A device and method for laser drilling of annular heat shield

A laser drilling and heat shield technology, applied in auxiliary devices, laser welding equipment, auxiliary welding equipment and other directions, can solve the problems of difficult parts clamping, affecting the processing progress of parts, and difficult clamping, etc., to achieve easy clamping and The effect of cutting, improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

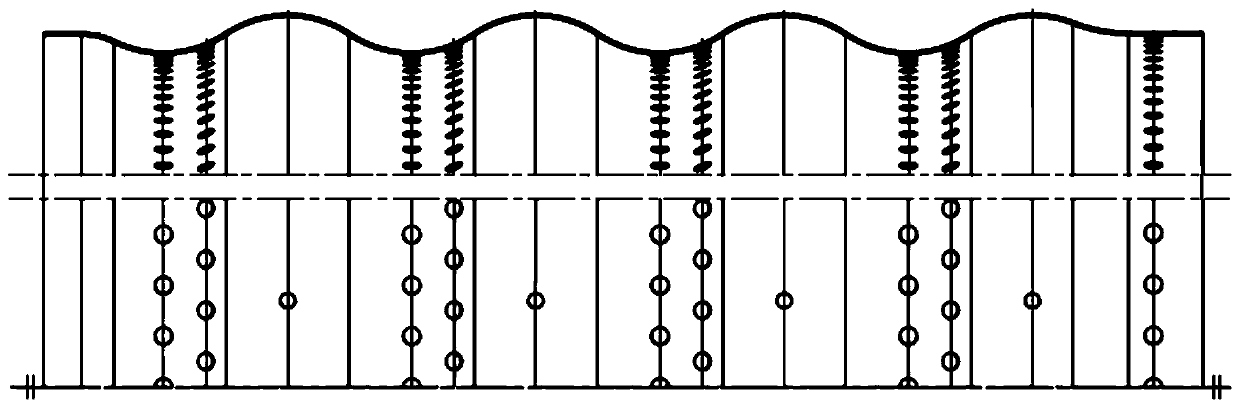

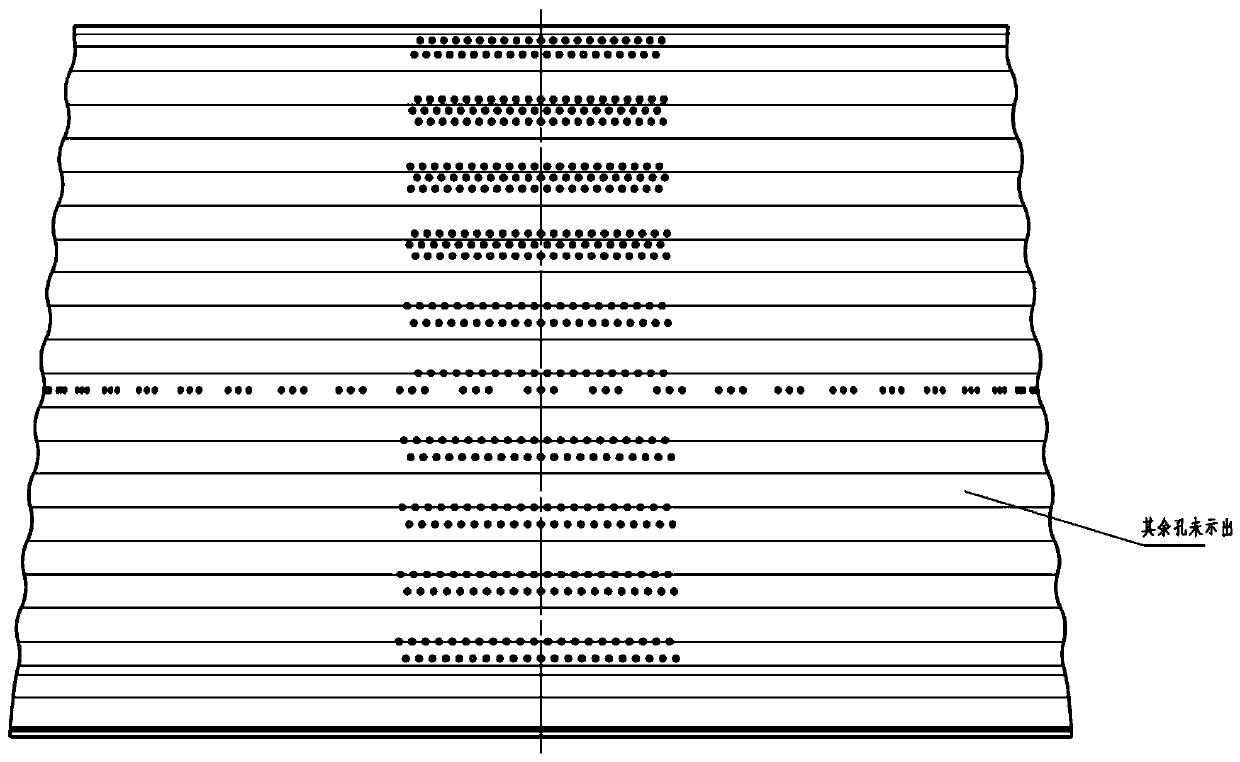

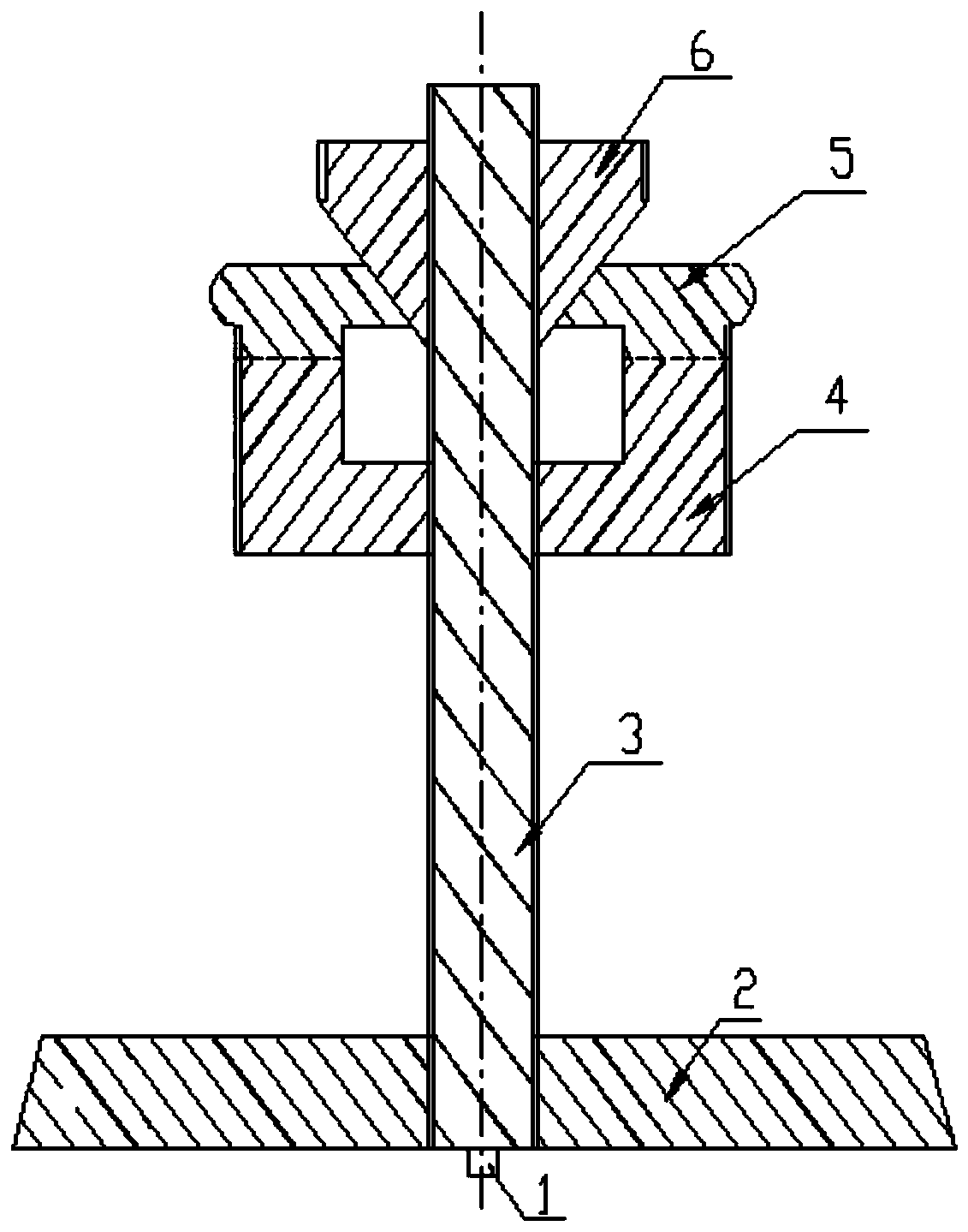

[0028] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0029] Such as Figure 3-6 As shown, the present invention includes a screw rod 3 with automatic alignment and centering effect on the laser drilling machine operating platform. The material used for the screw rod 3 is stainless steel, and its outer surface is threaded throughout. The height of the expansion disc 5 is suitable for the processing of parts with different heights; the bottom of the screw 3 is drilled with a threaded hole matching the positioning pin 1, and the function is to make the axis center of the threaded rod 3 coincide with the center of the console by connecting the positioning pin 1 to realize automatic Correction function;

[0030] It has a stabilizing plate 2 for stabilizing the screw 3 on the laser drilling machine operating platform. The material of the stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com