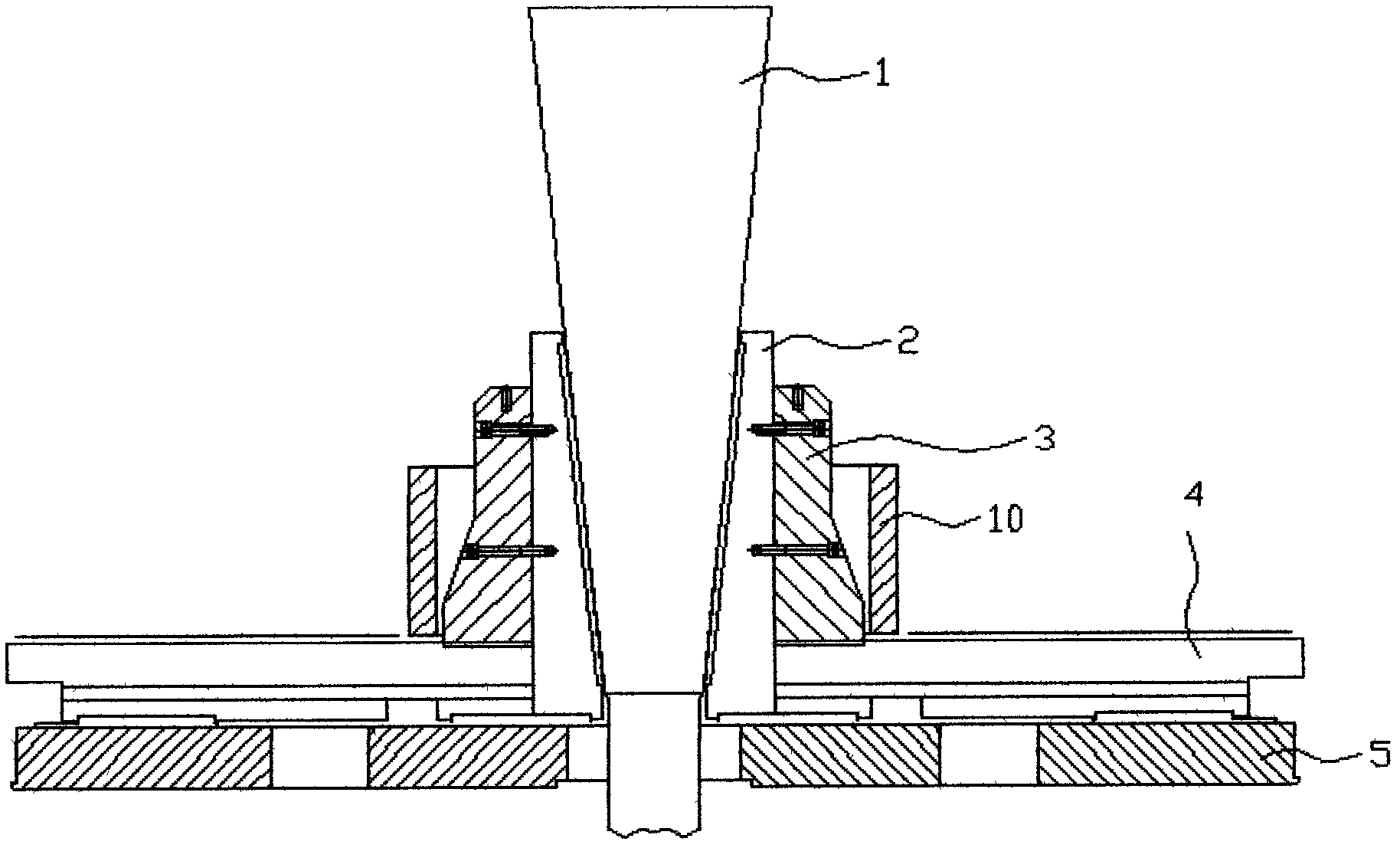

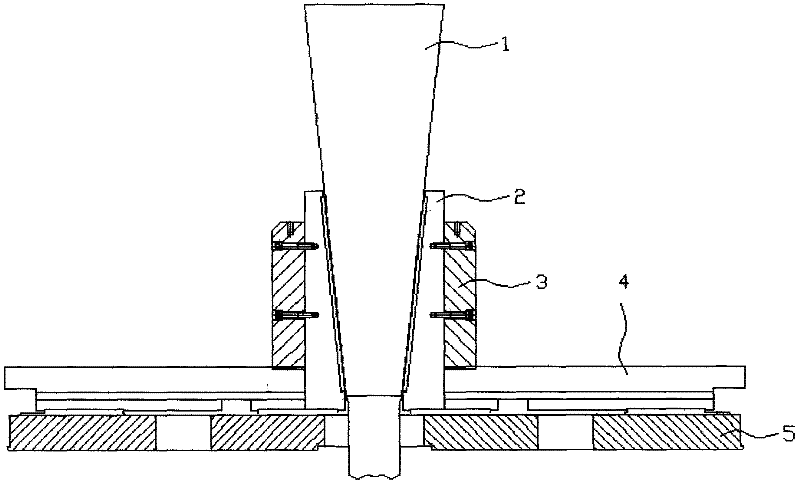

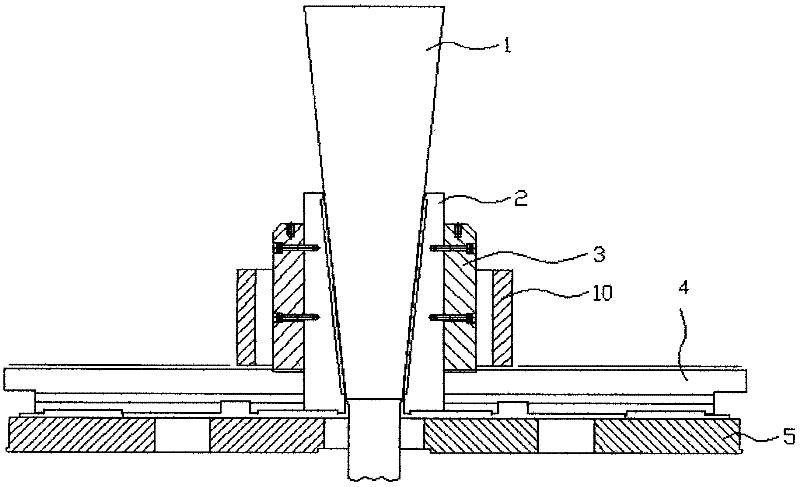

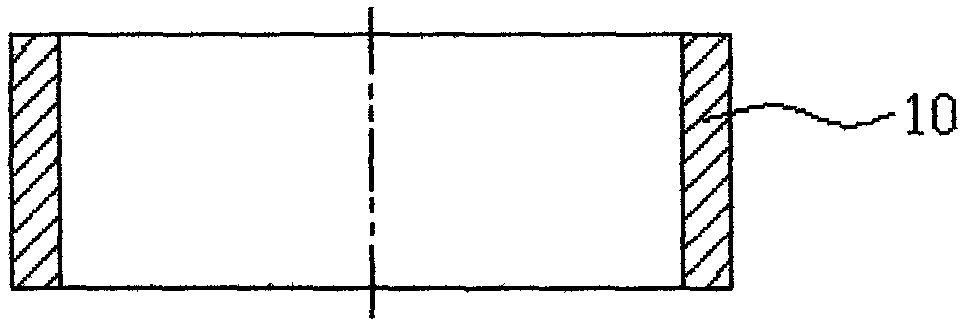

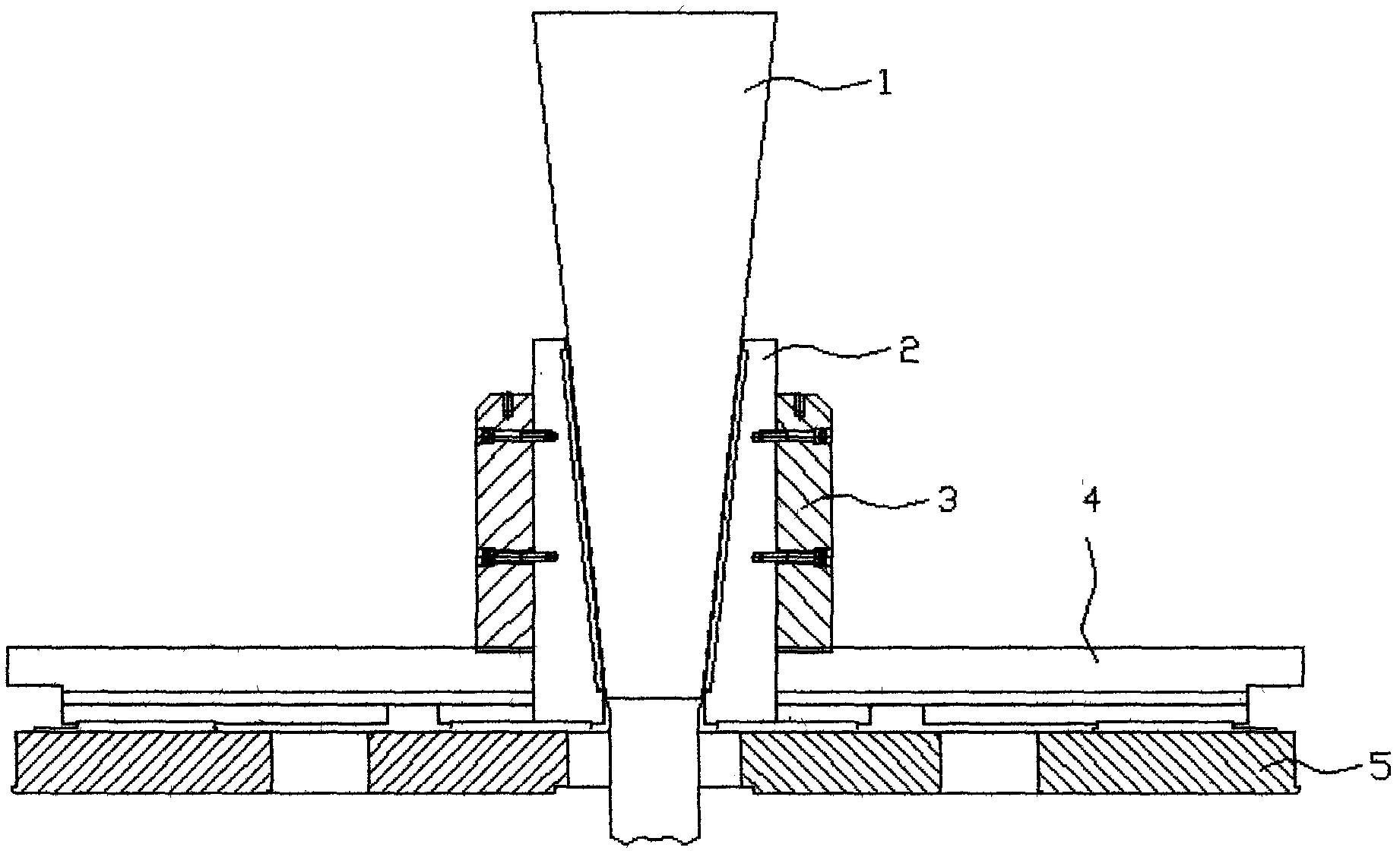

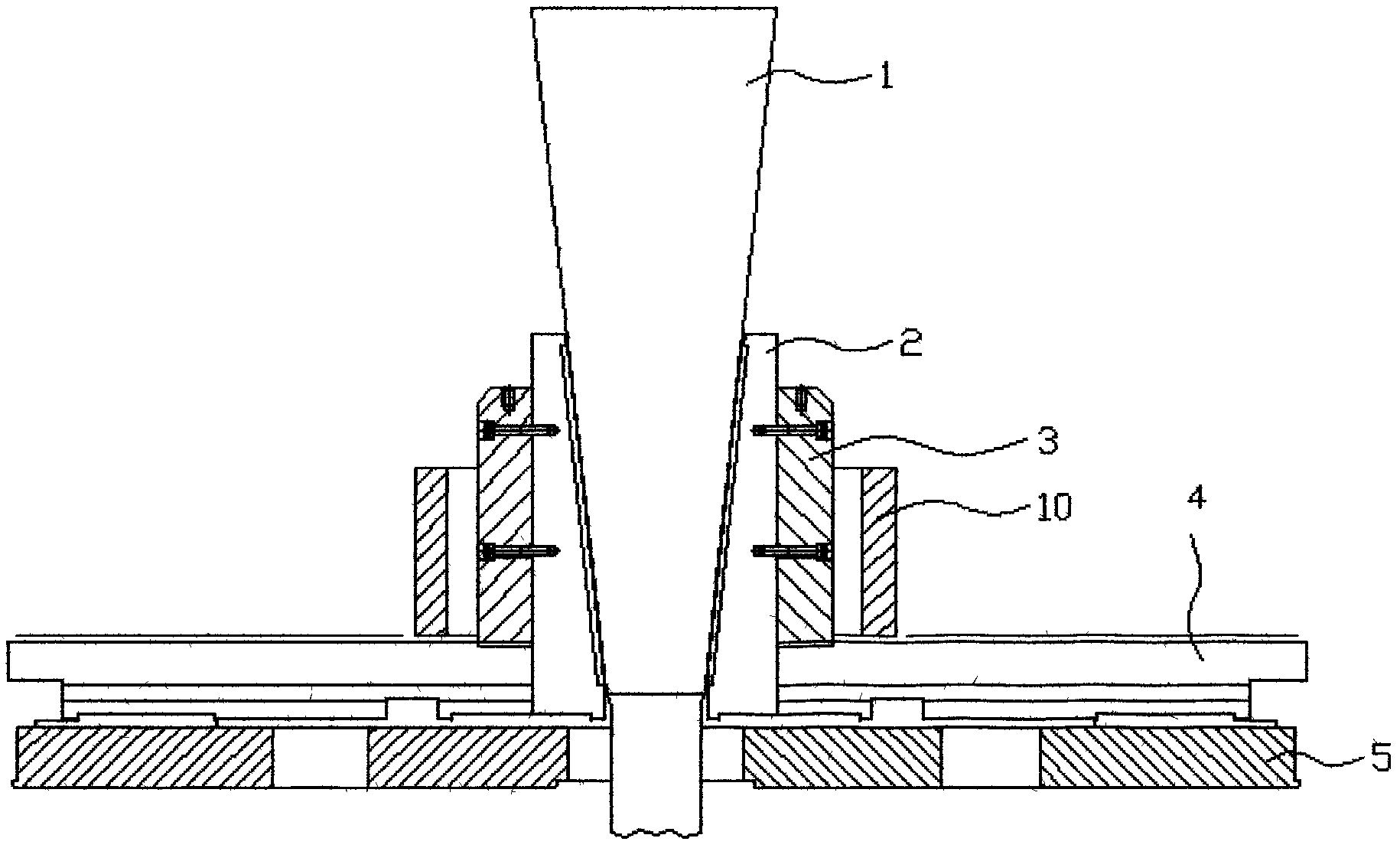

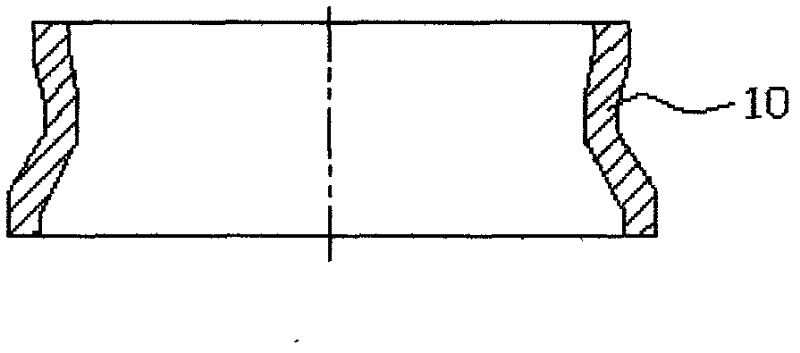

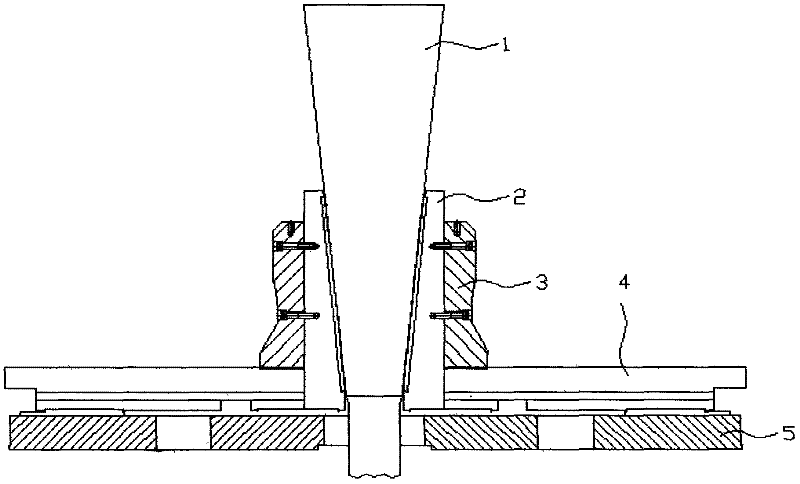

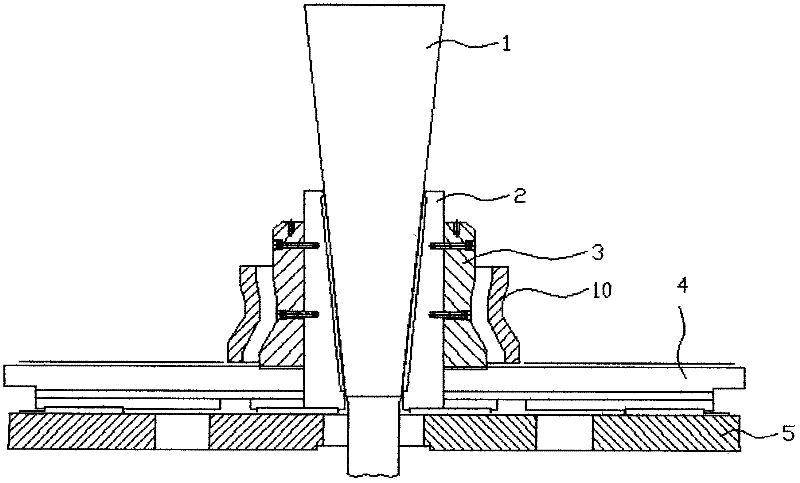

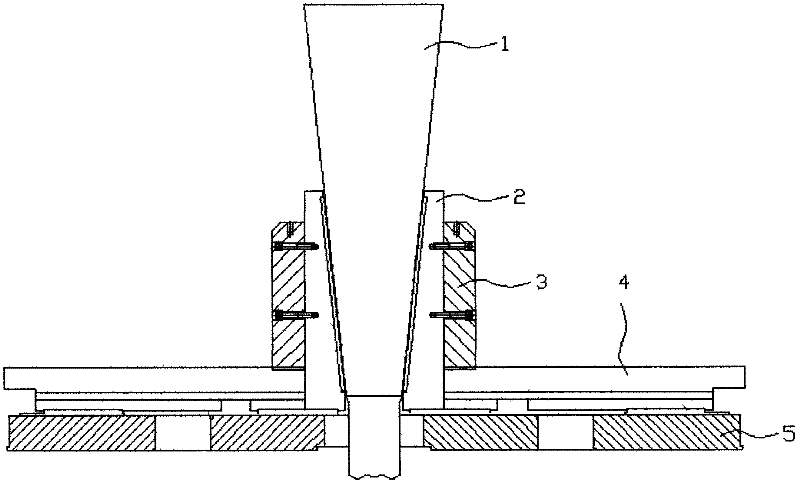

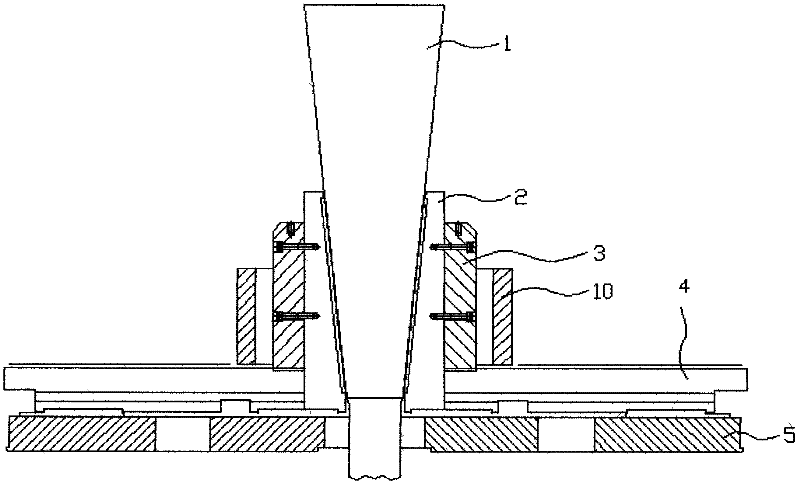

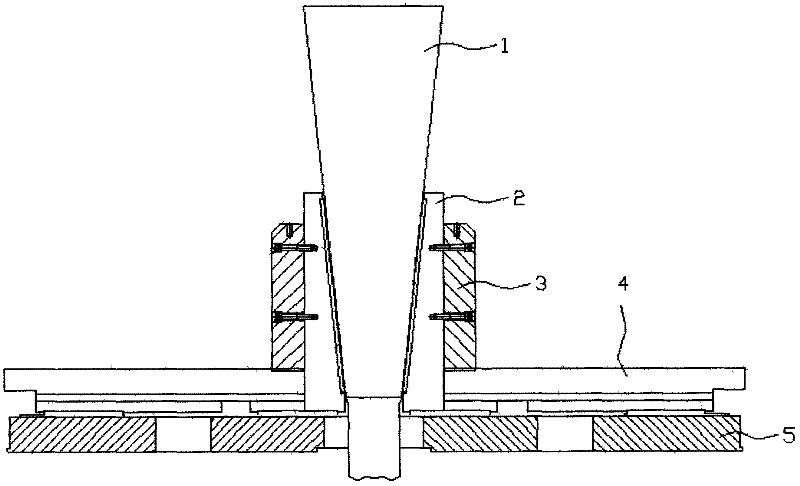

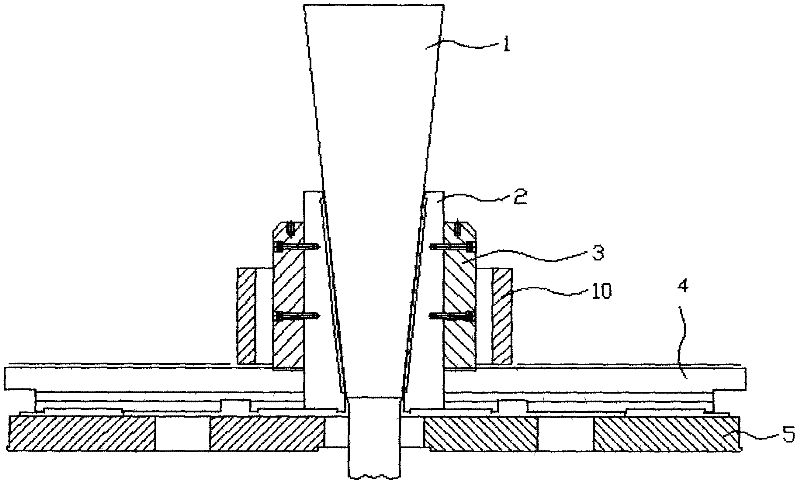

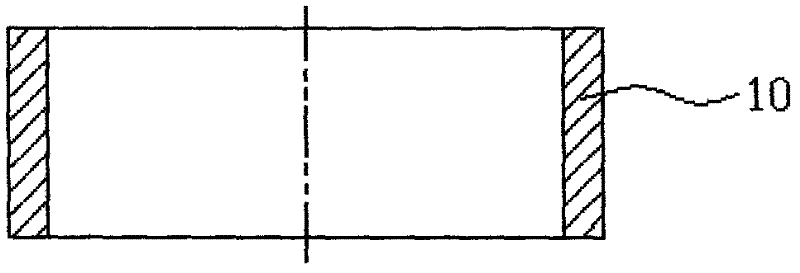

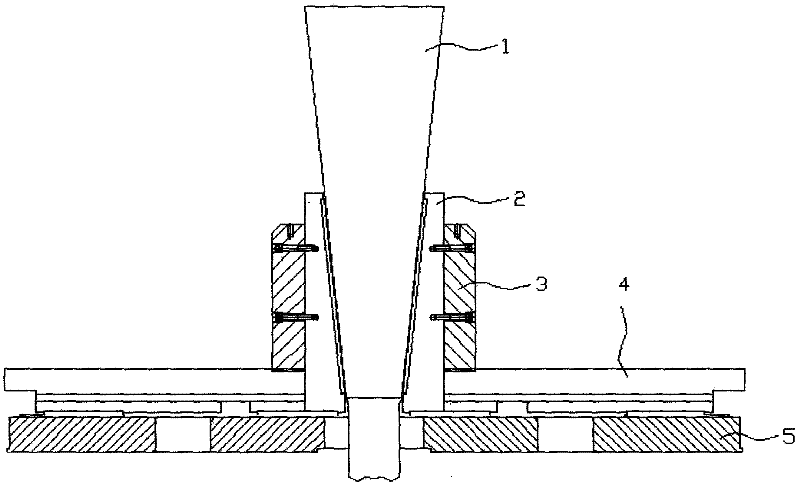

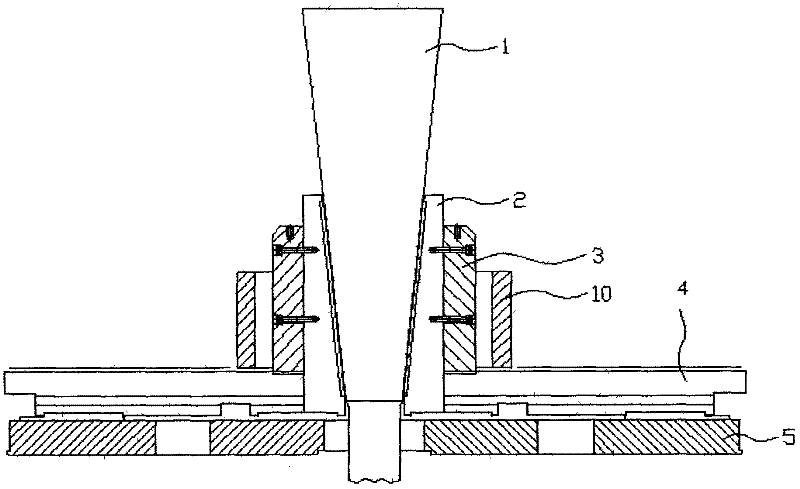

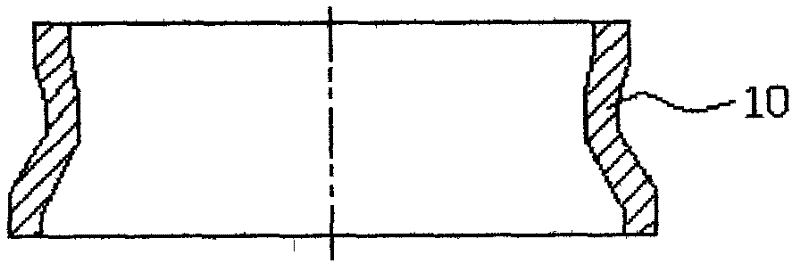

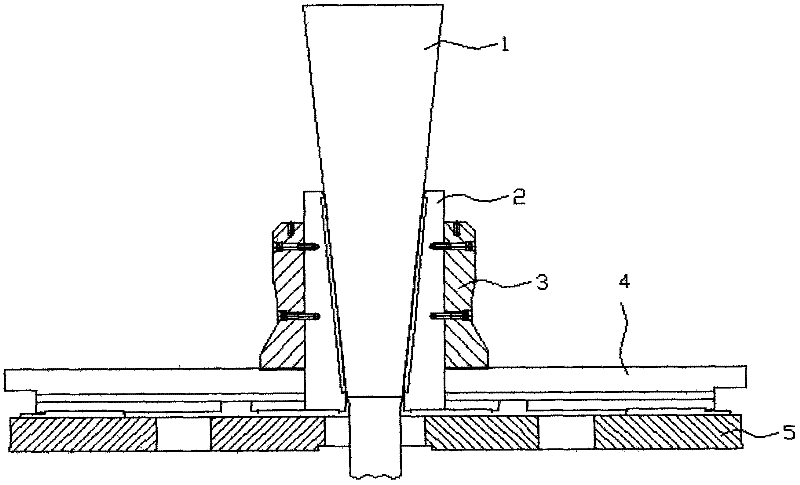

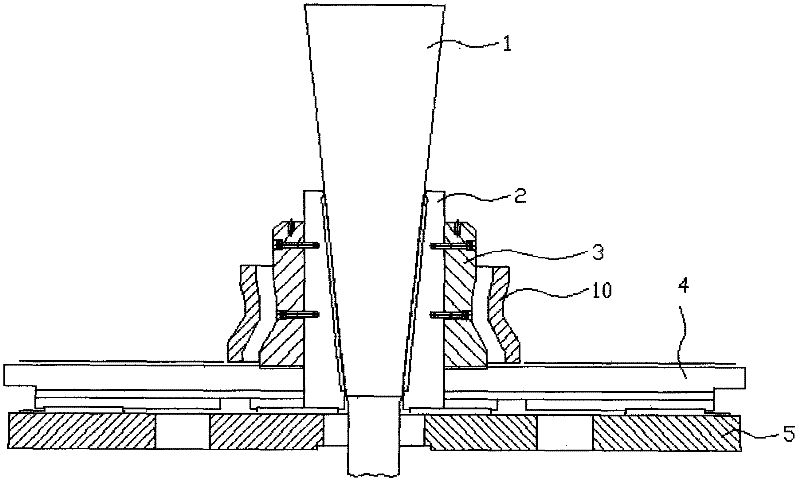

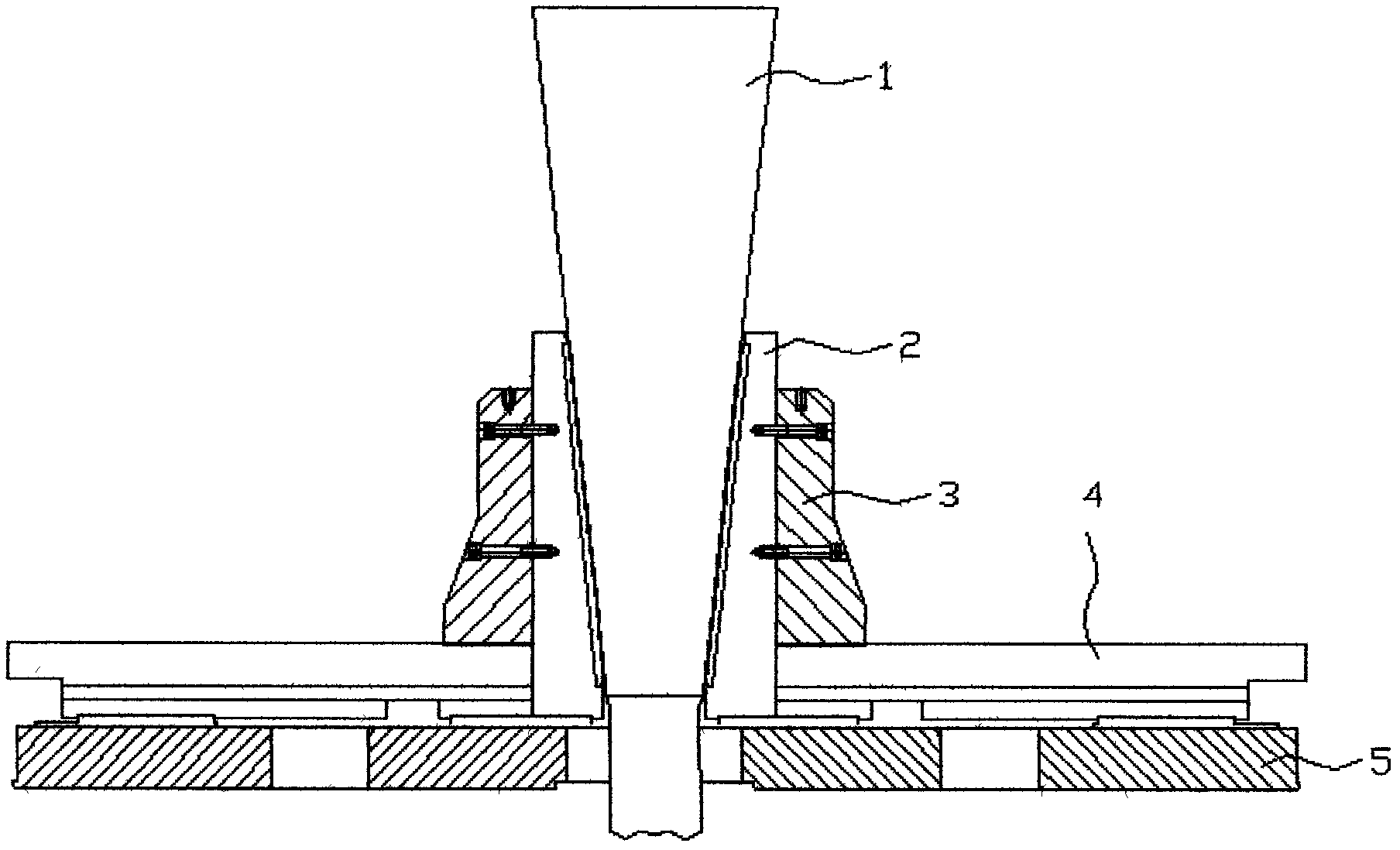

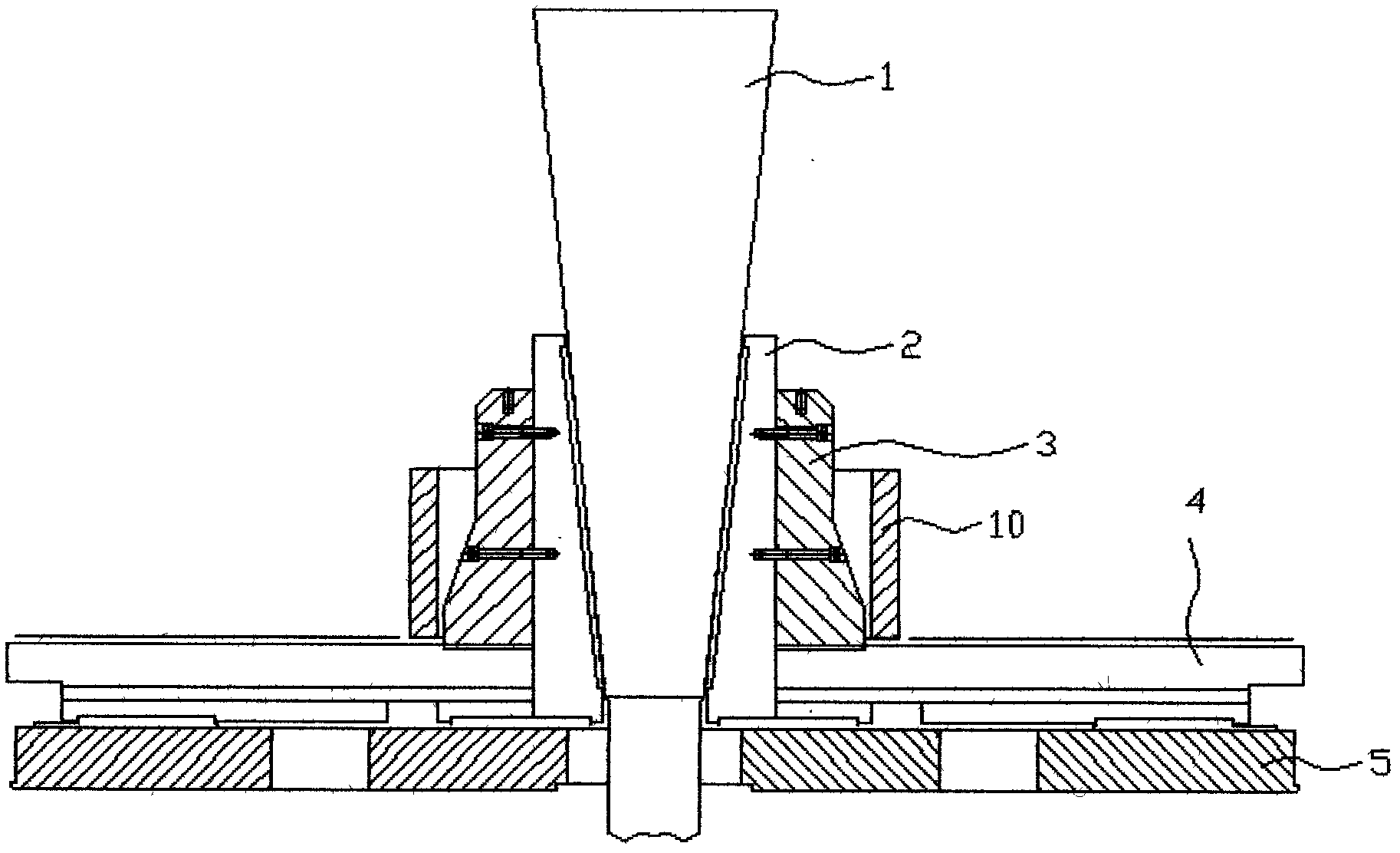

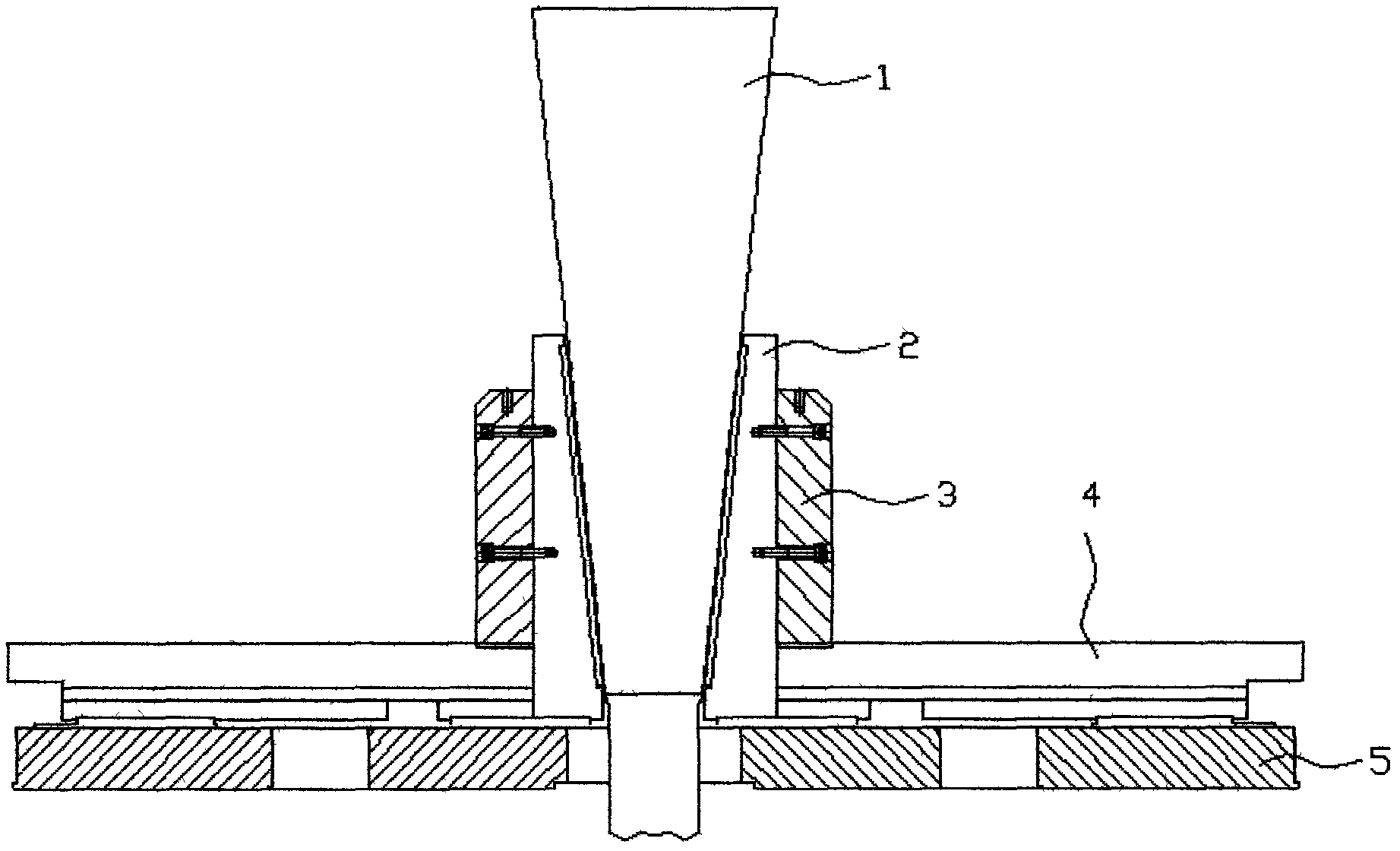

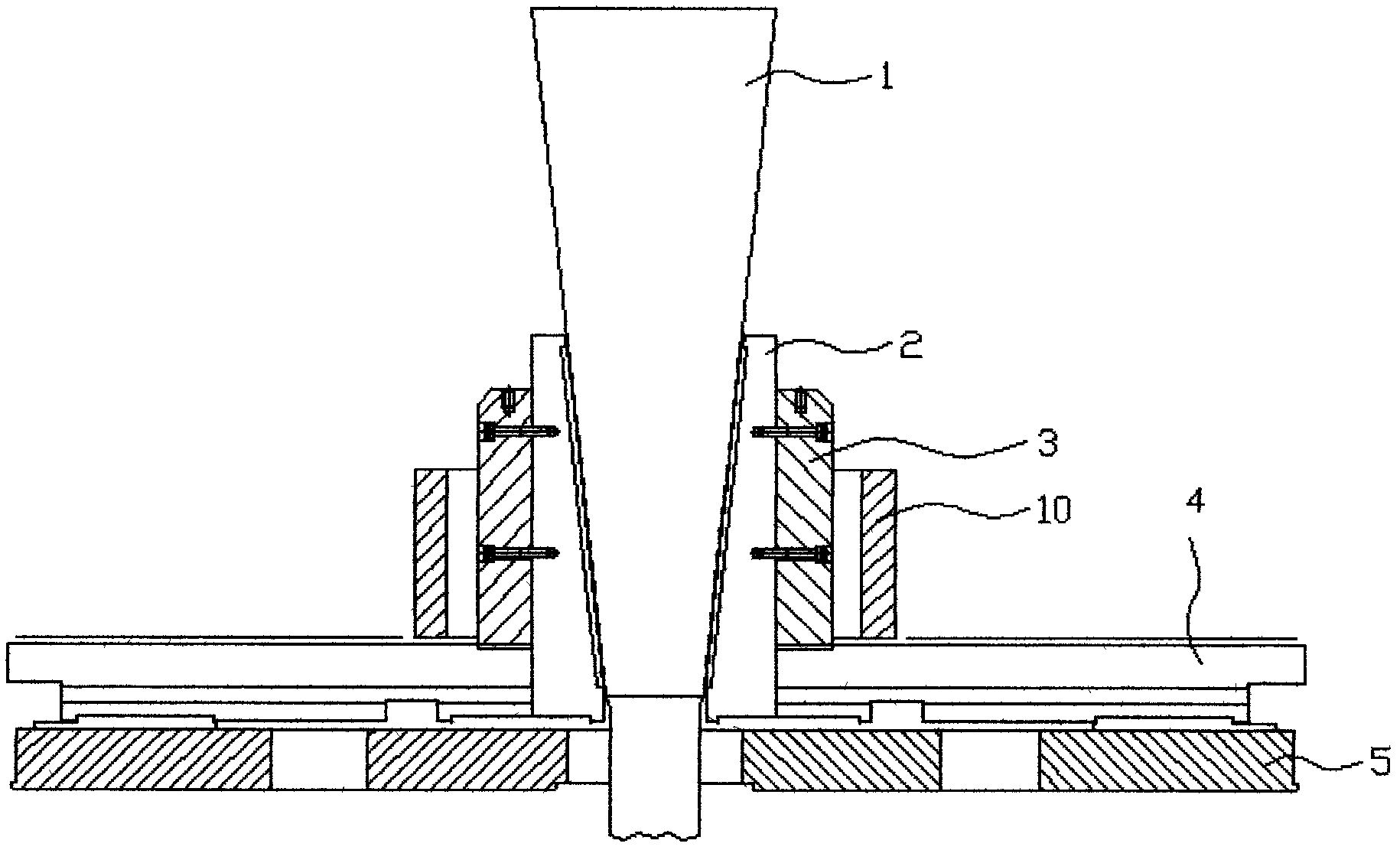

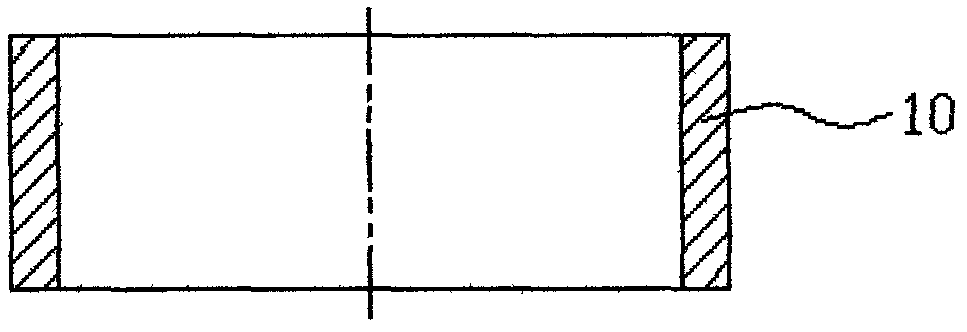

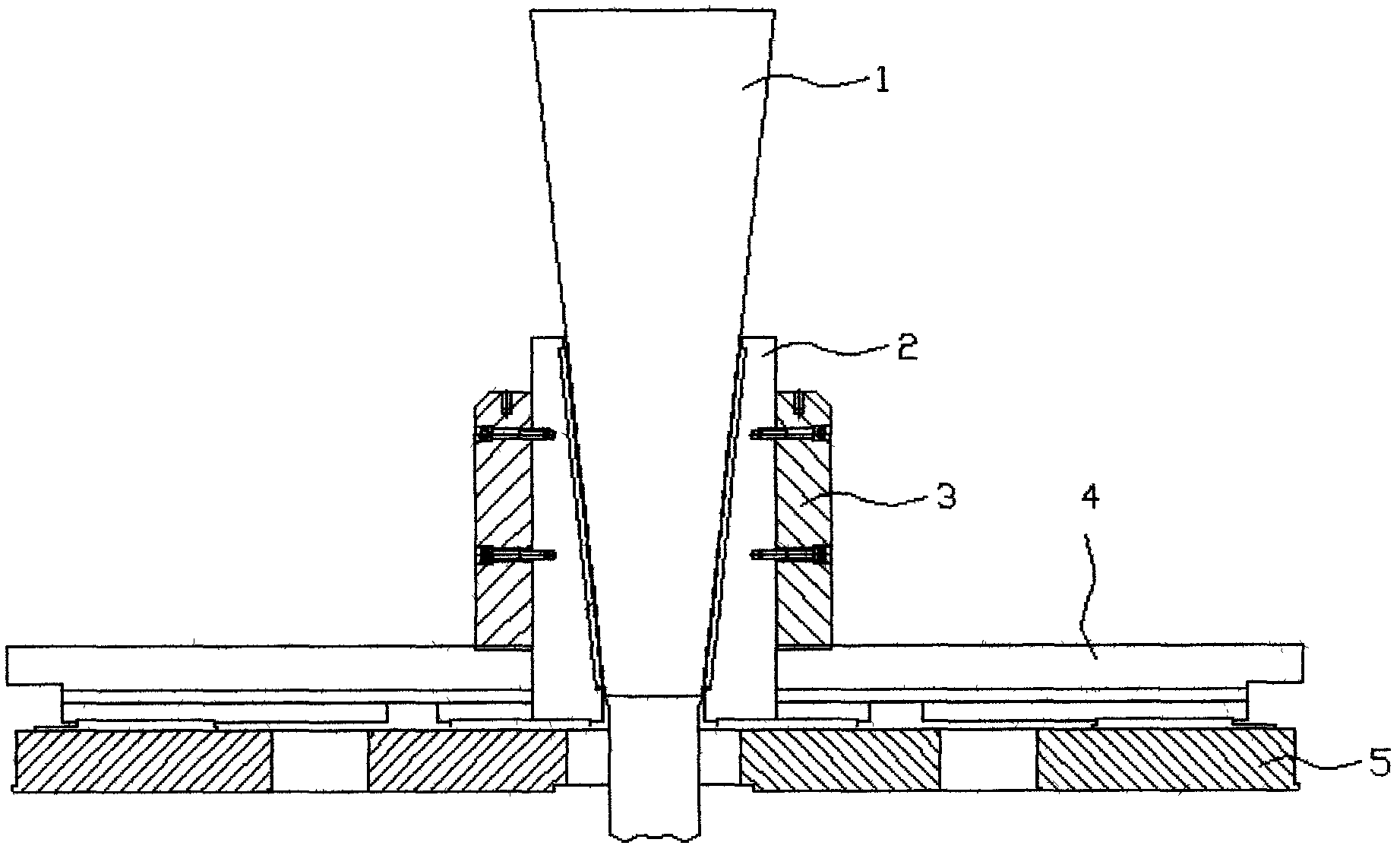

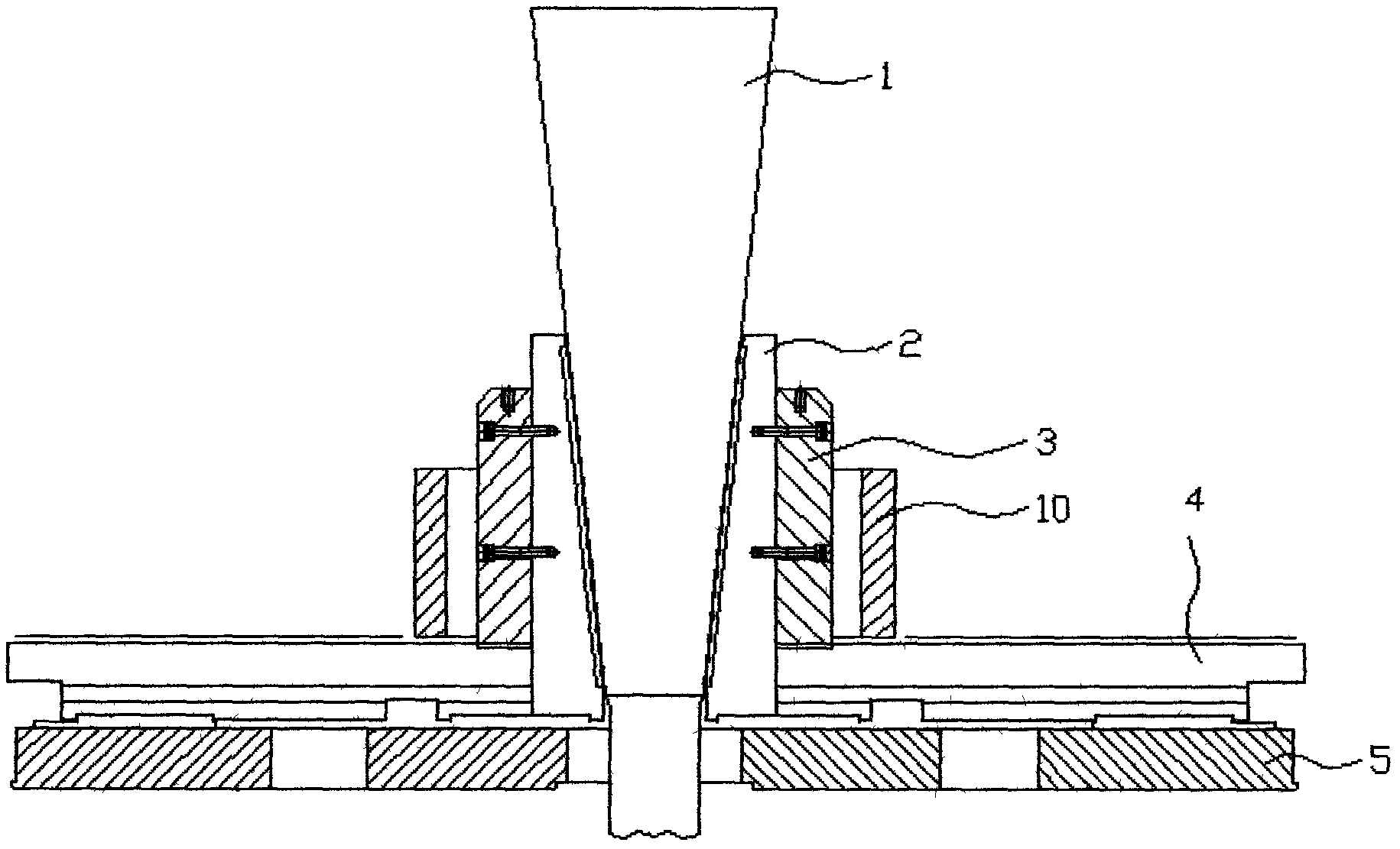

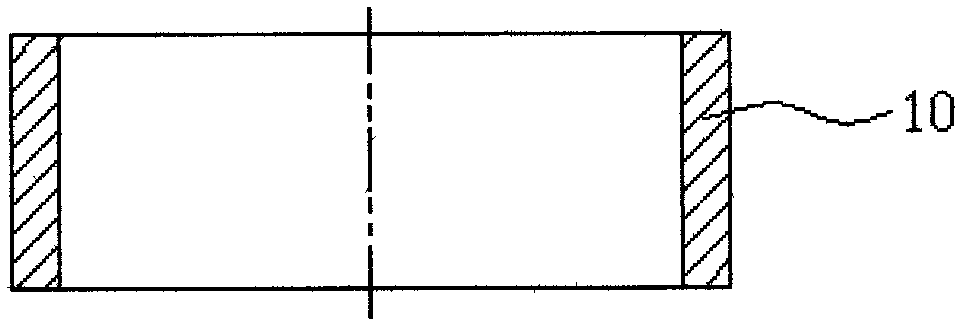

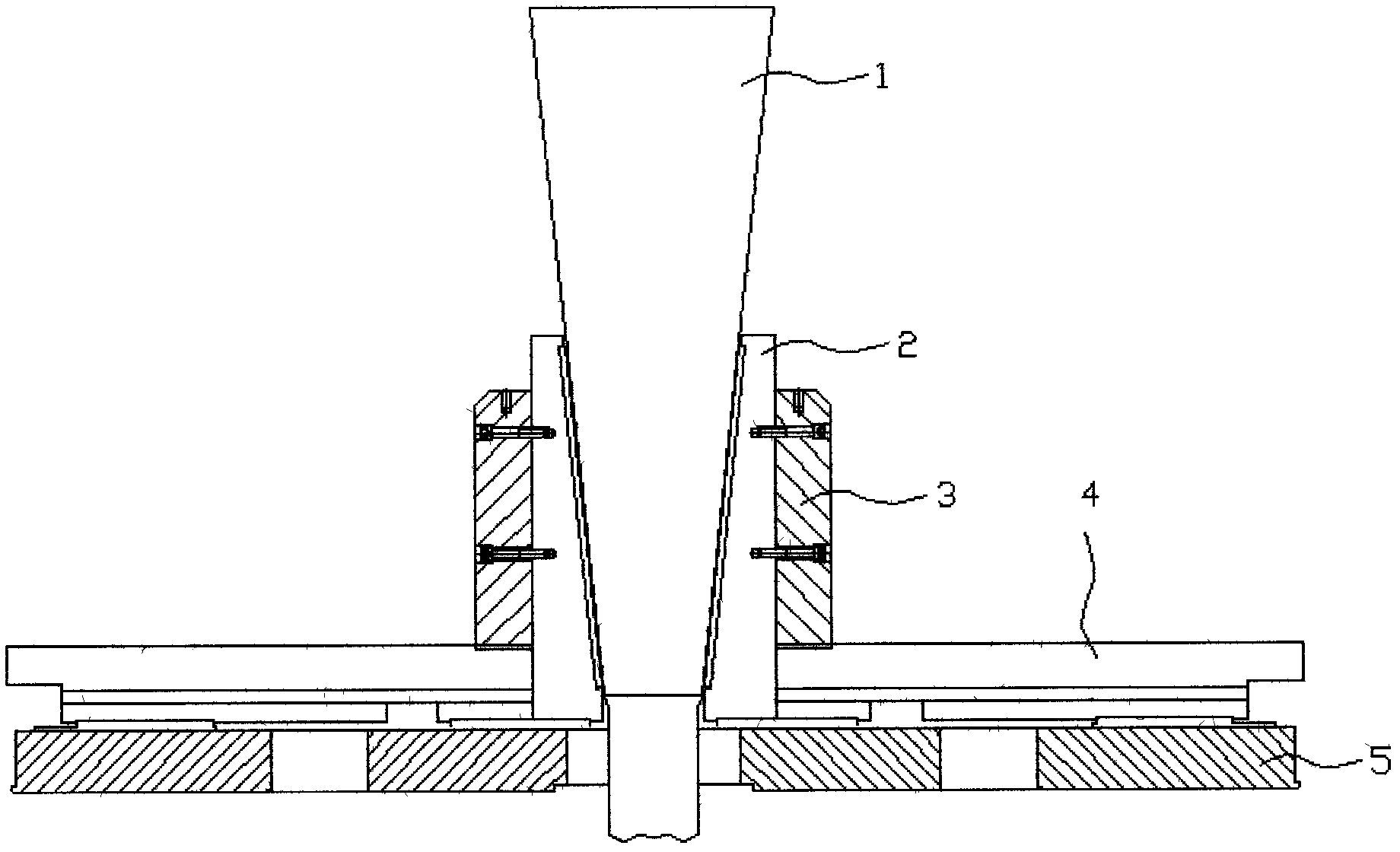

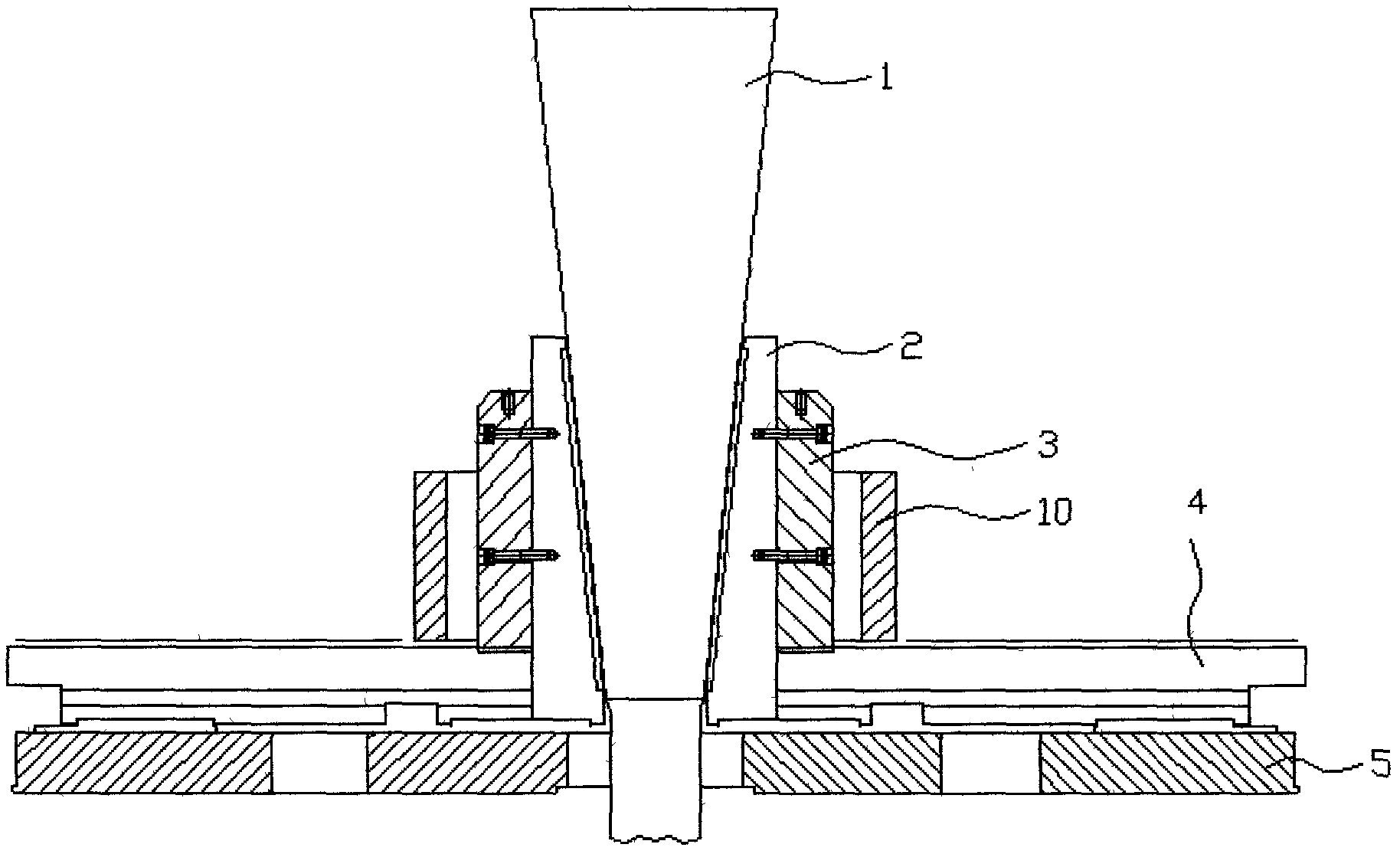

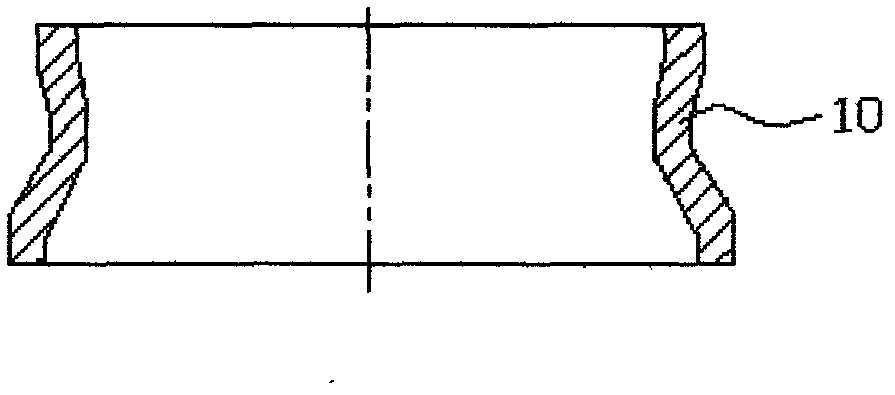

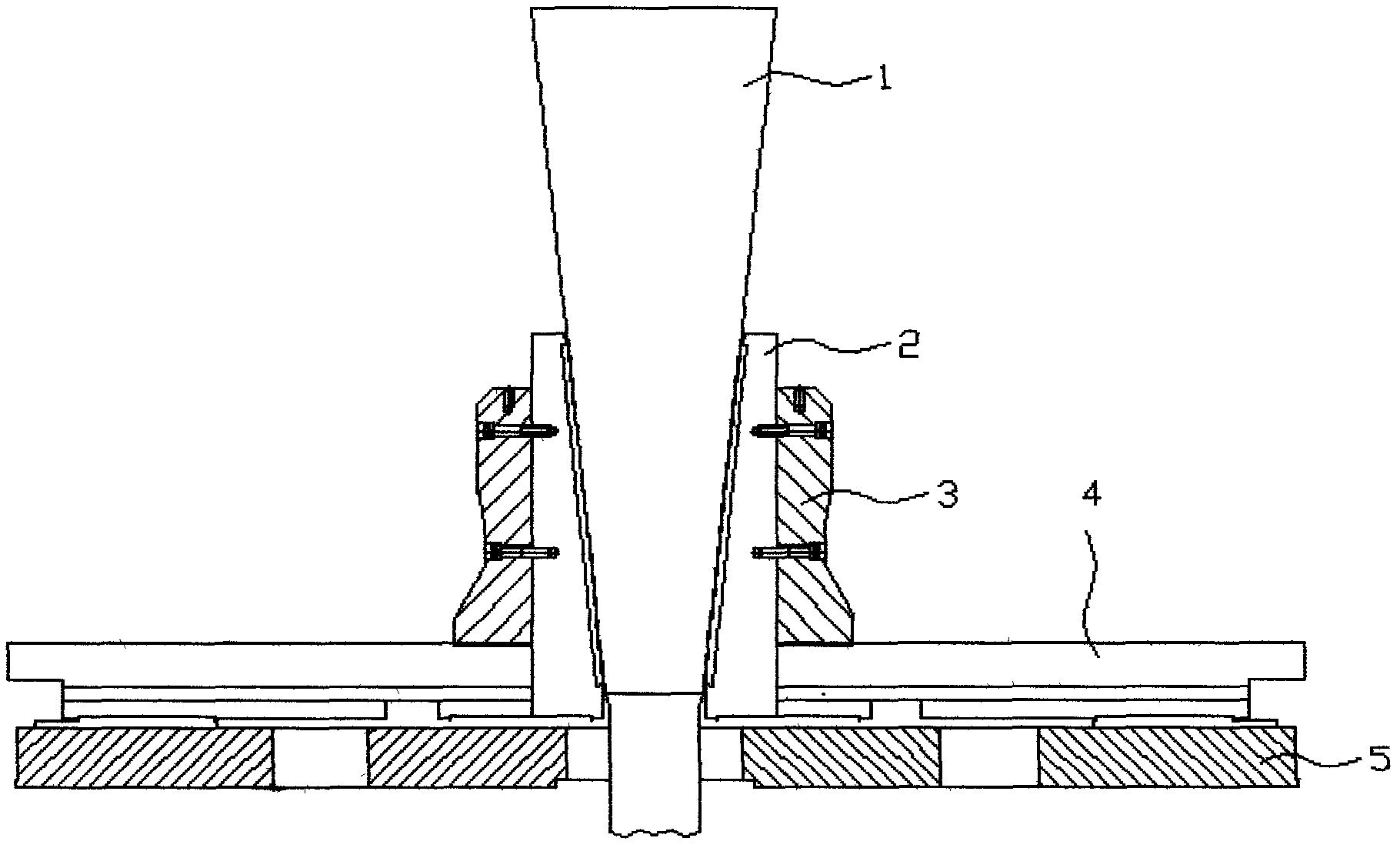

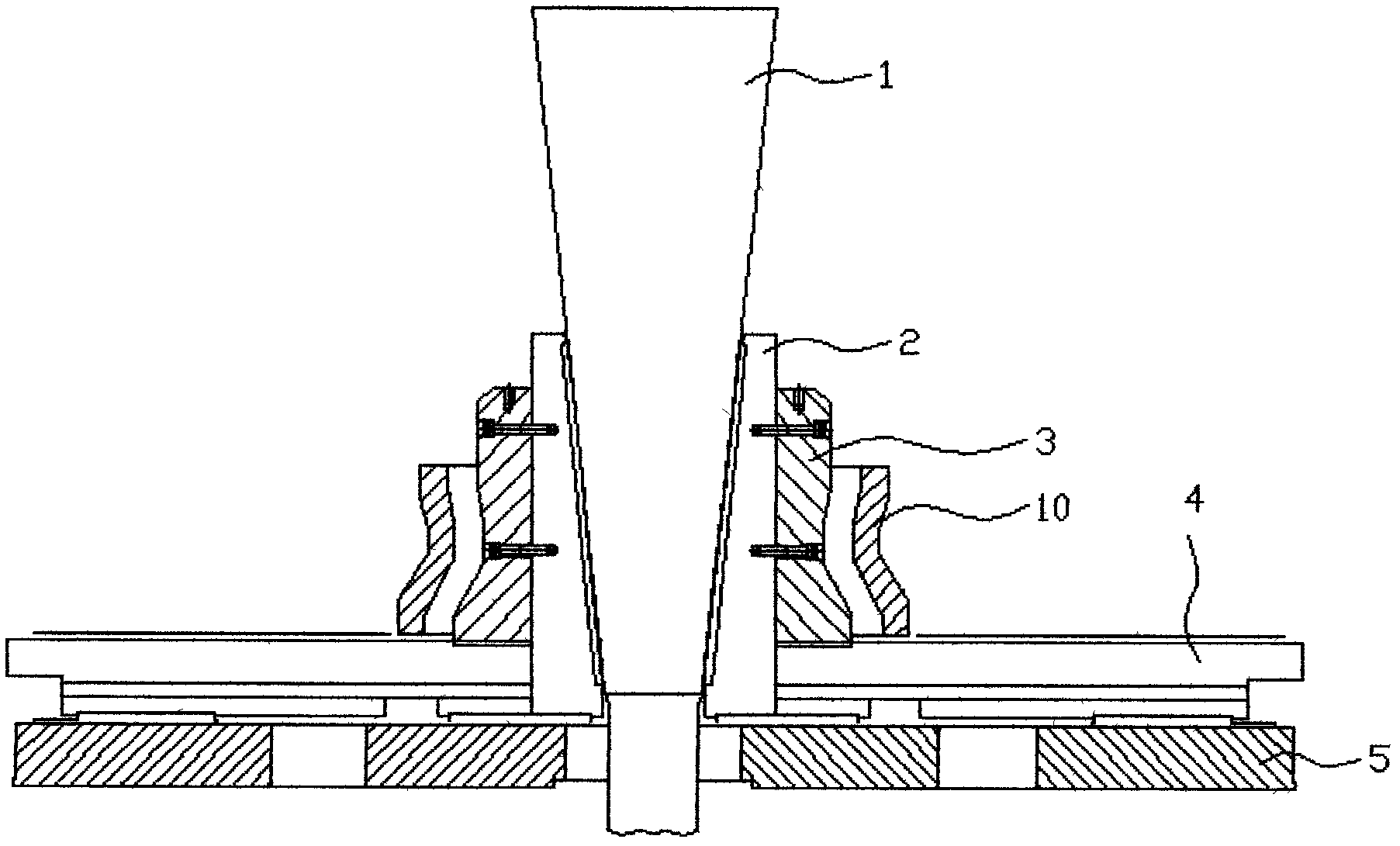

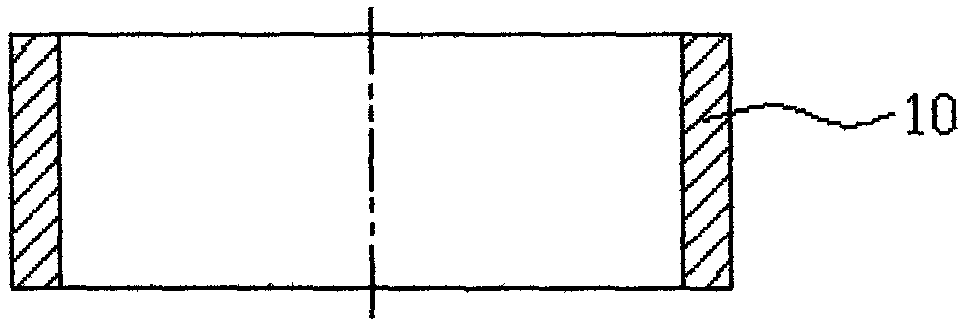

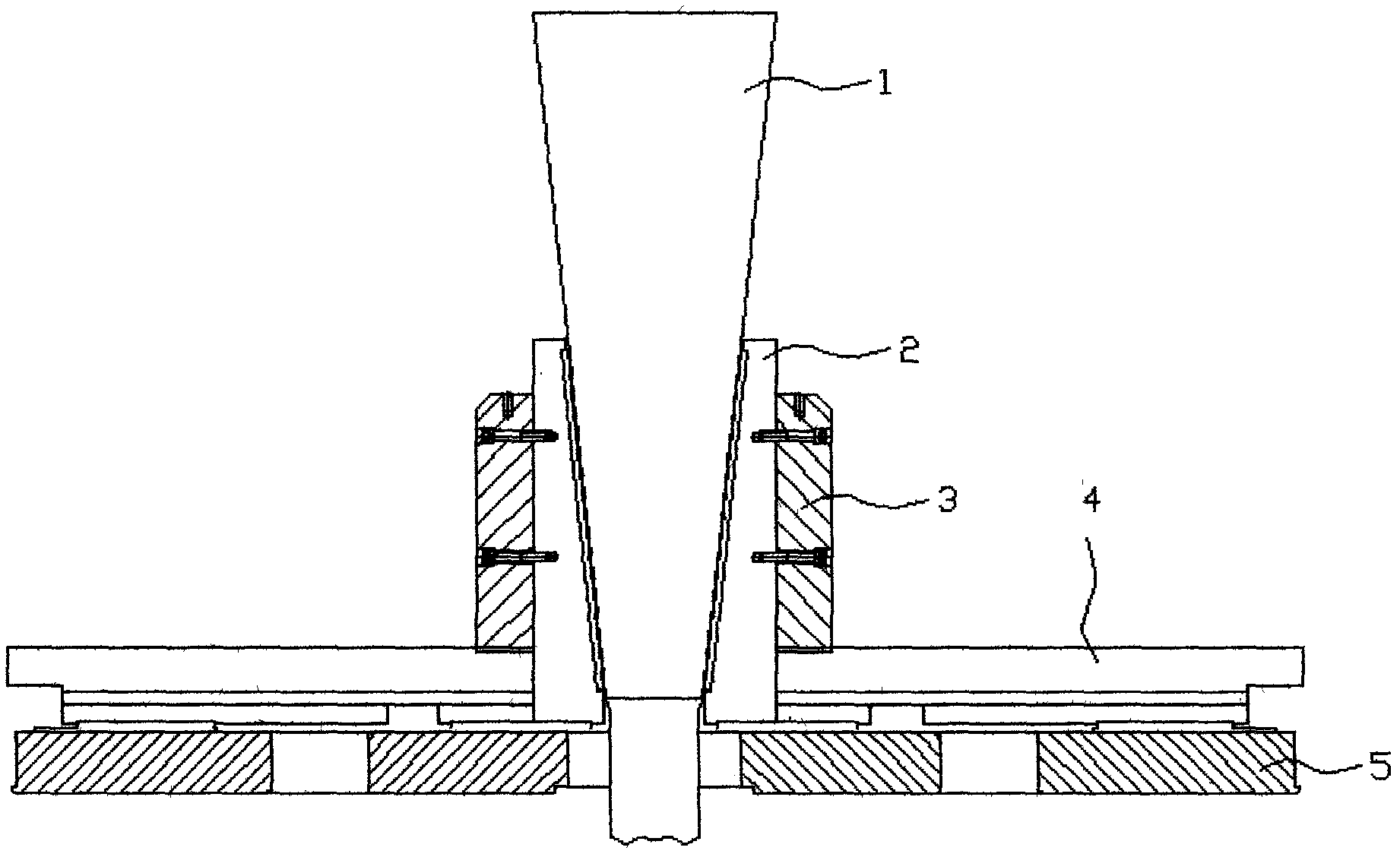

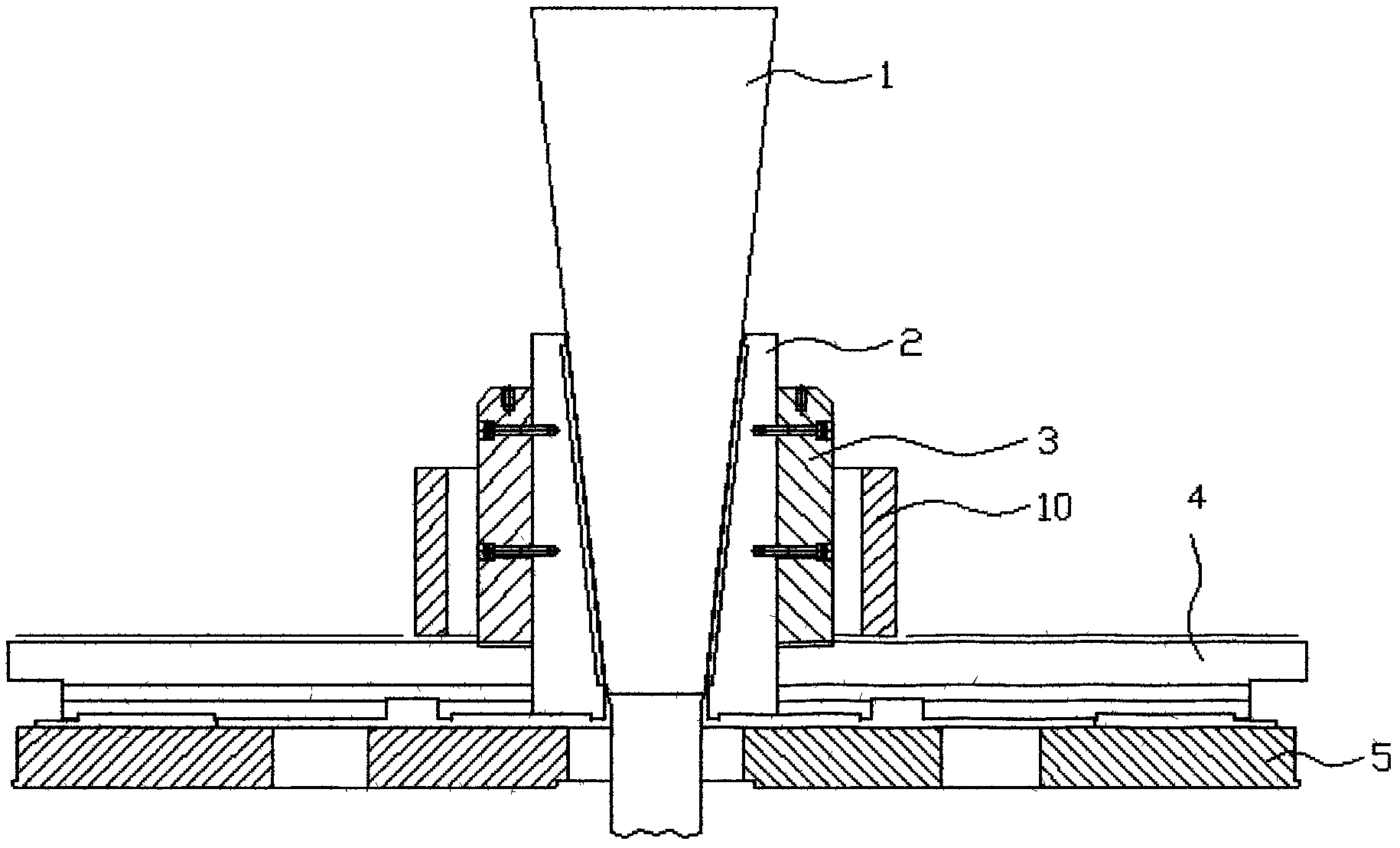

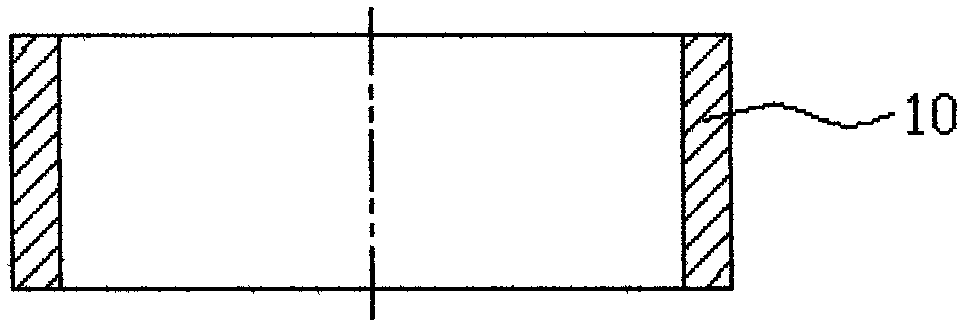

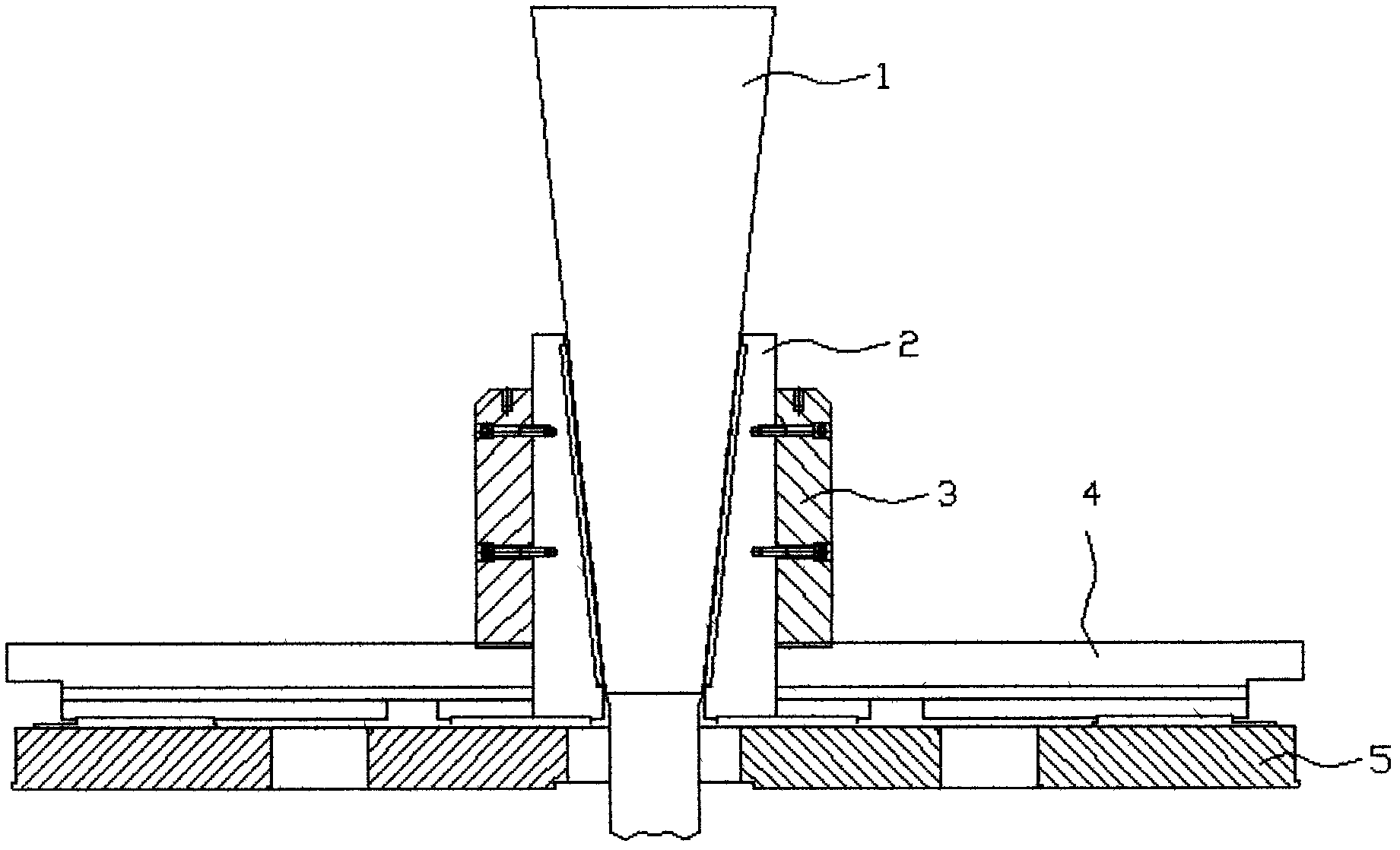

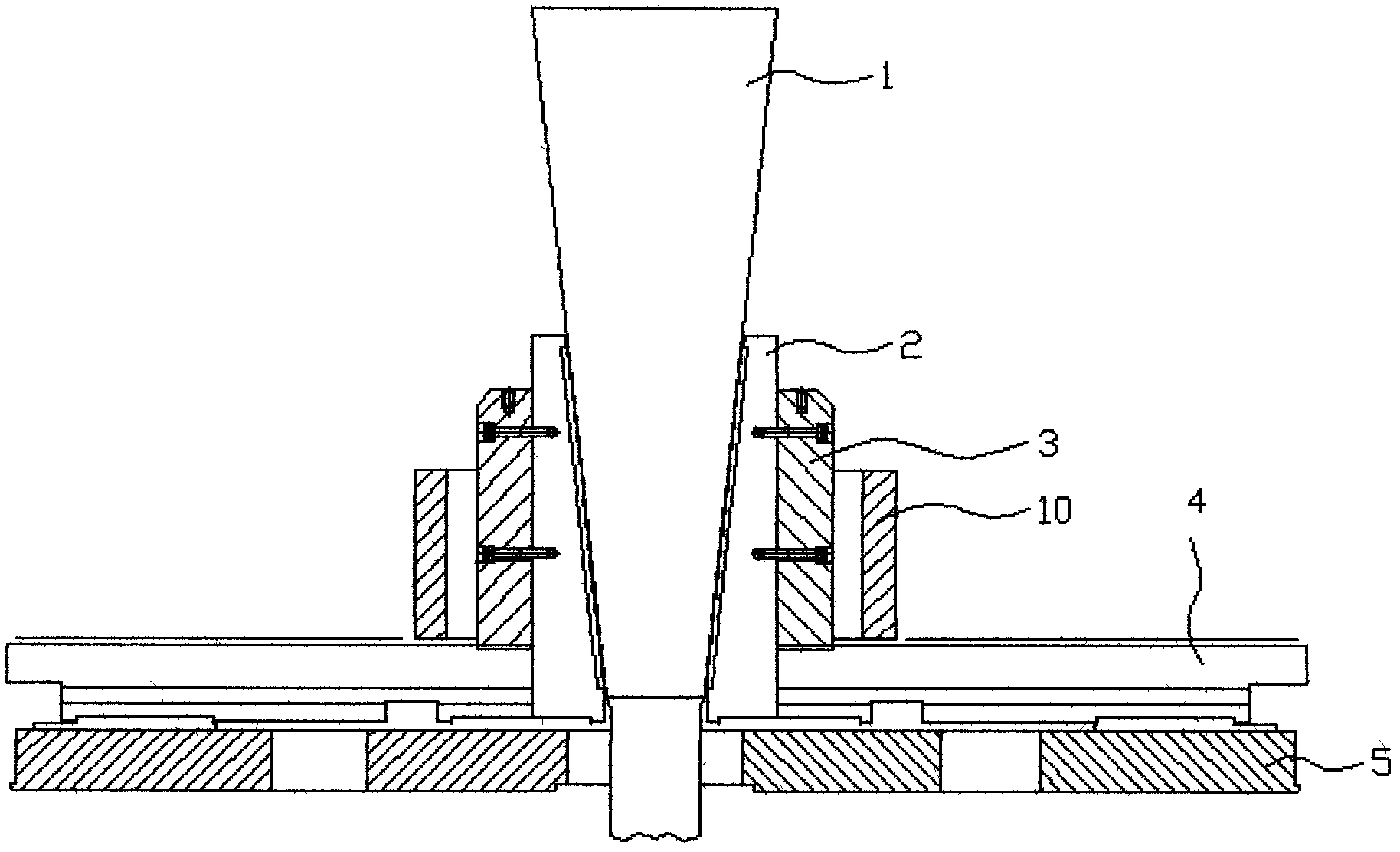

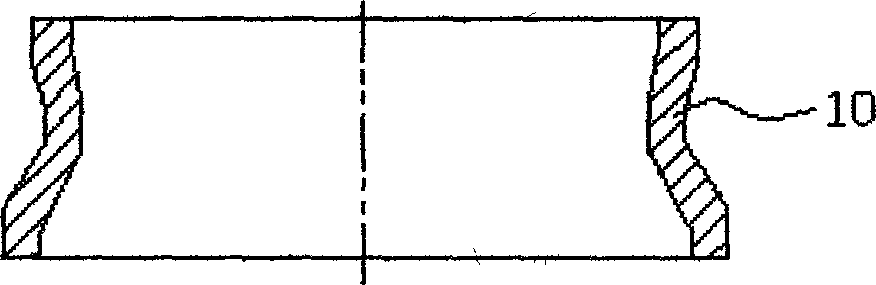

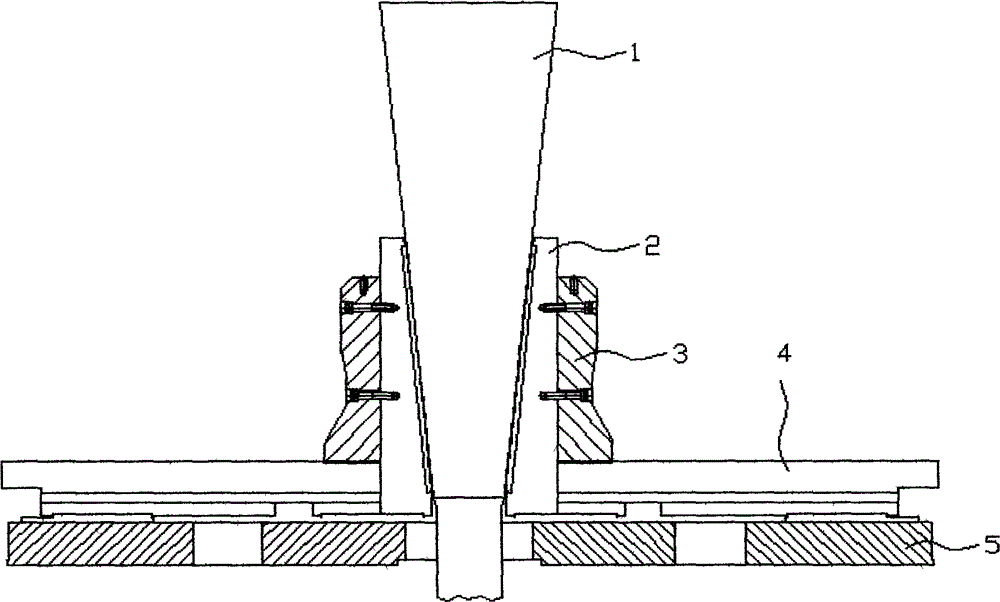

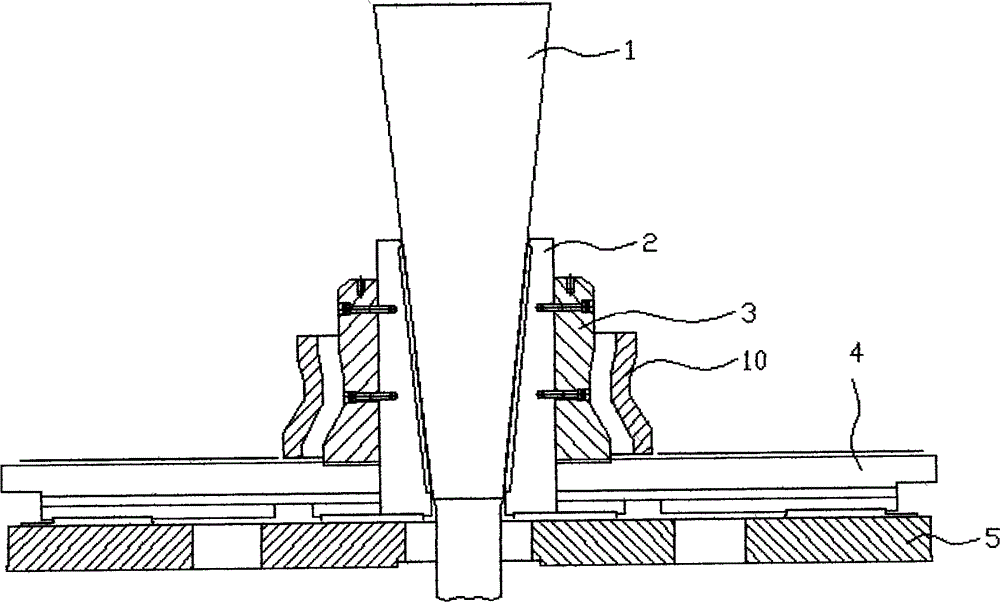

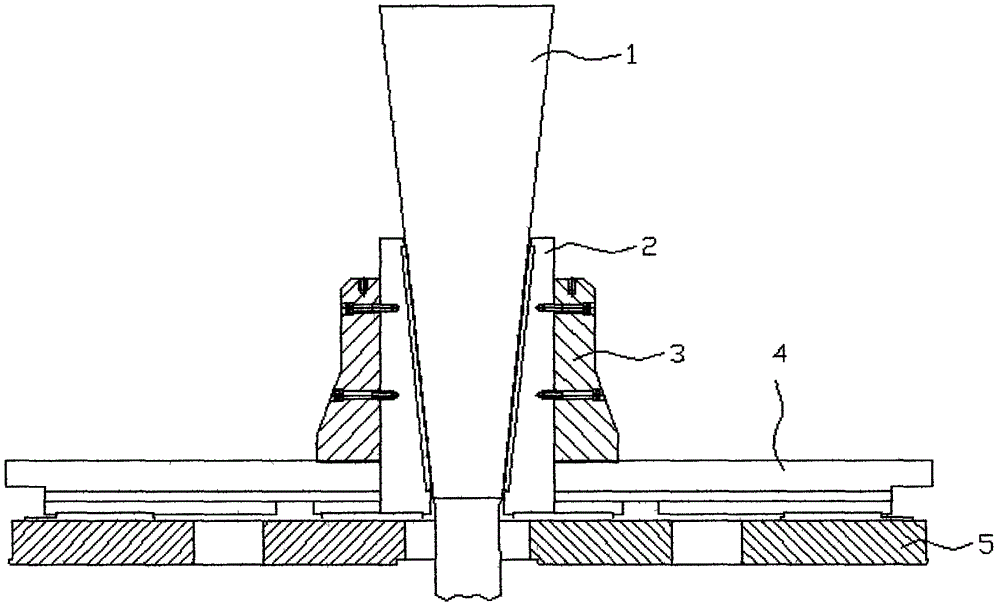

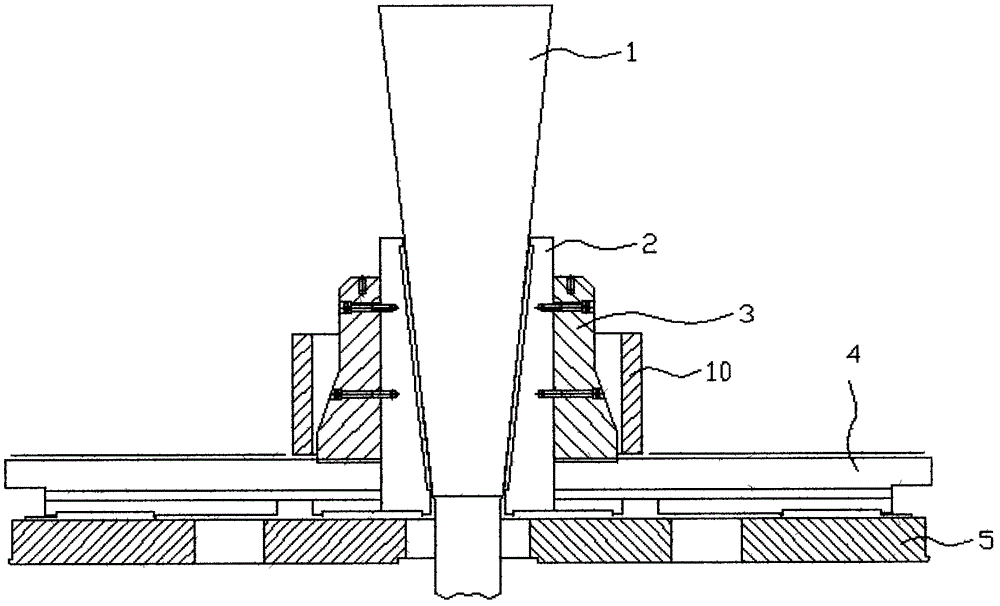

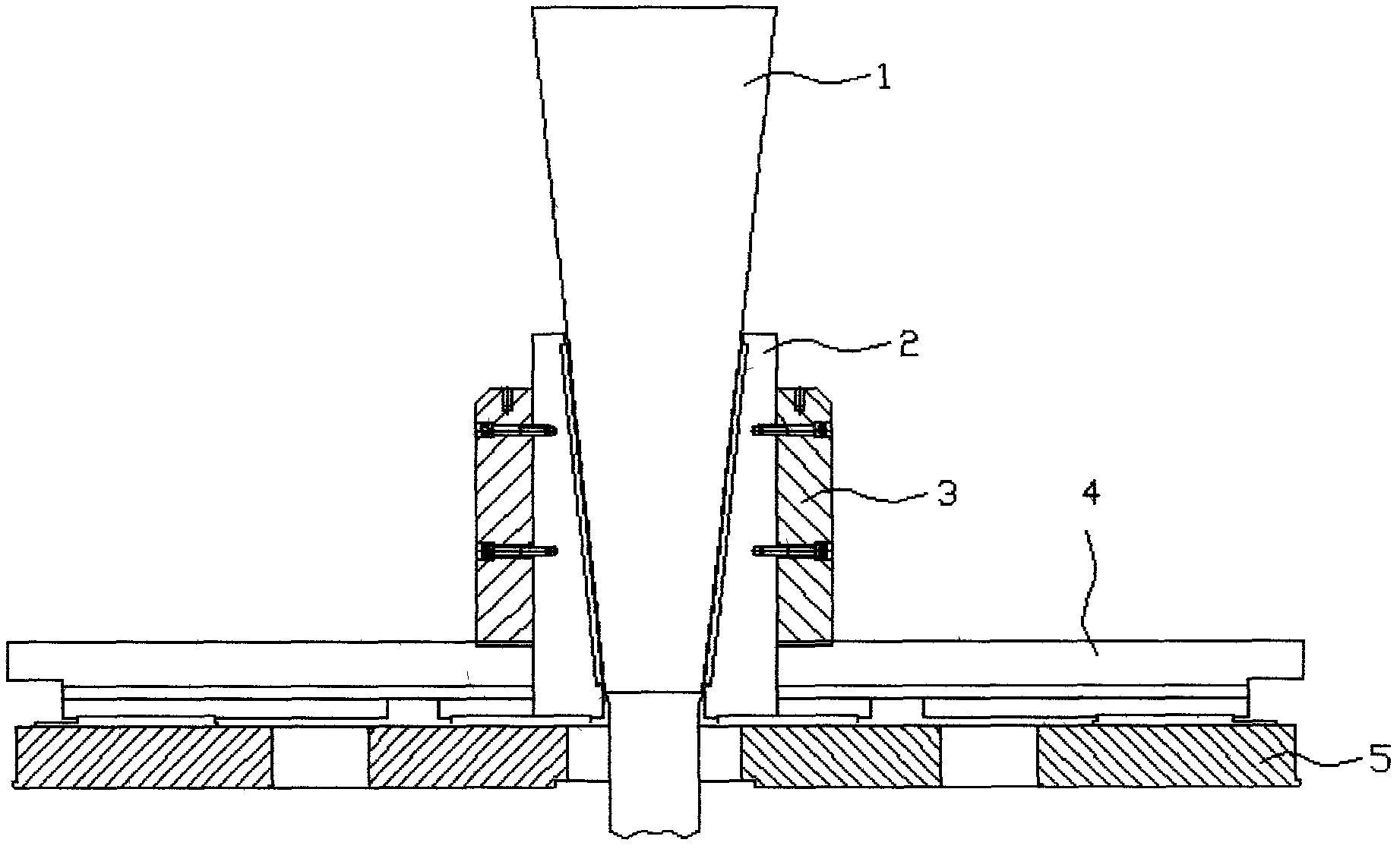

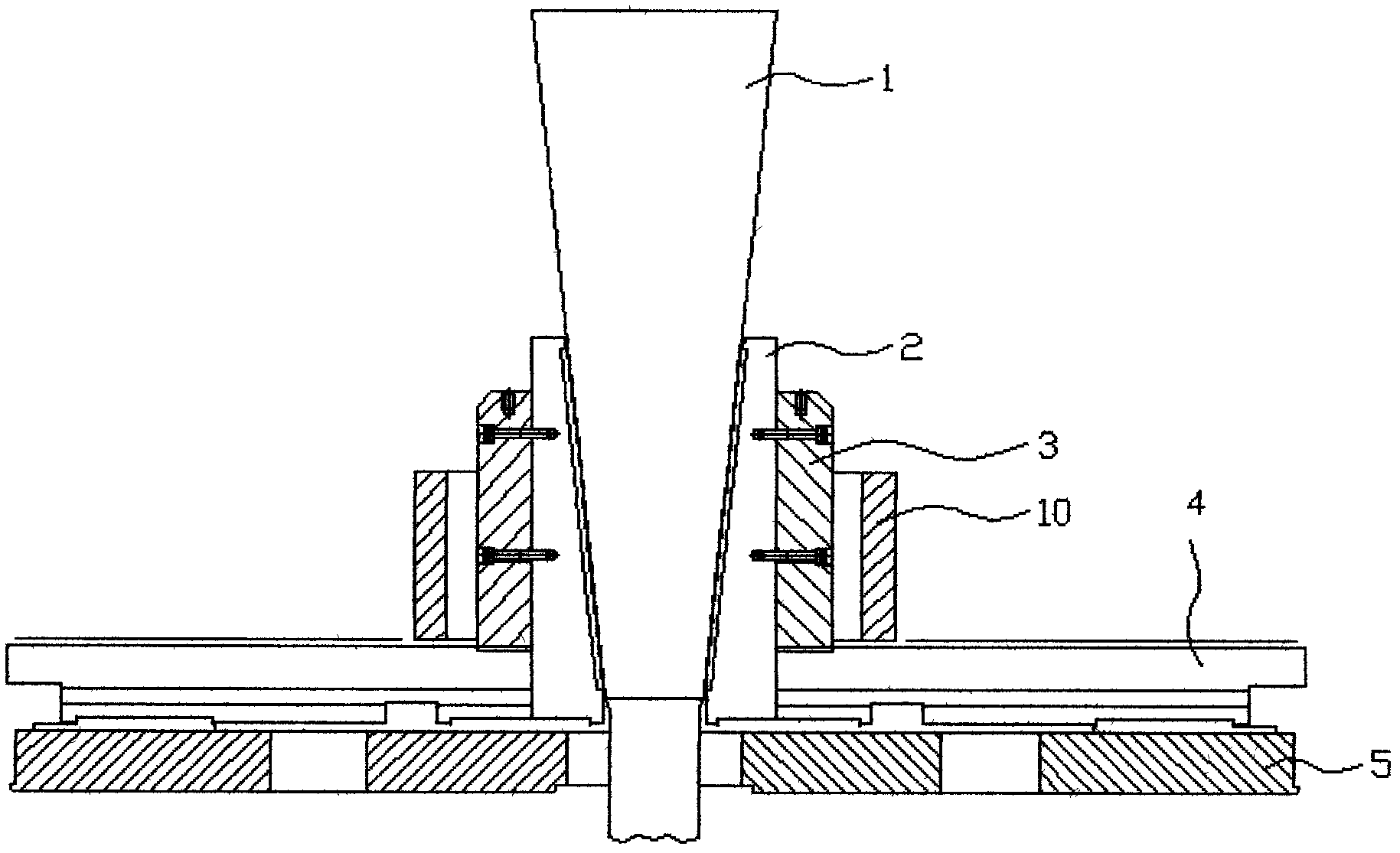

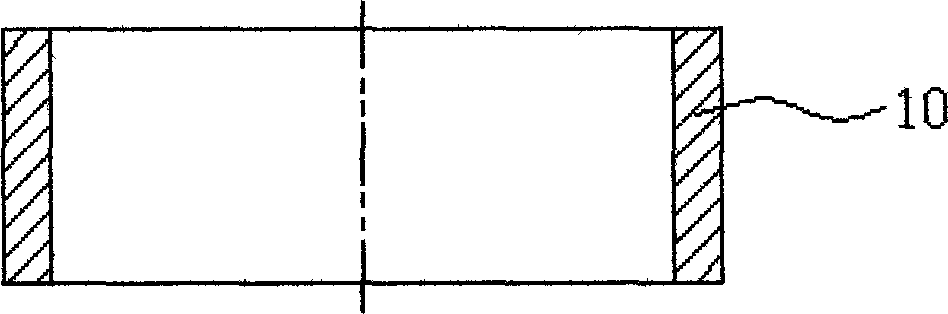

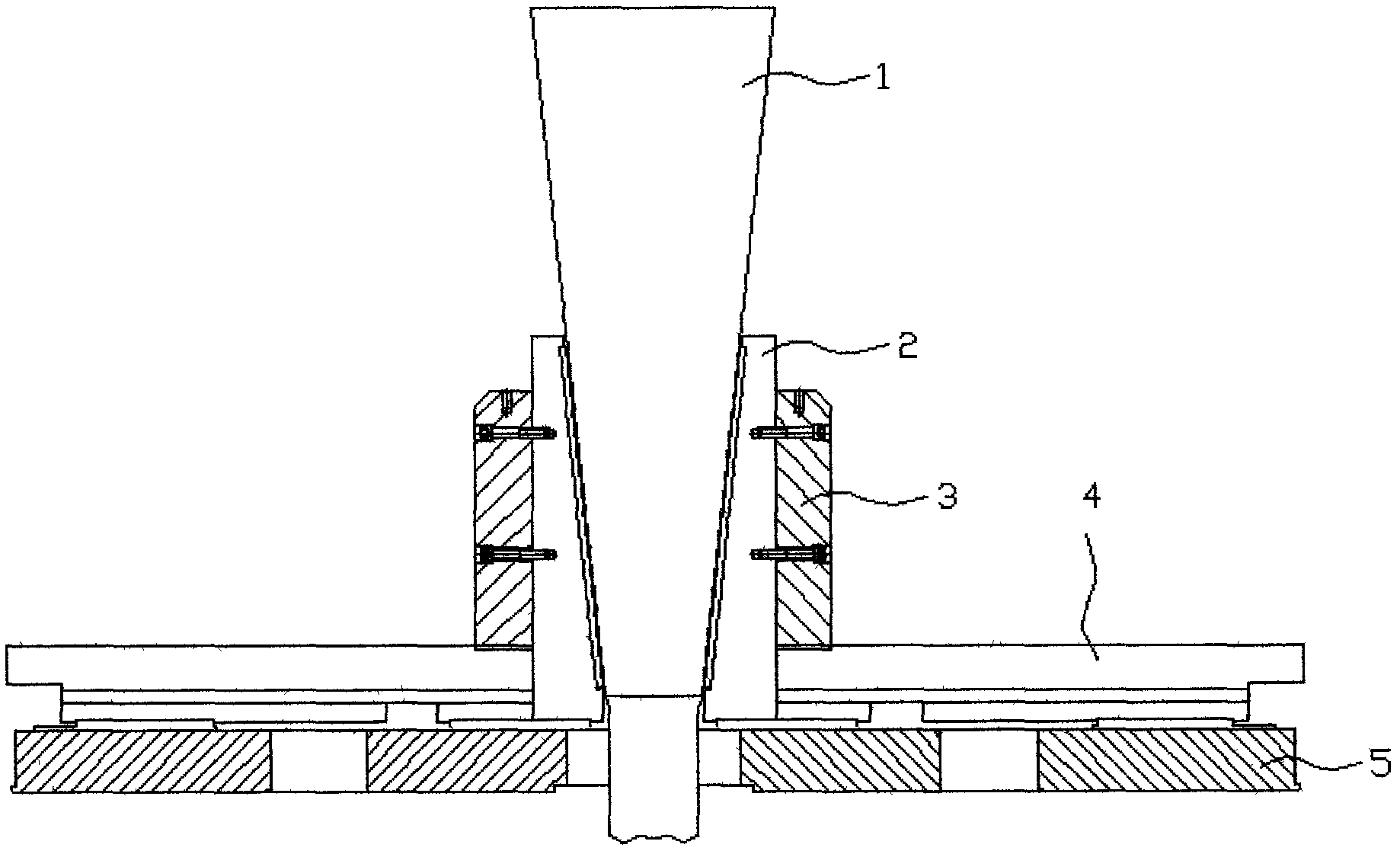

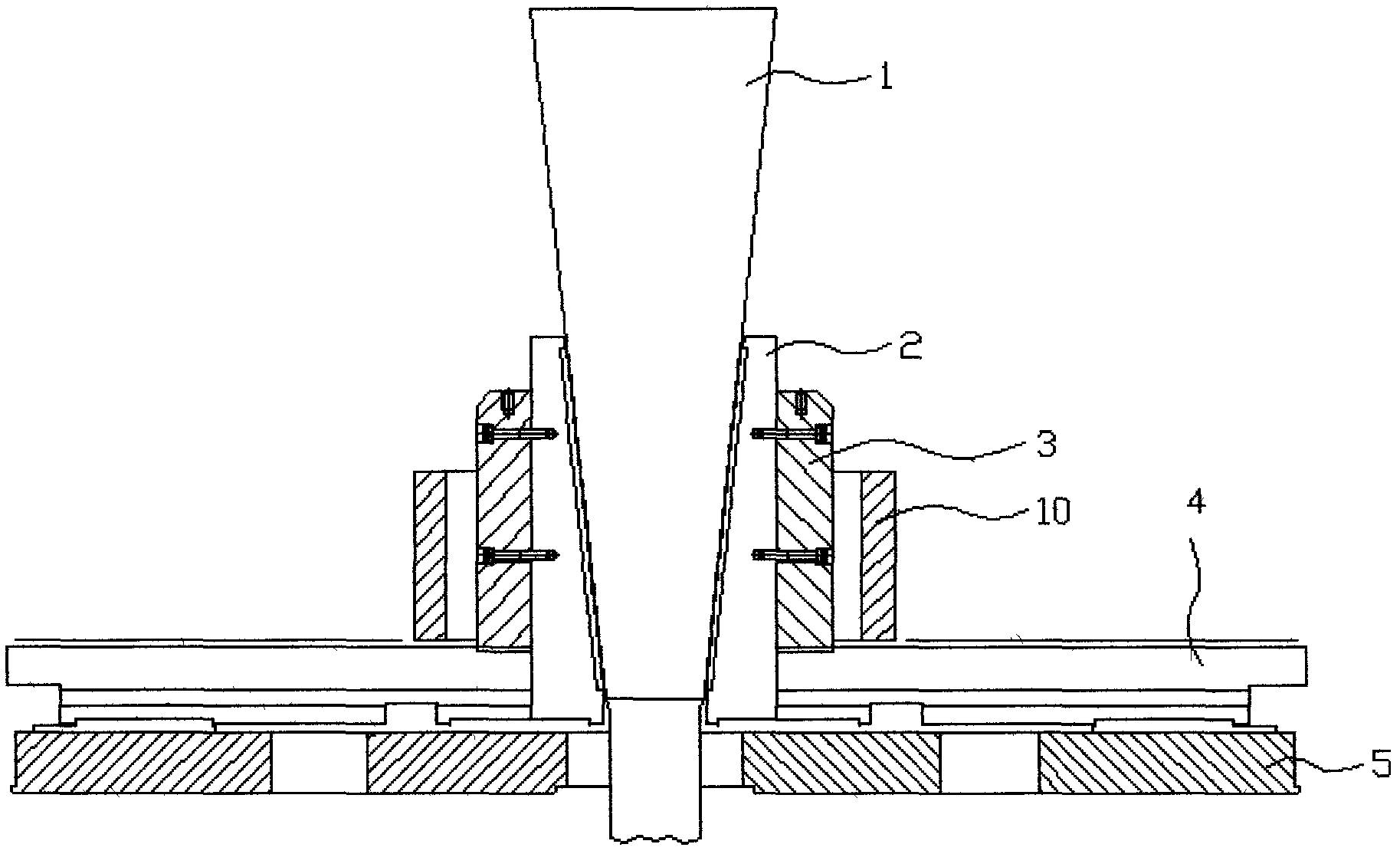

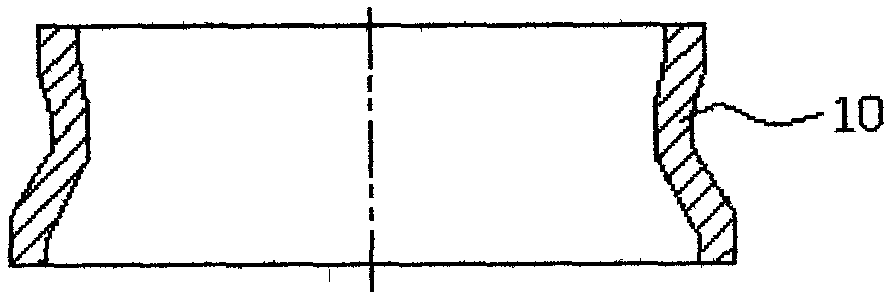

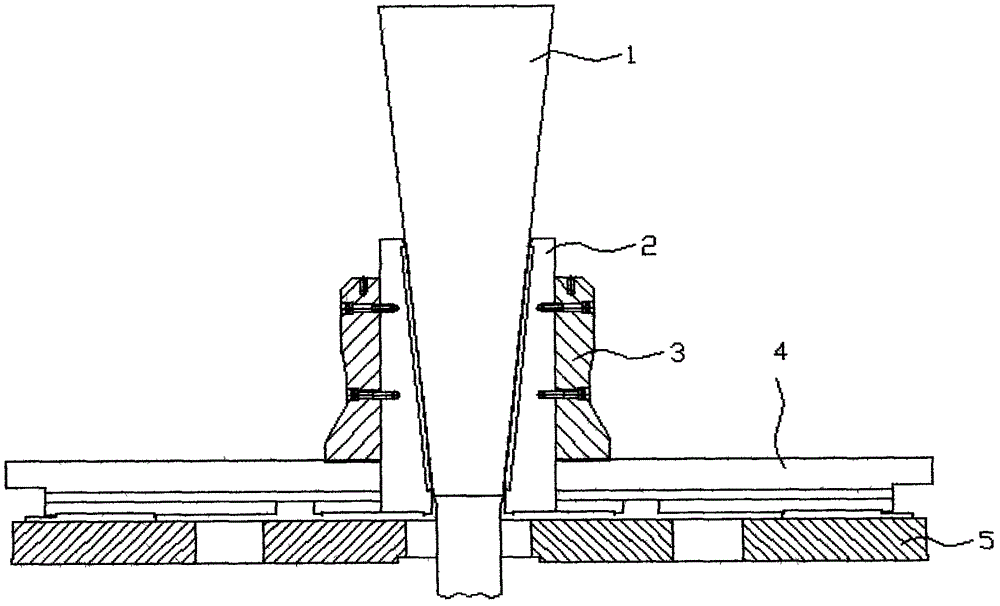

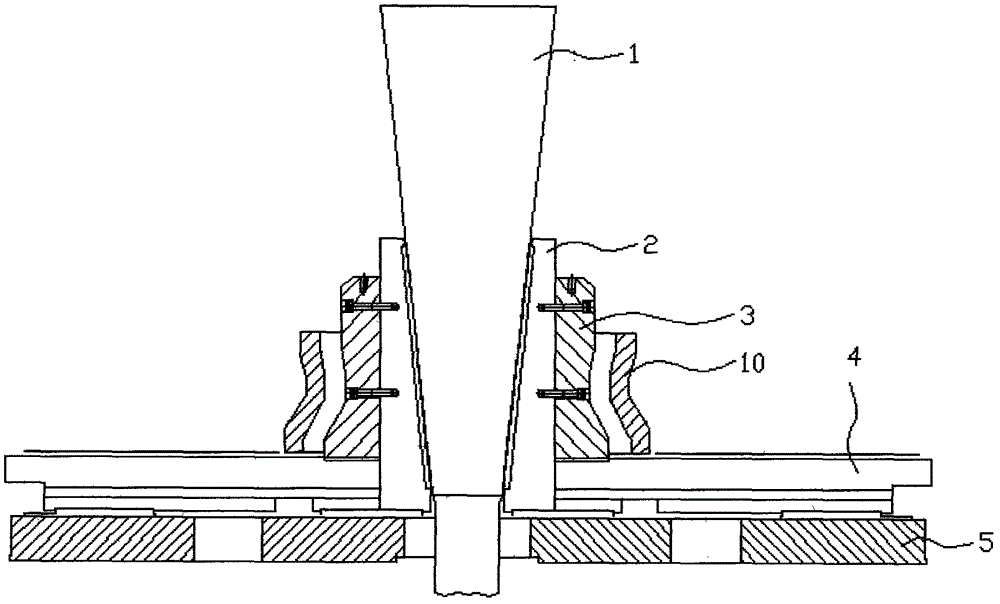

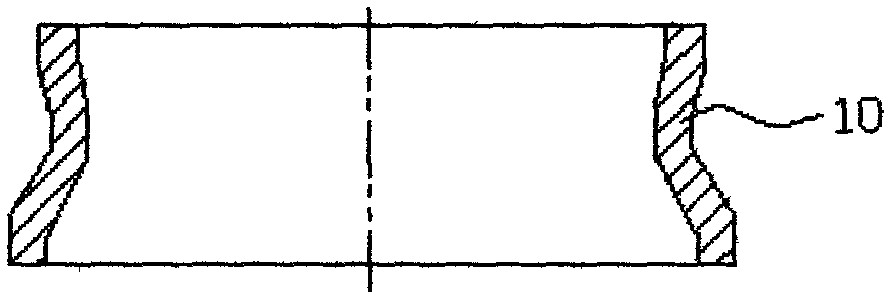

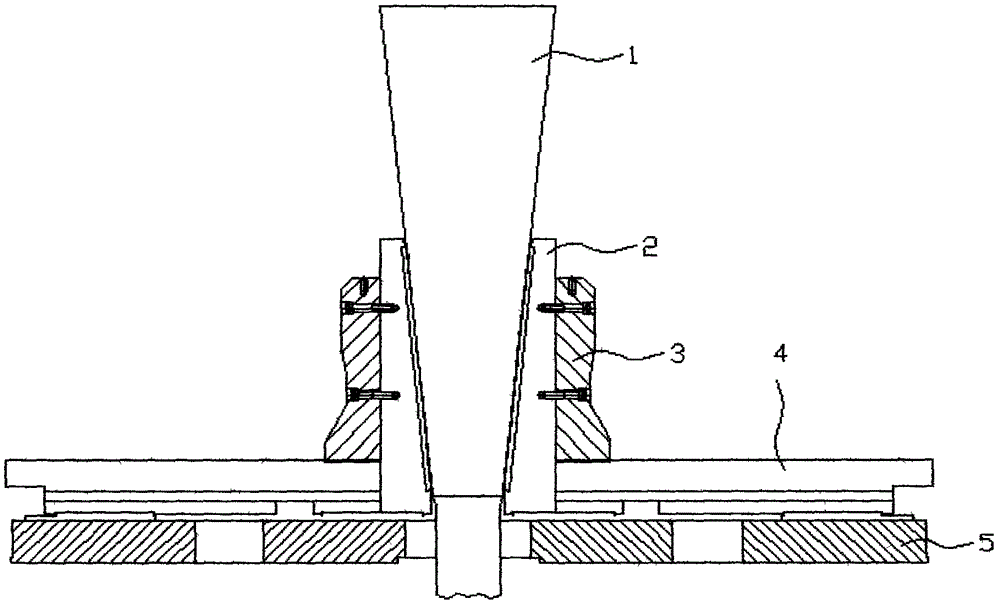

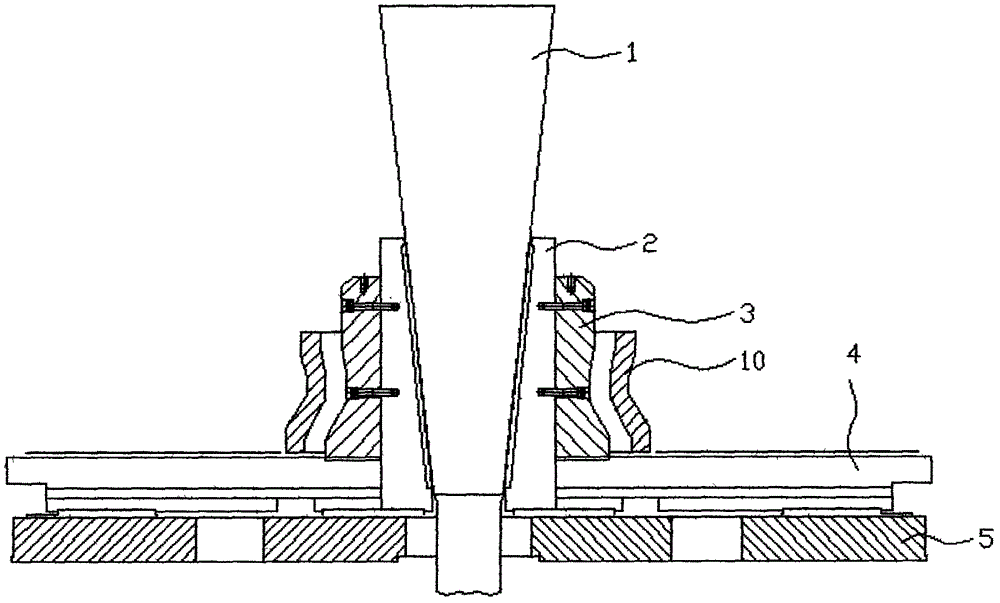

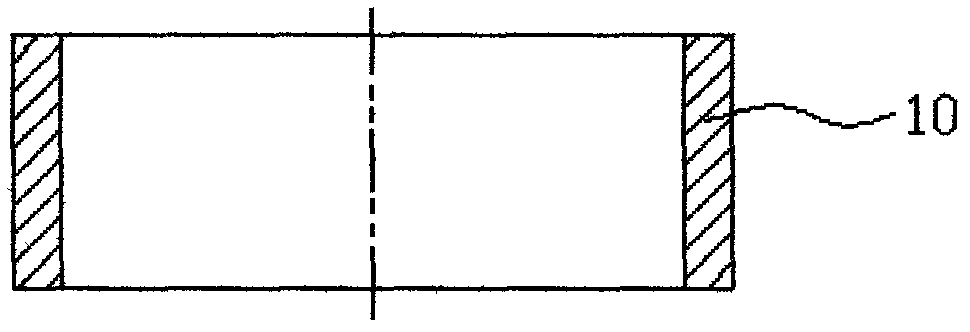

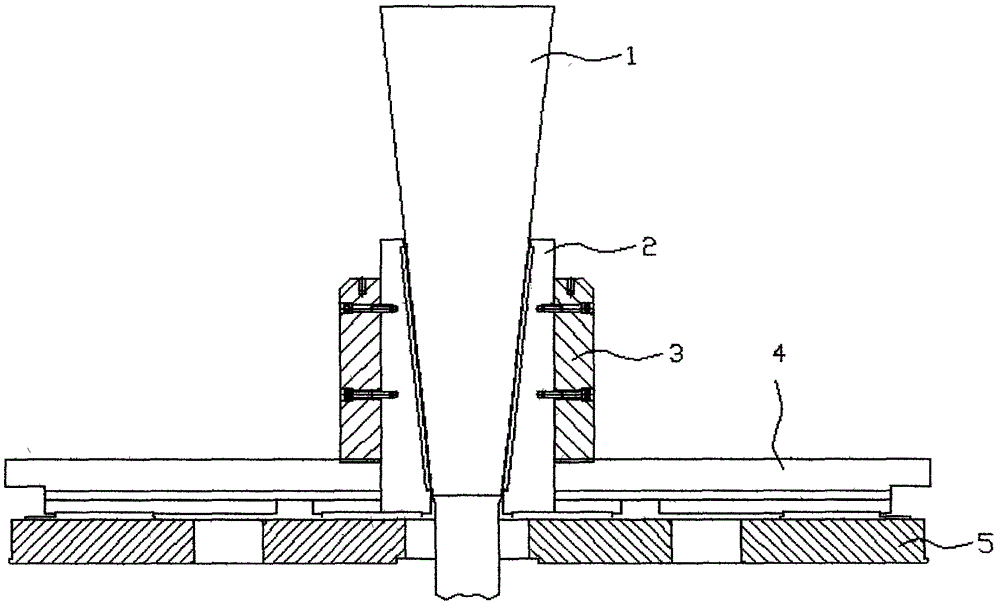

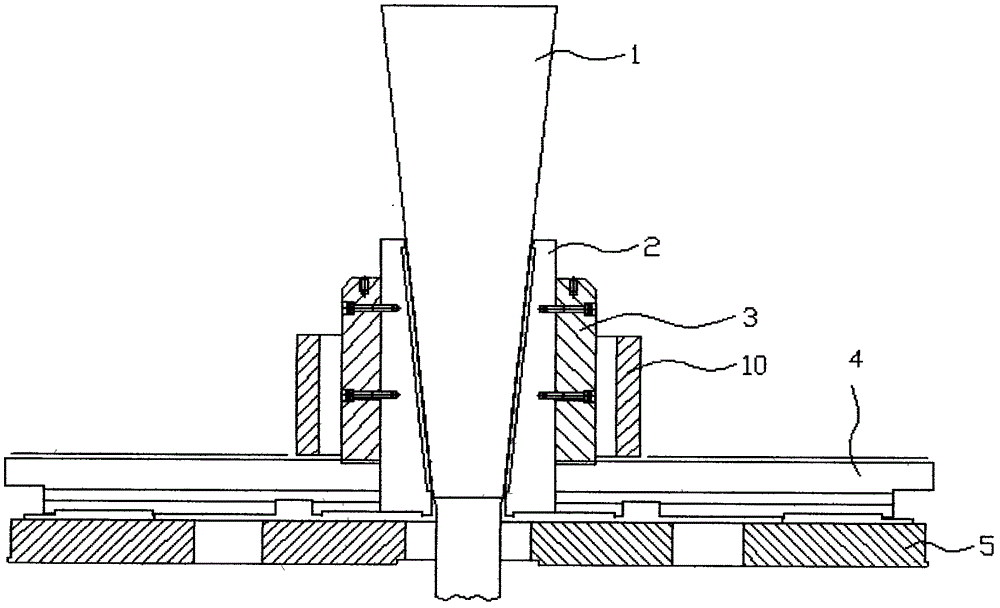

Disclosed is a method for heat bulge forming a rectangular ring rolled piece of stainless steel. The method comprises the steps of: mounting the hot-rolled rectangular ring rolled piece of stainless steel (10) over the periphery of a pre-heated bulge-forming block (3) in a bulge-forming machine; starting the bulge-forming machine to press the bulge-forming block radially from the inner circumferential surface of the ring rolled piece against the ring rolled piece to complete a first bulge-forming step, the bulge-forming temperature being 890°C-950°C, the bulge-forming duration being 15 s-25 s, the duration for pressure maintenance being 7 s-8 s, and the deformation amount being 0.9%-1.2%; then rotating the ring rolled piece at 45° about the central axis to complete a first rotation; completing a second bulge-forming step according to the abovementioned operation, the bulge-forming temperature being 850°C-910°C, the bulge-forming duration being 15 s-25 s, the duration for pressure maintenance being 9 s-10 s, and the deformation amount being 0.7%-1%; rotating the ring rolled piece again in the direction of the first rotation to complete a second rotation; and conducting a third bulge-forming step according to the abovementioned operation, the bulge-forming temperature being 800°C-870°C, the bulge-forming duration being 25 s-35 s, the duration for pressure maintenance being 13 s-15 s, and the deformation amount being 0.5%-0.8%. The dimensional accuracy of the bulge-formed ring rolled piece can reach 10 / 00-20 / 00 of the corresponding dimensions.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal bulging method of stainless-steel irregular ring rolled piece

ActiveCN102513456BHigh dimensional accuracySmall amount of reboundShaping toolsAbnormal shapedMaterials science

The invention discloses a thermal bulging method of a stainless-steel irregular ring rolled piece, and the method comprises the following steps of: sleeving the hot-rolled stainless-steel irregular ring rolled piece on the periphery of a pre-heated bulging block in a bulging machine; starting the bulging machine so that the ring rolled piece is squeezed from the inner circumference surface of the ring rolled piece in a radial direction, thus completing primary bulging, wherein the bulging temperature is 910-970 DEG C, the bulging time is 18-30 seconds, the pressure holding time is 8-9 seconds and the deformation amount is 0.9-1.1%; rotating the ring rolled piece around a center axis for 45 degrees, thus completing primary rotation; carrying out secondary bulging according to the previous steps, wherein the bulging temperature is 870-930 DEG C, the bulging time is 18-30 seconds, the pressure holding time is 12-14 seconds and the deformation amount is 0.8-1%; rotating the ring rolled piece according to a primary rotating direction again, thus completely secondary rotation; and carrying out tertiary bulging according to the previous steps, wherein the bulging temperature is 820-890 DEG C, the bulging time is 28-40 seconds, the pressure holding time is 18-20 seconds and the deformation amount is 0.6-0.9%. The size precision of the bulged ring rolled piece can reach 0.1-0.2% of the corresponding size. The bulged ring rolled piece formed by using the method disclosed by the invention is mainly used for fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for thermally bulging special titanium alloy ring rolled member

ActiveCN102500706BHigh dimensional accuracySmall amount of reboundShaping toolsAbnormal shapedTitanium alloy

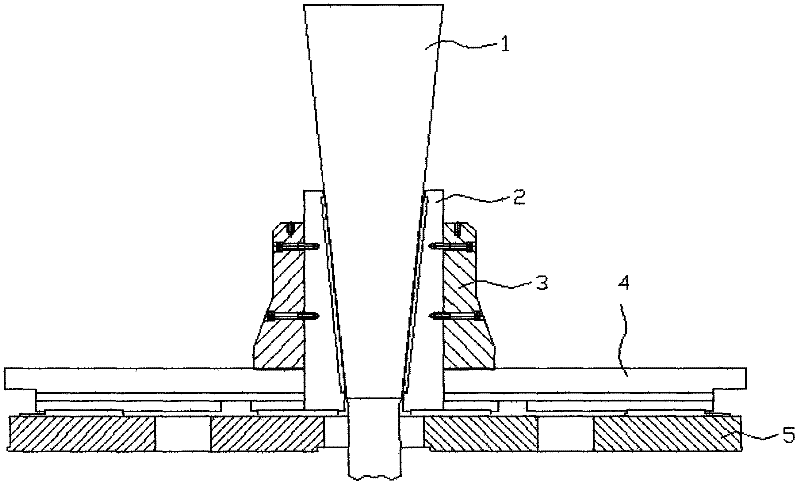

A method for hot bulge-forming a titanium alloy irregularly-shaped ring-rolled workpiece, having the steps of: sleeving a hot-rolled titanium alloy irregularly-shaped ring-rolled workpiece (10) over the periphery of a preheated bulge-forming block (3) in a bulge-forming machine, activating the bulge-forming machine to allow the bulge-forming block to squeeze the ring-rolled workpiece along the radial direction from the inner circumferential surface of the ring-rolled workpiece, thus completing a first bulge-forming, where the temperature for bulge-forming is between 790°C and 850°C, where the time for bulge-forming is between 14s and 19s, where the time for pressure-keeping is between 11s and 13s, and where the amount of deformation is between 0.3% and 0.8%; then, rotating the ring-rolled workpiece by 45° along the central axis, thus completing a first rotation; subsequently, performing, on the basis of said procedures, a second bulge-forming, where the temperature for bulge-forming is between 760°C and 820°C, where the time for bulge-forming is between 14s and 19s, where the time for pressure-keeping is between 11s and 13s, and where the amount of deformation is between 0.5% and 1%; rotating once again the ring-rolled workpiece in the direction of the first rotation, thus completing a second rotation; and performing, on the basis of said procedures, a third bulge-forming, where the temperature for bulge-forming is between 720°C and 790°C, where the time for bulge-forming is between 18s and 25s, where the time for pressure-keeping is between 15s and 17s, and where the amount of deformation is between 0.7% and 1%. The method increases dimensional accuracy of the ring-rolled workpiece, and eliminates for same the shortcomings of deformation and warping.

Owner:GUIZHOU ANDA AVIATION FORGING

Thermal expansion method for titanium alloy flash welding collar piece

ActiveCN102397937BHigh dimensional accuracyReduced dimensional accuracyThermal expansionFlash welding

The invention discloses a thermal expansion method for a titanium alloy flash welding collar piece, which comprises the following steps: heating an annealed titanium alloy flash welding collar piece, sleeving the titanium alloy flash welding collar piece on the periphery of a preheated expanding block in an expanding machine, and starting the expanding machine to allow the expanding block to press the collar piece radically from the internal circumferential surface of the collar piece to accomplish primary expansion, wherein the expansion temperature is 750 to 850 DEG C, the expansion time is 10 to 15 seconds, the pressure-keeping time is 8 to 9 seconds and the deformation rate is 0.1 to 0.15 percent; rotating the collar piece 45 DEG around a central axis to accomplish primary rotation; performing secondary expansion by the same operation, wherein the expansion temperature is 730 to 830 DEG C, the expansion time is 22 to 23 seconds, the pressure-keeping time is 18 to 20 seconds, and the deformation rate is 0.7 to 0.9 percent; rotating the collar piece in the same direction as the primary rotation to accomplish secondary rotation; and performing tertiary rotation by the same operation, wherein the expansion time is 700 to 800 DEG C, the expansion time is 33 to 43 seconds, the pressure-keeping time is 28 to 30 seconds and the deformation rate is 0.8 to 1 percent. The specification precision of the expanded collar piece can reach 0.1 to 0.2 of a corresponding specification, and the expanded collar piece is mainly used in the field of space navigation.

Owner:GUIZHOU ANDA AVIATION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com