Rotor type high sensitive water flowmeter

A rotary-wing water meter and rotary-wing technology are applied in measuring devices, instruments, volume measurement and other directions, which can solve the problems of increasing manufacturing difficulty, and achieve the effects of increasing casting and processing difficulty, low cost and avoiding economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

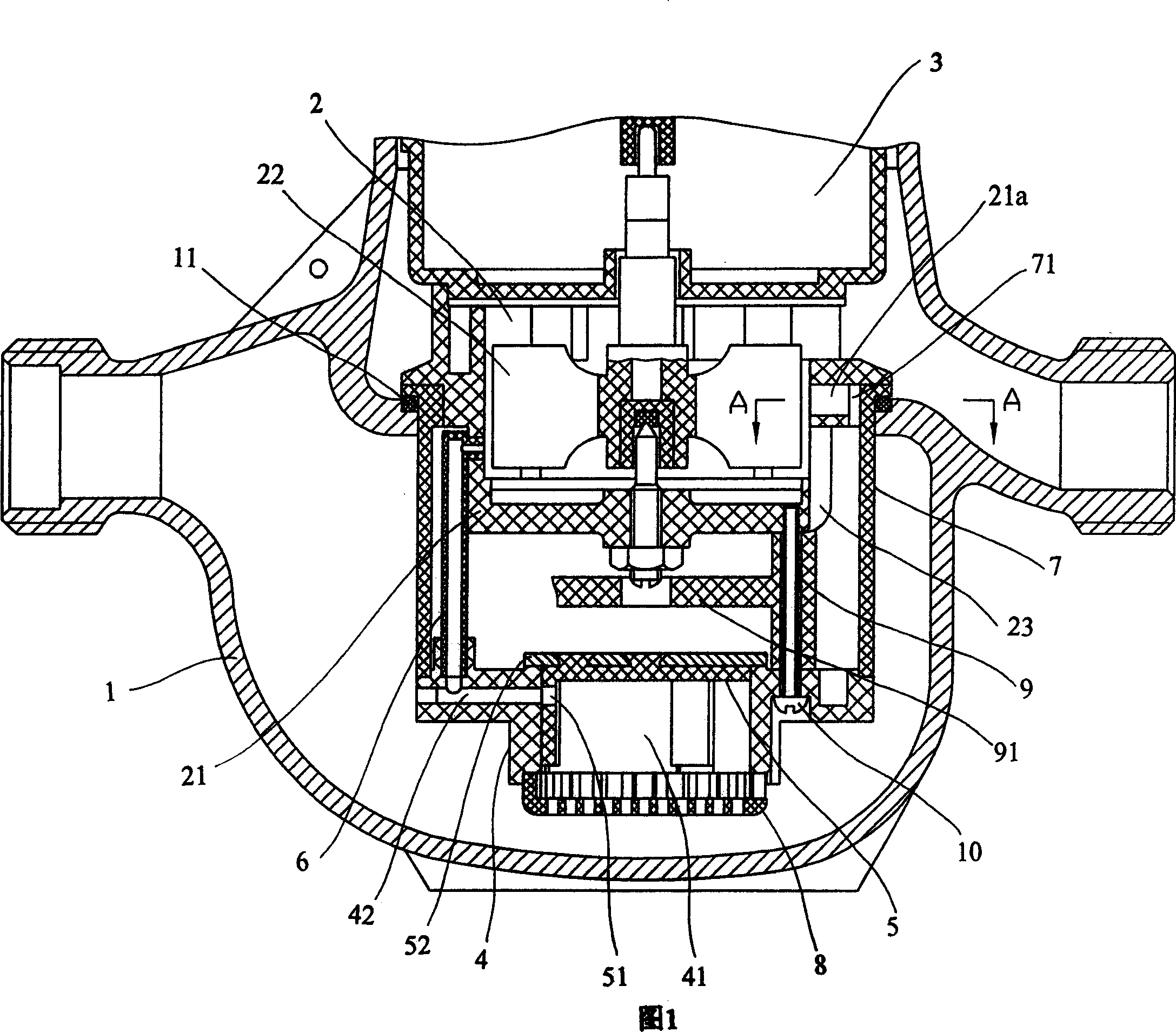

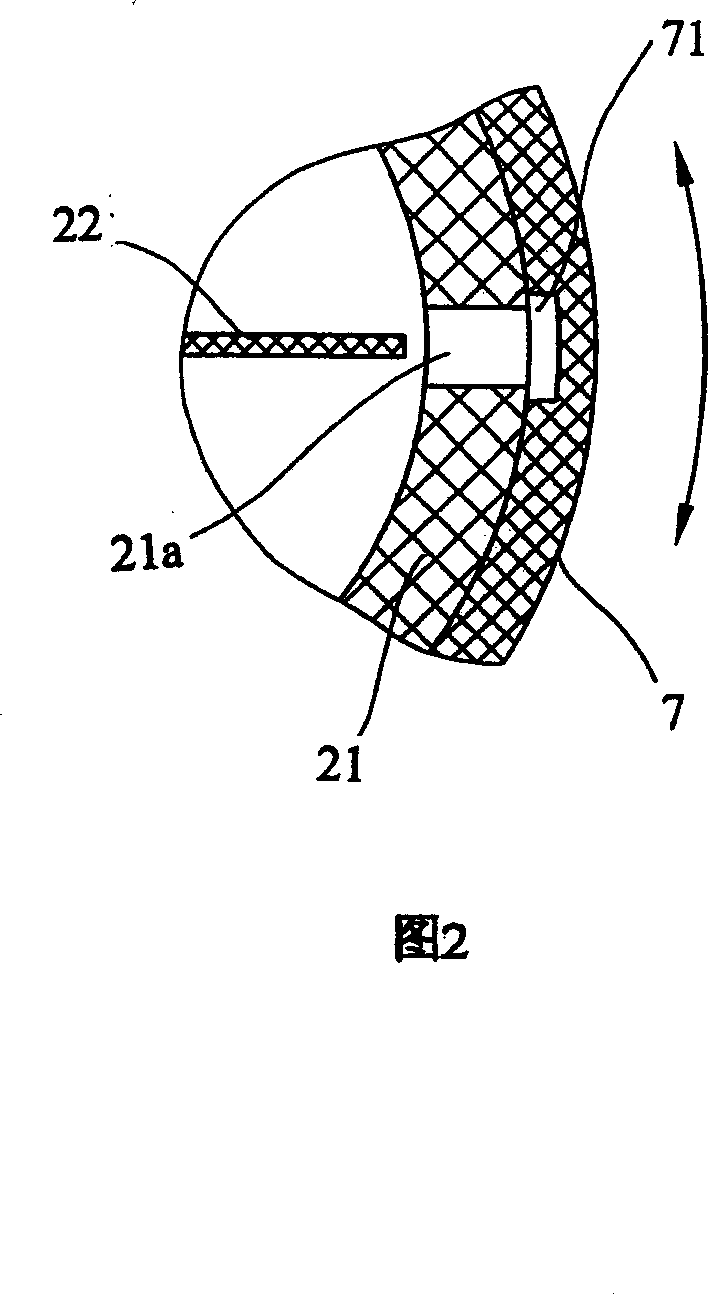

[0020] As shown in Figures 1 to 2, the rotor-type water meter includes a watch case 1, a rotor-type metering mechanism 2 and an indicating mechanism 3 arranged in the water flow channel inside it, wherein the indicating mechanism 3 is located on the metering mechanism 2 and is connected by transmission. The casing 21 of the metering mechanism 2 is provided with a rotor 22, and the lower part of the casing 21 is provided with a water inlet 23, and a flow diversion mechanism is also arranged under the metering mechanism 2, including:

[0021] A valve seat 4 has a water inlet hole 41 in its center and a small water hole 42 on its side wall, and a water filter screen cover 8 is also connected under the water inlet hole 41 of the valve seat 4;

[0022] A valve core 5 covers the water inlet hole 41 of the valve seat 4, and has a small hole 51 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com