Continuous radial loader for steam turbine reaction blade and its method

A technology for turbine blades and blades, applied in gas turbine devices, blade support elements, jet propulsion devices, etc., can solve problems such as blade and rotor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

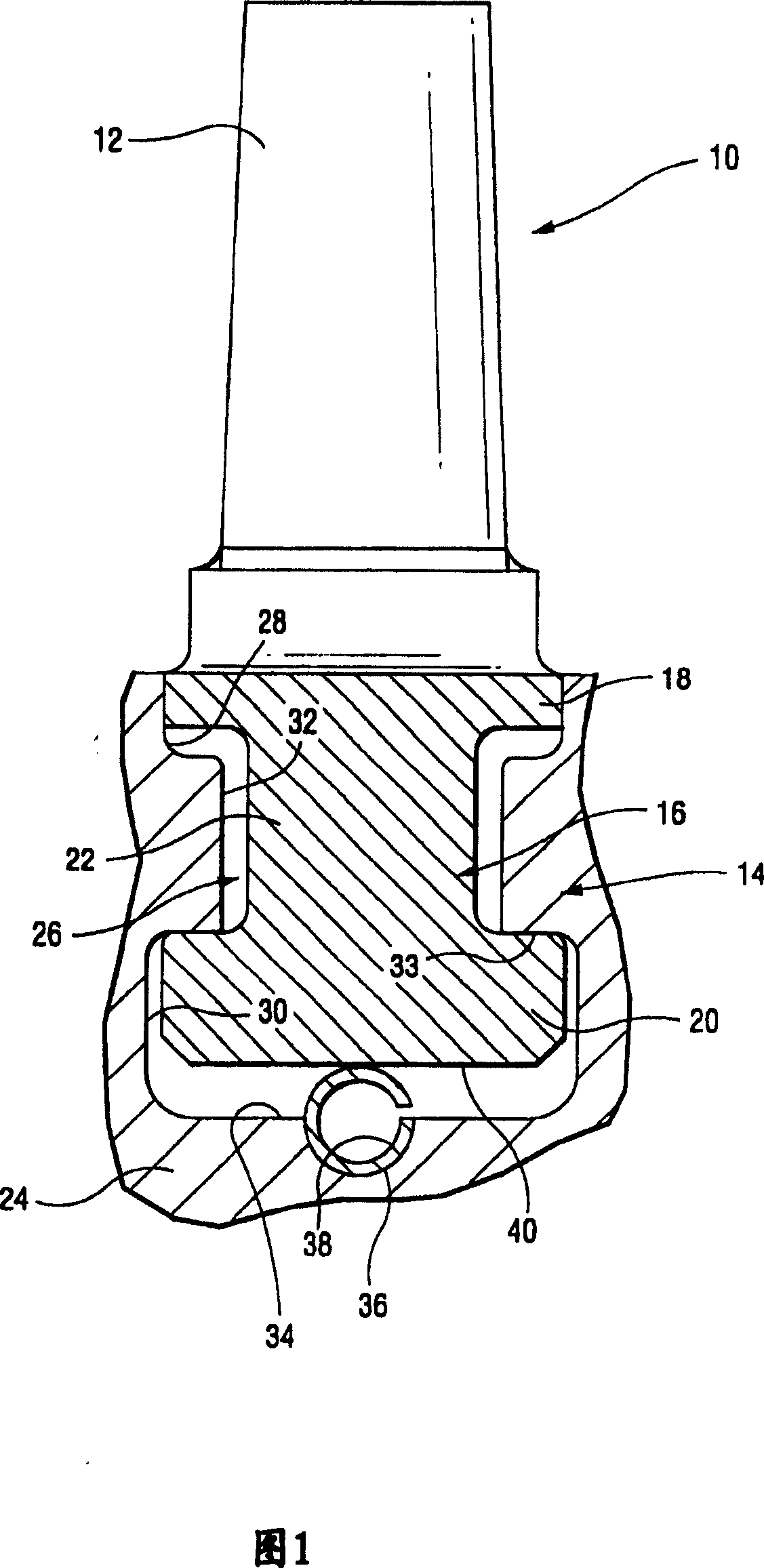

[0014] Referring to FIG. 1 , a turbine blade 10 includes an airfoil portion 12 and a root or base portion 14 configured as a male dovetail portion 16 . The male dovetail portion includes radially outer protrusions or hooks 18 and inner protrusions or hooks 20 spaced radially by a narrow neck 22 .

[0015] The rotor 24 is provided with an annular retaining slot configured as a female dovetail slot 26 around the periphery of the wheel and has a radially outer wide slot portion 28, a radially inner wide slot portion 30 and a The middle narrow groove portion 32, the radially outer wide groove portion 28 is used to receive the outer male protrusion 18, the radially inner wide groove portion 30 is used to receive the inner male protrusion 20, and the middle narrow groove portion 32 is used to receive the narrow neck 22 . The bottom surface 33 of the slotted portion 32 forms a so-called “hook” which engages with the inner protrusion 20 on the male dovetail portion 16 . In the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com