Combined truss node structure, bridge and construction method

A technology of combining trusses and nodes, applied in truss bridges, erecting/assembling bridges, bridges, etc., can solve problems such as affecting economic effects, driving up construction costs, and easy damage to junction plates, ensuring connection stability and reducing construction difficulty. , the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

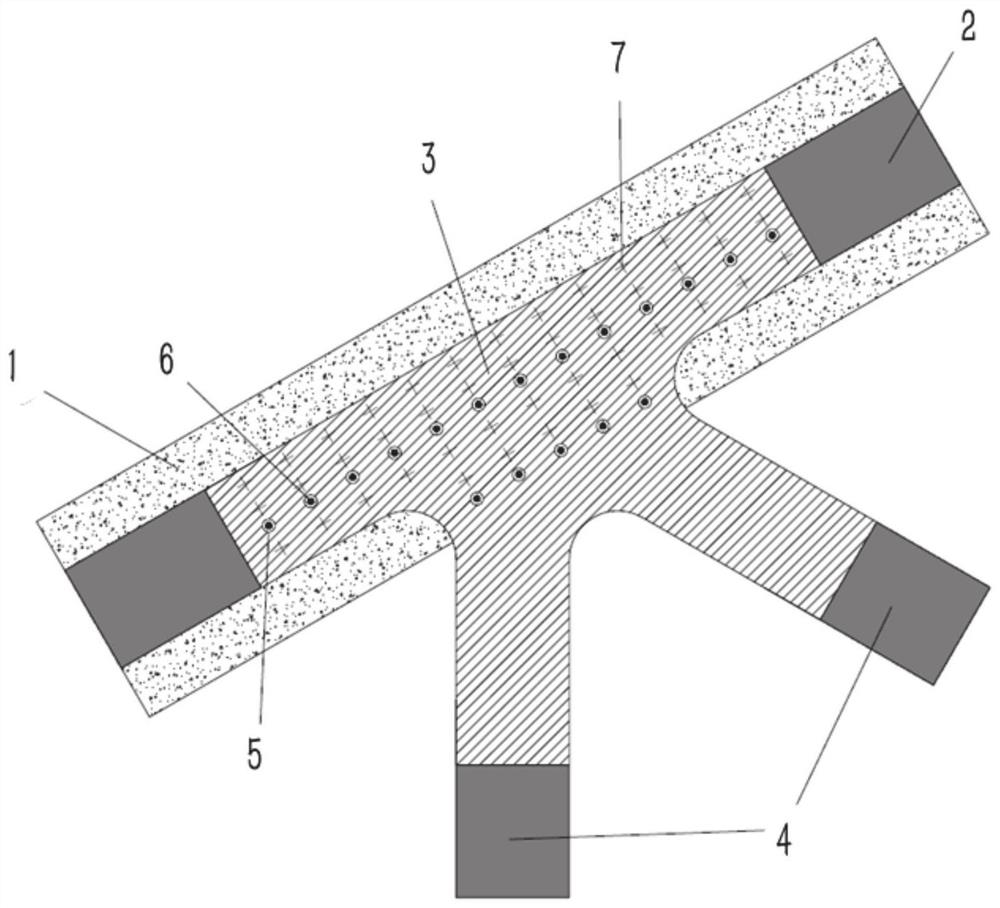

[0033] In a typical embodiment of the present disclosure, such as Figure 1-Figure 3 As shown, a composite truss node structure is given.

[0034] Aiming at the problem that the combined node position of the steel web member 4 and the concrete inner chord is easily damaged at the current node position, a composite truss node structure is provided, and the node structure of the prefabricated steel truss web-concrete composite truss structure is optimally designed to strengthen the Joint strength and stiffness, reducing the arrangement of shear keys in joint construction, and thus reducing construction costs and construction difficulties.

[0035] Specifically, the arrangement of shear keys in the node structure is reduced through the integrated node 3, the chord on the node 3 is connected to the external steel chord 2, the web on the node 3 is connected to the external steel web 4, and the integrated node 3 is buried A solid connection is formed in the concrete to meet the str...

Embodiment 2

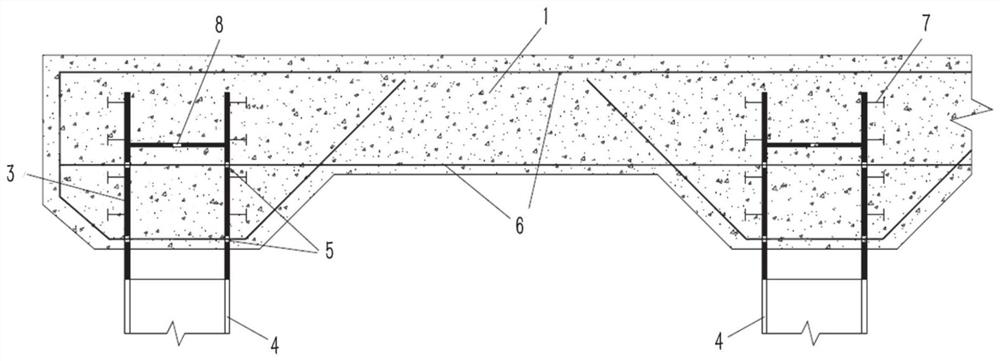

[0061] In another embodiment of the present disclosure, as Figure 1-Figure 3 As shown, a bridge is given, which is constructed using a composite truss node as described in Example 1.

[0062] The composite truss node structure is used for the node position of the prefabricated assembled steel truss web-concrete composite truss structure, and the node 3 is embedded in the concrete slab 1 of the bridge as a whole, so as to solve the problems of concrete vertical cracking and node damage, and reduce the 4 The workload of connection processing with concrete chord nodes.

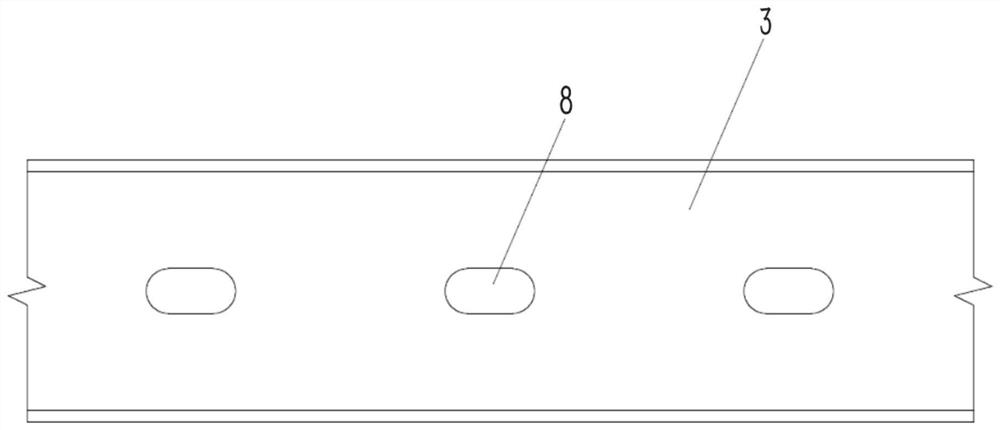

[0063] The node 3 is prefabricated in the factory, and the shear nail 7 is applied in advance, the first through hole 5 is opened as the first steel bar 6 through the hole, and the second through hole 8 is used as the concrete pouring hole; the concrete slab 1 of the bridge is used as the concrete layer of the node 3 , a plurality of nodes 3 are embedded in the concrete slab 1, and steel chords 2 arranged throu...

Embodiment 3

[0068] In yet another embodiment of the present disclosure, as Figure 1-Figure 3 As shown, a construction method of composite truss joints is given.

[0069] Include the following steps:

[0070] Install shear studs 7 on the integrated node 3 including the chord and the web, and open the first through hole 5 and the second through hole 8 on the node 3 along the direction perpendicular to the chord;

[0071] Connecting the node 3 to the external bridge structure, penetrating the first steel bar 6 in the first through hole 5, the first steel bar 6 is connected to the steel bar skeleton structure of the external bridge;

[0072] The concrete layer is coated circumferentially on the chord, so that the shear nails 7 and the first steel bar 6 are embedded in the concrete layer, and the second through hole 8 is filled in the concrete layer.

[0073] Specifically, in this embodiment, with reference to Embodiment 1, the above construction method is described in detail. Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com