Discontinuous carbon fiber cutting device capable of obtaining fibers with different lengths

A cutting device and discontinuous technology, applied in the field of fiber processing, can solve the problem of difficult integration of different parts, and achieve the effect of easy cutting and short fiber length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

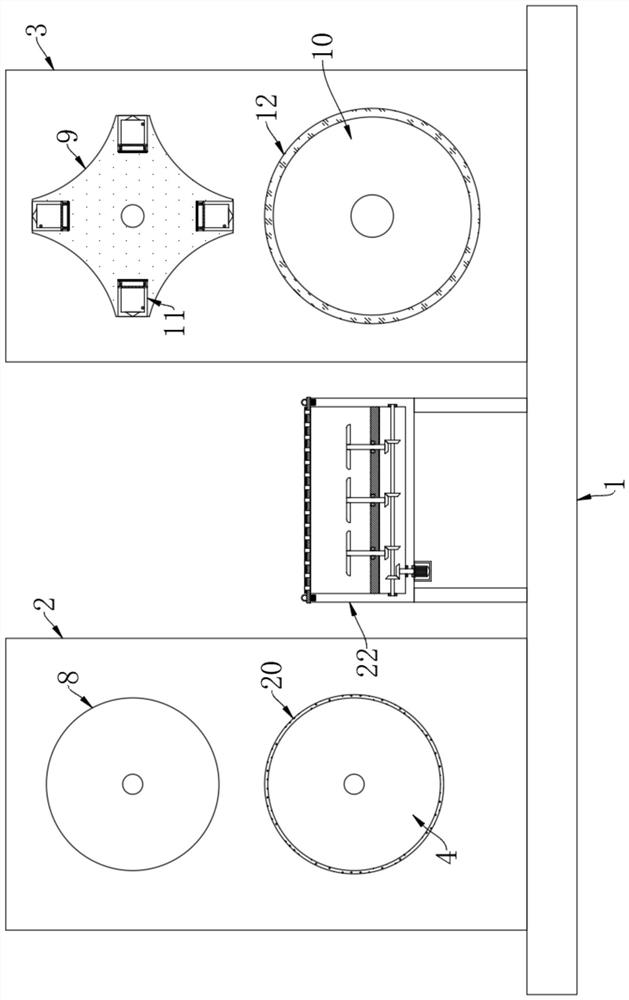

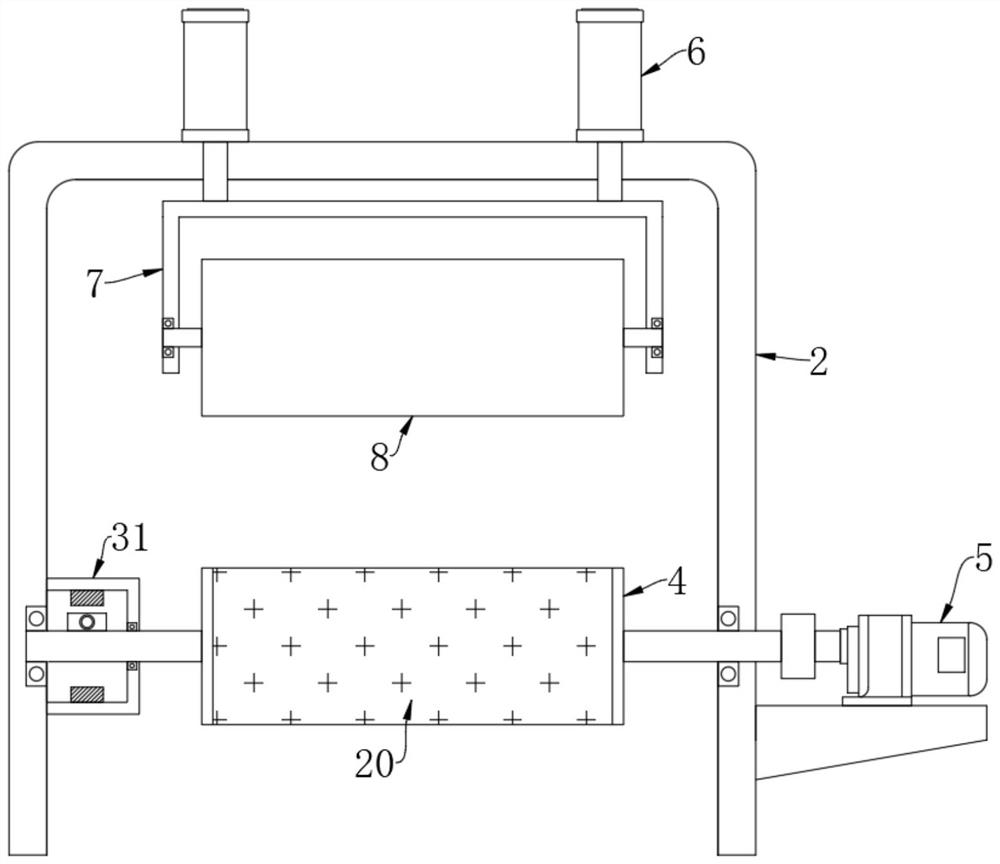

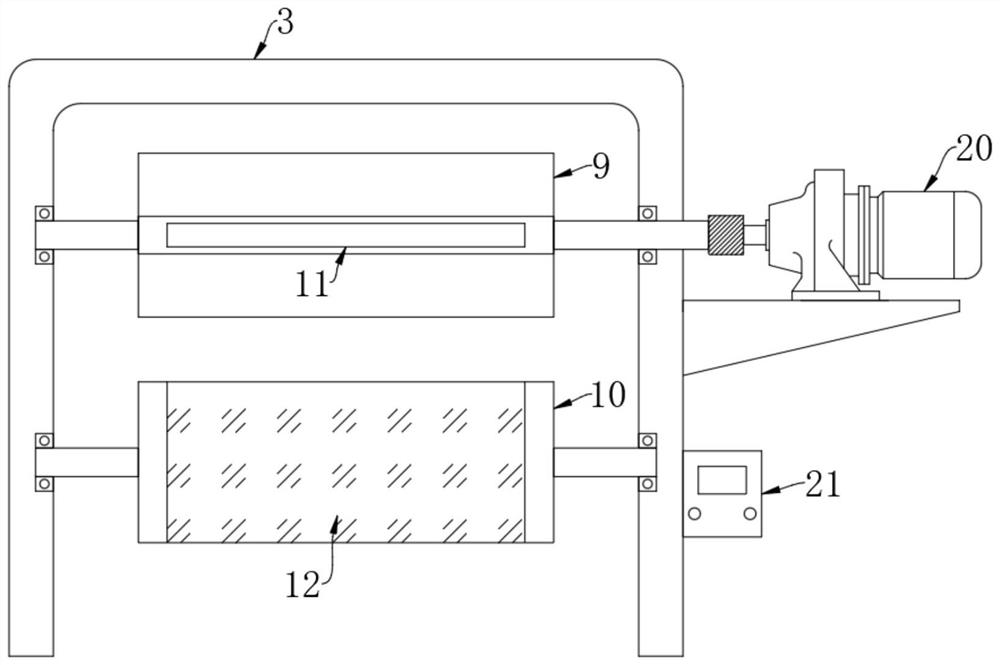

[0026] Such as Figure 1-8 As shown, a discontinuous carbon fiber cutting device that can obtain fibers of different lengths includes a base 1, a first frame 2 and a second frame 3 are fixedly connected to the base 1, and a feed roller 4 is rotatably connected to the first frame 2, And the transmission shaft transmission connection of the feed roller 4 is connected with the first servo motor 5, and the first frame 2 is fixedly provided with two cylinders 6, and the output ends of the two cylinders 6 are fixedly connected with the support base 7 together, on the support base 7 There is a pressure roller 8 matched with the feed roller 4 in rotation connection, and the pressure roller 8 can be adjusted to lift through the set cylinder 6, so that the pressure roller 8 can cooperate with the feed roller 4 to carry out fiber yarns of different thicknesses. Cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com