Connection structure for ball valve handle

A connection structure and handle technology, which is applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of loose nut, low mechanical strength, and handle falling off, etc., and achieve simple connection structure and long service life , the effect of not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

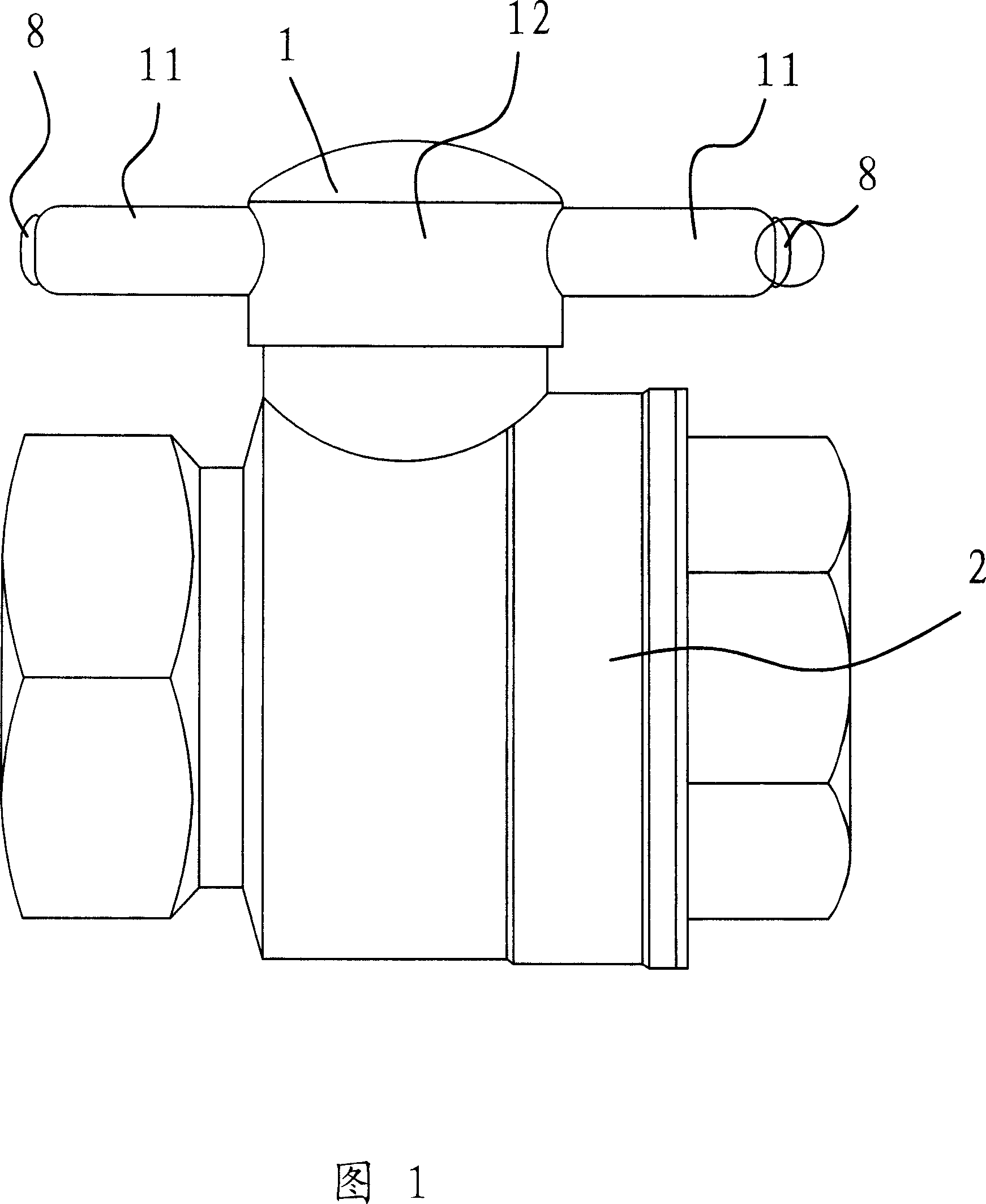

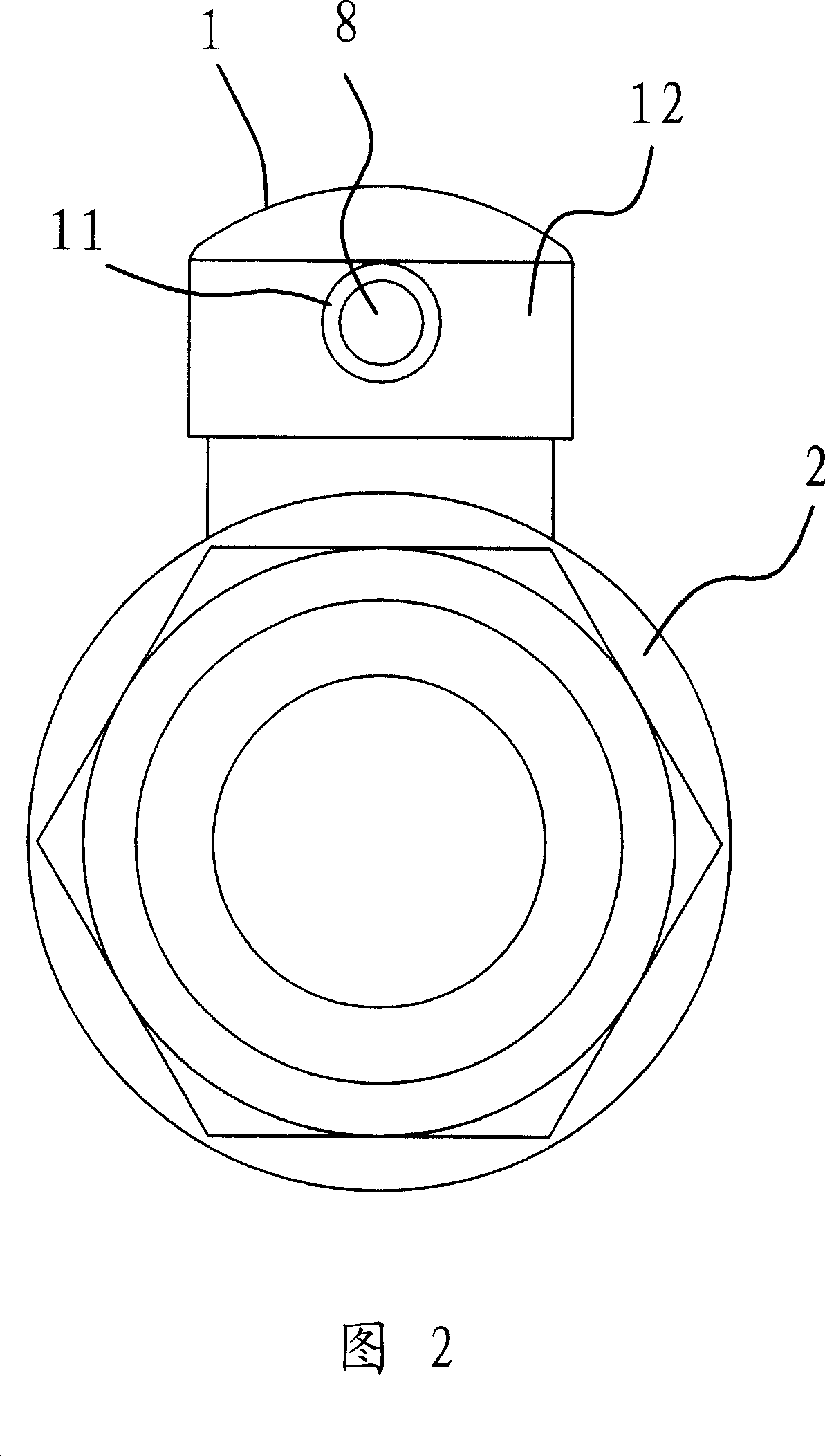

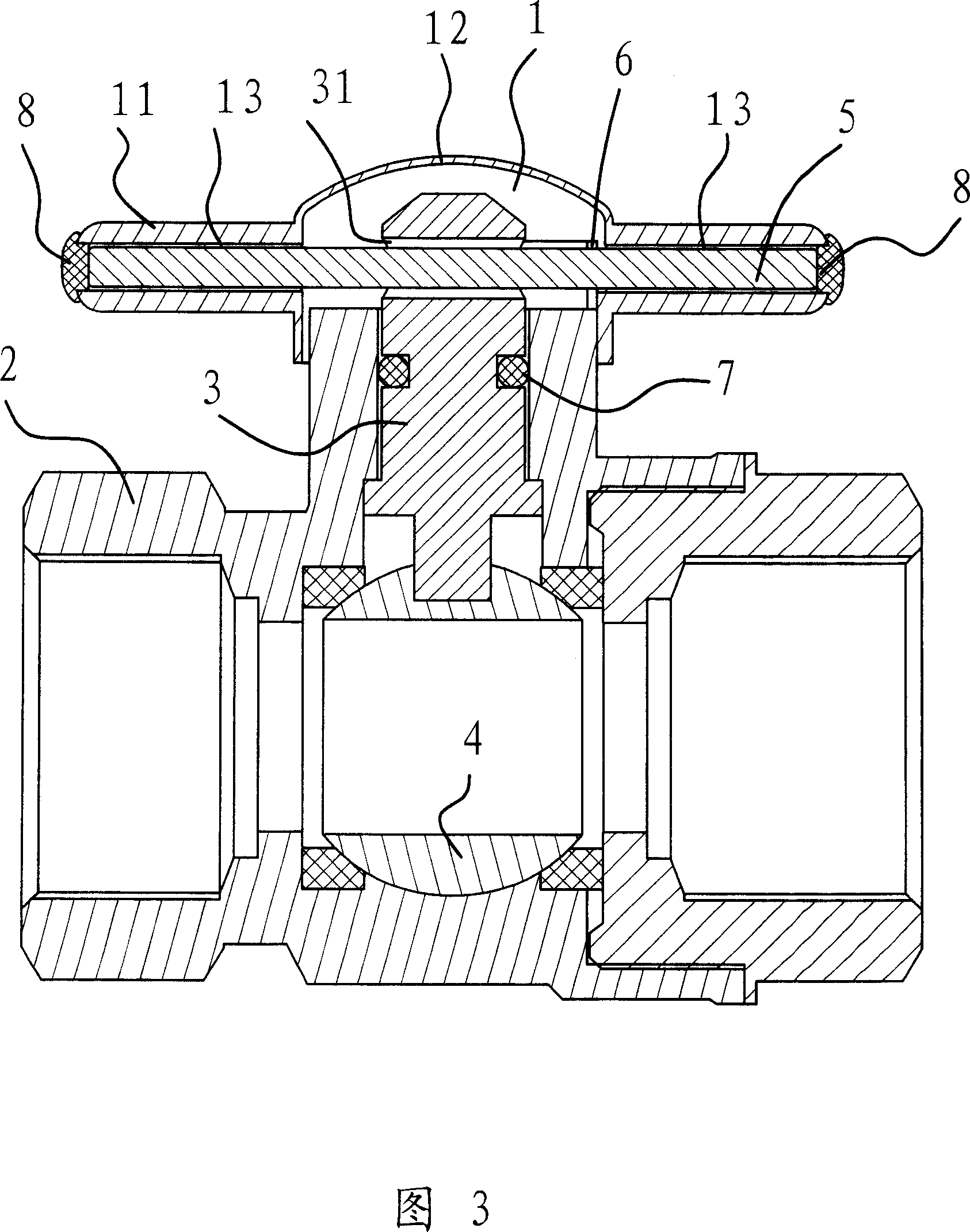

[0020] As shown in FIGS. 1 to 5 , the ball valve with the handle connection structure includes a valve body 2 , a valve core 4 , a valve stem 3 , a pin shaft 5 and a handle 1 . The handle 1 is mounted on the outside of the valve body 2 and connected with the valve stem 3 . A sealing ring 7 for sealing is provided between the valve body 2 and the valve stem 3 .

[0021] As shown in Figure 1, in the connecting structure of the ball valve handle, the handle 1 is composed of a handle body 12 and a handle 11, wherein the handle body 12 is cylindrical, and the handle 11 is bar-shaped. In this embodiment, there are two handles 11 in the handle 1 , which are respectively located on two sides of the handle body 12 . This structure is convenient to turn the handle 1.

[0022] As shown in FIG. 3 , the handle body 12 is connected with the handle 11 as a whole and formed at one time. The handle 1 of the present invention can be made of plastics, and can also be made of metal materials. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com