Self off-connecting auto desealing pipeline packer

A plugging device and pipeline technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of increasing oil and gas pipeline damage accidents, not being able to use one machine for multiple purposes, and affecting oil and gas production, etc., to achieve improvement Efficiency and economic benefits, reducing complexity and cost, and reducing the effect of oil and gas gathering and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

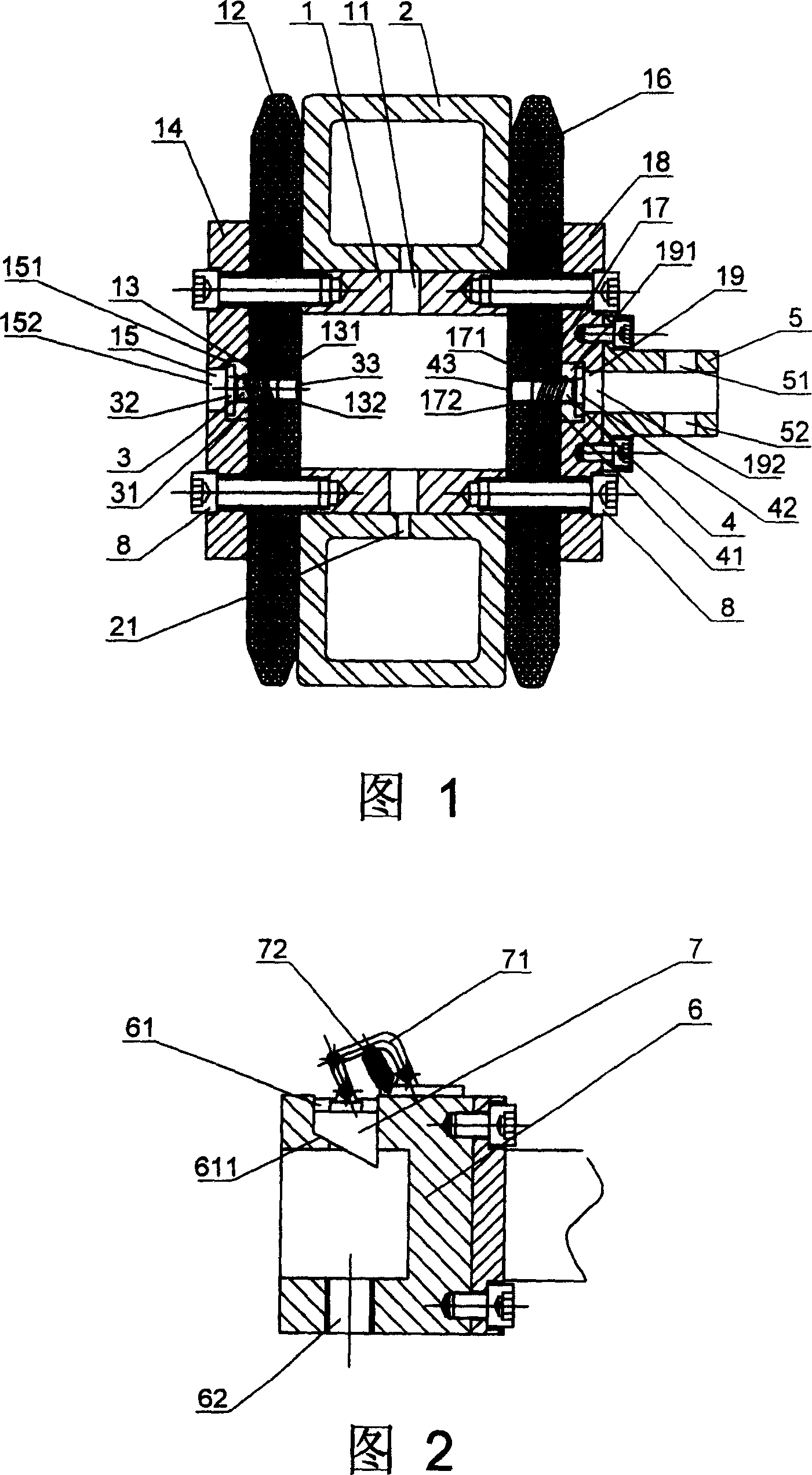

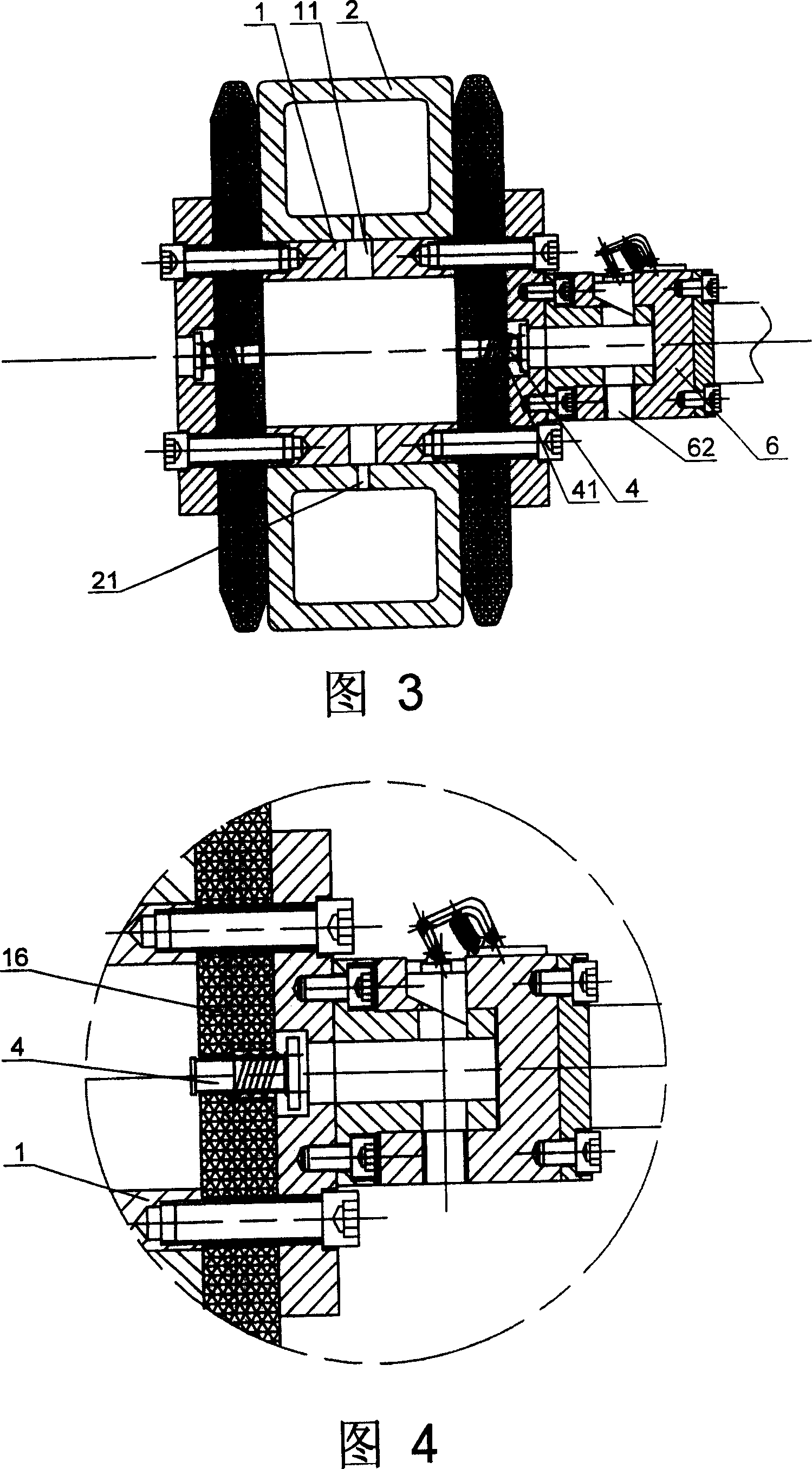

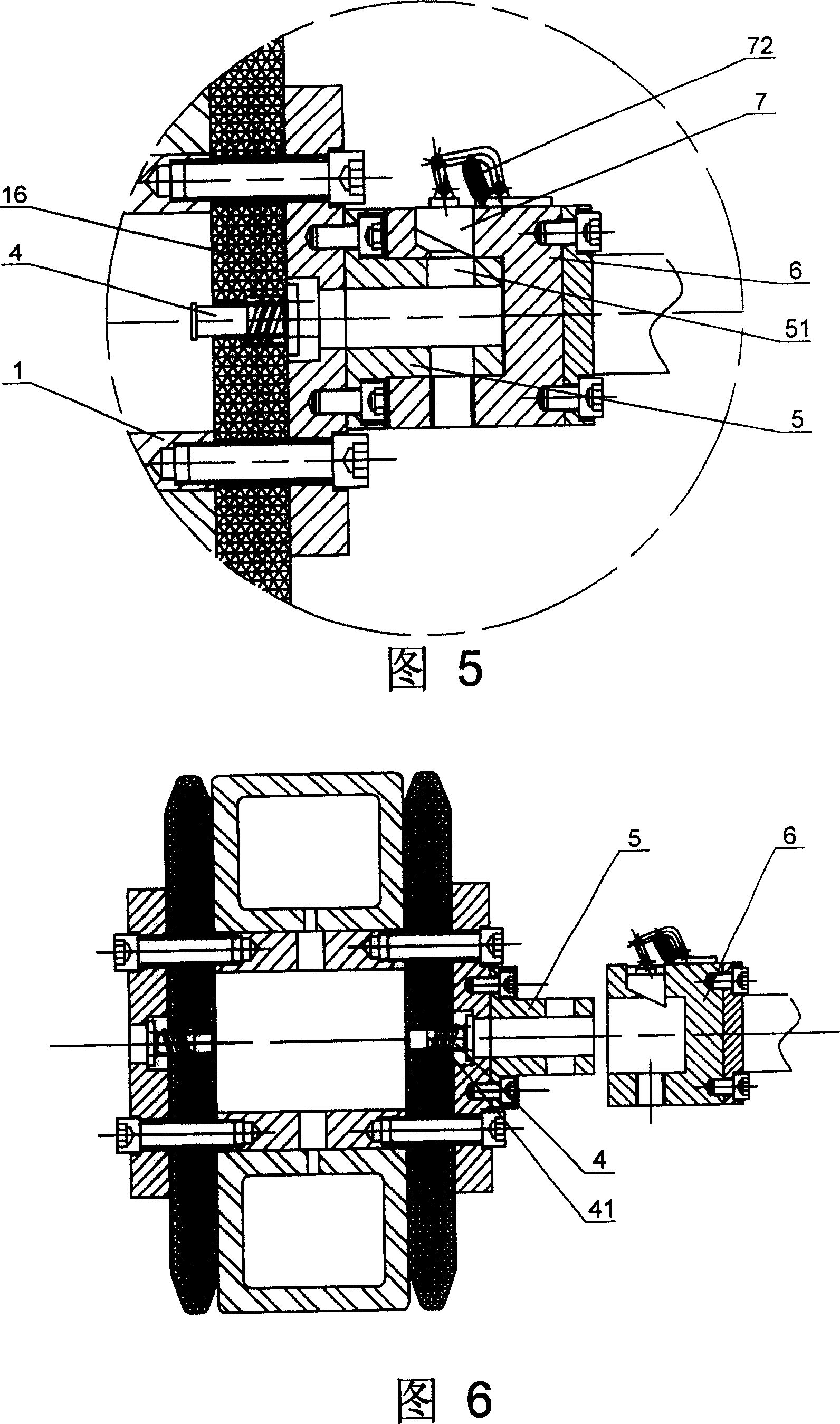

[0022] First, as shown in Fig. 1, Fig. 2 and Fig. 3, a self-decoupling and self-unsealing pipeline occluder provided by the present invention includes:

[0023] A central tube 1, the tube wall is provided with at least one through hole 11, the number of through holes 11 in this embodiment is specifically two;

[0024] An airbag 2, which is sleeved outside the tube wall of the central tube 1, and an air hole 21 is provided on the airbag 2 at a position corresponding to the through hole 11 of the central tube;

[0025] A first guard plate 12, which is fixedly connected to the left end of the central tube 1, and a stepped hole 13 is arranged in the center of the first guard plate 12;

[0026] A first splint 14, which is fixedly connected to the left end of the first guard plate 12, and a stepped hole 15 is arranged in the center of the first splint 14;

[0027] A first piston 3, which is accommodated in the stepped hole 13 of the first guard plate and the stepped hole 15 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com