Safety controller for running hoist

A technology for safe operation and control device, applied in the direction of safety device, transportation and packaging, load hanging components, etc., can solve the problems of increasing mechanical wear, reducing labor efficiency, increasing crane fuel consumption, etc., saving running time, improving The effect of labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

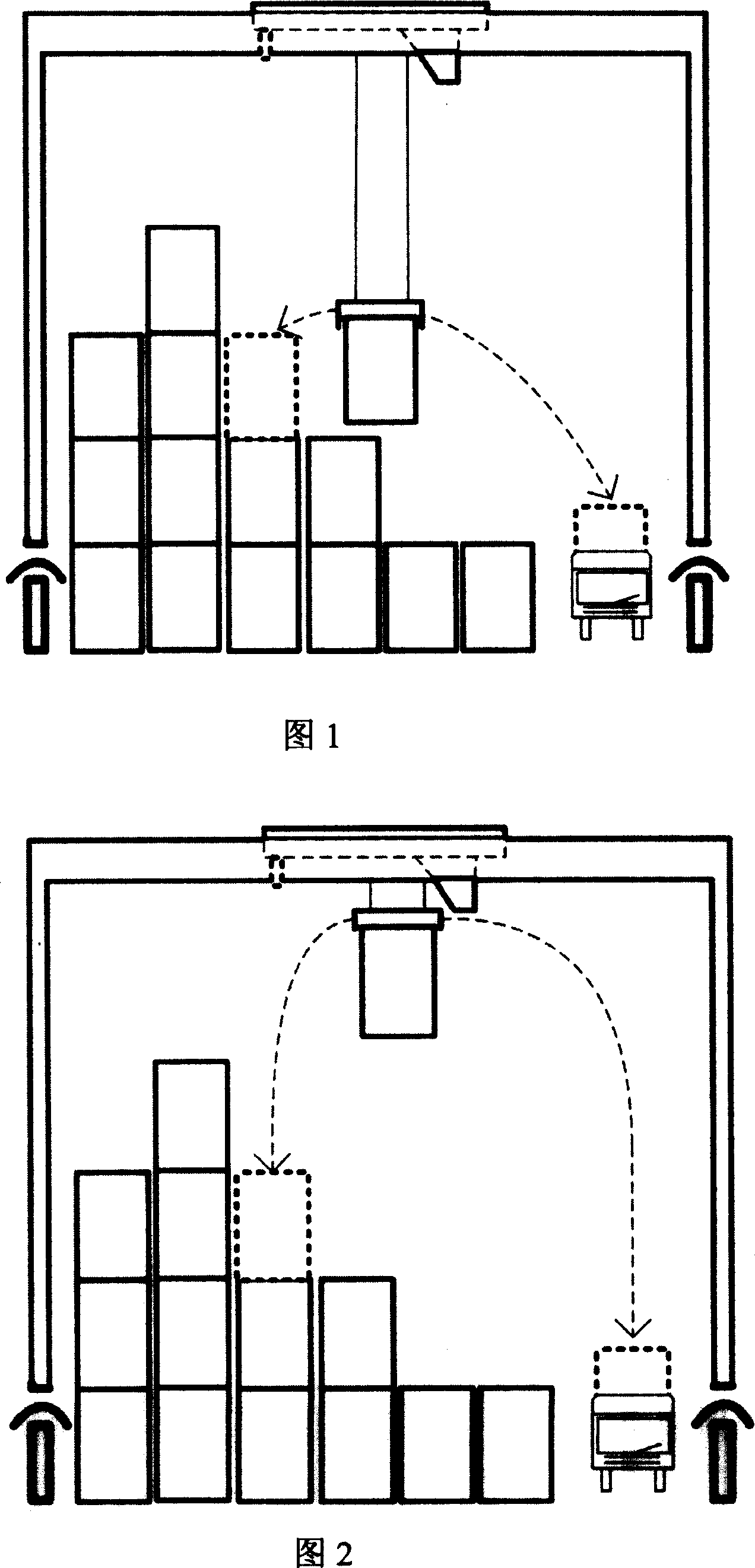

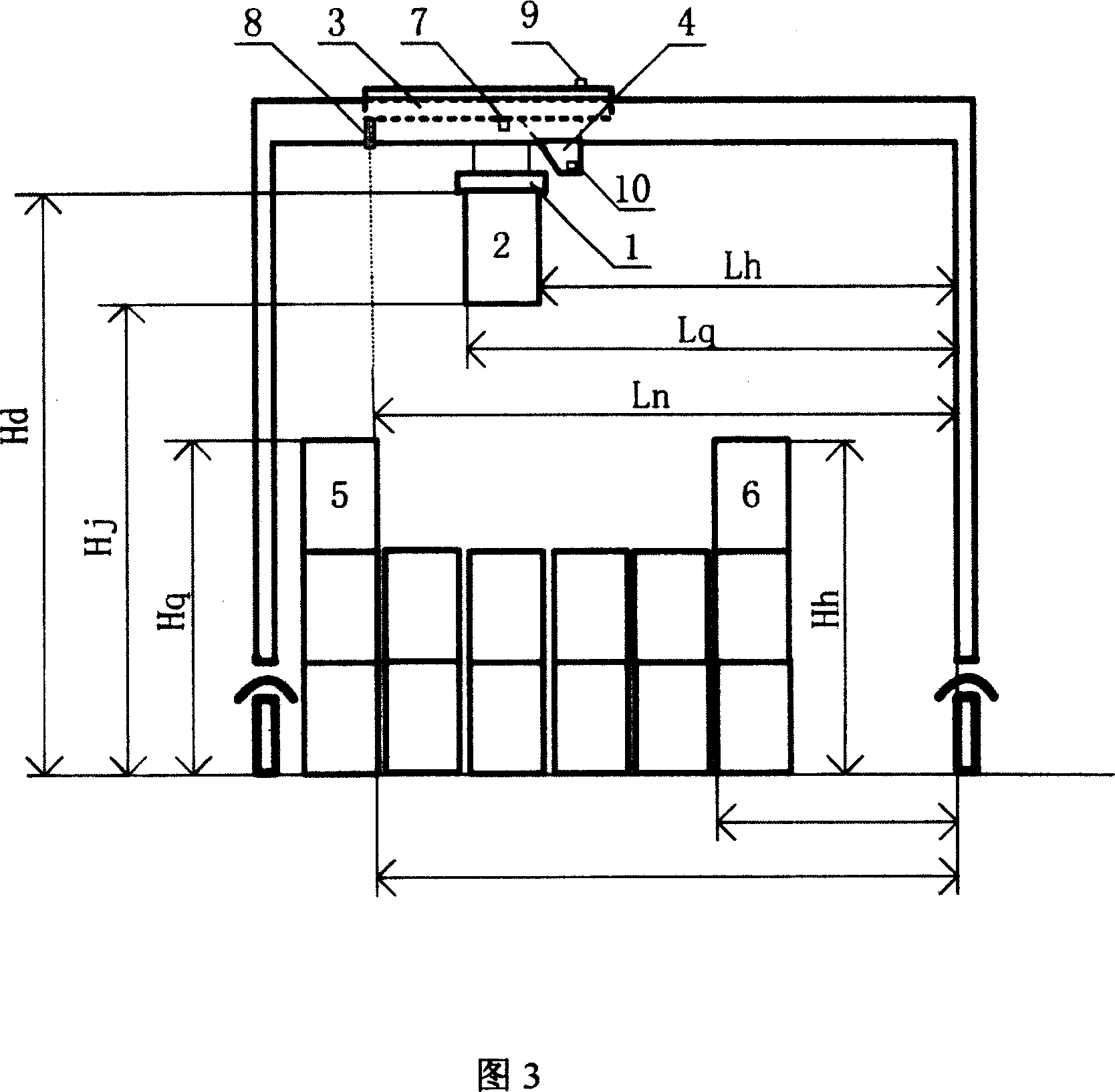

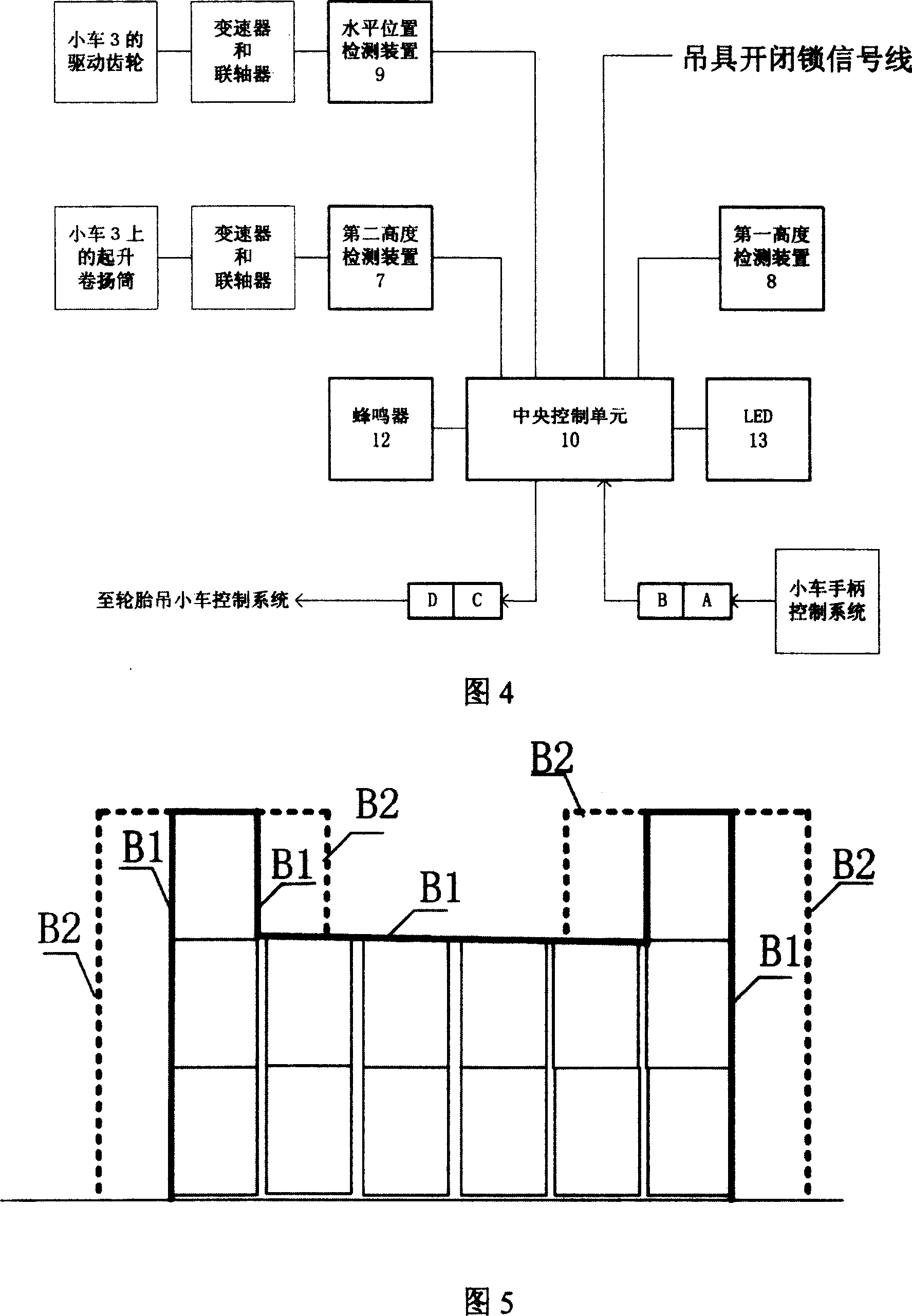

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Referring to Fig. 3, the goods referred to in this embodiment are containers. Crane comprises dolly 3 and carload 11, and dolly 3 can run back and forth (left and right) on the crossbeam of carload 11, and carload 11 can walk left and right direction (from inside to outside or from outside to inside in the figure). A spreader 1 is provided under the trolley for lifting the container 2 . The spreader 1 is driven by the power unit of the trolley, such as a winch (not shown), so that the spreader 1 including the suspended container 2 can be lifted up and down. Containers are piled up on the yard, wherein, container 5 is the container above the yard and is positioned at the front (to the left) of the dolly 3 walking passages, and container 6 is the container at the rear (to the right) of the dolly 3 walking passages above the yard.

[0021] The cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com