Automatic take-up tensioner

A tensioner, an automatic technology, applied in the direction of the wire tensioning appliance, the parts of the bundling machine, the manufacturing tools, etc., can solve the problems affecting the normal use of the tensioner and the jamming of the brake baffle, and achieves a simple structure, Low cost, compact structure and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

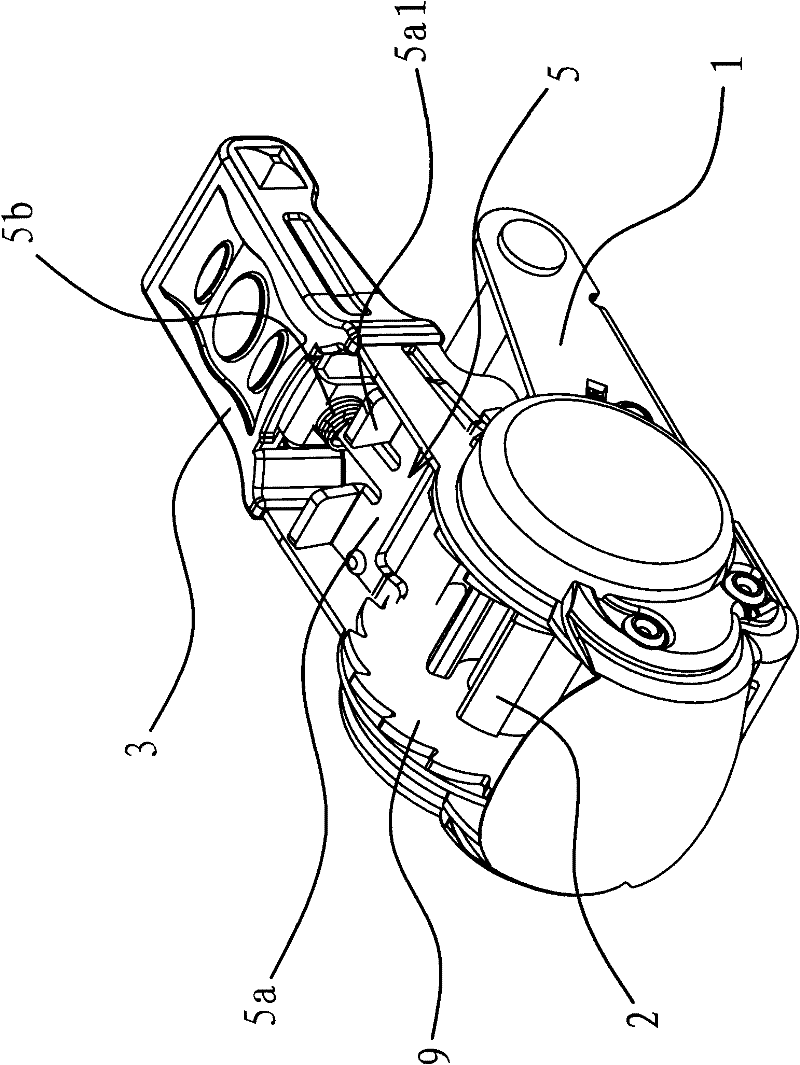

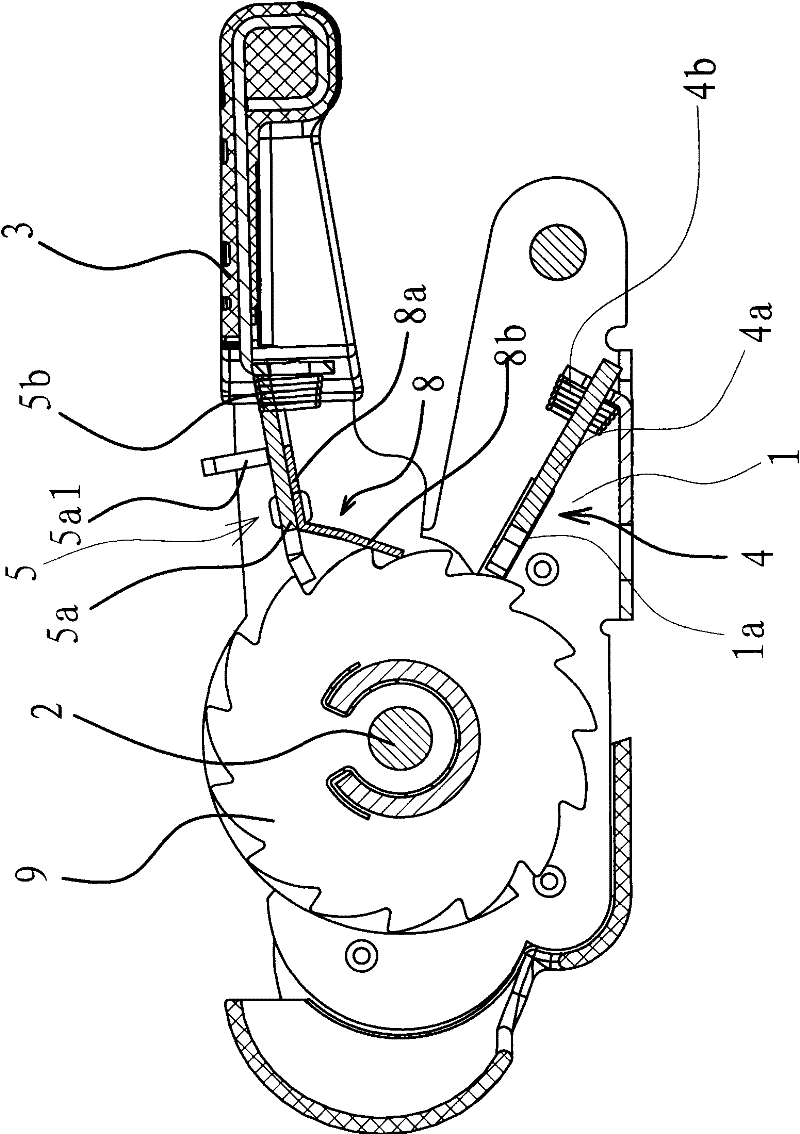

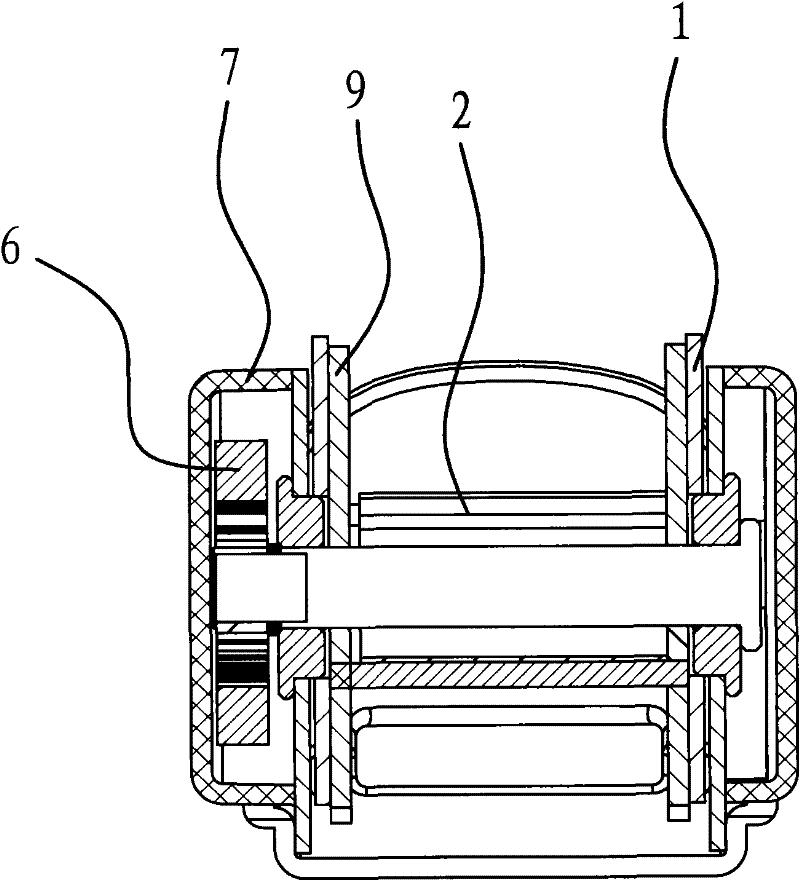

[0031] like figure 1 and figure 2 As shown, this automatic take-up tensioner is made up of belt shaft 2, support 1, handle 3, blocking assembly one 4, blocking assembly two 5 and scroll spring 6 etc., and it is a kind of device for binding goods.

[0032] The handle 3 is hinged on the bracket 1 through the belt shaft 2 , that is to say, the two ends of the belt shaft 2 are respectively connected to both sides of the bracket 1 , and the belt shaft 2 can rotate relative to its joint with the bracket 1 . On the belt shaft 2, a binding belt for binding goods is also wound.

[0033] A blocking component 1 4 capable of abutting against the ratchet 9 is provided on the bracket 1 , and a blocking component 2 5 capable of abutting against the ratchet 9 is provided on the handle 3 . Blocking assembly one 4 comprises blocking piece one 4a, spring one 4b and the guide hole one 1a that is arranged on the bracket and is bar-shaped, and blocking piece one 4a is positioned at guide hole on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com