Compensation method for improving colour saturability and image quality of flat plasma display

A flat-panel display, image quality technology, applied in static indicators, instruments, nonlinear optics, etc., can solve the problems of low light transmittance, negative impact of plasma flat-panel display brightness, and unsatisfactory, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

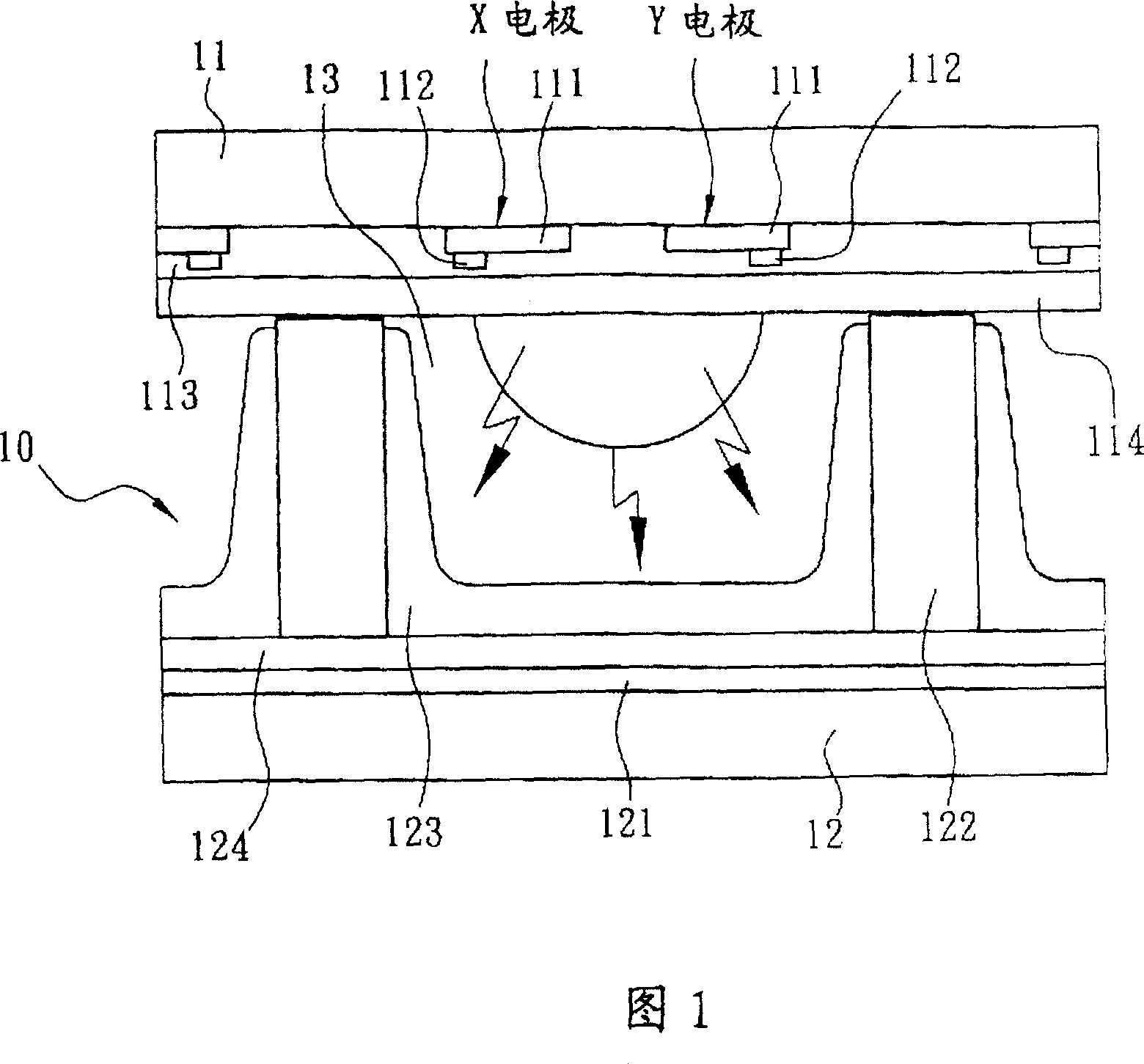

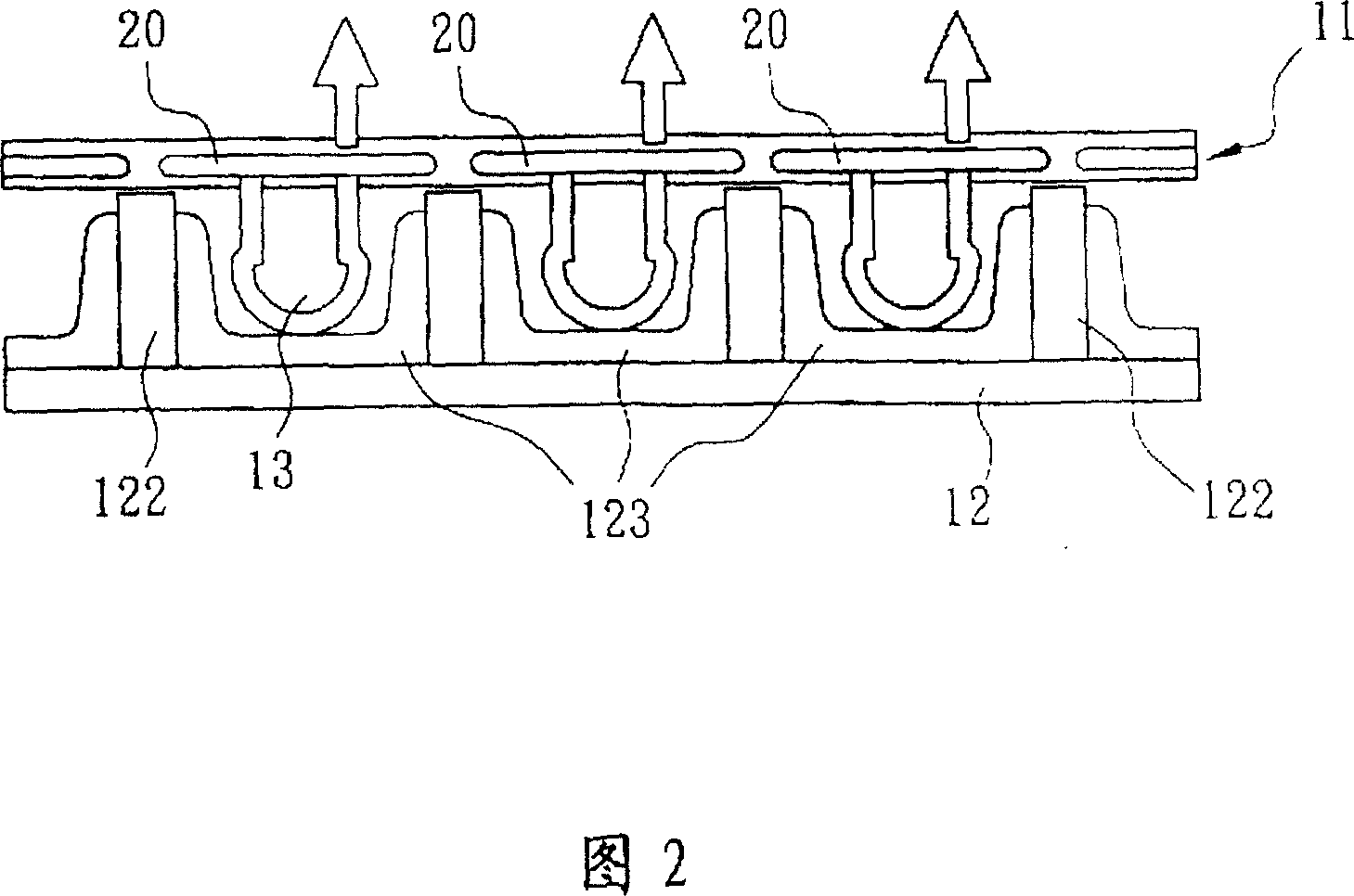

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

[0023] On a general plasma flat-panel display, since the presented image is composed of a huge number of pixels (pixels) (the number of pixels depends on the resolution of the plasma flat-panel display), and any pixel (pixel) is It is composed of corresponding discharge cells (Cell) that produce three colors such as red (Red), green (Green) and blue (Blue). Therefore, when a plasma flat-panel display displays images, the color presented by each pixel (pixel) , in fact, it is a color formed by mixing three colors of light such as red, green and blue generated by each discharge cell (Cell).

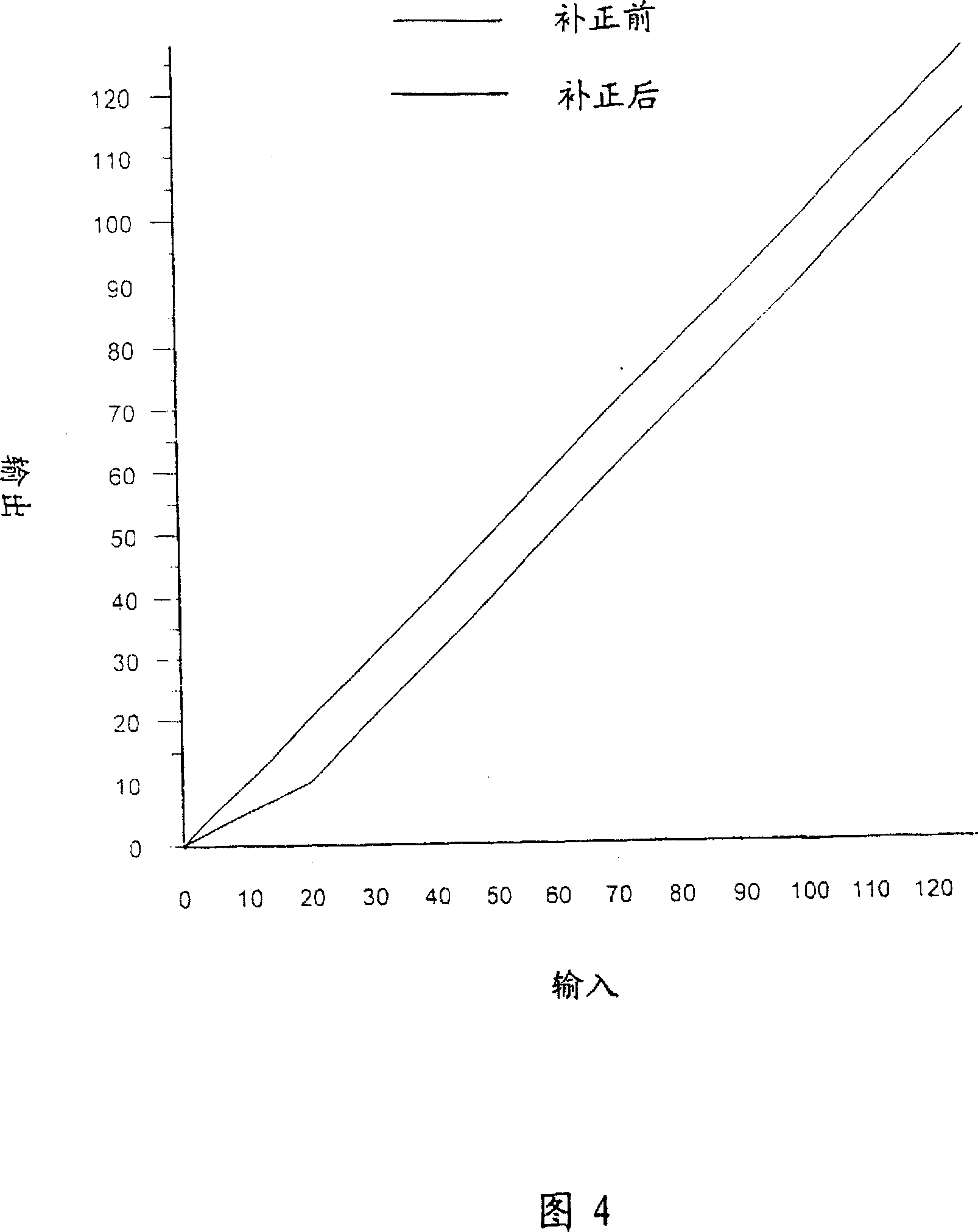

[0024] Therefore, if the red, green and blue color lights produced by each discharge cell (Cell) of each image point on the plasma flat panel display are represented by a, b, and c respectively as their grayscale values, and each image point ( plxel) corresponding to the three-color discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com