Method and special apparatus for recovering hydrocarbon oil from oil sand

A special equipment and oil sand technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems of high recovery cost and environmental pollution, and achieve the effects of low recovery cost, simple method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

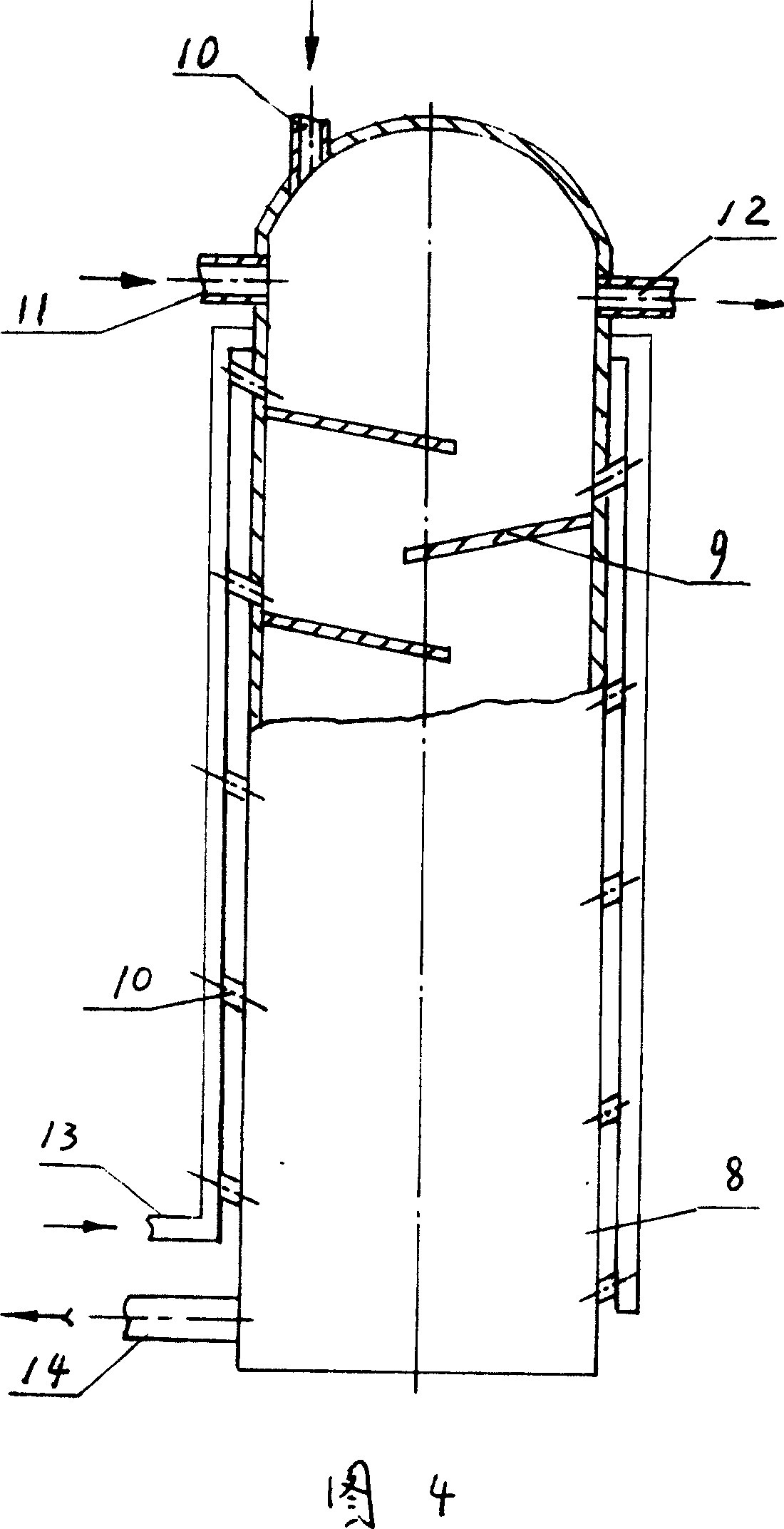

[0017] A method for recovering hydrocarbon oil from oil sands is to send the oil sands into a closed container, and then stir the oil sands flowing in the closed container by mechanical rotation or oxygen-free gas blowing to make them appear In bulk form, inject oxygen-free gas at a temperature of 400-500°C into the container to vaporize the oil in the oil sand in the container, or directly heat the container to make the oil sand in the container reach a temperature of 400-500°C to make the oil The oil in the sand is gasified, and after the oil and gas flow out of the container, it is cooled to normal temperature to recover hydrocarbon oil.

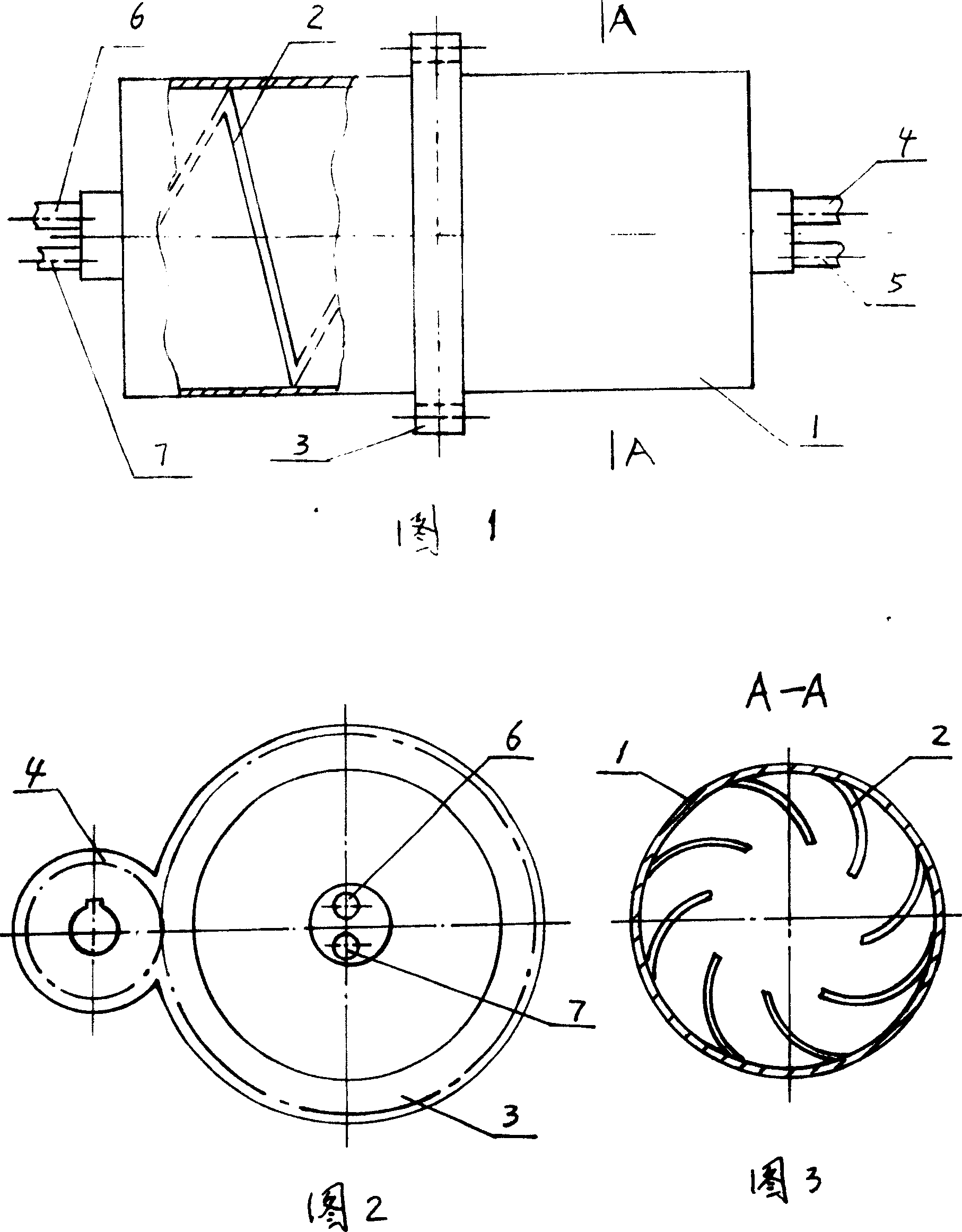

[0018] Referring to Figure 1-2, the special equipment for the rotary kiln structure has a rotary kiln body 1, and a stirring piece 2 is welded on the inner wall of the rotary kiln body 1, and the stirring piece 2 is a spiral piece....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com