Capacitive ultra-large strain sensor

A strain sensor and capacitive technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of unable to realize the design of curved surface measurement structure, unable to meet the needs of large strain measurement, etc., to achieve good application prospects, high resolution High efficiency, good linearity and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

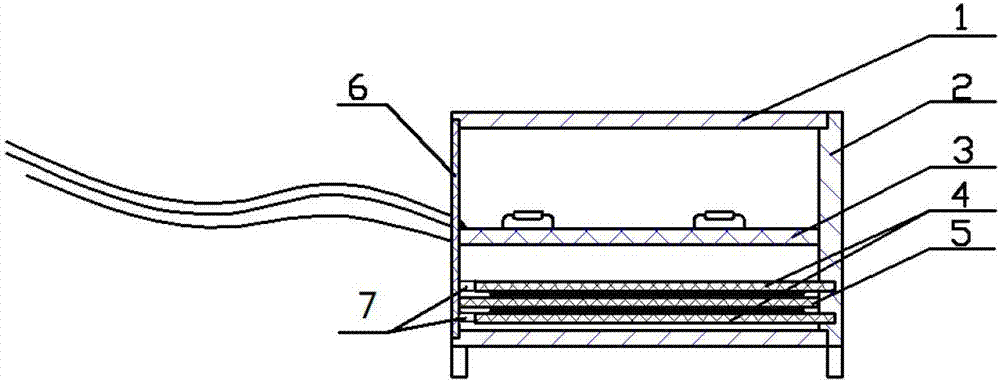

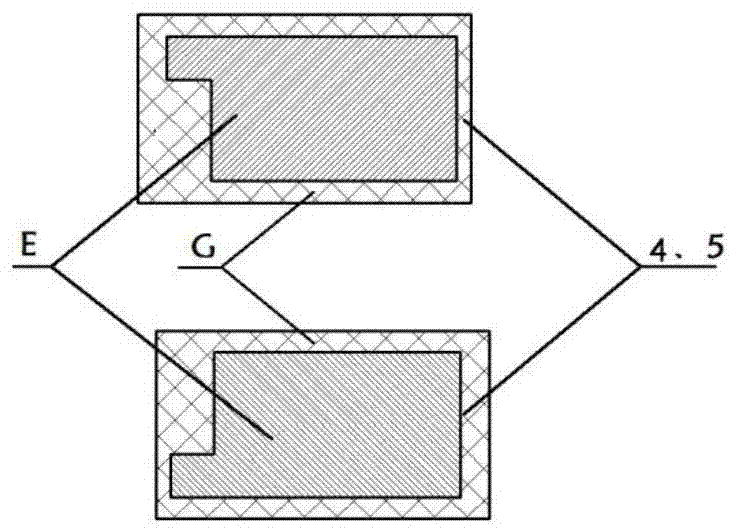

[0014] refer to figure 1 , represents the structure diagram of the capacitive ultra-large strain sensor involved in the present invention, and its shape is a rectangular frame structure, which consists of a housing 1, a drag frame 2, a circuit assembly board 3, a capacitive moving plate 4, a capacitive fixed plate 5, The lead plate is composed of 6, and the structural diagram of the capacitive ultra-large strain sensor is shown in figure 1 shown. The circuit component board 3 is first fixed on the lead plate 6 by welding and then glued and fixed on the inner wall of the casing 1, the capacitive plate 4 is fixed with the drag frame 2 with glue, and the drag frame 2 is fixed with the casing 1. The slideway 7 forms a sliding connection. The capacitor fixed plate 5 is fixed on the lead plate 6 by welding, and then secondly cured by applying glue around it, and finally the lead plate 6 and the shell 1 are bonded and fixed. When the sensor is installed, one end of the housing 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com