Thermal expansion method for titanium alloy flash welding collar piece

A technology of flash welding and titanium alloy, which is applied in the field of thermal expansion of titanium alloy flash welding ring parts, can solve the problems of roundness and poor dimensional accuracy of flash welding ring parts, and achieve the effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] The main chemical element content (percentage by weight) of the alloy is: Al content 5.5%-6.8%, V content 3.5%-4.5%, Fe content ≤ 0.30%, C content ≤ 0.10%, N content ≤ 0.05 %, H content ≤ 0.015%, O content ≤ 0.20%, the sum of other elements ≤ 0.40%, and the balance is Ti.

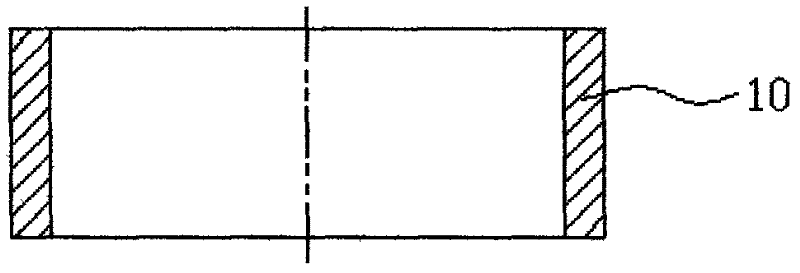

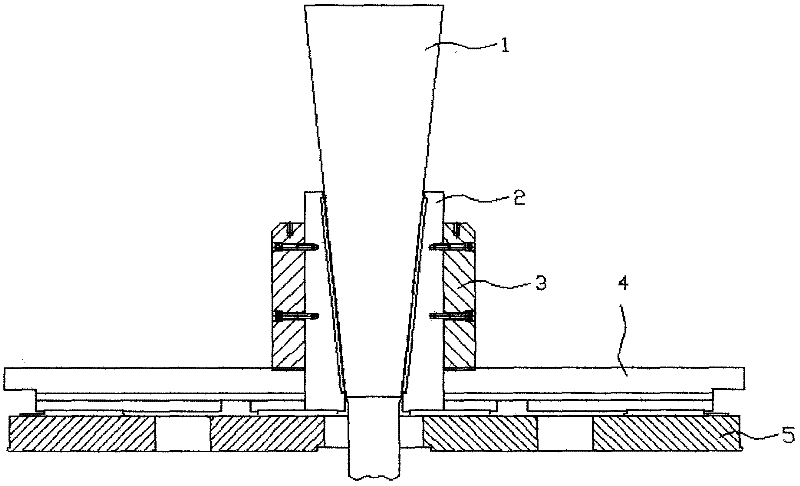

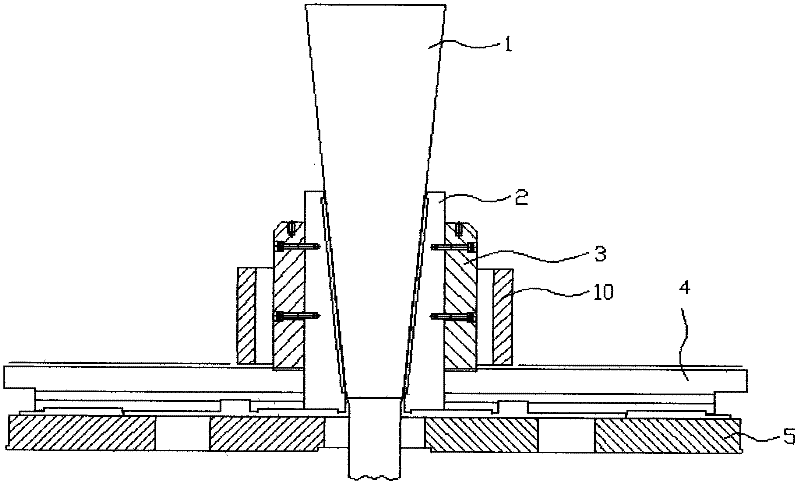

[0043] The structural diagram of the bulging machine for implementing the thermal bulging method of the present invention is as follows: figure 2 As shown, the bulging machine is mainly composed of a mandrel slider 1, a radial slider 2, a bulging block 3, a workbench 4 and a guide rail 5. The mandrel slider 1 is conical and is set in the radial slider 2 to cooperate with the conical inner peripheral surface of the radial slider 2. The mandrel slider 1 can be driven by the hydraulic cylinder of the bulging machine on the radial slider 2. Move up and down in the axial direction and squeeze the radial slider 2; the radial slider 2 is installed on the guide rail 5 of the bulging machine and can move ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com