Heating device for automatic anode linkage of MEMS high-temperature pressure sensor

A pressure sensor and anodic bonding technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor heat resistance and complex body structure of peripheral devices, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

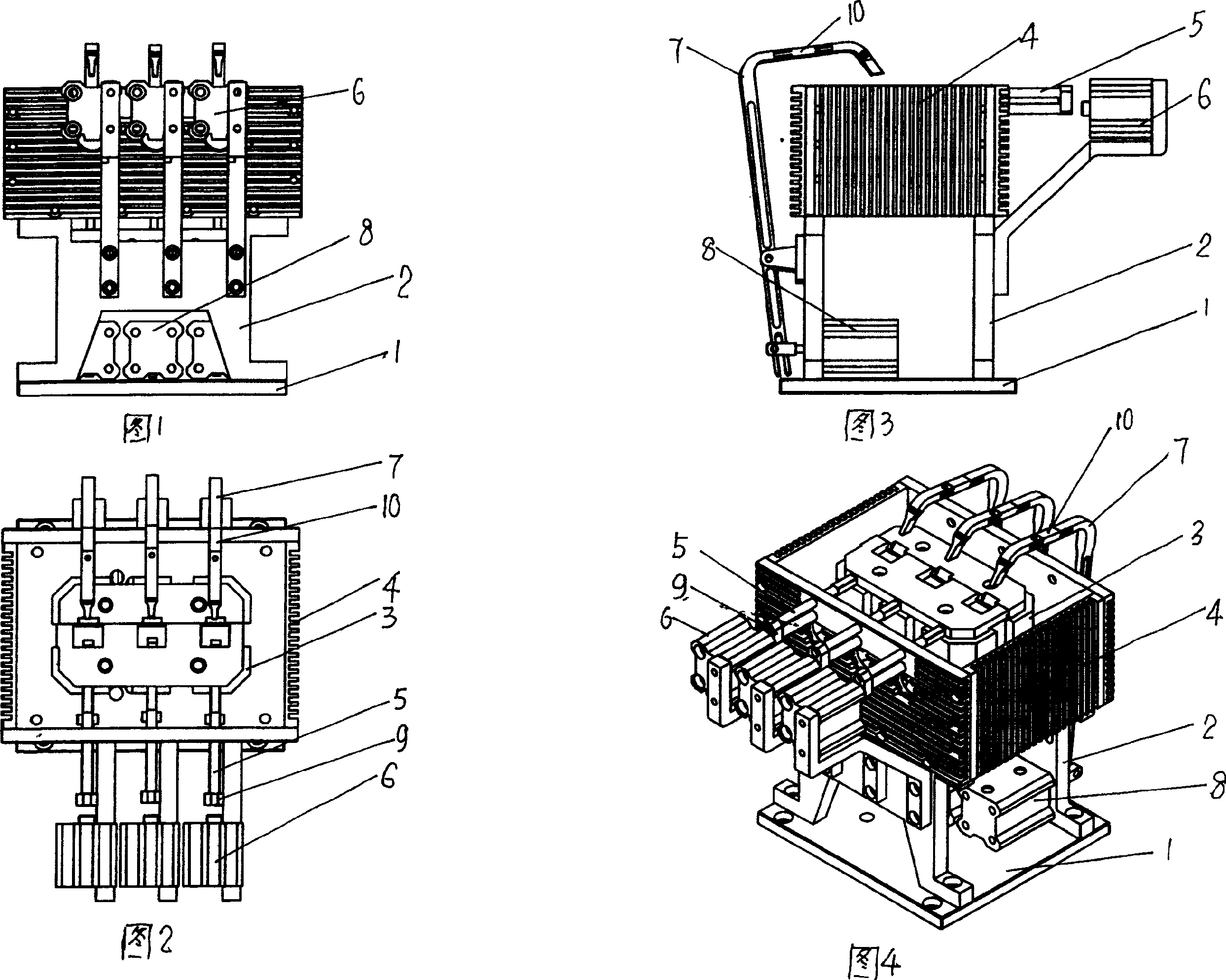

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0014] The composition of the heating device for automatic anode bonding of MEMS high-temperature pressure sensors includes a base plate 1, a support 2 is installed on the base plate, a heating block 3 is installed on the support, and heat sinks 4 are arranged around the heating block. There are round holes for heating rods and temperature sensors. The heating rods and temperature sensors are installed in the heating block. A clamp 5 and a clamp cylinder 6 matching the clamp are set on one side of the heating block. There is a return spring on the clamp. The other side of the package head 7 and the package head driving cylinder 8 are arranged, and there are heat-insulated connectors 9 and 10 between the clamps, the package head and their connectors. Multiple heating rods and temperature sensors are arranged on a heating block, the number of clamps, clamp cylinders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com