Switch transformation installation wth input in low voltage

A switching conversion, low-voltage input technology, applied in the output power conversion device, the conversion of DC power input to DC power output, and the adjustment of electrical variables, etc. The effect of saving design costs and improving cost competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

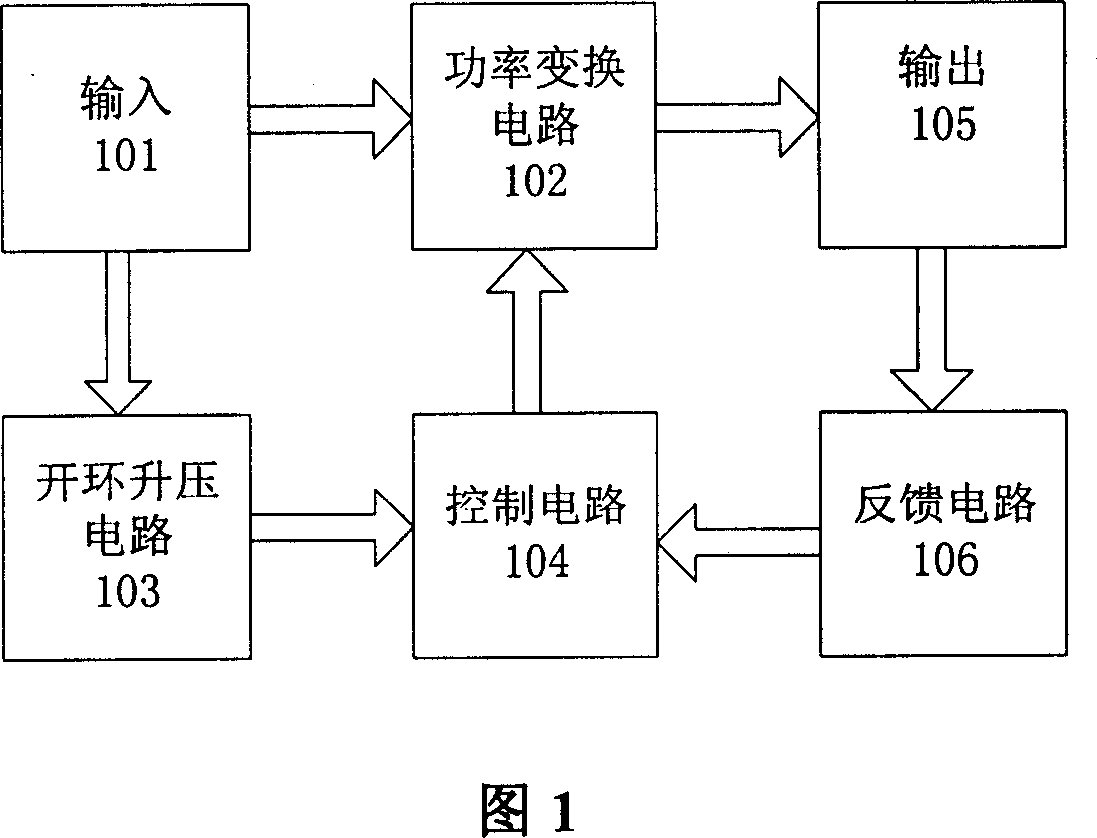

[0021] The low-voltage input switch conversion device disclosed by the present invention is shown in FIG. 1 . It mainly consists of the following parts: an input circuit 101 , a power conversion circuit 102 , an output circuit 105 , a feedback circuit 106 , a control circuit 104 and an open-loop boost circuit 103 . The voltage signal of the input circuit 101 is filtered and then connected to the power conversion circuit 102 for power conversion. At the same time, 101 is connected to the open-loop boost circuit 103 to provide the input voltage. After the open-loop boost circuit 103 boosts the input voltage, it is connected to the control circuit. 104 provides an auxiliary power supply, the control circuit 104 is connected to the power conversion circuit 102 for power conversion, and the power conversion circuit 102 is connected to the output circuit 105 for rectification and filtering and outputs the converted voltage. The output circuit 105 is connected to the feedback circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com