Tow cutter

A cutter and tow technology, which is applied in the direction of fiber bundle to fiber sliver/yarn, etc., can solve the problems of clamping knife and tow not being able to cut 100% to achieve quality assurance, scientific and reasonable cutting edge curve, and highlight substantive features Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

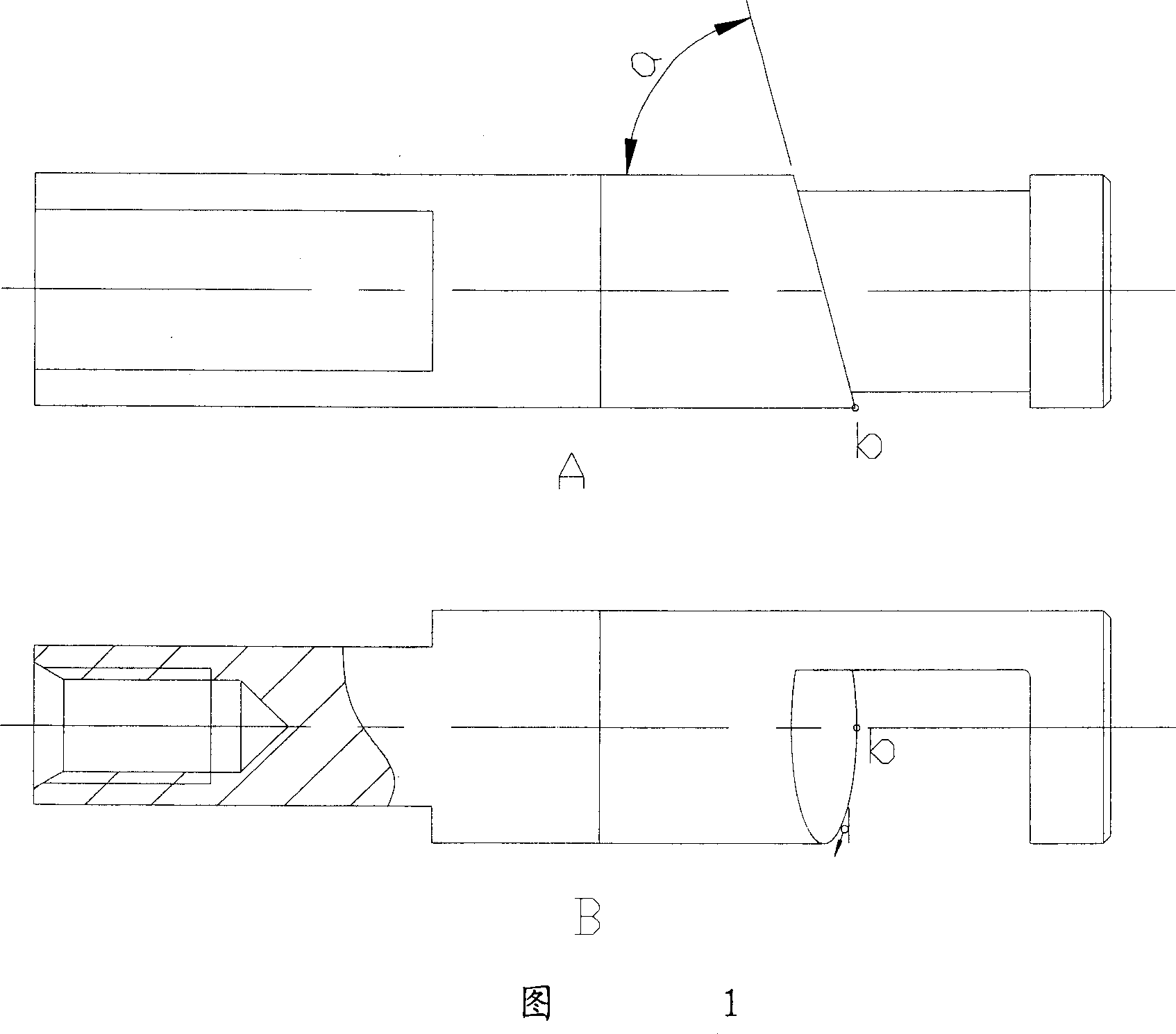

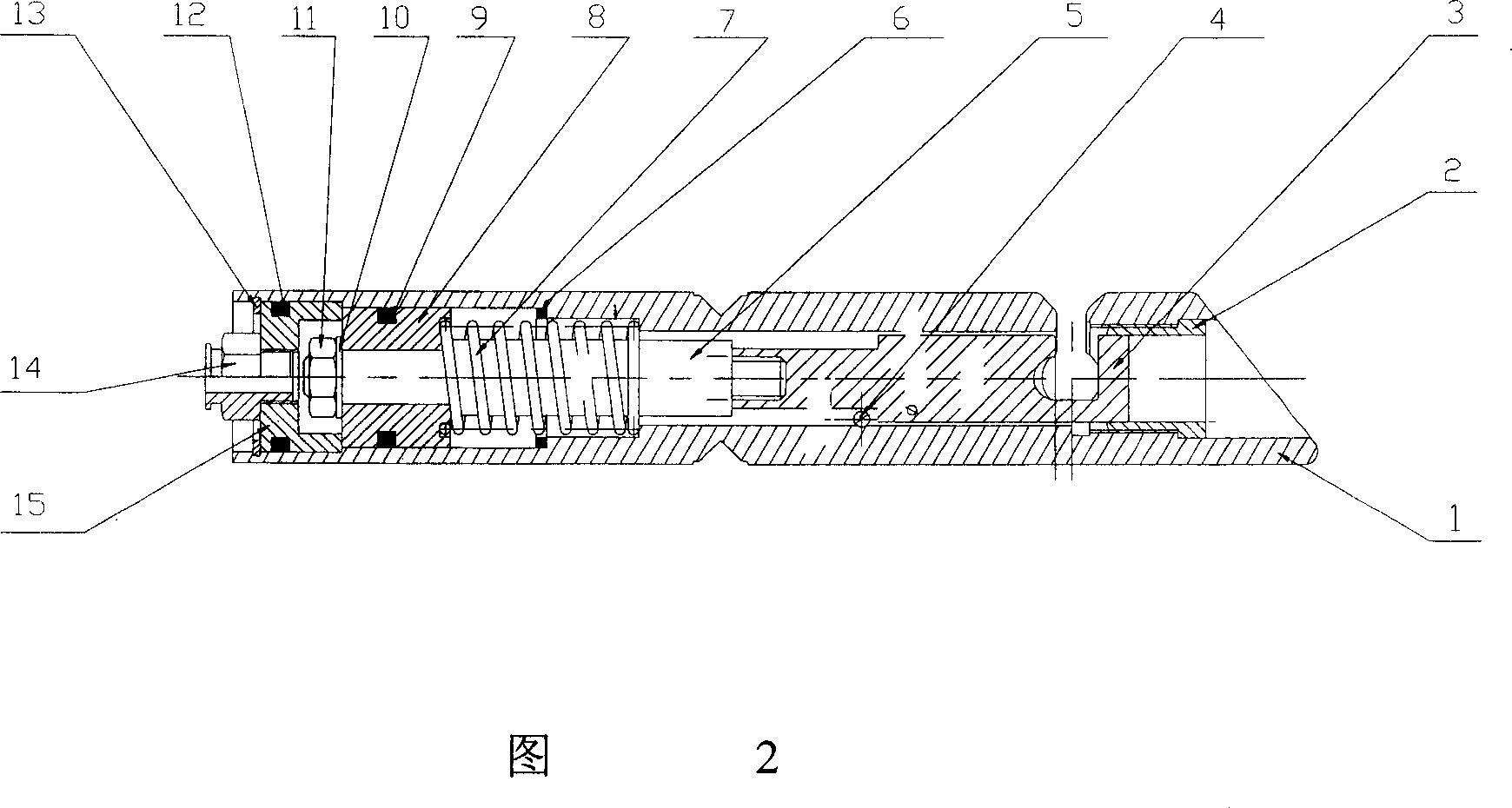

[0014] The tow cutter of this embodiment is shown in FIG. 1 , and a ring knife 2 is press-fitted and fixed in the stepped hole at the front end of the tubular housing 1 . The rear end of the shaft-shaped knife 3 is fixedly connected with the cylinder shaft 5 through threaded connection, and is installed in the housing by sliding fit. The cylinder shaft 5 rear end is a spring 7, a piston 8, a joint 14, and a rear plug 15 forming a cylinder assembly with it. All the other parts 6 are gaskets, 9 are O-rings, 10 gaskets, 11 are nuts, 12 are O-rings, and 13 are inner retaining rings, which play sealing and fastening connections respectively. Since the structure of the cylinder assembly is the same as the known technology, it will not be described in detail.

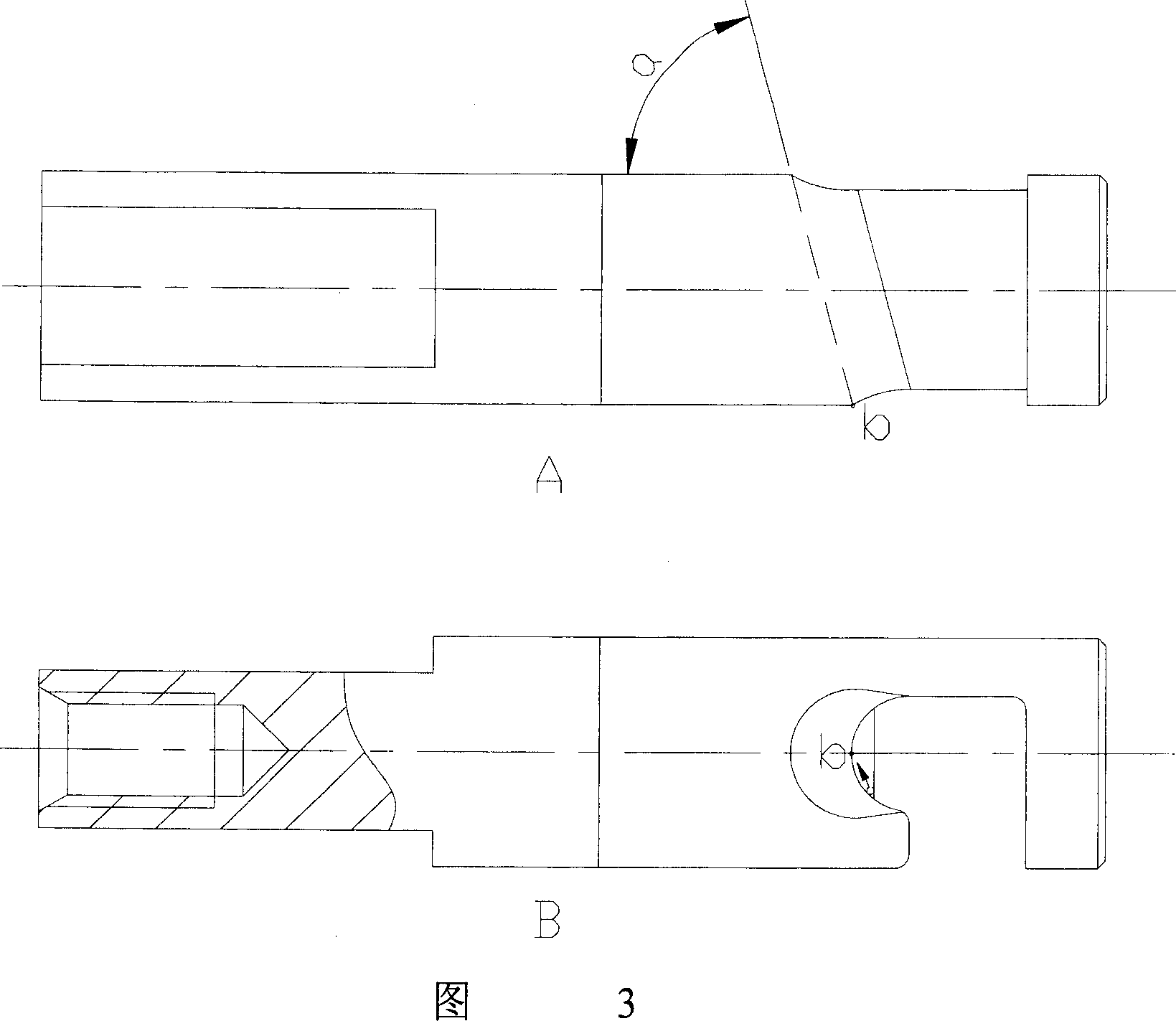

[0015] The concrete structure of shaft-shaped cutter 3 is as shown in Figure 3, and the front end is shaped on breach, and the cutting edge of shaft-shaped cutter is formed by the inner concave conical surface of acute angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com