Vertically brushing electric toothbrush

An electric toothbrush, vertical brush technology, applied in dentistry, cleaning teeth, medical science and other directions, can solve problems such as difficult to achieve tooth protection, and achieve the effect of removing dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

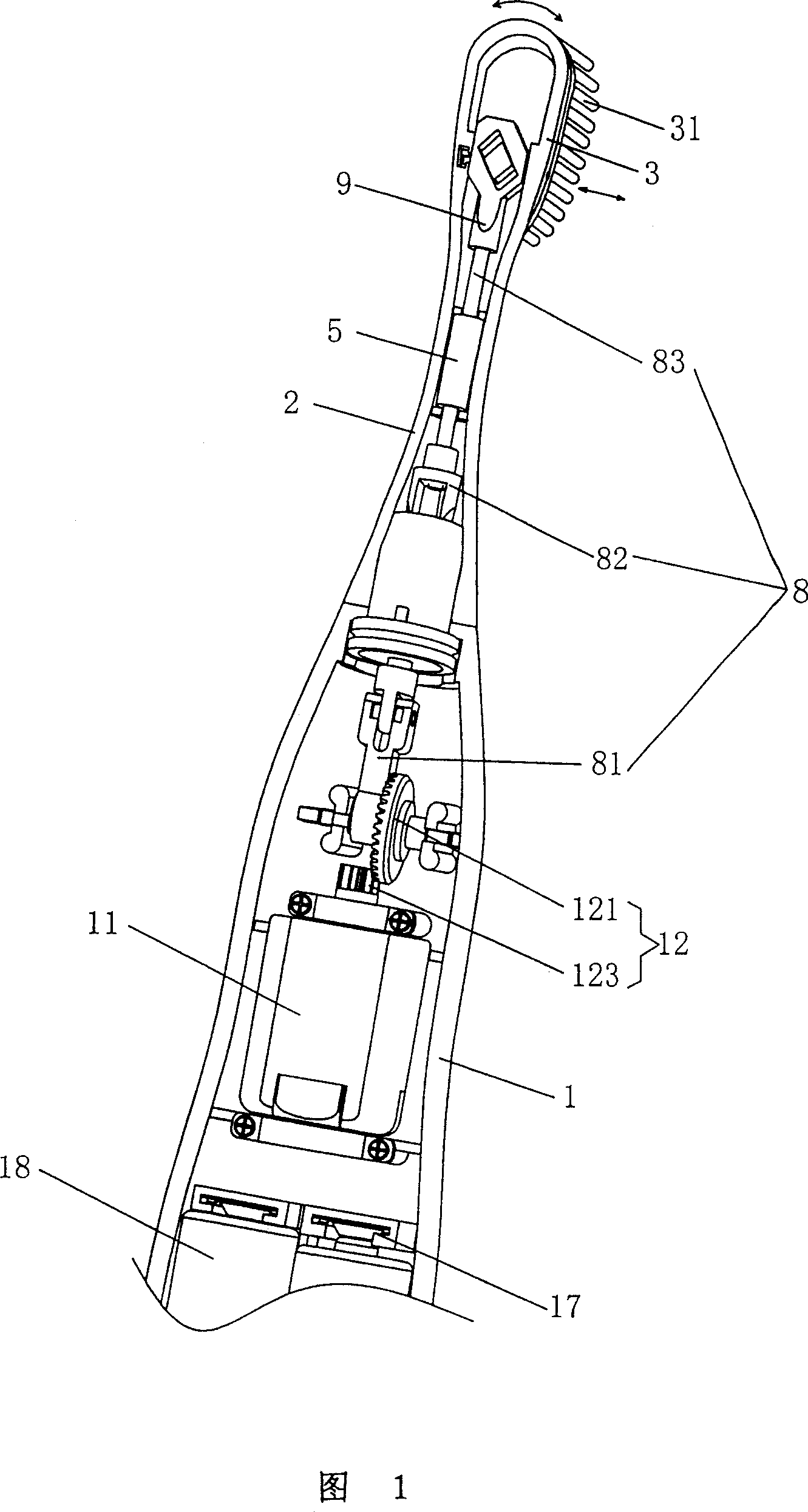

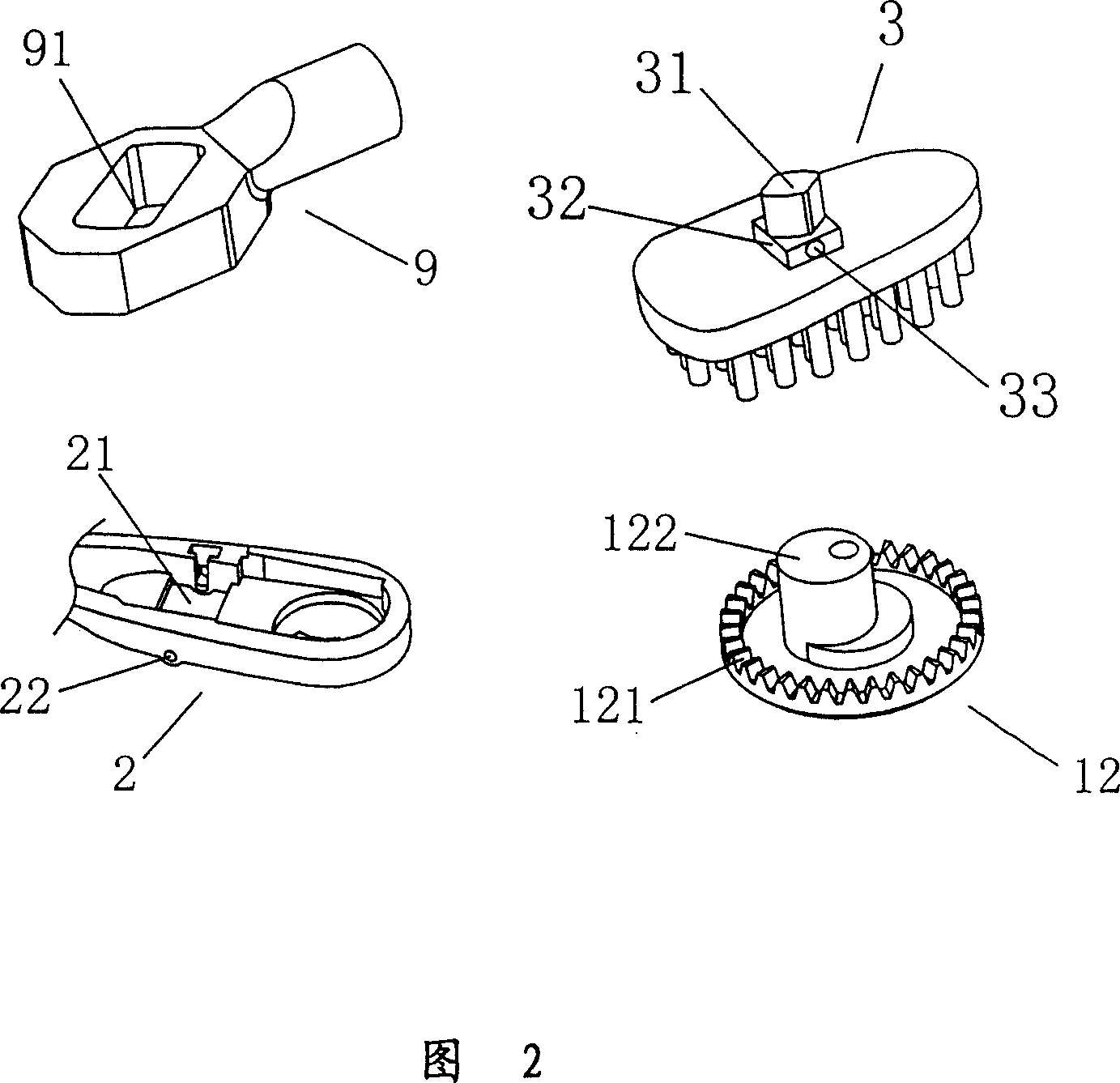

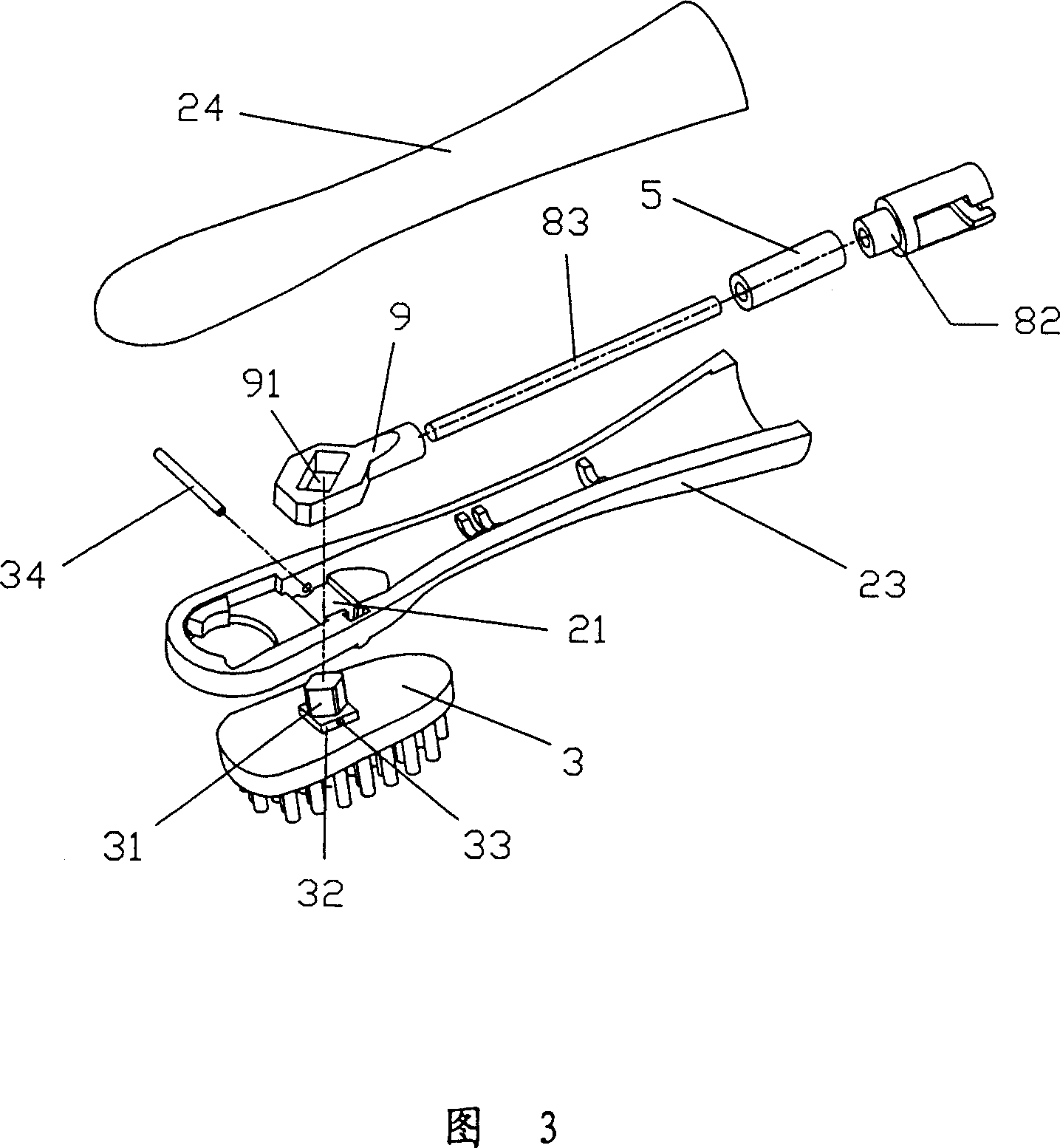

[0019] As shown in Figure 1, the vertical brush type electric toothbrush of the present invention comprises: the motor 11 that is placed in toothbrush body 1 inner cavity and the speed change gear set 12 that is driven by motor 11, the toothbrush handle 2 that is installed on toothbrush body 1 top and is arranged on The toothbrush head 3 in the front section of the toothbrush handle 2 is movably connected with the toothbrush handle 2 , and the front of the toothbrush head 3 is fixed with toothbrush hairs 31 . Described transmission gear set 12 comprises the driving gear 123 that is fixed on the power output shaft of motor 11 and the driven gear 121, is provided with eccentric shaft 122 (Fig. The rotary motion of the speed change gear set 12 is converted into the reciprocating linear motion of the toothbrush head driving pull rod 9 . The connecting rod device 8 includes a connecting rod 81, a connecting head 82 and a pull rod shaft 83 which are sequentially connected from back ...

Embodiment 2

[0026]The difference between this embodiment and the first embodiment is that a circular rotating brush head 4 is added at the front end of the toothbrush handle 2 to improve brushing efficiency. As shown in Figures 5 and 6, the rotating brush head 4 has a central axis hole 41 The central axis hole 41 is rotatably matched with the hanging shaft 27 fixed on the toothbrush handle 2, a driving shaft 42 is vertically protruded on the left side of the central axis hole 41, and a section of arc-shaped neck is arranged on the right side of the central axis hole 41. The arc-shaped neck and the back of the rotating brush head 4 form an anti-slip groove 44. Correspondingly, the front end of the toothbrush handle 2 has a circular through hole 25, and a fan-shaped convex key 26 is protruded on its right side wall. The brush head 4 is suspended on the toothbrush handle 2 and can rotate within a certain angle around the toothbrush handle 2 hanging shaft 27 . A pull piece 92 is extended on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com