Picture element structure and manufacturing method and storage capacitance structure therefor

A technology of pixel structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of easy leakage of stored electricity, and achieve the effects of improving easy leakage, wide use value, and difficult leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, The structure, manufacturing method, steps, features and functions thereof are described in detail below.

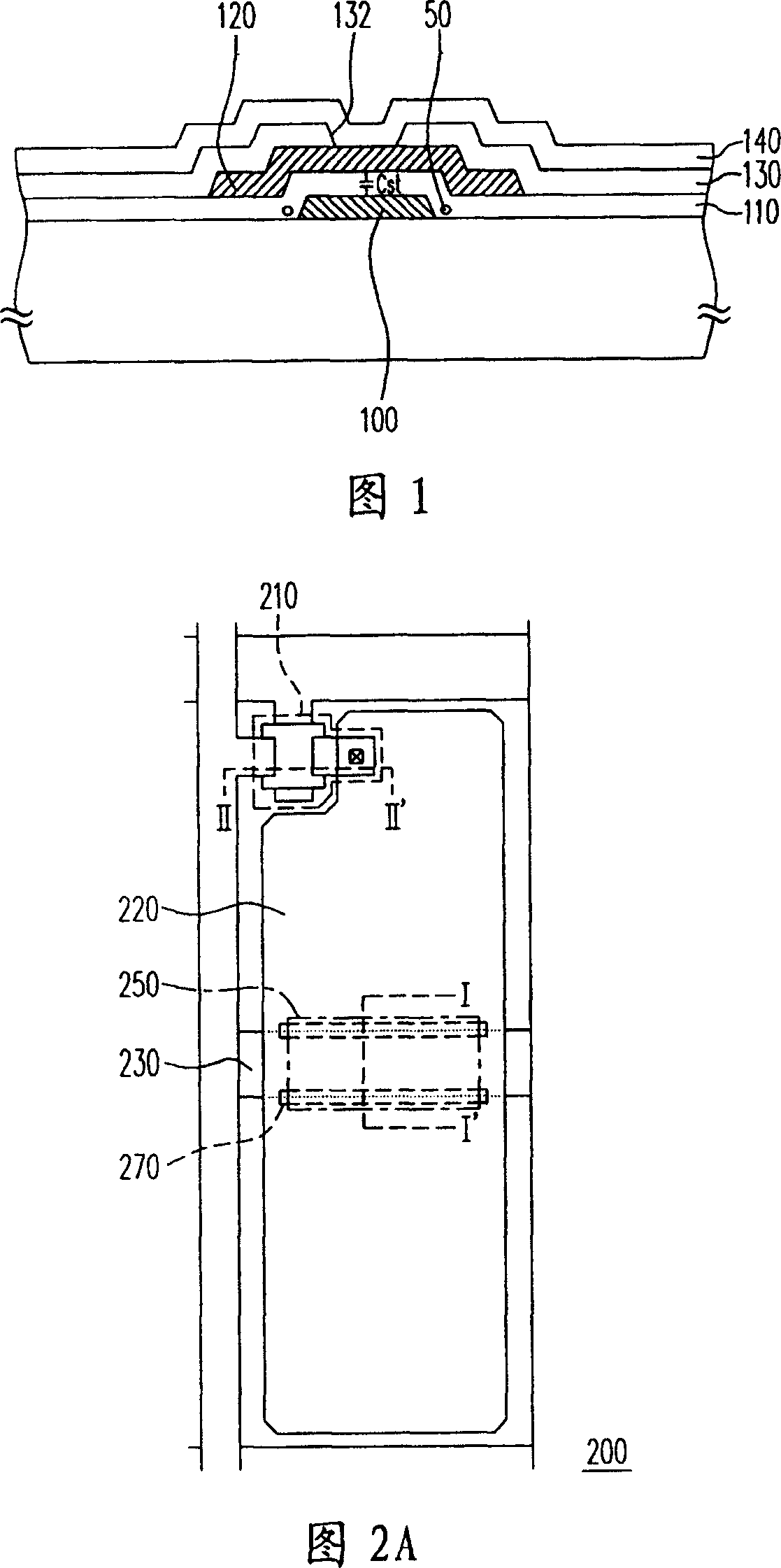

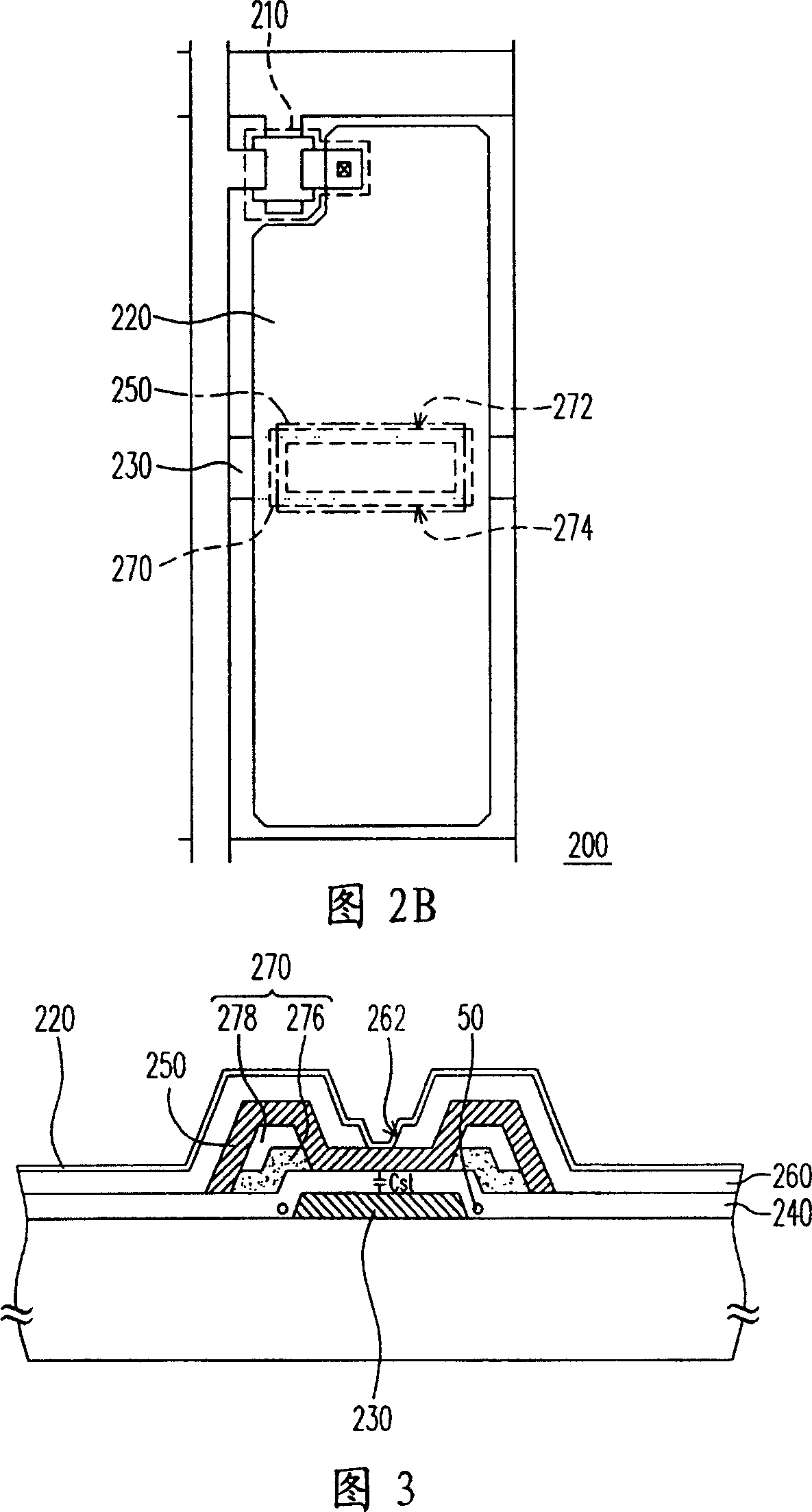

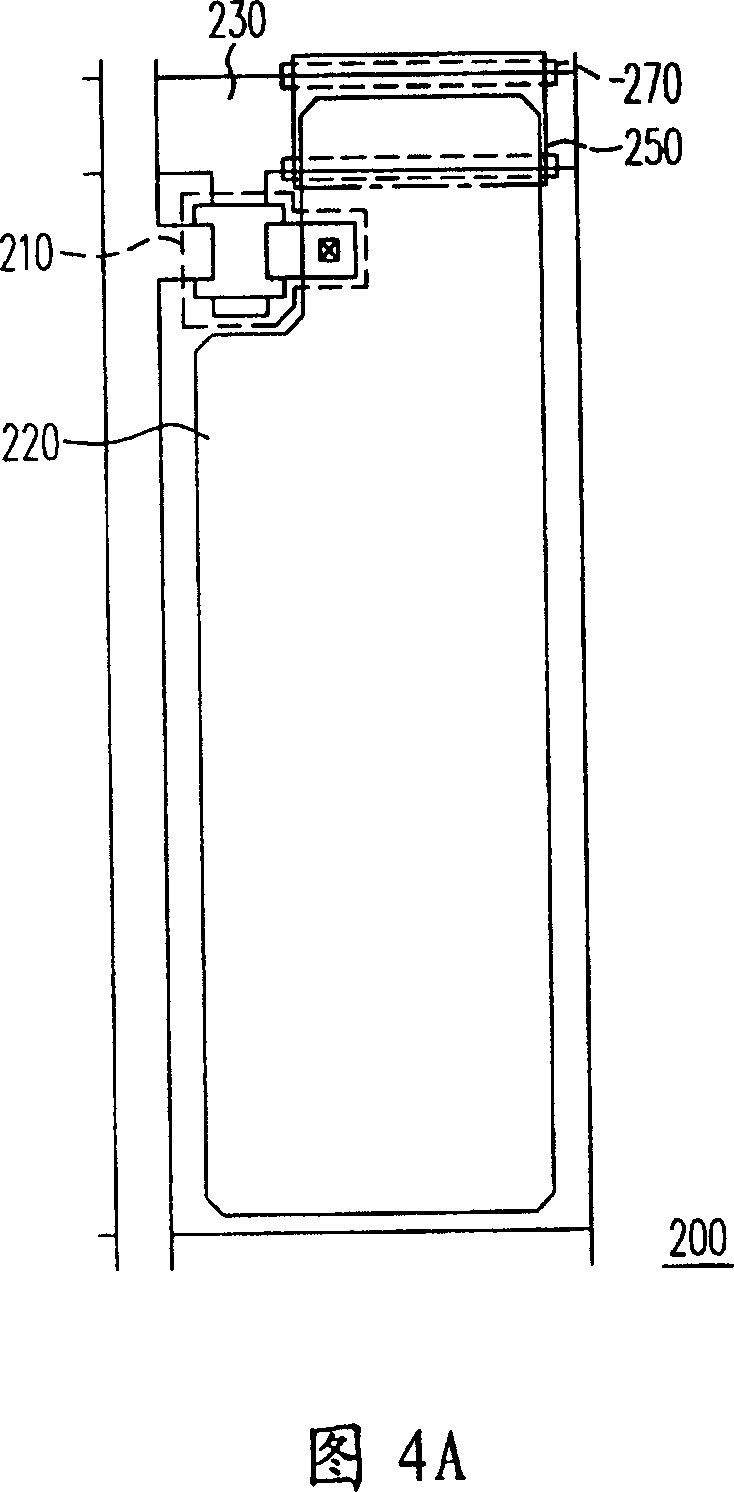

[0068] Please refer to FIG. 2A and FIG. 3 at the same time. FIG. 2A is a top view of a pixel structure according to a preferred embodiment of the present invention, and FIG. 3 is a cross-sectional view of line I-I' in FIG. 2A. The pixel structure 200 of the preferred embodiment of the present invention includes an active device 210 , a pixel electrode 220 , a lower electrode 230 , a gate insulating layer 240 , an upper electrode 250 , a protection layer 260 and a leakage current suppression layer 270 . The pixel electrode 220 is electrically connected to the active device 210 , and the lower electrode 230 is disposed below the pixel electrode 250 . In addition, the gate insulating layer 240 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com