High branch pruning device for garden

A pruning device and high branch technology, applied in the field of high branch pruning devices for gardens, can solve the problems of labor, shortening the continuous working time of pruning personnel, and increasing the cleaning workload of pruning personnel, so as to increase the workload, ensure smoothness, and speed up cutting. The effect of the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

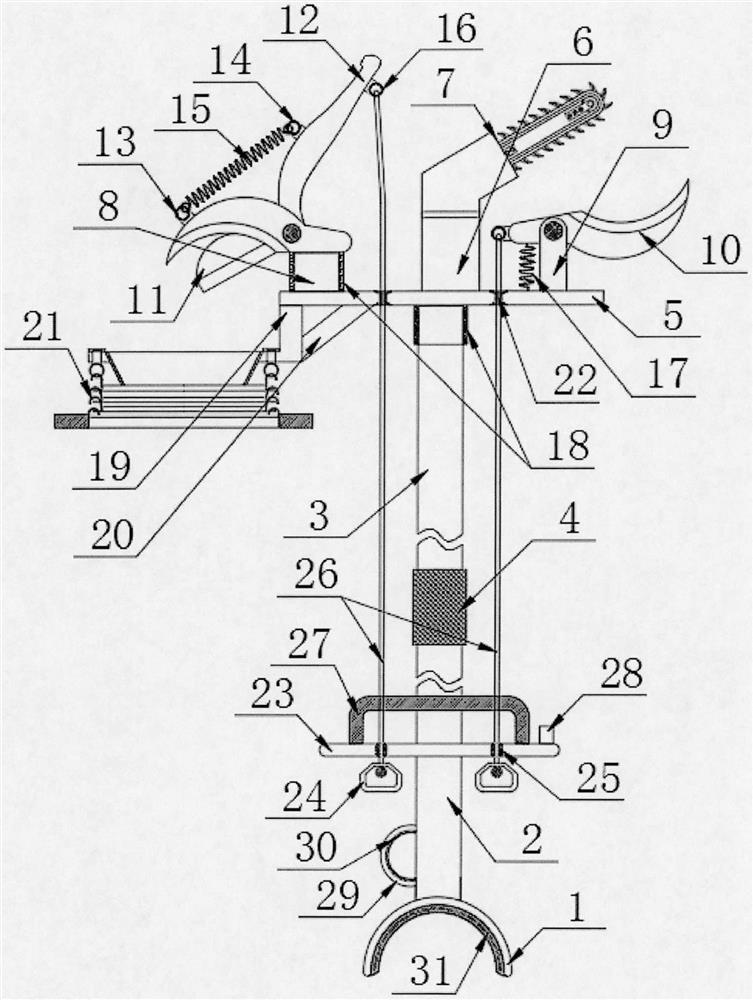

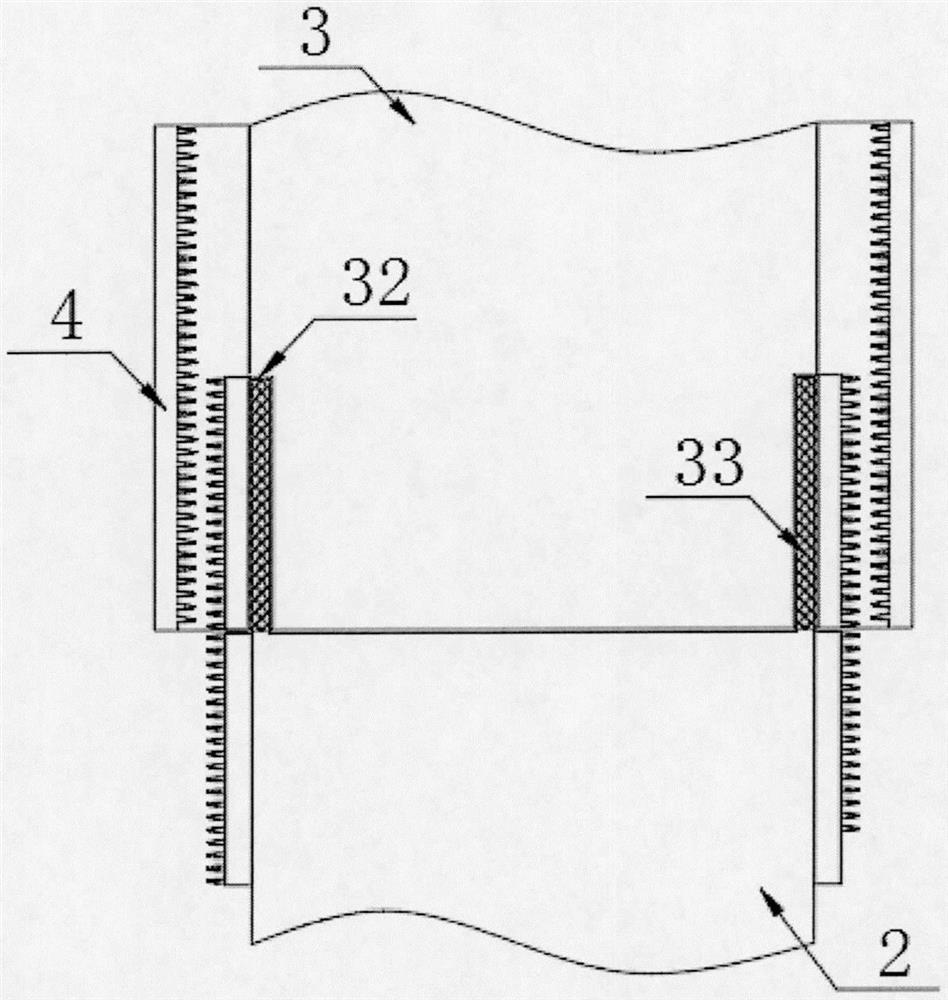

[0031] The present invention provides such Figure 1-6The high-branch pruning device shown in the garden comprises a base 1, a first pole 2 is arranged on the top of the base 1, a second pole 3 is arranged on the top of the first pole 2, and a second pole 3 is arranged on the top of the first pole 2. A connecting sleeve 4 is provided at the joint between the pole 2 and the second pole 3, a top plate 5 is provided on the top of the second pole 3, a power supply 6 is provided at the top middle of the top plate 5, and a power supply 6 is provided at the top of the power supply 6 There is a sawing mechanism 7, a first column 8 is provided on one side of the power supply 6 and a second column 9 is provided on the other side, and a first cutter 10 is provided on the top of the first column 8 and the second column 9 , the bottom of the first cutter 10 at the top of the first column 8 is equipped with a second cutter 11, and one end of the second cutter 11 is fixedly connected with a ...

Embodiment 2

[0038] Further, in the above technical solution, a reinforcing rod 20 is inclined between the connecting rod 19 and the top plate 5, so that a triangular frame is formed between the connecting rod 19, the reinforcing rod 20 and the top plate 5, thereby greatly improving the material guiding mechanism. 21 Stability during use.

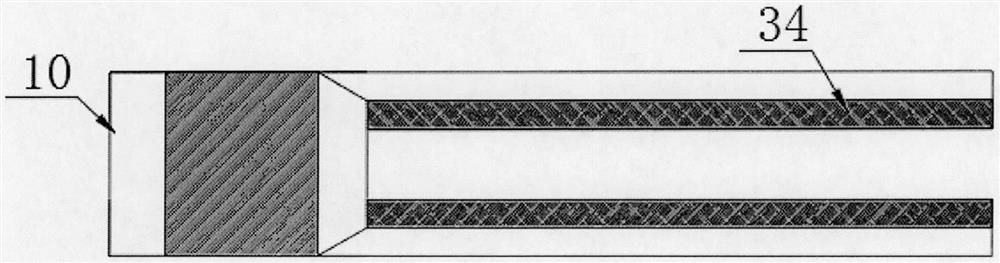

[0039] Further, in the above technical solution, the first cutter 10 is provided with a cutter head 34, the number of the cutter head 34 is provided with two, and the two cutter heads 34 are in the shape of the central axis of the first cutter 10. Axisymmetrically arranged, the distance between the two cutter heads 34 is equal to the maximum distance between the two transmission chains 77, on the one hand, it can ensure that the branches are cut off completely, and on the other hand, it can ensure the smoothness of the branch incision. The projection shape of the head 34 in the main viewing direction is arc-shaped, and the branches to be pruned can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com