Cellulose red alga polysaccharide film coating premix and preparation method thereof

A red algae polysaccharide, film coating technology, applied in sugar-coated pills, pill delivery, pharmaceutical formulations and other directions, can solve the problems of surface wear, poor film strength, poor adhesion of finished products, etc. Choice, good appearance and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

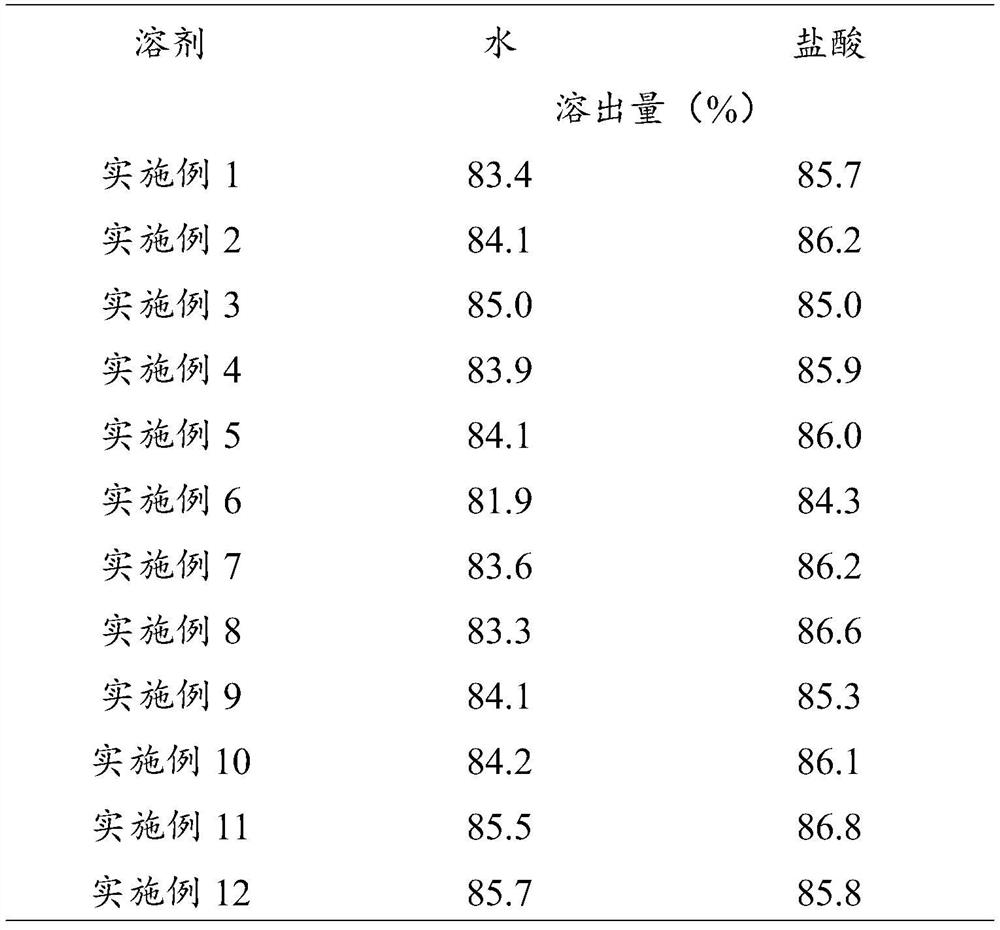

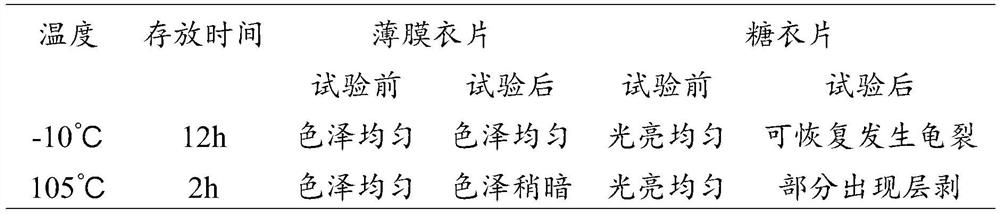

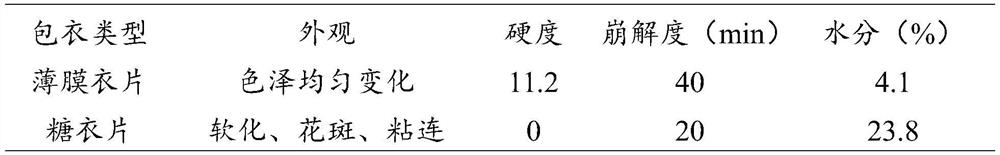

Examples

Embodiment 1

[0040] Weigh κ-carrageenan 0.4kg, iota-carrageenan 0.2kg, hypromellose 8.3kg.

[0041] The above-mentioned mixture by weight was mixed with a two-dimensional motion mixer for 25 minutes to prepare a film coating premix. Pour the mixed solution of ethanol and water with a mass ratio of 1:3 and the film coating premix into the liquid preparation tank, the quality of the mixed solution is 18 times that of the mixed raw materials. Raise the temperature to 85°C, add the premixing agent while stirring when the temperature is reached, and stir for 30 minutes, then cool down to 45°C, and stand at a constant temperature for 30 minutes; the stomach-soluble colorless transparent cellulose red algae polysaccharide film coating solution is obtained.

Embodiment 2

[0043] Weigh 1 kg of κ-carrageenan, 0.5 kg of iota-carrageenan, 2.5 kg of ethyl cellulose, and 6 kg of hypromellose.

[0044] The above-mentioned mixture by weight was mixed with a two-dimensional motion mixer for 35 minutes to prepare a film coating premix. Pour the mixed solution of ethanol and water with a mass ratio of 1:10 and the film coating premix into the liquid preparation tank, and the quality of the mixed solution is 24 times that of the mixed raw materials. Raise the temperature to 95°C, add the premixing agent while stirring when the temperature is reached, and stir for 30 minutes, then cool down to 55°C, and place at a constant temperature for 30 minutes; the stomach-soluble colorless transparent cellulose red algae polysaccharide film coating solution is obtained.

Embodiment 3

[0046] Weigh 0.8 kg of κ-carrageenan, 0.3 kg of iota-carrageenan, 1.6 kg of ethyl cellulose, 1.3 kg of sodium carboxymethyl cellulose, and 6 kg of hypromellose.

[0047] The above-mentioned mixture by weight was mixed with a two-dimensional motion mixer for 29 minutes to prepare a film coating premix. Pour the mixed solution of ethanol and water with a mass ratio of 1:10 and the film coating premix into the liquid preparation tank, and the quality of the mixed solution is 22 times that of the mixed raw materials. Raise the temperature to 83°C, add the premixing agent while stirring after reaching the temperature, and then cool down to 49°C after stirring for 20 minutes, and keep it at a constant temperature for 35 minutes; the stomach-soluble colorless transparent cellulose red algae polysaccharide film coating solution is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com