Method for thermally bulging high-temperature alloy rectangular ring rolled member

A high-temperature alloy and rectangular ring technology, which is applied in the field of thermal expansion of high-temperature alloy rectangular ring-rolled parts, can solve the problems of low dimensional accuracy and inapplicability of ring-rolled parts, and achieve the effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042]The main chemical element content (percentage by weight) of the alloy is: C content ≤ 0.08%, Cr content 17.0% ~ 21.0%, Ni content 50.0% ~ 55.0%, Co content ≤ 1.0%, Mo content 2.80% ~3.30%, Al content 0.30%~0.70%, Ti content 0.75%~1.15%, Nb content 4.75%~5.50%, B content ≤0.006%, Mg content ≤0.01%, Mn content ≤0.35 %, Si content ≤0.35%, P content ≤0.015%, S content ≤0.015%, Cu content ≤0.30%, Ca content ≤0.01%, Pb content ≤0.0005%, Se content ≤0.0003% , The balance is Fe.

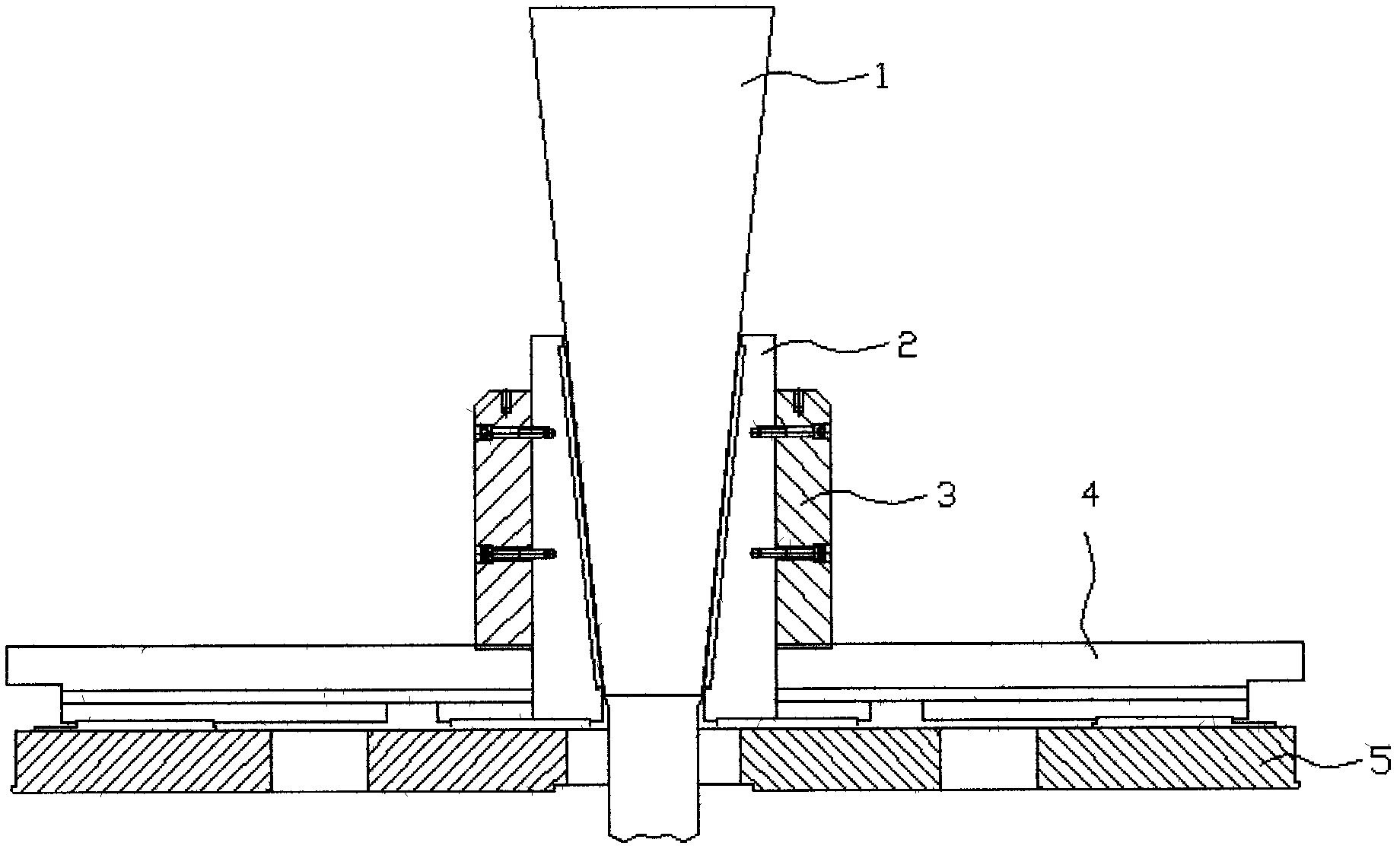

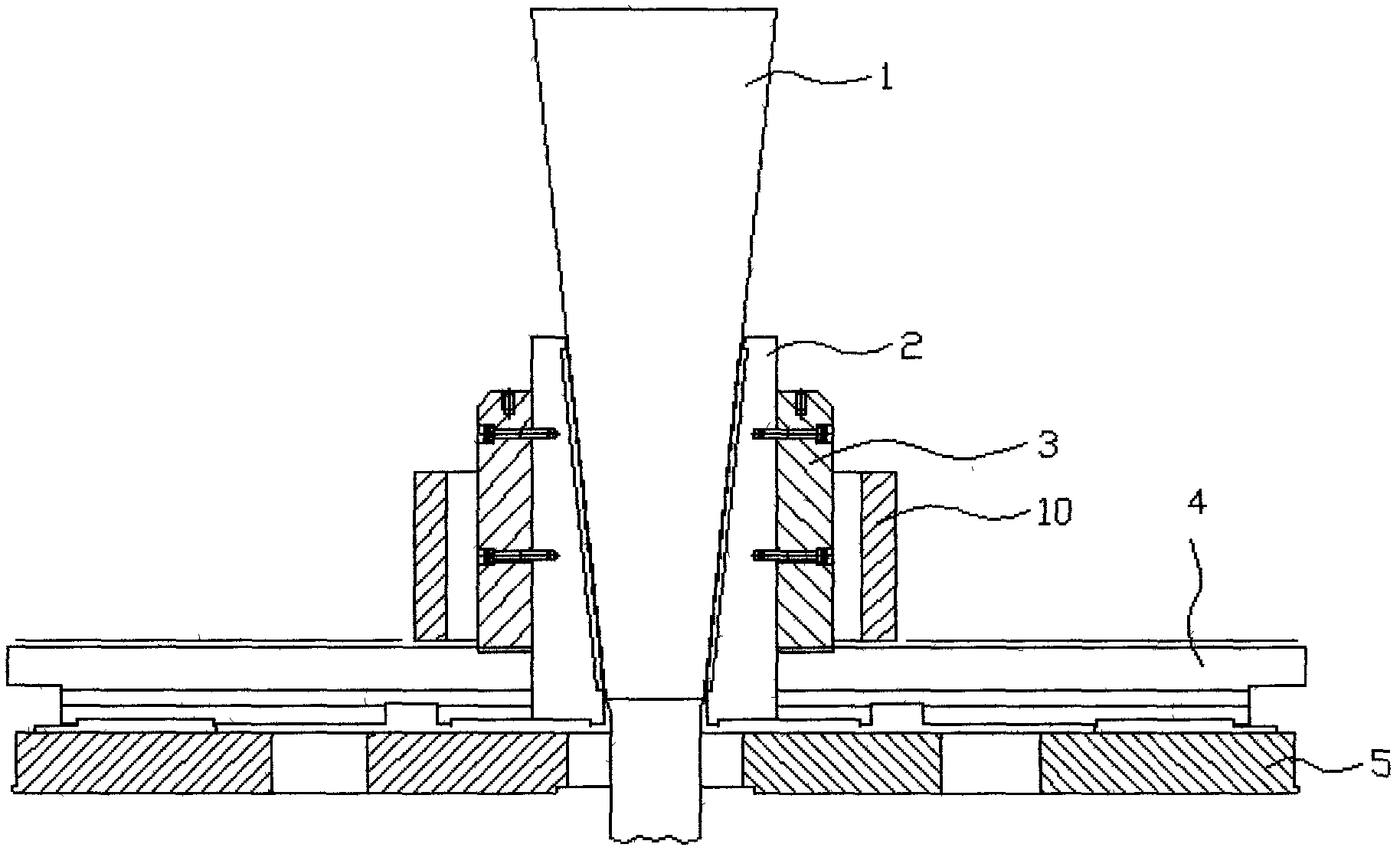

[0043] The structural diagram of the bulging machine for implementing the thermal bulging method of the present invention is as follows: figure 2 As shown, the bulging machine is mainly composed of a mandrel slider 1, a radial slider 2, a bulging block 3, a workbench 4 and a guide rail 5. The mandrel slider 1 is conical and is set in the radial slider 2 to cooperate with the conical inner peripheral surface of the radial slider 2. The mandrel slider 1 can be driven by the hydraulic cylinder of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com