Delivery , clamping, welding and cutting device and method for adult incontinence pants

A technology for adult incontinence trousers and a cutting device, which is applied to clothing, underwear, baby underwear, etc., can solve the problems of inability to use adult incontinence trousers for production, inability to weld adult incontinence trousers, and inability to use finished adult incontinence trousers to cut off, etc. gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

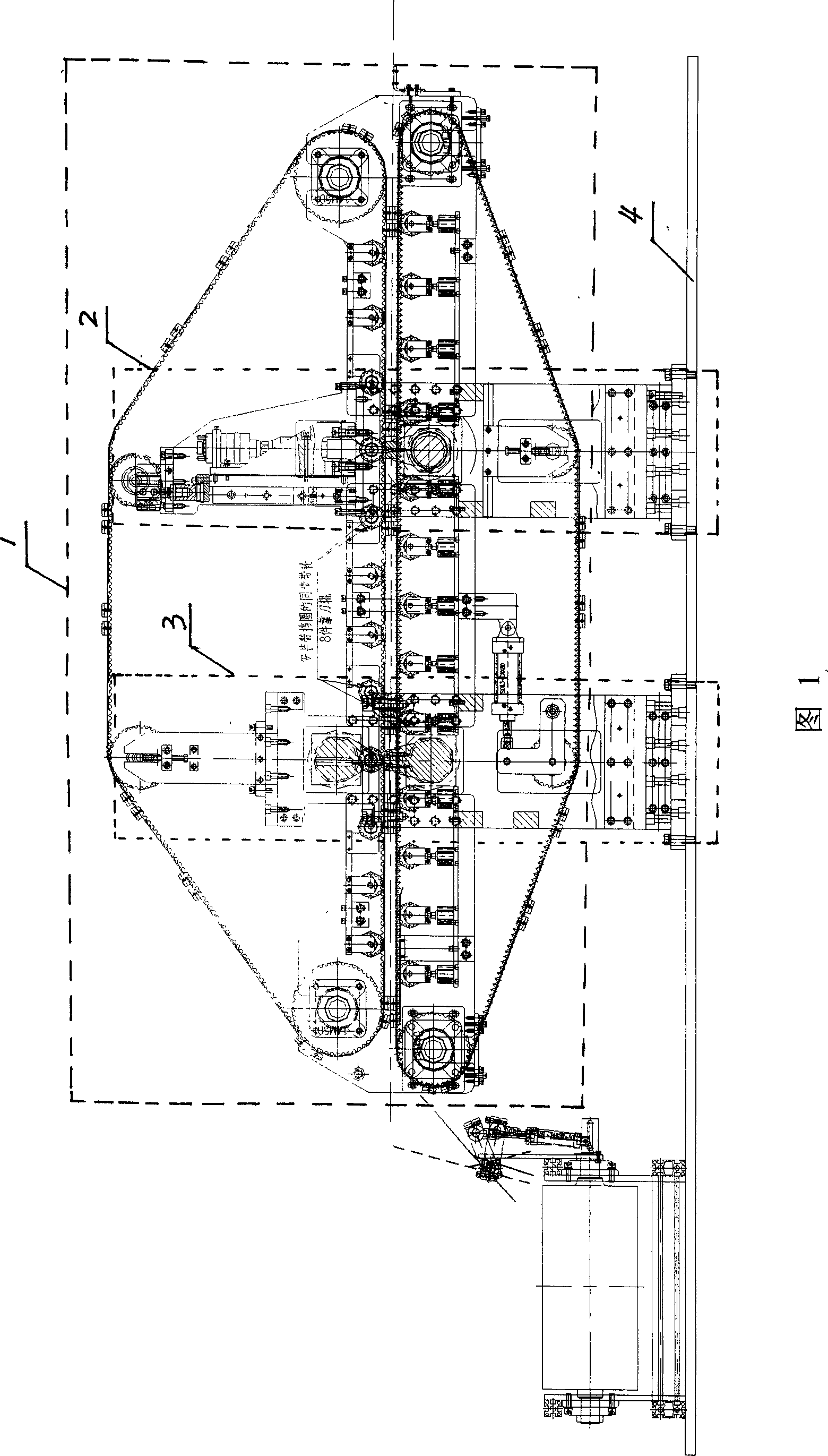

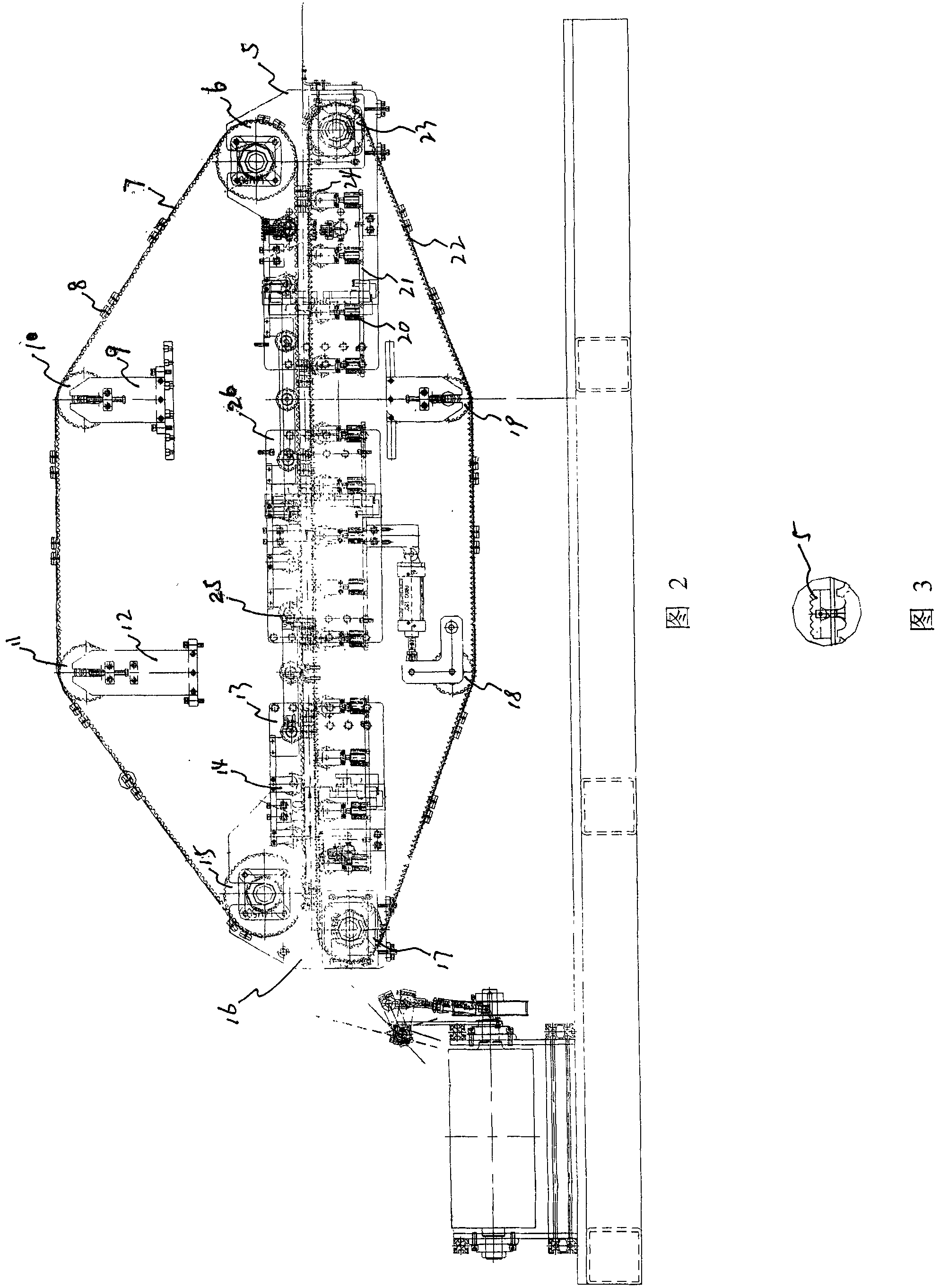

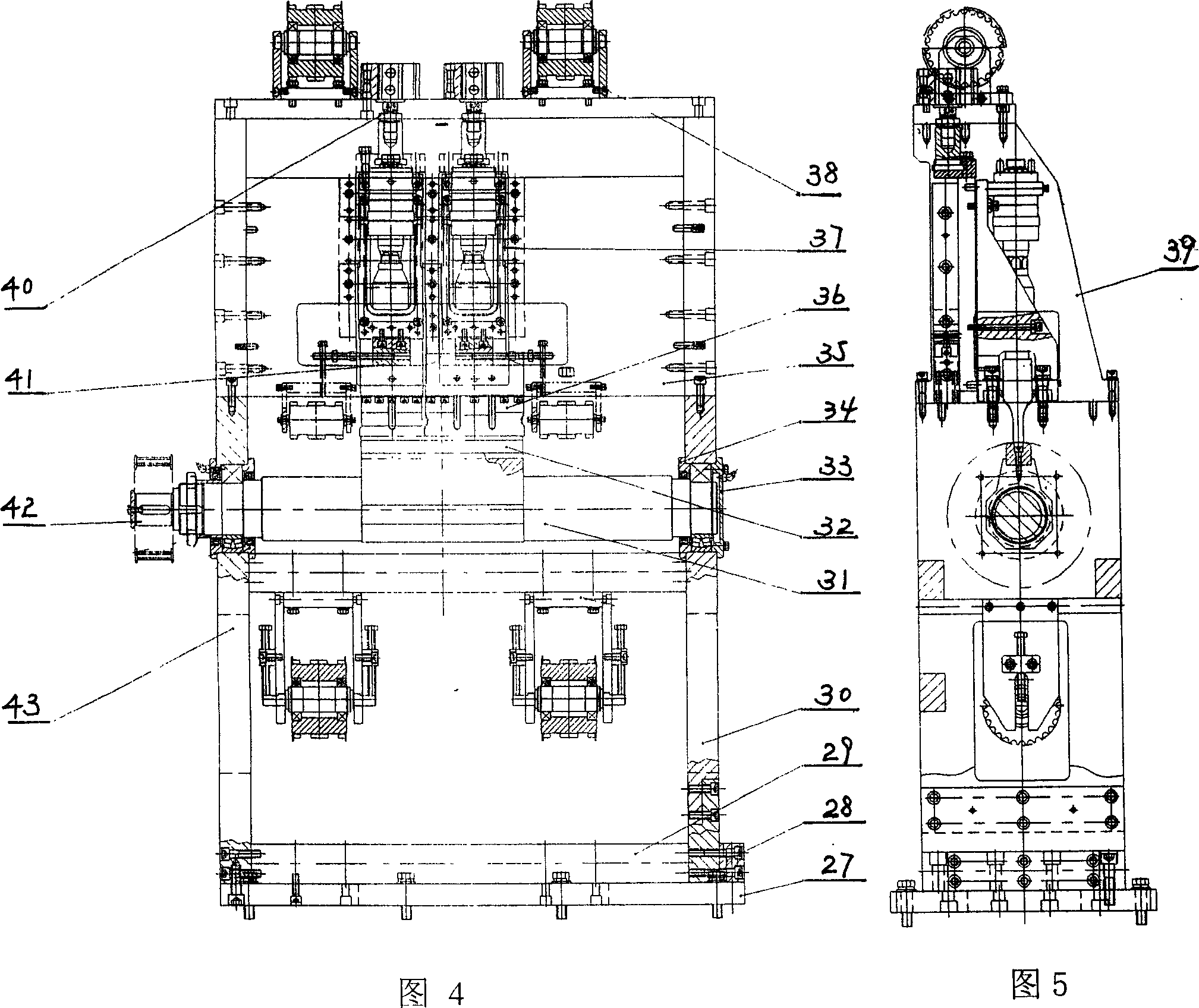

[0034] Embodiment 1: with reference to attached Figure 1-7 . Adult incontinence pants conveying, clamping, welding and cutting device, which includes a base 4, which is composed of a conveying and clamping device 1, an ultrasonic welding device 2 and a finished product cutting device 3, and the ultrasonic welding device 2 and the cutting device 3 are located on the base 4 one after the other. Above, the conveying belt 7 of the trapezoidal circulation conveying mechanism in the conveying and clamping device 1 passes through the channel formed by the embossing block 32 and the ultrasonic die head 36 in the ultrasonic welding device 2, and passes through the passage formed by the bottom knife block 47 and the cutting device 3 in the cutting device 3. The passage formed by the knife 48, the conveyor belt 22 of the inverted trapezoidal circulation conveying mechanism in the conveying and clamping device 1 passes through the passage formed by the embossing block 32 and the ultrason...

Embodiment 2

[0038] Embodiment 2: On the basis of Embodiment 1, the adult incontinence trousers transport clamping welding cutting method is characterized in that: the elastic adult incontinence trousers in the transport clamping device are transported by a trapezoidal circulation conveying mechanism

[0039] When the adult incontinence trousers conveying channel is composed of the belt and the inverted trapezoidal circular conveying mechanism conveyor belt, two or more sets of self-controlled cylinder lifting mechanisms under the conveyor belt on the inverted trapezoidal circular conveying mechanism below the channel push the conveyor belt upwards, The elastic adult incontinence trousers are clamped and forced to stretch by the pressure plates on the upper and lower conveyor belts. At this time, the embossed shaft in the ultrasonic welding device drives the embossed block to rotate under the drive of the transmission wheel. When the embossed block and the ultrasonic mold When the heads ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com