Reciprocating extrusion grain refining equipment and extrusion refining method therewith

A grain refinement, reciprocating technology, applied in metal extrusion dies, metal extrusion mandrels, etc., can solve the problem of inability to obtain isotropic bulk materials, inability to obtain bulk materials, and uniform grain deformation. and other problems, to achieve the effect of reducing labor intensity, reducing production costs and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

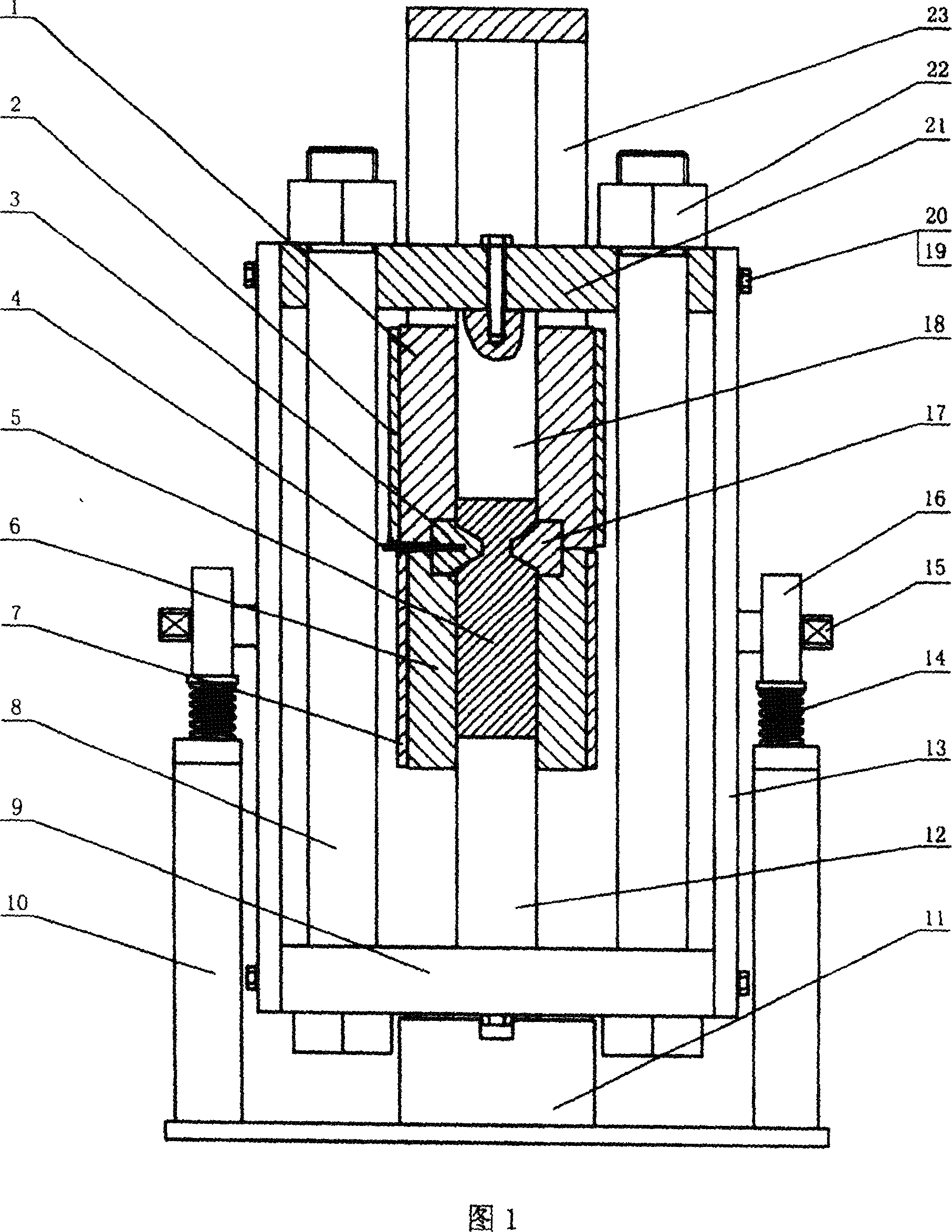

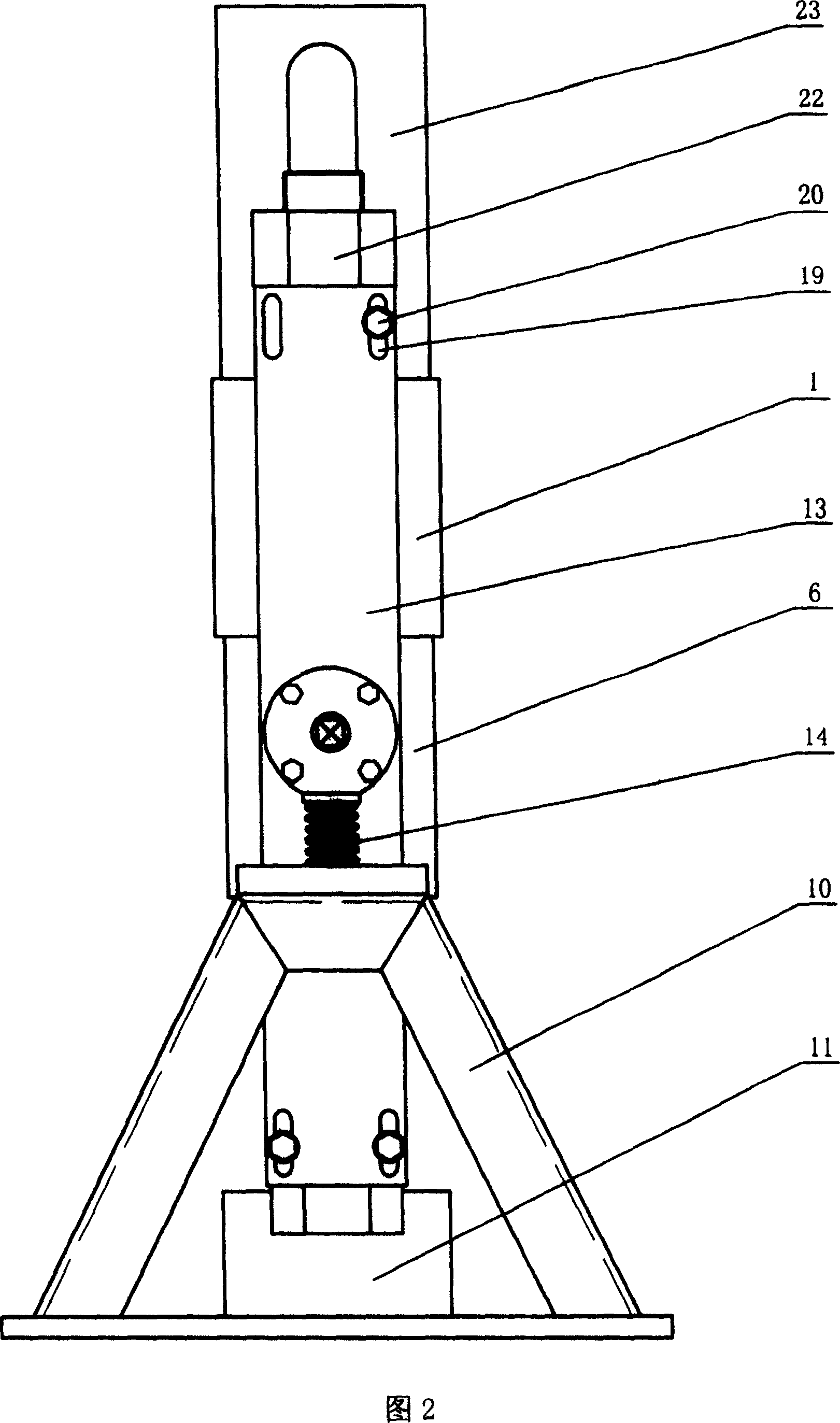

[0042] Reciprocating extrusion of pure aluminum to obtain fine-grained high-strength rods.

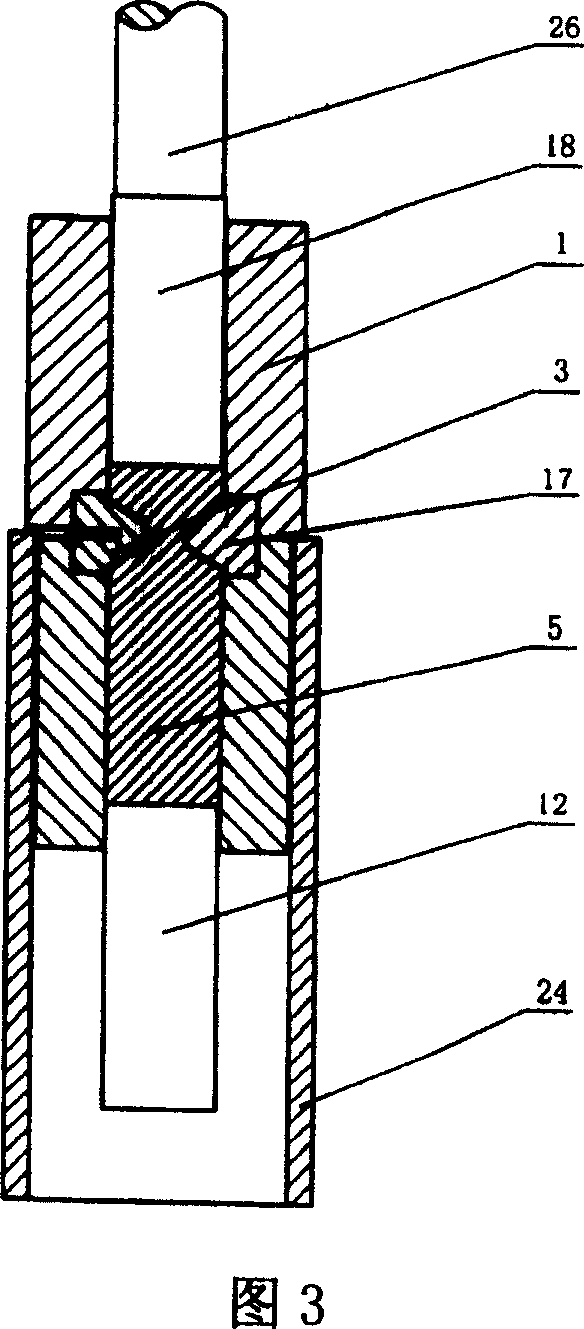

[0043] 1. Press the first half-die 3 and the second half-die 17 into the first extrusion barrel 1 and the second extrusion barrel 6 with a press to close the molds, set the extrusion ratio to 12, and then squeeze the Press pure aluminum 5 into the mold cavity formed by the first extrusion barrel 1, the first half die 3, the second half die 17 and the second extrusion barrel 6;

[0044] 2. The press exerts pressure on the upper mold connecting beam 21 to make the pressure reach 6mpa, so that the two ends of the second male mold 18 and the first male mold 12 are pressurized, and the extruded pure aluminum 5 is pre-deformed to realize The extruded pure aluminum 5 has the same volume as the mold cavity, tighten the nuts 22 and bolts 20, fix the positions of the lower mold connecting beams 9 and 21, and connect the first heating body 2 and the second heating body 7 to the power supply respe...

Embodiment 2

[0049] Reciprocating extrusion conventionally solidified Mg-9Al-10Si alloy to obtain high strength, toughness and high performance Mg-Al-based Mg 2 Si self-generated composites.

[0050] The conventionally solidified Mg-9Al-10Si alloy is subjected to 300°C / 5h aging treatment, and then the following extrusion steps are performed:

[0051] 1. Press the first half-die 3 and the second half-die 17 into the first extrusion barrel 1 and the second extrusion barrel 6 with a press to close the molds, set the extrusion ratio to 12, and then perform aging The processed extruded conventional solidified Mg-9Al-10Si alloy material 5 is packed into the mold mold formed by the first extrusion barrel 1, the first half die 3, the second half die 17 and the second extrusion barrel 6. Cavity;

[0052] 2. The press exerts force on the upper mold connecting beam 21 to make the pressure reach 7mpa, so that the two ends of the second male die 18 and the first male die 12 are pressurized, and the e...

Embodiment 3

[0057] Reciprocating extrusion of Mg-Zn-Y rapid solidification foil strips makes it a uniformly deformed ultra-high-strength magnesium alloy profile.

[0058] The conventional solidified Mg-Zn-Y magnesium alloy is made into a rapid solidification foil strip on a single-roll rapid solidification equipment, and the thickness of the foil strip is 20-100 μm, and the Mg-Zn-Y magnesium alloy is pre-pressed into For bulk materials, the pre-pressing temperature is <300°C, and then the following extrusion steps are carried out:

[0059] 1. Press the first half-die 3 and the second half-die 17 into the first extrusion barrel 1 and the second extrusion barrel 6 with a press to close the molds, set the extrusion ratio to 12, and then squeeze the The pressed magnesium alloy 5 is loaded into the mold cavity formed by the first extrusion barrel 1, the first half die 3, the second half die 17 and the second extrusion barrel 6;

[0060]2. The press exerts force on the upper mold connecting be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com