Three-dimensional integral weaving method for multi-directional preform

A technology of overall weaving and auxiliary tooling, which is applied in the direction of braids, textiles and papermaking, etc., to achieve the effects of wide adaptability, improving integrity and comprehensive performance, and reducing fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

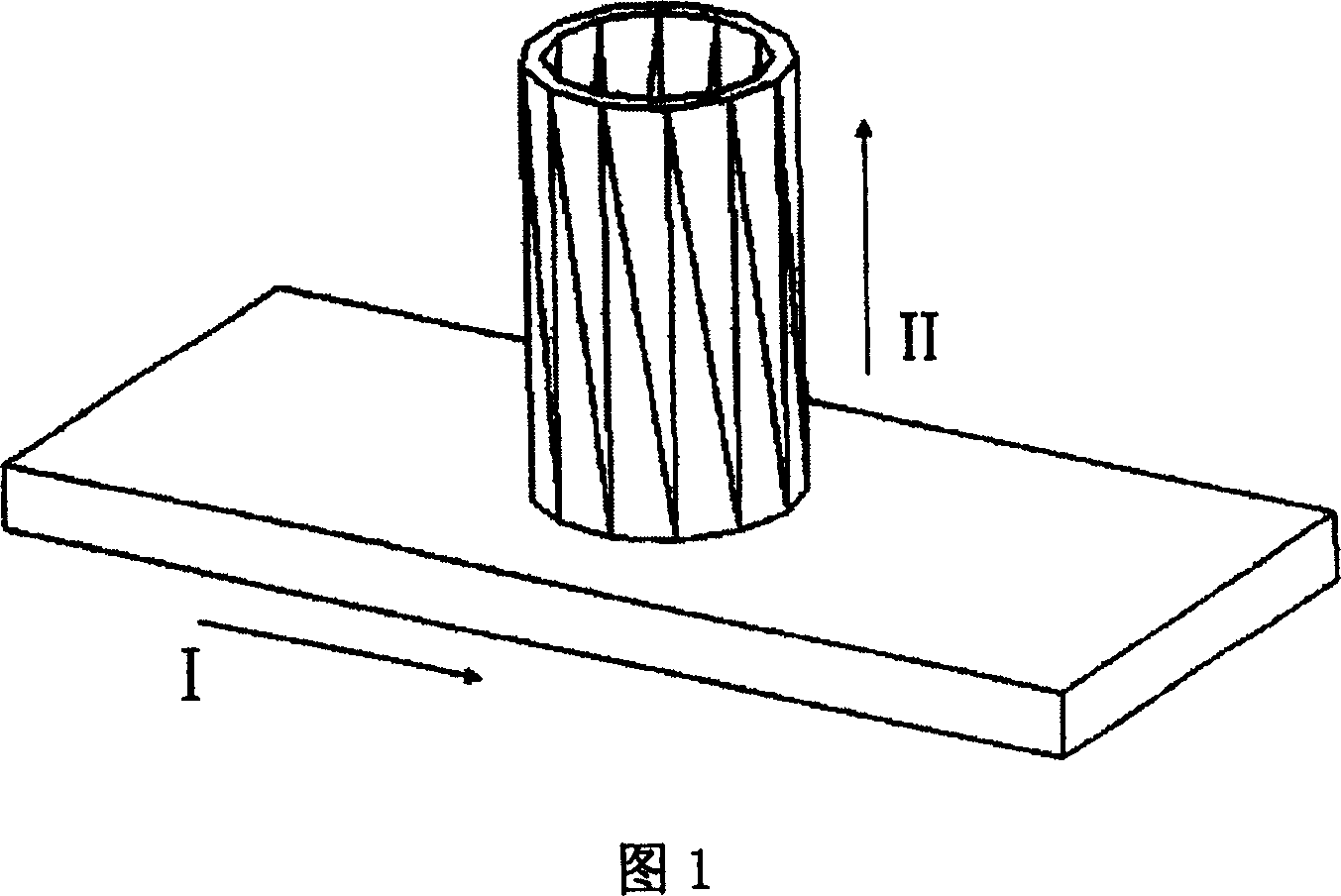

[0033] Adopt the weaving method of the present invention to weave flat plate and vertical circular pipe joint parts (see Fig. 1) in two forming directions.

[0034] The main molding direction I of the product is designed as a flat part, and the second molding direction II is a round tube part. The rectangular width of the flat part is 53mm, the thickness is 5mm, and the length is 250mm; the inner diameter of the round tube part is 22mm, the outer diameter is 26mm, and the starting point of the round tube part is 60mm from the starting surface of the flat plate. The flat panel adopts four-step three-dimensional five-directional square weaving. The knitting yarn is T300-6K carbon fiber, the knitting angle is 20°, the knitting flower node length is 4.5 mm, and the number of yarns required for the design knitting is 605. Knit to the yarn adding position of the circular tube and start pre-feeding the yarn required for circular tube braiding. 350 yarns are used in the design of th...

Embodiment 2

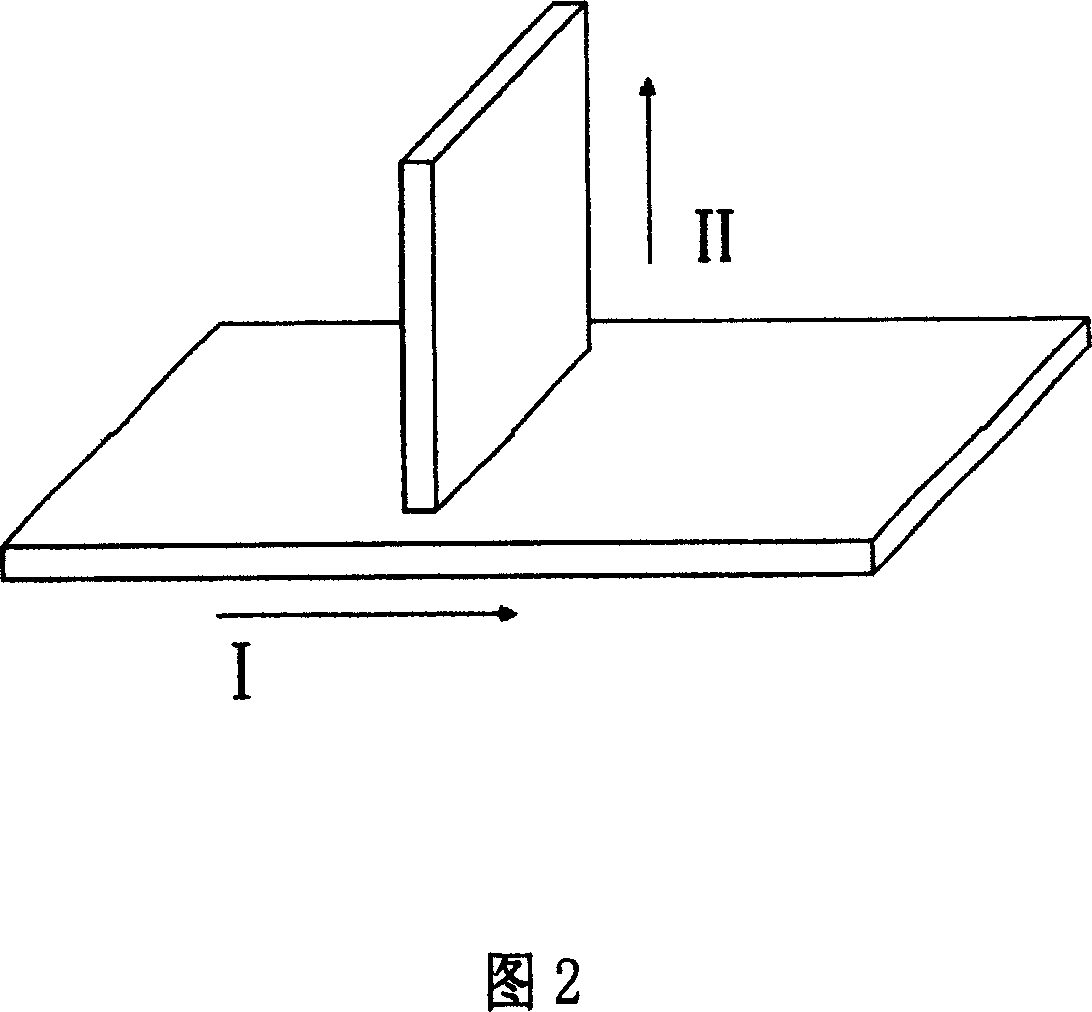

[0037] Adopt the weaving method of the present invention to weave two forming direction T-shaped joint parts (referring to Fig. 2).

[0038] The main molding direction I and the second molding direction II of the product are both flat plate parts, but the two sizes are different. The width of the former plate is 25mm, the thickness is 5mm, the length is 350mm, and the length of the woven flower joint is designed to be 4mm; the section width of the latter plate is 20mm, the thickness is 5mm, the length is 200mm, and the length of the woven flower joint is designed to be 4mm. The two forming directions are perpendicular to each other. The main forming direction I (flat part) adopts four-step three-dimensional five-way square weaving, the weaving yarn is T300-12K carbon fiber, the weaving angle is 25°, and the number of yarns required for design weaving is 136. The second forming direction II (vertical part) adopts three-dimensional four-way weaving square weaving, the weaving y...

Embodiment 3

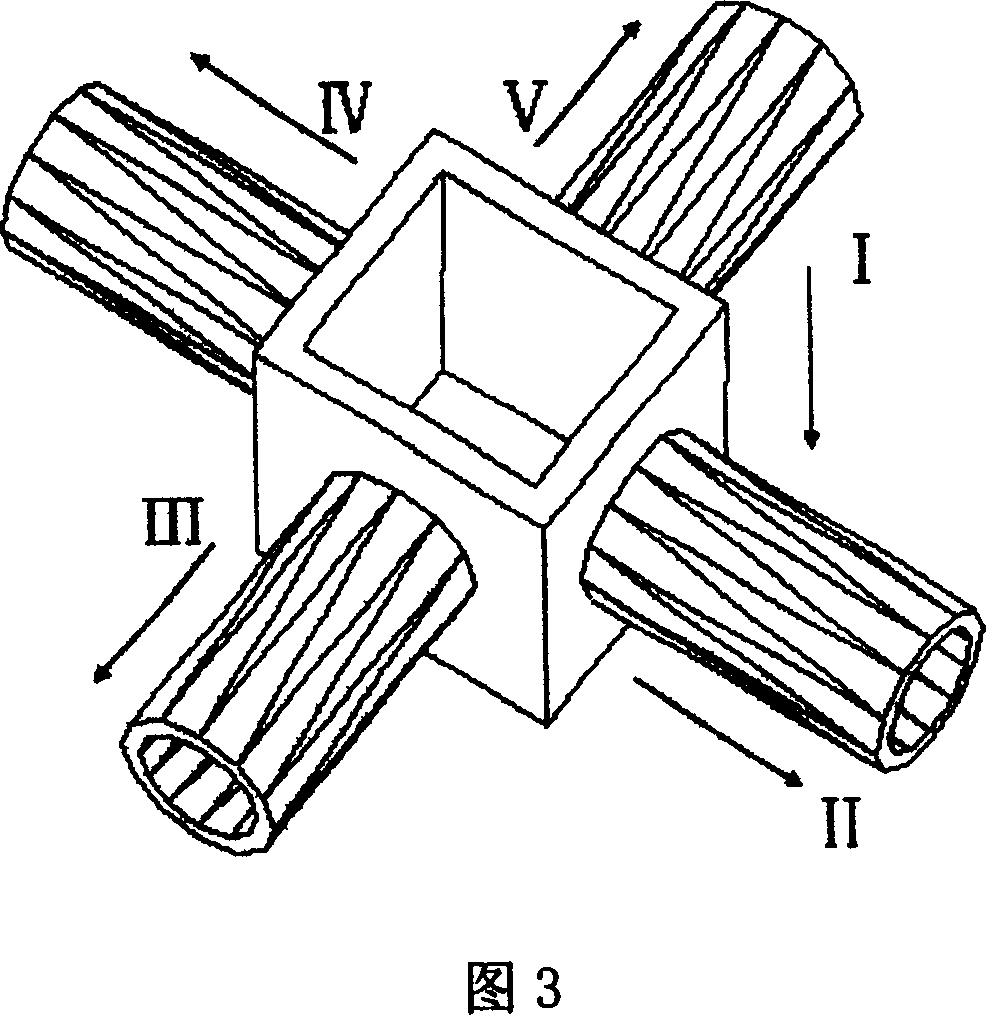

[0040] Adopt the method of the present invention to braid four round pipes in five forming directions and a box-shaped body to vertically connect joint parts (referring to Fig. 3 ).

[0041]The product takes the box-shaped body part as the main forming direction I, and adopts the box-shaped cross-section square weaving process; the round tubes on the four sides can be the second forming direction II or arranged in order of forming directions II, III, IV and V (See Figure 3), using a circular weaving process to weave. First, the initial section of the box-shaped body of the multi-directional product is used as the initial section of weaving, and the weaving yarn arrangement is designed according to the size and shape of the section. The weaving yarn is T700 12K carbon fiber, which is arranged in a box shape on the chassis of the machine. The weaving adopts the three-dimensional five-way weaving method, and the length of the flower node is 5mm; the round tube part uses the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com