Plastic-steel counterweight

A manufacturing method and plastic-steel technology, applied to wheel counterweights and other directions, can solve the problems of easily broken cast iron counterweights, waste of steel materials, unsightly appearance, etc., and achieve the effects of good counterweight formability, elimination of pollution, and beautiful appearance.

Inactive Publication Date: 2007-09-05

杨根有

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, tractor counterweights (or counterweights) in various countries in the world have been using counterweights made of steel or cast iron materials for decades or hundreds of years. The counterweights generally have an unsightly appearance, especially cast iron counterweights are easily broken. A lot of steel materials are wasted, and there are defects such as high cost, easy to rust, and pollute the environment, which are not welcomed by customers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0019] 24 kg of waste polyethylene particles and 36 kg of powdered iron ore were evenly mixed in a mixer. Then use an extruder to extrude into strips at 150°C, then place the strips in a mold, press and mold them with a universal four-column hydraulic press, and obtain a plastic-steel counterweight after cooling.

[0020] Example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

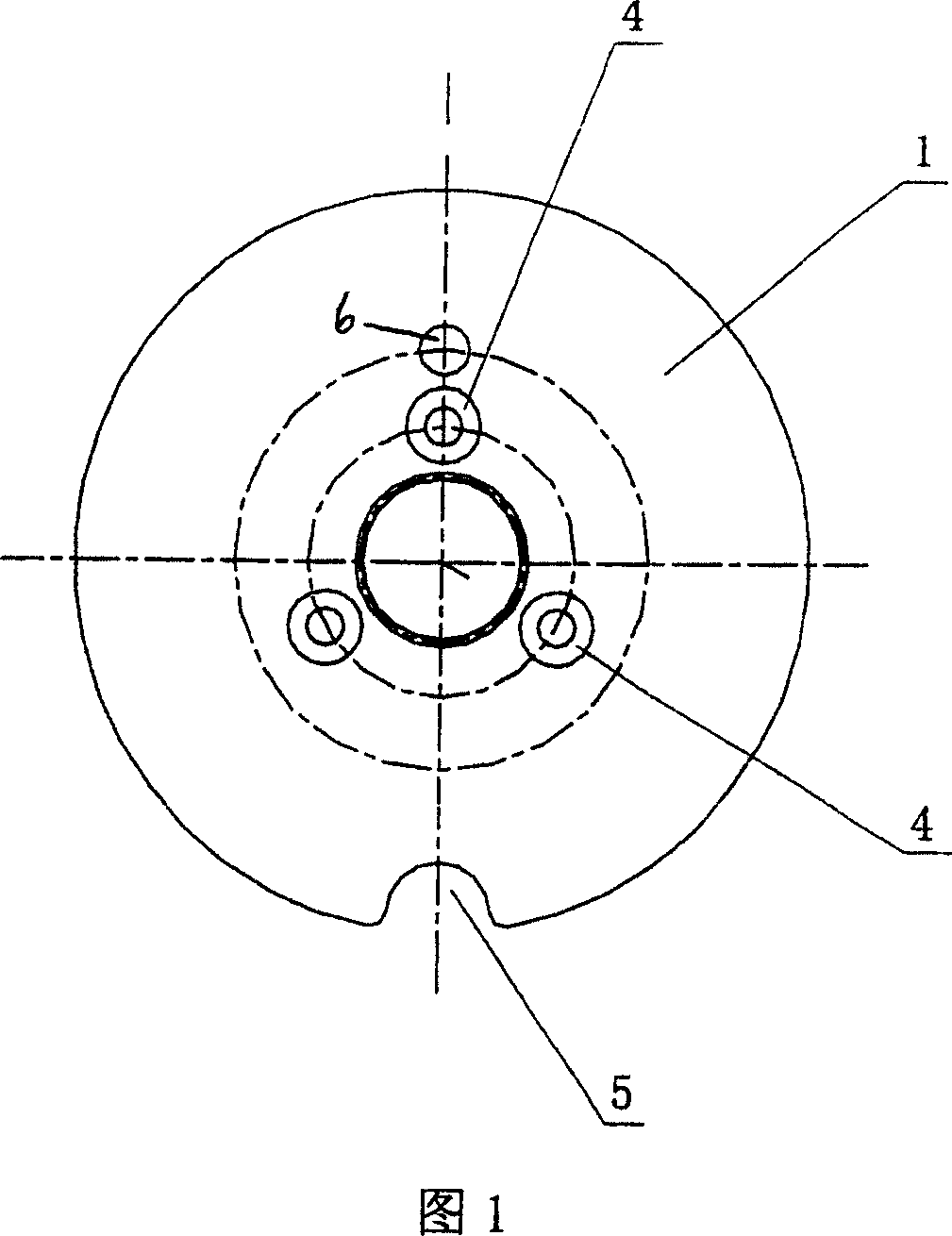

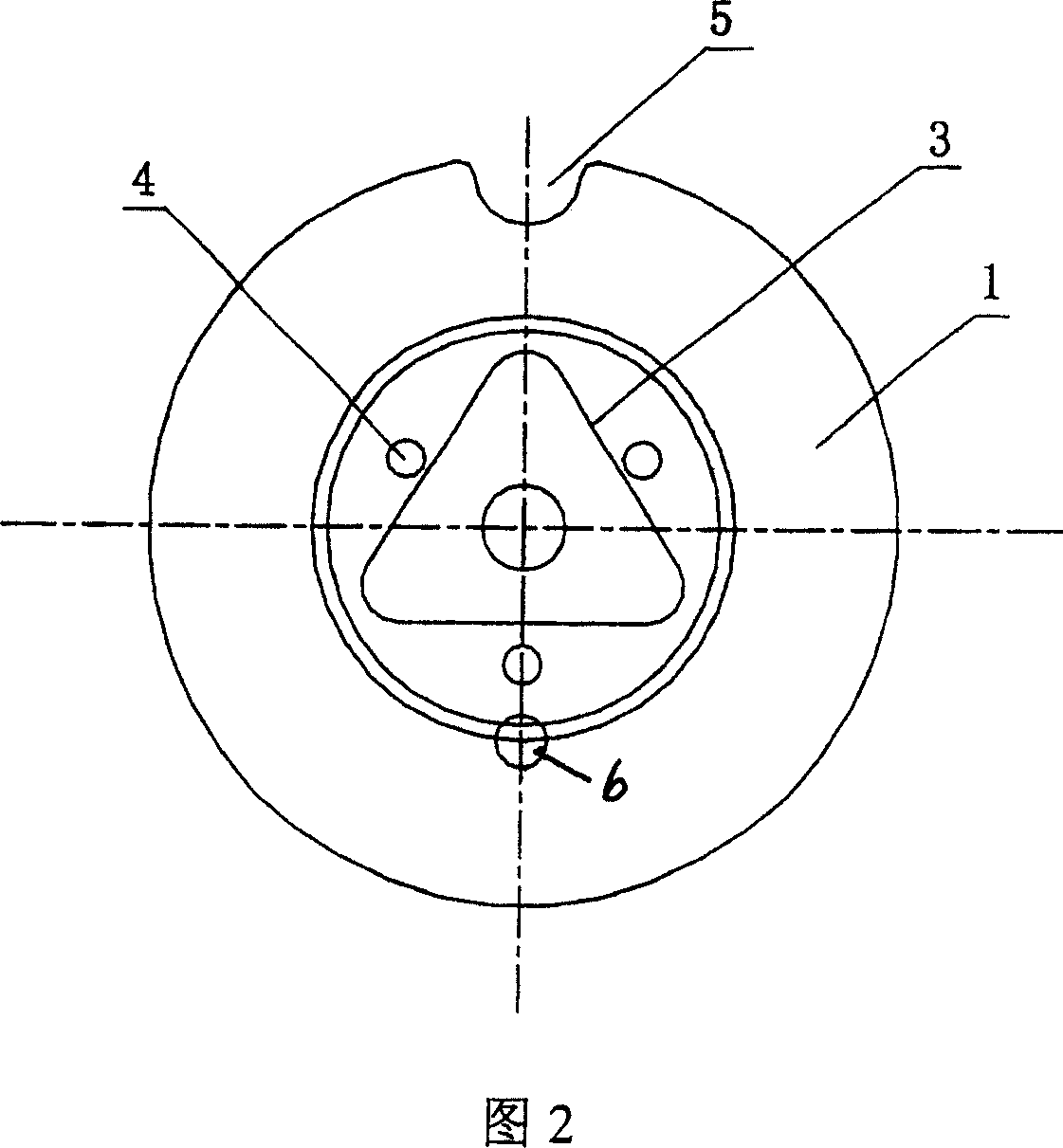

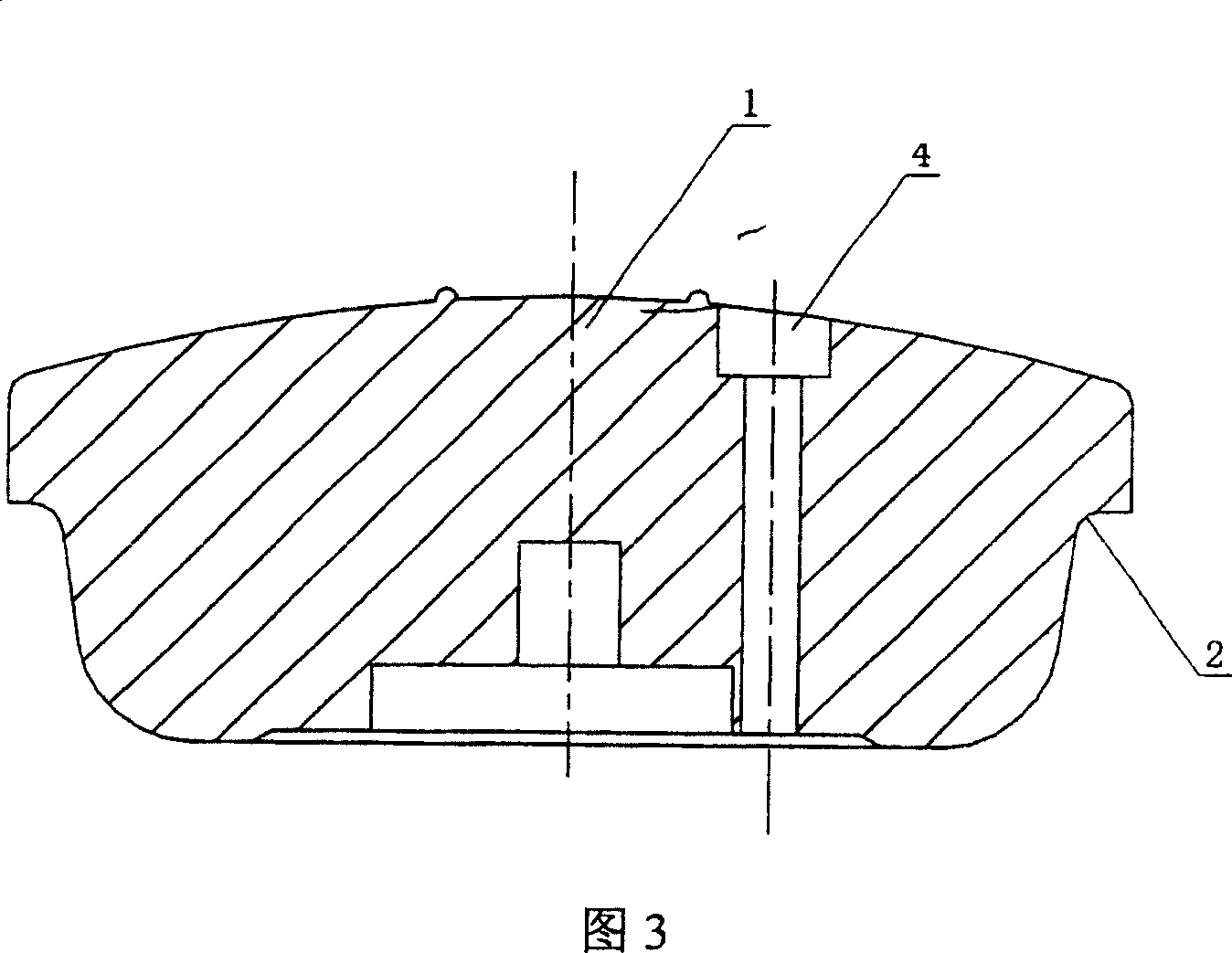

The present invention is novel plastic-steel balance weight and its making process. The plastic-steel balance weight has 160 mm thickness, right side shape like a snail, back side with equilateral triangle notch in the center, homogeneously distributed installing holes and inflating notch in the edge. The plastic-steel balance weight is made with plastic and heavy material and through hot pressing. The present invention has the advantages of simple making process, low production cost, high durance, no environmental pollution, etc.

Description

technical field [0001] The invention relates to the field of counterweights, in particular to a plastic-steel counterweight and a manufacturing method thereof. Background technique [0002] With the rapid development of industrial and agricultural economies around the world, especially the agricultural economy is moving towards intensification and mechanization. In my country, with the rapid development of the national economy, agricultural mechanization is developing rapidly. Various agricultural machinery, especially various types of tractors, such as small four-wheel tractors and large-wheel tractors, are widely used in China. [0003] At present, tractor counterweights (or counterweights) in various countries in the world have been using counterweights made of steel or cast iron materials for decades or hundreds of years. The counterweights generally have an unsightly appearance, especially cast iron counterweights are easily broken. A lot of steel materials are wasted,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B60B15/28

Inventor 杨根有

Owner 杨根有

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com