High-performance fabric and preparation method thereof

A high-performance, fabric technology, applied in textiles, fabrics, textiles, and papermaking, can solve problems such as waste of resources, complex structural design, and long production processes, and achieve energy saving and environmental protection in the production process, moisture absorption, sweat cooling, and production processes. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

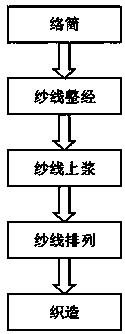

[0018] figure 1 It is a process step diagram of the preparation method of the high-performance fabric of the embodiment of the present invention; the fabric is woven from 32tex warp and weft yarns, and the warp and weft yarns are blended from hemp, organic cotton and jade fiber, and the preparation method includes the following steps : a) winding, b) yarn warping, c) yarn sizing, d) yarn alignment, e) weaving.

[0019] The high-performance fabric mentioned in the present invention uses 32tex hemp / organic cotton / jade fiber cold-touch blended yarn as warp and weft yarns, and is prepared by optimizing process parameters by adopting plain weave warp weaving. The blending ratio of the blended yarn selected for this high-performance fabric is: hemp 36%, organic cotton 42%, and jade fiber 22%. Among them, hemp fiber has the functions of comfort, natural anti-mold and antibacterial, anti-radiation, heat resistance, and natural anti-ultraviolet rays. Jade fiber is a new type of fiber...

Embodiment

[0021] The specific preparation method is as follows:

[0022] a) Winding, using Japanese Murata NO.21 C-S winding machine to wind the 32tex hemp / organic cotton / jade fiber blended yarn to form a yarn with a certain winding density and good shape for the subsequent process In order to solve the problems of hemp in blended yarns that are prone to friction and fluffing, poor cohesion, and jade fibers are prone to static electricity and hairiness, etc., the winding process parameters have been optimized. The winding process parameters are: tension scale 3.5, speed 960m / min, short thick places 145%×1.5cm, long thick places 50%×10cm, long thick places -50%×30cm.

[0023] b) Yarn warping, using Benninger ZC-L warping machine, according to the three uniform principles of winding density, piece yarn tension and piece yarn arrangement, the yarn after winding is processed according to the following warping process parameters Warping treatment: warping speed 810m / min, tension scale 3.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com